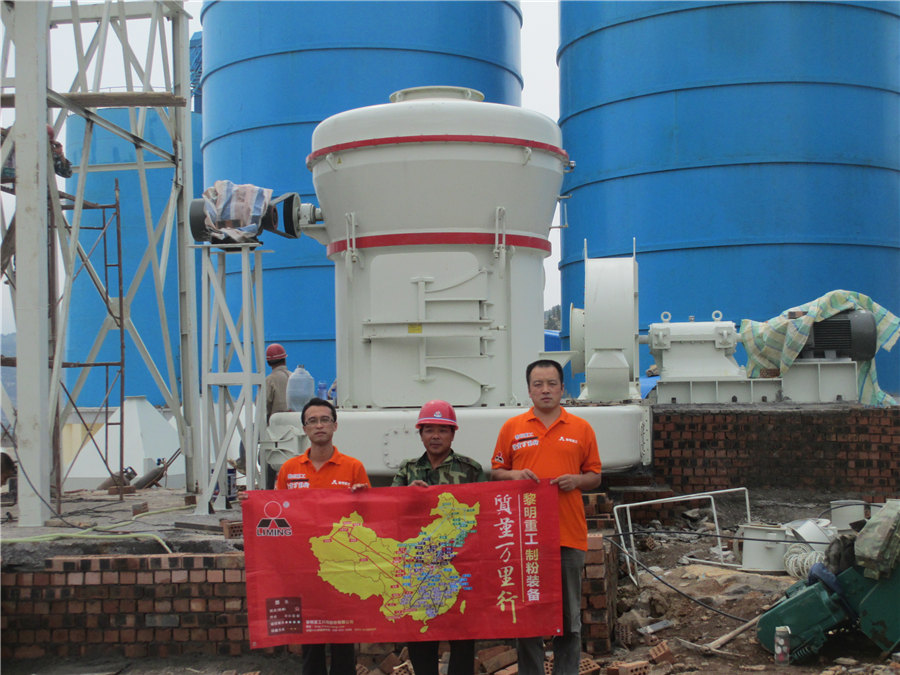

Main structure of kaolin grinding production line

Kaolin Vertical Grinding Mill Production Line

2024年2月2日 The main structure of the kaolin vertical grinding mill production line is similar to the traditional raw meal vertical grinding mill In order to adapt to the grinding of highsilicaaluminum materials such as kaolin, pyrophyllite, and white foam stone, the stable material The use of kaolin for geopolymer formation produced a relatively weak structure due to its low surface area; which minimized the dissolution rate of Si and Al by alkali reactant and limitedSimplified kaolin production and processing flow The crushed small pieces of kaolin powder are sent to the silo by an elevator, and then sent to the grinding chamber of the mill for grinding evenly and quantitatively by a vibrating feeder Kaolin grinding production process LZZG2023年12月5日 The main structure of the kaolin vertical mill production line is similar to the traditional raw meal vertical mill In order to adapt to the grinding of highsilicaaluminum Kaolin vertical mill production line powder making process

Kaolin grinding production line and equipment selection

2022年8月10日 Kaolin is a clay or clay rock dominated by kaolinite minerals Kaolin is named after the porcelain white clay produced in Gaoling Village, Jingdezhen, Jiangxi Province, China Also known as: white cloud soil, 2024年10月8日 Based on its structure, kaolin exhibits unique properties, such as its nonswelling nature, small particle size, welldefined dimensions, specific chemical structure, elemental makeup, and low cation exchange capacity (CEC) Transforming Petrochemical Processes: CuttingEdge 1991年9月1日 Structurally, kaolinite consists of alumina octahedral sheets and silica tetra hedral sheets stacked alternately and has the theoretical formula (OH) sSi4A1401o and the Kaolin: processing, properties and applications ScienceDirectThe kaolin manufacturing process involves transforming raw kaolin clay into a refined product suitable for industrial use This article delves into the intricacies of the kaolin manufacturing Kaolin Manufacturing Process and Plant Production Line

