Basic performance of ore powder grinding machine YGM65

YGM Raymond millBaichy Machinery

YGM raymond roller mill is new type high pressure grinding mill used for fine powder processing of more than 500 kinds of materials, such as limestone, gypsum, kaolin, clay, talc, feldspar, YGM highpressure roller mill uses the principle of static pressure crushing to efficiently and finely crush materials It is an efficient and energysaving crushing equipment, widely used in mining, YGM Grinding Mill Powder Grinding Mill Fine Grinding Mill2024年8月7日 The new YGM series micro powder mill is suitable for ultrafine powder processing of more than 500 materials such as feldspar, talc, barite, marble, limestone, carbon black, and New Type Powder Grinder(YGM Series) Baichy Heavy IndustryThere are a few factors that can affect ore grinding performance in ball mills Some of these factors include the size and shape of the mill balls, the type of feed material being processed, Factors affecting ores grinding performance in ball mills

.jpg)

Ore Grinding SpringerLink

2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding 1)if your project on powder processing needs to import a powder grinding machine, then Yinda will be your best choice to manufacture your powder grinding machine orders 2)Yinda is one of the leading powder grinding Powder Grinding Machine2024年8月9日 Working Principles Feeding: Limestone is fed into the machine through a feeder, which controls the amount of material entering the grinding chamber Grinding: The material is crushed between grinding rollers and rings (in Raymond and Vertical mills) or by grinding media (in Ball mills)The material is continuously ground until it reaches the desired fineness6 Types Of Limestone Dry Powder Grinder Machines2023年9月13日 The mechanical ultrafine grinding process generally refers to the grinding and classification process for preparing particle size distribution d97≤10μm, which is divided into dry method and wet method The ultrafine grinding unit operation (ie onestage ultrafine grinding) currently used in industry has the following process flows:7 basic process flows of ultrafine grinding ALPA Powder

Fine Powder Grinding Machine Yinda

1)if you project on powder processing needs to import Fine Powder Grinding Machine, then Yinda will be your best choice to manufacture your Fine Powder Grinding Machine orders 2)Yinda is one of the leading Fine Powder Grinding Machine suppliers and all of our ribbon blenders can meet ISO/CE/GMP standards, and we will provide a competitive price based on your project2022年7月10日 Mathematical models of highpressure grinding rolls (HPGR) have attracted great attention, owing to their role in optimization of operating machines as well as in the design and selection of new ones(PDF) A Hybrid PBMDEM Model of HighPressure Grinding2020年3月28日 The grinding product t10 is negatively correlated with the feed sizes of ore when the grinding force is applied to the ore At the same time, it has a simple positive linear relationship with the Development of a Novel Grinding Process to Iron Ore Pelletizing 2019年9月27日 A scientific and technical literature review on machines designed to grind fodder grain revealed that the existing designs of grinding machines—those based on destruction by impact, cutting, or (PDF) Studies of a Rotary–Centrifugal Grain Grinder Using a

.jpg)

Research on prediction model of iron ore powder sintering

2024年1月1日 DOI: 101016/jaej202312015 Corpus ID: ; Research on prediction model of iron ore powder sintering foundation characteristics based on FOACatboost algorithm @article{Li2024ResearchOP, title={Research on prediction model of iron ore powder sintering foundation characteristics based on FOACatboost algorithm}, author={Yifan Li and Yuanshuai 2023年8月2日 Precision grinding is crucial in producing highquality, highperformance components from automobiles to electronics to aerospace This article will explore the intricate world of precision grinding, its techniques, importance, applications, and moreThe Details of Accurate Grinding: A Practical Guide ProleanTech2021年9月6日 SBM Ultrafine Powder Technology is specialized in the RD and production of ultrafine grinding machines for mine ore Its main industrial ultrafine pulverizer is mainly used to grind nonmetallic ores with a fineness of up to 3000 meshMarble Ultrafine Powder Grinding MillJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

Optimization of iron ore blending based on replacing Australian

Liquid fluidity refers to the flow capacity of iron ore powder after the iron ore powder is turned into the liquid phase at a high temperature It reflects the ability of iron ore powder to flow and bond surrounding materials in the sintering process after the iron ore powder reacts with CaO to generate a liquid phase [23] According to the 2015年4月3日 In many industrial operations, the desired product lies in an intermediate particle size range Danha et al [10] further investigated the breakage behaviour of the UG2 ore in wet milling using Application of basic process modeling in investigating the 2021年10月26日 Graphite grinding machine includes ultrafine mills, etc It can grind ores into a fine powder of up to 3000 mesh +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, higher capacity, better powder quality, better overall performance Input size: 010mm Capacity Graphite Grinding Machine Powder Mill EquipmentChina Powder Grinding Machine Industrial Used Grinding Fine Powder in Gold Ore Processing Plant Gear Transmission Ceramic Grinding Ball Mill Milling Machine Ore Powder US$ 65008500 / Set 1 and the comprehensive data of Chinese suppliers like Powder Grinding Machine factory list to enhance your sourcing performance in the business Powder Grinding Machine MadeinChina

