Tin powder grinding equipment working principle

.jpg)

Grinding for food powder production ScienceDirect

2013年1月1日 The principle of this technology is to control the grinding limiting factors (moisture, sugar content and caking) by drying the food materials under their critical grinding wet The 2021年5月5日 Grinding Machine Working Principle: In brief, we can say the working of the Grinding Machine is the Workpiece is fed against the rotating abrasive wheel The action of rubbing or friction generates between wok price Grinding Machine: Definition, Parts, Working Principle, How the mill works In operation, the feeding device gravityfeeds material at a constant rate to the roll gap between the top pair of rolls The material enters the nip point (where the gap Roller mills: Precisely reducing particle size with greater efficiencyAn air classifier mill applies impact grinding and air classification in one step The mill uses airflow to convey feed material to the mill’s grinding chamber, classifies the material into fine How to operate an air classifier mill to meet your fine grinding goals

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer Gentle Grinding Action – Allows uniform size distribution, resulting in minimal fines generation Low Heat Generation – Essential when milling fatty, sticky or heat sensitive products Low Powder Processing Equipment Systems Qlar2023年7月4日 Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the Roller Mill SpringerLinkExplore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines Discover how these versatile tools optimize grinding efficiency in Ball Mill Grinding Machines: Working Principle, Types, Parts

Micro Powder Grinding Mill

Working Principle of Micro Powder Grinding Mill Micro Powder Grinding Mill is mainly formed by mill body, blower fan, ultrafine analyzer, Magnesite grinding equipment includes ultrafine mills, vertical mills, highpressure mills, etc It can 2021年5月5日 Grinding Machine Working Principle: In brief, we can say the working of the Grinding Machine is the Workpiece is fed against the rotating abrasive wheel The action of rubbing or friction generates between wok price Grinding Machine: Definition, Parts, Working The copper powder recovery equipment can recycle and treat the metallic dust pollution generated by the grinding and brushing process in PCB production, reduce the cost of wastewater treatment, save water and electricity, and Copper Powder Recovery Equipment JXSC Mineral2019年10月17日 1 Working principle 2 Structure Let's dive right in! 1 Working Principle of Rod Mill Rod mill is a common equipment for grinding operation in mineral concentrator, which is mainly suitable for rough grinding operationThe Working Principle and Structure of Rod Mill

Coarse Powder Grinding Mill SBM Ultrafine Powder Technology

Working Principle of Coarse Powder Grinding Mill European Coarse Powder Grinding Mill European Coarse Powder Mill mainly consists of frame, rotor, support CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and Ball Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powdersBall Mill Grinding Machines: Working Principle, Types, Parts Ammonia Nitrogen Electrolysis Water Treatment Equipment; Tin Stripping Solution And Tin Recycling the metal powder Structures Working Principle Vibrator Screen Structure The main parts of a Vibrating Screen Machine Working Principle Vibrating screen uses electric exciter as a vibrating source, the material will be thrown around the Vibrating Screen JXSC Mineral2023年9月28日 Material feeding: The feed material is introduced into the mill through a feed hopper or a screw feeder It can be in the form of dry powder or a wet slurry Grinding chamber: The material enters the grinding chamber, which is a Working principle of jet mill Jet Mill Equipment Manufacturer

Air Classifying Mill ALPA Powder Equipment

Air Classifier Mill: The material is uniformly sent into the grinding chamber by the feeding system, and is strongly impacted by the highspeed rotating grinding disc At the same time, it is subjected to the centrifugal force to collide with the crushing ring gear, and is subjected to various comprehensive forces such as shearing, friction, and collision2021年11月23日 Jet mill, as one of the ultrafine grinding equipment, is also one of the important equipment in the grinding industry After the compressed air of the fluidized bed pulverizer is frozen, filtered and dried, it forms a supersonic airflow through the nozzles and is injected into the pulverizing chamber to fluidize the materialClassification and working principle of jet mill ALPA Powder Equipment3 Fine crushing or coarse grinding: The feed material is usually comes from the secondary crushers 4 Fine Grinding: The objective of fine grinding is to produce ultrafine material less than one micron Size Parameter for Different Comminution Processes: Suitable parameters of feed and product material for different crushingLECTURE NOTES ON Mineral Processing (3rd Semester 2024年2月3日 Multimill; Working and principle Last Updated on: February 3, 2024 by Naresh Bhakar Multimill is used widely in pharmaceuticals (granulation section), cosmetics, chemicals, and bulk drugs for cutting granules into small Multimill; Working and principle in Pharmaceutical »