.jpg)

An overview of kaolin and its potential application in

2023年8月1日 Kaolinite, the primary component of kaolin, is a white, soft, and nonplastic clay that acts as an important filler in this polymer field It produces a smooth surface finish, 2020年4月14日 The production line with an output of 300 t/d magnesium oxide (MgO) has been established in Jiangsu province, which is also a demonstration line of 600 t/d for kaolin Research and Design of Suspension Calcining Technology and 2024年2月3日 The main structure of the kaolin vertical mill is: powder separator, upper polish body, lower polish body, frame, grinding device (grinding roller + grinding disc), transmission arm device (moving arm + moving arm), pressurizing device, It is composed of limit device, driving device (main motor + main reducer), etcAdvantages of Kaolin Vertical Grinding Mill2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine

(PDF) The use of red mud and kaolin waste in the

2022年9月12日 Kaolin for paper coating industry and bauxite for alumina and aluminium production are amongst the most important commodities The latter is responsible for the generation of red mud, a wellknown 2022年4月20日 Limestone crushing and grinding production line 20/04/2022 admin Limestone Properties The main component of limestone is calcium carbonate (CaCO 3) with a Mohs hardness of 3 Production advantages: simple structure, easy installation; deep crushing cavity, Limestone crushing and grinding production line SBM Ultrafine We offer complete industry grinding mill production line for designs, marble, heavy calcium, kaolin, barite, bentonite, pyrophyllite, etc And the finished powder can be used as highquality fillers and additives in coatings, plastics, VMX Superfine Grinding Mill consist of main mill, feeder, classifier, blower, pipe system, VMX Superfine Vertical Mill Grinding Mill Fertilizer production 24 S A HOSSEINI ET AL carried out in the ra nge 2 θ of 0 ˚ 70 ˚, at a scanning rate of 1 ˚ /min Infrared (IR) spectra were recorded with a BrukerProduction of γAl2O3 from Kaolin ResearchGate

Effects of Dry Grinding on Kaolin Minerals III Halloysite

The effects of severalhundredhour mechanicalmortar dry grinding of halloysite were studied by Xray diffraction, differential thermal, electron microscopic and other methods and they were compared with those of kaolinite and Kibushiclay It has been found that there are two sorts of structural change caused by dry gringing in halloysite as in the case of kaolinite One is the 2018年5月2日 In the production of calcined kaolin, the online monitoring of the calcination reaction is becoming more relevant for the generation of optimal products In this context, this study aimed to assess the suitability of using infrared (IR) spectroscopy as a potential technique for the online characterization of the calcination of kaolinFull article: Toward an online characterization of kaolin calcination 2014年9月1日 The structural analysis and surface morphology of kaolin has been studied Kaolin is a soft white mineral that has a large array of uses Kaolin as found in nature usually contains varying amounts STRUCTURAL ANALYSIS AND SURFACE MORPHOLOGY OF KAOLIN 2018年5月2日 Main infrared spectral features that characterize the kaolin calcination process in the SWIR (Frost et al 2002), MWIR (Drits et al 2016), and LWIR (Percival et al 1974) rangesToward an online characterization of kaolin calcination process

The Introduction of A Whole Gypsum Powder Production Line

1 Introduction of gypsum powder production line Gypsum is a versatile material that is indispensable in the field of industrial construction The gypsum powder production line is obtained by grinding natural dehydrate gypsum ore (raw gypsum) or industrial byproduct gypsum (desulfurization gypsum, phosphogypsum, etc) through a special mill and heating and The tahini production line is similar to peanut butter production line It consists of some key equipment, including sesame cleaning machine, roasting machine, lifter, cooling belt, sesame grinder mills, mixing tank, paste pump, vacuum Sesame Grinding Machine Tahini Production LineE3S Web of Conferences The raw material used to synthesis the zeolite was kaolin, since its major components are silica and alumina, consisting of 6049%8302% SiO2 and 1063%2419% alumina Feasibility Study for Production of Zeolite A based on KaolinGrinding kaolin powder can be processed by professional superfine vertical grinding mill HCM new type of kaolin superfine vertical grinding mill has the advantages of high income, less worry, high grinding efficiency and low civil construction cost The Best Kaolin Superfine Vertical Grinding Mill Made By HCM

