Crushing station process description

.jpg)

Crushing Plant Design and Layout Considerations 911 Metallurgist

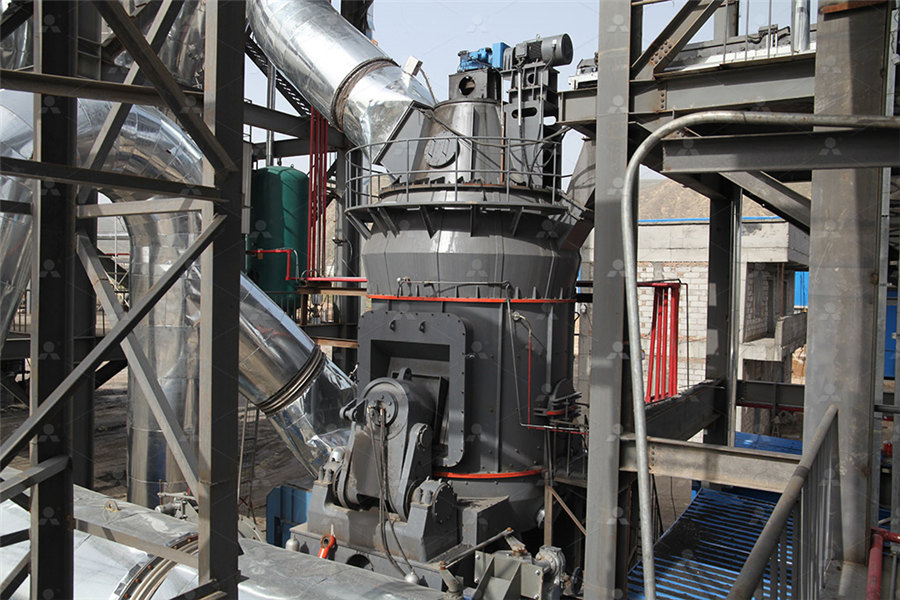

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a 2019年5月10日 The answer might be three if you’re referring to stations in a complete crushing plant – primary, secondary and tertiary crushers Of Simplifying the crushing process Pit QuarryCrushing is the first mechanical stage in the process of comminution in which a principal objective is the liberation of the valuable minerals from the gangue Crushing is typically a dry operation Crushing Plant an overview ScienceDirect TopicsThe mobile crushing station is suitable for the recycling of mine or urban construction waste resources, and can be configured according to the special requirements of customers for MOBILE CRUSHING AND SCREENING STATION

Combining legacy and expertise Mining Crushing Stations Metso

Metso Mining Crushing Stations includes 3 mining crushing and screening plant solutions that are unique, costefficient and productive to fit your needsour endtoend process has helped develop our Metso Outotec Mining Crushing Stations Metso Outotec Mining Crushing Stations are unique, costefficient and productive solutions All are Combining legacy and expertise Mining Crushing Stations2023年1月31日 Primary crushing station is a facility for primary crushing of ore (rock) According to the mining technology, the primary crushing station can be divided into openair primary Primary Crushing Station SpringerLinkThe SMPG station has a modular approach that focuses on a few different configuration pillars to build your optimal station These pillers include capacity, mobility, flow control, process control, (SMPG) crushing station provides a modular and intelligent

.jpg)

MeasurementControl for Crushing and Screening Process

2023年6月3日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for 2024年11月15日 800tph Stone Crushing Plant: A pinnacle in stone crushing technology This highcapacity plant is meticulously engineered to crush and process large stones into essential aggregates or sand, vital for mining, quarrying, and construction industries Equipped with powerful jaw crushers, efficient cone crushers, advanced sand making machines, dependable 800tph Stone Crushing Plant TAYMACHINERYDescription A complete stationary crushing plant consists of different parts, including conveyors, feeders, crushers, SMAT stationary crushing station in the Philippines can process a wide range of raw materials, including river pebbles, limestone, construction waste, granite, iron ore, Stationary Crushing Plant SMAT Philippines2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage

.jpg)

Psychoacoustic Evaluation of Rock Crushing Plant Noise

crushing station starts up Also, the distance from the crusher is correlated with the loudness values The UBA values are shown in Table IV and in Figure 5 In the first work phase, the highest UBA is at the microphone 5 which is the farthest from the crushing station and the closest microphones have lower values When the process advances,2020年10月22日 In the production process of openpit mines, transportation costs account for 45–60% of the total cost Therefore, a reasonable and economic transportation system can effectively improve Layout optimization of crushing station in openpit mine based aggregate primary crushing applications Inpit crushing minimizes material handling costs by reducing truck hauling requirements The result is a minimum truck fleet with less manpower required The ability to relocate the primary station allows for greater flexibility in mine planning and reduced life of mine operating costs Main benefitsStationary Semimobile crushing solutions Primary gyratory The screening process is an essential part of the mineral processing This article focuses on what screening is, semicontinuous transportation process and the layout requirements of mobile crushing station Shirley Jun 07, 2021 Mobile Crushing Station Transportation Process and Layout Requirements read more Load More Posts Crushing Screening