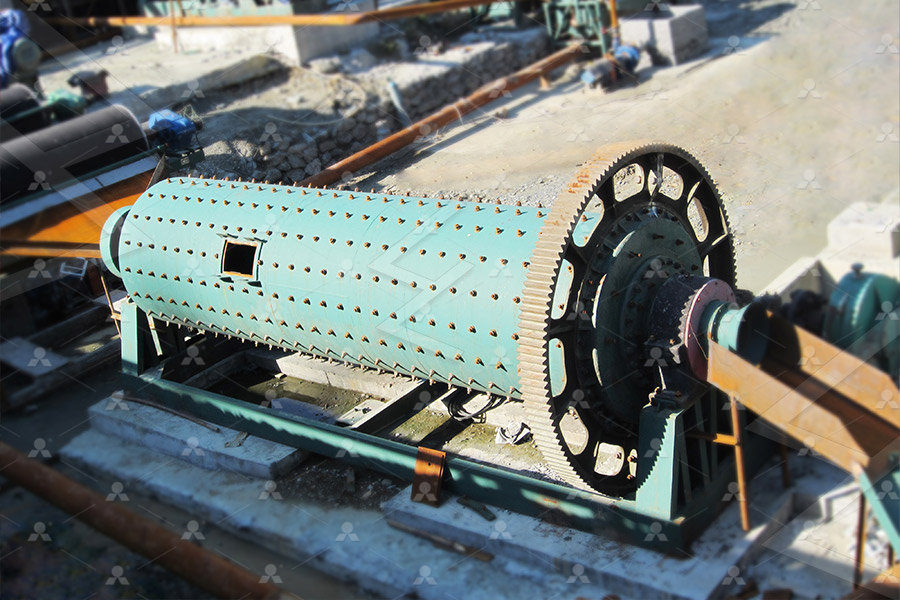

Ball mill: Principles, construction, working, uses,

2024年1月28日 2 Impact and Attrition: As the mill rotates, the grinding media (balls) collide with the material, crushing and grinding it This impact and attrition process reduce the size of the material 3 Reduction to Fine Powder: The 2021年7月27日 The working principle and main purpose of jet mill 27/07/2021 Milled powder would go up to classifying area by airflow For ultrafine grinding of nonmetallic minerals, the choice of grinding equipment is crucial; PROJECTS SITES Mineral; Chemical;The working principle and main purpose of jet mill ALPA Powder Equipment2016年8月22日 Working Principle of Micro Powder Grinding Mill Date: 02:55:40 Micro Powder Grinding Mill is an equipment in metallurgy, building materials, chemical industry, mine It has features of small noise, fine powder, uniform discharge I will talk about the Working Principle of Micro Powder Grinding Mill in this articleWorking Principle of Micro Powder Grinding MillNo 1599, Pingzhuang West Road, Shanghai , China +86135 6414 3944 sales@jetmillmfgJet mill working principle

.jpg)

Classifying Separating ALPA Powder Equipment

The classifier wheel with highspeed rotation would create a strong centrifugal force to separate coarse and fine powder Qualified fine powder would go through the wheel vane then into the cyclone or bag filter, while coarse entraining fine powder would lose its speed and fall down along the wall of chamber to the inlet of secondary air3 Our grinding equipment has large processing capacity and can meet the high output needs of mining and metallurgical enterprises 4 JXSC ball mill is designed to be energysaving and environmentally friendly It often forms a closedcircuit ring grinding device with a spiral classifier to produce powder with a relatively uniform particle sizeBall Mill Mining Grinding Mill JXSC Machinery2006年11月28日 Drawing from the third edition of the bestselling Powder Technology Handbook, this book concentrates on handling methods and unit operations for powder and particle processing techniquesItexamines the purpose and factors involved in each processincluding planning, equipment, measurements, and other necessary considerationsPowder Technology Handling and Operations, Process 2012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed Grinding in Ball Mills: Modeling and Process Control

Tin Stripping Solution And Tin Recycling Equipment

Tin Recycling Equipment Structures A typical tin recycling plant consists of the following modules Filter unit: For initial removal of impurities Electrolysis tanks: For recovery of tin by deposition using electrolysis Precipitation tank: Recovery of tin by chemical precipitation Recycling system: Recycling of the treated liquid back into the processHGM series ultra fine powder grinding mill is a new type of mining equipment for making micro powders with threering rollers What Is The Working Principle Of The HGM Micropowder Grinding Mill HGM series ultrafine powder mill consists of a main mill, As the highpressure fan continuously sucks the air inside the equipment, HGM Micropowder Grinding Mill Fine Grinding Mill Grinding 2022年10月17日 Low speed: At low speed, the mass of balls will slide or roll up one over another and will not produce a significant amount of size reduction High Speed: At highspeed balls are thrown to the cylinder wall due to centrifugal Ball Mill; Principle, Working, and Construction » 2024年1月23日 Gypsum powder is formed by a series of treatments on a large bulk of gypsum, with a finished particle size usually around 80325 mesh In terms of the entire production process of gypsum grinding, the equipment required mainly includes jaw crushers, Raymond grinders, etcGypsum Powder Grinding And Processing Plant Equipment