.jpg)

Ultra Fine Grinding Mill SBM Ultrafine Powder Technology

Composition of ultrafine grinding production line HGM series ultrafine grinding mill production line mainly consists of main unit, classifier, powder collector, dust cleaner, blower, soundproof room, crusher, bucket elevator, storage hopper, and vibrating feeder Structure of ultrafine grinding mill Working Principle of Ultra Fine 2023年4月14日 The structure of kaolin was analyzed using infrared spectroscopy, scanning electron microscopy, and Xray diffraction, and the alterations to the kaolin microstructure were thoroughly researched Preparation and Characterization of Modified Kaolin by a 2023年10月17日 In this context, this study aimed to assess the suitability of using infrared (IR) spectroscopy as a potential technique for the online characterization of the calcination of kaolinEffect of calcination temperature in Kaolin membranes structure2021年10月1日 In this study, kaolin treated by wetgrinding process was utilized as an accelerator in Portland cement Wetgrinded kaolinPortland cement system was designed, and 1–4% wetgrinded kaolin was Preparation of nanokaolin by wetgrinding process and its

.jpg)

How to configure the cristobalite grinding production line?

2022年8月30日 The price positioning of the cristobalite grinding production line produced by SBM is very affordable, which reduces the user’s production investment in the operation and makes it more profitable SBM can not only provide users with more costeffective and more reliable cristobalite grinding powder production equipment, but also a complete range of Kaolin grinding milling production line belongs to the secondary main processing stage The kaolin raw materials will be crushed and then is the grinding line In kaolin grinding production line, the crushed kaolin materials can be broken into fine powder to satisfy clients' production needsKaolin Grinding Milling Machine Used in Kaolin Processing Line of grinding on the structure of kaolinite for a better understanding of its structural behavior change [10] At first, the dry grinding of kaolinite was found to result in the reduction of its particle size due to the cleavage and fracturing of the kaolinite crystal [1113] In the late 1950s, it was thoughtComparison of Dry Grinding Effect on Commercial QuartzFree 2009年1月1日 As shown in Figure 31, there is one main production line (Line 1, Line 3, Line 4, Line 12, Line 5, Line 6, Line 7 and Line 8), with Line 12 being a parallelmachine line consisting of κ sublines, a feeder line (Line 2), a feed The Design of Production Lines SpringerLink

Production of γAl2O3 from Kaolin Scientific Research Publishing

The Kaolin, used as a starting material was supplied from Zonoz mines (Marand, Iran) The chemical composition of Zonoz kaolin is given in Table 1 After extracting from mine and grinding the kaolin, it was ground in an agate mortar to particles below 05 mm in size The powdered kaolin was calcined at 800˚C for 2 h in anthe potential utilisation of kaolin enrichment wastes Since this paper is based on the results of chemical analysis of the Yosypivka deposit, it would be pertinent to further elaborate on the main aspects of its geological structure The geological structure of the Yosypivka deposit includesSUSTAINABLE EXTRACTION AND PROCESSING OF RAW 2023年5月10日 Optimization of hierarchical ZSM5 structure by variation of the first hydrothermal step at different times provides insight into the evolution of micro/mesopores and its effect as a catalyst for (PDF) Optimization of hierarchical ZSM5 structure from kaolin as 2010年1月1日 The metakaolin was produced by thermal treatment (calcination) of the starting highquality kaolin clay from Serbia The optimal calcination parameters, for which nearly complete dehydroxylation Thermal treatment of kaolin clay to obtain metakaolin