R)8OC`6F[ZIB.jpg)

Terex MPS process plant for Seneca Crushing and Screening

2023年7月26日 As part of its Design, Build, Own and Operate (DBOO) operating model – a 2020 extension to its traditional crushing and screening business – leading South African contractor, Seneca Crushing and Screening, recently opted for a turnkey, bespoke process plant from Terex Mineral Processing Systems (MPS) for a Northern Cape contract Despite the Rated process capacity: 1500t/h~10000t/h Material feed size: Semicontinuous mining technology with semimobile crushing station has advantage of low cost, high efficient in transportation 03 Description Qty User 1 60110E 2 150010000t/h SemiMobile Gyratory Crushing StationTYHI The mobile jaw crusher is a new type of crushing equipment suitable for crushing various ores or rocks with a compressive strength below 250Mpa, such as construction waste, basalt, granite, coal gangue, cement clinker, iron ore, bauxite, quartz stone and so onIn addition to mobile jaw crushers we also have mobile cone crushers, mobile impact crushers, mobile hammer Mobile jaw crushing stationDongmeng Road and Bridge Machinery Co, Ltd is China Mobile jaw crushing station manufacturers and OEM/ODM Mobile jaw crushing station factory, suppliers, Description:It is widely used in construction waste crushing and Custom Mobile jaw crushing station Manufacturers,

.jpg)

XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone

XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone crusher, crushing station, mobile crushing station、Equipment Manufacturer Welcome to XKJ GROUP! Provide you with professional ore crushing solutions sales01@xkjgroup Tel So what is the production process of lime powder?What equipment is Details 0924, 20242023年1月31日 The openair primary crushing station can be divided into fixed primary crushing station, semimobile primary crushing station, and mobile primary crushing station (1) Fixed primary crushing stations are always located outside the boundary of openpit stope or intermediate platform, and some are also located in the concentrator, which have the Primary Crushing Station SpringerLink2021年12月24日 Quarry production process is drilling hole by hydraulic drills → multirow holes millisecond differential compression blasting →excavator loading blasted ores to truck →selfdumper transport ore to crushing station bin 262 Limestone crushing The limestone crushing station is near the existing limestone crushing station, and 2600m far from the cement plant in Process description PDF SlideShareDescription SMAT mobile crushing plant has various configuration methods Simplified Process A mobile crushing station set feed, crushing, conveying, screening and other functions in one Practical, costeffective 06 Choice of Mobile Crushing Plant SMAT Philippines

.jpg)

Gyratory Crushing Station Parts Canhu

Gyratory Crushing Station Liners Liner, Gyratory Body, Mantle, Arm Guard (made of Mn14, Mn18 high manganese steel material) Get A Quote Protective Case Discover Protective Case Discover Protective Case Discover Protective Case Discover Descriptions Related Cases Specs Products FAQs About Gyratory Crusher The largest crusher in the world is a gyratory crusher, which The mobile crushing and screening plants are composed of primary crushing and screening station and secondary one, belt conveyor, etc Every Mobile crushing station is an independent working unit, which can respectively assume their different responsibility, and the belt conveyer is responsible for material transmitting and piling up between each crushing stationWheeled Mobile Jaw Crusher Station – Hongxing Machinery(HXJQ)Journal of Applied Engineering Science Vol 16, No 3, 2018 ISSN 14514117 344 Andrey Ostroukh, et al Automated process control system of mobile crushing and screening plantAUTOMATED PROCESS CONTROL SYSTEM OF MOBILE CRUSHING It then passes Diankoya Station, crosses Sonamba River to the south of Médina, runs southeast until the west of Kérouané Township where the Station is established, crosses the Milo River and finally arrives at the foothills of the Simandou Mining Area 133 Mine The Mining Project will include the following components:PROJECT DESCRIPTION Winning Consortium Simandou

.jpg)

800tph Stone Crushing Plant TAYMACHINERY

800tph Stone Crushing Plant: A pinnacle in stone crushing technology This highcapacity plant is meticulously engineered to crush and process large stones into essential aggregates or sand, vital for mining, quarrying, and construction industries Equipped with powerful jaw crushers, efficient cone crushers, advanced sand making machines, dependable vibrating screens, and robust 2019年10月2日 Our new SemiMobile Crushing Station with Top Service (TS) Gyratory Crusher is ideal for inpit crushing and conveying (IPCC) operations The SemiMobile Crushing Station consists of movable modules that can be SemiMobile Crushing Station FLSmidth2023年8月8日 To extract phosphorus from phosphate rock, Ftmmachinery will explain to you the process flow of phosphate rock and the equipment we can provide, from the four stages of crushing grinding flotation – dehydration Phosphate Rock Processing: 6 Useful Ways and 4 StagesMetso's Foresight™ semimobile primary gyratory (SMPG) crushing station provides a modular and intelligent solution that increases maintainability and safety for maximum productivity Metso's Foresight™ SMPG crushing station offers a modular, Process control driven by online process optimization and data analytics capabilities;Semimobile primary gyratory (SMPG) Metso