.jpg)

ultra fine powder grinding mill machine working principle

This is a 3D stone powder production line working flow, from the large size stone lumps to the ultra fine stone powder and packedyou will know how many mach2024年1月17日 For nonmetallic mineral grinding, the choice of processing equipment is very important Different types of grinding equipment are suitable for minerals of different attributes, and have specific correspondences to hardness, raw material size, humidity, output, etc, and understanding the working principle, performance characteristics and scope of application of 11 types of grinding equipment commonly used in the nonAuxiliary Equipment; Feeding Conveyor; Home; Products/Rock Powder Grinding Mill Rock Powder Grinding Mill Discharge fineness: 3253000 mesh Feed size: 20mm Output: 120 t/h Working Principle Of Rock Powder Grinding Mill The Rock Powder Grinding MillThe working principle of HC series pendulum high calcium grinding mill machine of high calcium powder production equipment is: take the closed circuit system as an example: raw materials with suitable particle size are sent to the host machine through the feeding mechanism (vibration feeder, belt feeder, screw feeder, airlock feeder, etc);News What Is The Production Equipment Of High Calcium Stone Powder

Multifunctional Ginger Grinding Machine Reputable Vegetable

Working Principle of MultiFunction Ginger Grinder Dry type grinding machine makes use of highspeed relative motion between movable and fixed fluted discs to crush the material through impact friction of the grinding tooth and collision among the materials Then, the ground material will be filtered through 10120 mesh screenThe working principle of the YGM mill is similar to that of the Raymond mill, but the grinding device is equipped with a highpressure spring with a pressure of 10001500 kgWhen the grinding mill starts working, the grinding roller rotates around the main axis and rolls close to the grinding ring under the action of highpressure spring and centrifugal forceYGM Grinding Mill Powder Grinding Mill Fine Grinding MillWorking Principle of Micro Powder Grinding Mill Micro Powder Grinding Mill is mainly formed by mill body, blower fan, ultrafine analyzer, Magnesite grinding equipment includes ultrafine mills, vertical mills, highpressure mills, etc It can Micro Powder Grinding Mill2021年5月5日 Grinding Machine Working Principle: In brief, we can say the working of the Grinding Machine is the Workpiece is fed against the rotating abrasive wheel The action of rubbing or friction generates between wok price Grinding Machine: Definition, Parts, Working

Copper Powder Recovery Equipment JXSC Mineral

The copper powder recovery equipment can recycle and treat the metallic dust pollution generated by the grinding and brushing process in PCB production, reduce the cost of wastewater treatment, save water and electricity, and 2019年10月17日 1 Working principle 2 Structure Let's dive right in! 1 Working Principle of Rod Mill Rod mill is a common equipment for grinding operation in mineral concentrator, which is mainly suitable for rough grinding operationThe Working Principle and Structure of Rod MillWorking Principle of Coarse Powder Grinding Mill European Coarse Powder Grinding Mill European Coarse Powder Mill mainly consists of frame, rotor, support CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and Coarse Powder Grinding Mill SBM Ultrafine Powder TechnologyBall Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powdersBall Mill Grinding Machines: Working Principle, Types, Parts

.jpg)

Vibrating Screen JXSC Mineral

Ammonia Nitrogen Electrolysis Water Treatment Equipment; Tin Stripping Solution And Tin Recycling the metal powder Structures Working Principle Vibrator Screen Structure The main parts of a Vibrating Screen Machine Working Principle Vibrating screen uses electric exciter as a vibrating source, the material will be thrown around the 2023年9月28日 Material feeding: The feed material is introduced into the mill through a feed hopper or a screw feeder It can be in the form of dry powder or a wet slurry Grinding chamber: The material enters the grinding chamber, which is a Working principle of jet mill Jet Mill Equipment ManufacturerAir Classifier Mill: The material is uniformly sent into the grinding chamber by the feeding system, and is strongly impacted by the highspeed rotating grinding disc At the same time, it is subjected to the centrifugal force to collide with the crushing ring gear, and is subjected to various comprehensive forces such as shearing, friction, and collisionAir Classifying Mill ALPA Powder Equipment2021年11月23日 Jet mill, as one of the ultrafine grinding equipment, is also one of the important equipment in the grinding industry After the compressed air of the fluidized bed pulverizer is frozen, filtered and dried, it forms a supersonic airflow through the nozzles and is injected into the pulverizing chamber to fluidize the materialClassification and working principle of jet mill ALPA Powder Equipment