Chemical Composition and Particle Size Analysis of Kaolin

2017年10月17日 The mineral and elemental composition, crystal structure and particle size distribution of kaolin clays have been determined to ascertain its industrial significance2021年11月17日 The main mineral composition of kaolin is 90% kaolin + 10% halloysite, quartz, jellyfish stone, etc, commonly known as “china clay” The world’s kaolin resources are rich and widely distributed At present, the world has identified about 209 billion tons of kaolin resources In the world, the Americas are the main producing areas of kaolin, and kaolin production Ultrafine grinding of kaolin ALPA Powder Equipment2023年11月23日 Kaolin is one of the most important clay minerals that attracts attention due to its various application areas such as the ceramic industry In this study, the effects of solid/ball ratio and grinding time on the mechanical activation of kaolin were investigated Samples with 10 µm particle size were activated in The Fritsch Pulverisette 5 Ball Mill (Two Chamber Mill) at Effect of solid/ball ratio and grinding time on the mechanical 2023年1月1日 Ammacio kaolin deposits is found in Gibe Woreda, Hadiya Zone, southwest of the Central Main Ethiopian Rift at a distance of 330 km from Addis AbabaGEOLOGICAL, MINERALOGICAL, PHYSICOCHEMICAL

Advantages of Kaolin Vertical Grinding Mill

2024年2月3日 The main structure of the kaolin vertical mill is: powder separator, upper polish body, lower polish body, frame, grinding device (grinding roller + grinding disc), transmission arm device (moving arm + moving arm), pressurizing device, It is composed of limit device, driving device (main motor + main reducer), etc2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine 2022年9月12日 Kaolin for paper coating industry and bauxite for alumina and aluminium production are amongst the most important commodities The latter is responsible for the generation of red mud, a wellknown (PDF) The use of red mud and kaolin waste in the 2022年4月20日 Limestone crushing and grinding production line 20/04/2022 admin Limestone Properties The main component of limestone is calcium carbonate (CaCO 3) with a Mohs hardness of 3 Production advantages: simple structure, easy installation; deep crushing cavity, Limestone crushing and grinding production line SBM Ultrafine

.jpg)

VMX Superfine Vertical Mill Grinding Mill Fertilizer production

We offer complete industry grinding mill production line for designs, marble, heavy calcium, kaolin, barite, bentonite, pyrophyllite, etc And the finished powder can be used as highquality fillers and additives in coatings, plastics, VMX Superfine Grinding Mill consist of main mill, feeder, classifier, blower, pipe system, 24 S A HOSSEINI ET AL carried out in the ra nge 2 θ of 0 ˚ 70 ˚, at a scanning rate of 1 ˚ /min Infrared (IR) spectra were recorded with a BrukerProduction of γAl2O3 from Kaolin ResearchGateThe effects of severalhundredhour mechanicalmortar dry grinding of halloysite were studied by Xray diffraction, differential thermal, electron microscopic and other methods and they were compared with those of kaolinite and Kibushiclay It has been found that there are two sorts of structural change caused by dry gringing in halloysite as in the case of kaolinite One is the Effects of Dry Grinding on Kaolin Minerals III Halloysite2018年5月2日 In the production of calcined kaolin, the online monitoring of the calcination reaction is becoming more relevant for the generation of optimal products In this context, this study aimed to assess the suitability of using infrared (IR) spectroscopy as a potential technique for the online characterization of the calcination of kaolinFull article: Toward an online characterization of kaolin calcination

.jpg)

STRUCTURAL ANALYSIS AND SURFACE MORPHOLOGY OF KAOLIN

2014年9月1日 The structural analysis and surface morphology of kaolin has been studied Kaolin is a soft white mineral that has a large array of uses Kaolin as found in nature usually contains varying amounts 2018年5月2日 Main infrared spectral features that characterize the kaolin calcination process in the SWIR (Frost et al 2002), MWIR (Drits et al 2016), and LWIR (Percival et al 1974) rangesToward an online characterization of kaolin calcination process