Crushing Plant an overview ScienceDirect Topics

Crushing may be in open or closedcircuit, depending on the required product size distribution Two basic crushing flowsheets are shown in Figure 61: (a) the older style (“traditional”) 3stage crushing circuit ahead of a rod mill, and (b) the more modern opencircuit primary crushing prior to SAG milling with crushing and recycling of “critical size” material (see Chapters 5 and 7 2024年6月27日 Crushing Station With Horizontal Shaft Impact Crusher in Recycled Asphalt Application,China,heavy duty, Four samples shall be produced from the constituent product to be cut by the process: Description: This specification covers the Crushing Station With Horizontal Shaft Impact Crusher in Figure 2: Primary jaw crushing station in a deep mine The primary jaw crushing station is usually installed underground in mines and operates in open circuit as shown in Figure 2 The ROM ore is fed to the crushing station through the discharging zone, also called gate of the ore pass, at a controlled mass flow rateOptimal energy management for a jaw crushing process in deep The process design criteria define the project’s production requirements, and typically include those shown in Table 1 Table 1 Production requirements Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive strengthsCrushing Plant Design and Layout Considerations MINE

AUTOMATED PROCESS CONTROL SYSTEM OF MOBILE CRUSHING

Mobile crushing and screening plant with cone crusher Cone crushers are the most effective for medium and fi ne crushing of strong and highly durable rocks They carry out crushing continuously due to the rotation of the eccentric conical rotor the "crushing cone" inside the outer stationary coneMining Crushing Stations combines legacy and expertise to bring unique, from plant design expertise to equipment, parts and services for every stage of your process Explore Mining Explore commodities this allows the fully connected plant to always be monitoring station conditions to ensure that no time or resources are wastedMining crushing stations Metso2023年6月3日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for MeasurementControl for Crushing and Screening Process2024年11月15日 800tph Stone Crushing Plant: A pinnacle in stone crushing technology This highcapacity plant is meticulously engineered to crush and process large stones into essential aggregates or sand, vital for mining, quarrying, and construction industries Equipped with powerful jaw crushers, efficient cone crushers, advanced sand making machines, dependable 800tph Stone Crushing Plant TAYMACHINERY

Stationary Crushing Plant SMAT Philippines

Description A complete stationary crushing plant consists of different parts, including conveyors, feeders, crushers, SMAT stationary crushing station in the Philippines can process a wide range of raw materials, including river pebbles, limestone, construction waste, granite, iron ore, 2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stagecrushing station starts up Also, the distance from the crusher is correlated with the loudness values The UBA values are shown in Table IV and in Figure 5 In the first work phase, the highest UBA is at the microphone 5 which is the farthest from the crushing station and the closest microphones have lower values When the process advances,Psychoacoustic Evaluation of Rock Crushing Plant Noise2020年10月22日 In the production process of openpit mines, transportation costs account for 45–60% of the total cost Therefore, a reasonable and economic transportation system can effectively improve Layout optimization of crushing station in openpit mine based

Stationary Semimobile crushing solutions Primary gyratory

aggregate primary crushing applications Inpit crushing minimizes material handling costs by reducing truck hauling requirements The result is a minimum truck fleet with less manpower required The ability to relocate the primary station allows for greater flexibility in mine planning and reduced life of mine operating costs Main benefitsThe screening process is an essential part of the mineral processing This article focuses on what screening is, semicontinuous transportation process and the layout requirements of mobile crushing station Shirley Jun 07, 2021 Mobile Crushing Station Transportation Process and Layout Requirements read more Load More Posts Crushing Screening2023年7月26日 As part of its Design, Build, Own and Operate (DBOO) operating model – a 2020 extension to its traditional crushing and screening business – leading South African contractor, Seneca Crushing and Screening, recently opted for a turnkey, bespoke process plant from Terex Mineral Processing Systems (MPS) for a Northern Cape contract Despite the Terex MPS process plant for Seneca Crushing and ScreeningRated process capacity: 1500t/h~10000t/h Material feed size: Semicontinuous mining technology with semimobile crushing station has advantage of low cost, high efficient in transportation 03 Description Qty User 1 60110E 2 150010000t/h SemiMobile Gyratory Crushing StationTYHI