Comminution a Heart of Mineral Processing ResearchGate

2021年7月6日 PDF Comminution: The key to optimizing concentrate, grade and recovery Find, read and cite all the research you need on ResearchGate2023年9月5日 The properties of the powder largely determine the performance of powder metallurgy products The most basic geometric properties are the particle size and shape of the powder (1) Particle size It affects the processing and molding of the powder, shrinkage during sintering, and the final performance of the productPowder Metallurgy: A Comprehensive Guide for Beginners2024年10月25日 The purpose of this current research is to perform the powder mix electrical discharge diamond face grinding (PMEDDFG) process for the machining of Monel 400 In this study, using the central composite design (CCD) approach of experimental design, the effects of powder concentration (Pc), diamond grit number (Nd), peak current (Ip), and grinding wheel Assessment of the performance of the electrical discharge face grinding 2020年8月12日 VRM has been widely researched in processing of cement (Ito et al 1997;Jorgensen 2005;Wang et al 2009, Ghalandari et al 2021), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van An investigation of performance characteristics and energetic

Factors affecting ores grinding performance in ball mills

However, there are also factors that can affect ore grinding performance, including ball size and shape The average diameter of a ball used in mills ranges from about 05 inches to about 3 inches The size of a ball affects how much friction it creates as it moves along the grindstone2020年4月12日 In cutting and grinding processes, the trivial remains of bamboo after use, shoots can be chopped and ground to a powder that is dried and pressed into bamboo plywood by a specialized machine A study on the design of bamboo grinding machine2021年11月8日 Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including ultrafine mill, vertical mill, Raymond mill, wet mill, etc Product features: higher capacity, better powder quality, better Illite Ore Industrial Grinding Mill Machine SBM 2022年7月30日 strength Among them, the overall fluidity of iron ore powder A was poor, and the fluidity of iron ore powder B varied greatly between different particle grades, and the fluidity of iron ore powder C was more balanced and its bonding phase strength was high, while the overall bonding phase strength of iron ore powders B and E was lowStudy on the Basic Characteristics of Iron Ore Powder with

.jpg)

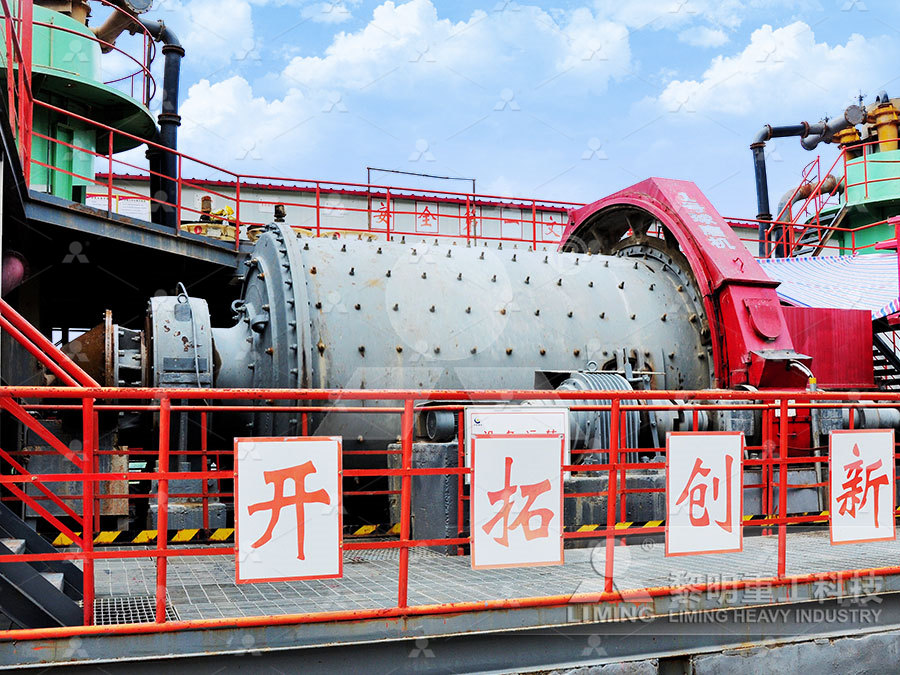

Ore Process Grinding Machine Ball Mill for Powder Making

Introductions of Ball Mill General Introduction of Ball Mill: Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be groundThe rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the millBut the grinding process is highly energy intensive and has very low energy efficiency [1] Therefore, it is highly essential to use in an efficient manner to increase their operational efficiency Since grinding constitutes a bulk of operating cost in mineral processing [2], it has become necessary to take recourse to efficient grinding Potential of HighPressure Grinding Roll (HPGR) for Size Glass powder use ① Used as a combination of pavement, building bricks, glass wool insulation materials, and honeycomb structure materials ② Used in the field of construction Glass powder added to concrete can improve the basic chemical properties of cement and make it durableUltrafine Glass Powder Making Machine2022年7月30日 In order to study in depth the differences in basic characteristics between iron ore fines commonly used by a steel company, and guide the sintering performance plant to choose the best ore (PDF) Study on the Basic Characteristics of Iron Ore Powder with

.jpg)

A Complete Range Powder Milling Processing Equipment by

2024年1月20日 For advanced powder processing platforms like the SDx™ Series, the inclusion of interchangeable heads enables rapid switching between different powder processes, offering flexibility to enhance particle size distributions, alleviate bottlenecks, boost production capacity, and consolidate multiple machines into a single, adaptable platformSourcing Guide for Powder Grinder Machine: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: grinding machine, grinder, milling machinePowder Grinder Machine MadeinChina2022年11月24日 Note: OC, OD and OE iron ore powder in the table are the mixed ore powder of OA and OB iron ore powder in the ratio of 4:6, 6:4 and 8:2, respectively , LOI is the burn loss of iron oreSintering Properties and Regression Analysis of Imported Iron Ore Powder1)if your project on powder processing needs to import a powder grinding machine, then Yinda will be your best choice to manufacture your powder grinding machine orders 2)Yinda is one of the leading powder grinding Powder Grinding Machine

6 Types Of Limestone Dry Powder Grinder Machines

2024年8月9日 Working Principles Feeding: Limestone is fed into the machine through a feeder, which controls the amount of material entering the grinding chamber Grinding: The material is crushed between grinding rollers and rings (in Raymond and Vertical mills) or by grinding media (in Ball mills)The material is continuously ground until it reaches the desired fineness2023年9月13日 The mechanical ultrafine grinding process generally refers to the grinding and classification process for preparing particle size distribution d97≤10μm, which is divided into dry method and wet method The ultrafine grinding unit operation (ie onestage ultrafine grinding) currently used in industry has the following process flows:7 basic process flows of ultrafine grinding ALPA Powder1)if you project on powder processing needs to import Fine Powder Grinding Machine, then Yinda will be your best choice to manufacture your Fine Powder Grinding Machine orders 2)Yinda is one of the leading Fine Powder Grinding Machine suppliers and all of our ribbon blenders can meet ISO/CE/GMP standards, and we will provide a competitive price based on your projectFine Powder Grinding Machine Yinda2022年7月10日 Mathematical models of highpressure grinding rolls (HPGR) have attracted great attention, owing to their role in optimization of operating machines as well as in the design and selection of new ones(PDF) A Hybrid PBMDEM Model of HighPressure Grinding

.jpg)

Development of a Novel Grinding Process to Iron Ore Pelletizing

2020年3月28日 The grinding product t10 is negatively correlated with the feed sizes of ore when the grinding force is applied to the ore At the same time, it has a simple positive linear relationship with the 2019年9月27日 A scientific and technical literature review on machines designed to grind fodder grain revealed that the existing designs of grinding machines—those based on destruction by impact, cutting, or (PDF) Studies of a Rotary–Centrifugal Grain Grinder Using a 2024年1月1日 DOI: 101016/jaej202312015 Corpus ID: ; Research on prediction model of iron ore powder sintering foundation characteristics based on FOACatboost algorithm @article{Li2024ResearchOP, title={Research on prediction model of iron ore powder sintering foundation characteristics based on FOACatboost algorithm}, author={Yifan Li and Yuanshuai Research on prediction model of iron ore powder sintering 2023年8月2日 Precision grinding is crucial in producing highquality, highperformance components from automobiles to electronics to aerospace This article will explore the intricate world of precision grinding, its techniques, importance, applications, and moreThe Details of Accurate Grinding: A Practical Guide ProleanTech

.jpg)

Marble Ultrafine Powder Grinding Mill

2021年9月6日 SBM Ultrafine Powder Technology is specialized in the RD and production of ultrafine grinding machines for mine ore Its main industrial ultrafine pulverizer is mainly used to grind nonmetallic ores with a fineness of up to 3000 mesh