Quartz ball mill

Quartz Ball Mill Quartz Sand Ball Mill for Quartz

Quartz ball mill (quartz sand ball mill) is a specialized quartz grinding equipment developed on the basis of traditional ball mill combining the characteristics of quartz ore The quartz ball mill designed and produced by our company has 2020年5月15日 This study investigates particle size reduction and interparticle agglomeration in clear and milky quartz ground in a planetary ball mill for up to 32 h Particle size distribution Evaluation of particle size reduction and agglomeration in dry 2023年10月27日 Kelsall et al investigated the influence of grinding media density on the grinding behaviour of a small amount of quartz in calcite in a continuous ball mill using A Review of the Grinding Media in Ball Mills for Mineral Processing 2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties Also(PDF) Grinding Media in Ball MillsA Review

.jpg)

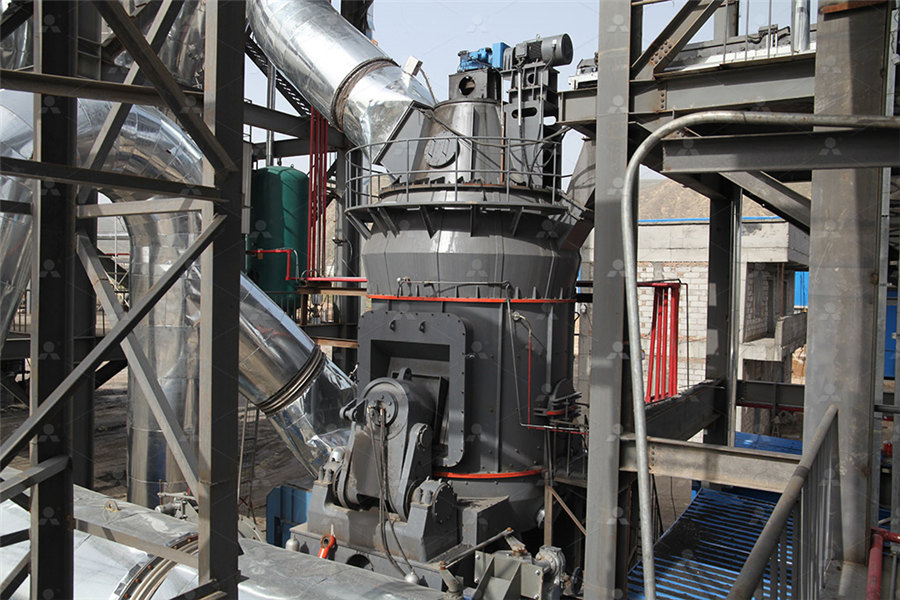

Quartz ultrafine grinding machine EPIC Powder

EPIC’s ball mill classification production line, Jet mill, air classifier, etc, are widely used in the fine processing of silica powder, greatly promoting the application field expansion, technical progress, and industrial upgrading of ultrafine quartz and In this study, the simulation of grinding of quartz is investigated in order to identify the optimal mill operating parameters With the use of population balance modeling the specific rate of Identification of Optimal Mill Operating Parameters during 2002年11月1日 Schellinger's calculated ball mill efficiency, in dry or wet ball mill grinding, ranges between 10% and 19%, with the higher figure occurring at the optimal mill loading In terms of The energy efficiency of ball milling in comminution2020年4月1日 This study investigates particle size reduction and interparticle agglomeration in clear and milky quartz ground in a planetary ball mill for up to 32 h Particle size distribution andEvaluation of particle size reduction and agglomeration in dry

Grinding Media in Ball Mills for Mineral Processing

2023年11月24日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the This paper covers theoretical and experimental explorations for the sake of determining the optimal ball charge in mills In the first part of the paper, on the basis of the theoretical analysis of the energygeometric correlations, which THE OPTIMAL BALL DIAMETER IN A MILLConsider the characteristics of your material, your desired particle size, and your production capacity to determine the ideal size and capacity of ball mill for quartz grinding Types of Ball Mills Available There are several types of ball mills available, including batch, continuous, and planetary ball millsHow to Choose the Right Size and Capacity of Ball Mill for Quartz Quartz grinding ball mills are subject to wear and tear over time, which can lead to reduced equipment life and increased maintenance requirements This can be exacerbated by a number of factors, such as poor quality grinding media or insufficient lubrication Dust ExposureHow to Prevent Common Problems and Safety Hazards ball mills

A Comprehensive Guide to Understanding Quartz Ball Mill

2020年7月15日 A quartz ball mill classification production line is a process that uses ball mills to grind and classify quartz particles The equipment used in this process includes a ball mill, a classifier, a dust collector, and other auxiliary equipment2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside diameter and Ball Mills 911Metallurgist2023年4月23日 One of the most used tumbling mills is the ball mill inders and balls of equivalent volume and a 95% calcite feed combined with a 5% quartz, ball load, density and shape (PDF) Grinding Media in Ball MillsA Review ResearchGate2002年11月1日 Review of the energy to produce new surface of quartz shows comminution efficiency ranging from about 01% to 10%, A ball mill employs steel balls to generate a grinding action, The energy efficiency of ball milling in comminution

Evaluation of particle size reduction and agglomeration in dry

2020年5月15日 This study investigates particle size reduction and interparticle agglomeration in clear and milky quartz ground in a planetary ball mill for up to 32 h Particle size distribution and specific surface area were assessed using laser scattering and nitrogen physisorption methods2017年1月1日 Ball mills have been the most common equipments used for comminution of ores in mineral industries due to their flexibility and versatility in reducing minerals to smaller sizes [1], [2], A typical study of grinding was carried out by Venkataraman and Fuerstenau [12] using a 1:l mix of calcite and quartz in a tumbling ball millGrinding kinetics of quartz and chlorite in wet ball millingContinuous Ball Mill is useful for grinding coarse feed to get fine powder in single continuous operationIt used is for grinding Feldspar, Quartz, iron ore, manganese ore, Zircon, steatite, Ceramics, Cement, Pencil, Paint, Chemical, Ink, Marble, Coal, any types of minerals etcBall Mill Shalimar Engineering2018年2月26日 The ball mill grinds ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuitsHow a Ball Mill Work? for Gold, Diamond Mining,

.jpg)

The Influence of the Grinding Media Diameter on

2024年6月14日 In almost every case, using each of the materials mentioned above requires grinding it to the required grain size, often below 1 mm or even up to several dozen nanometers This grinding is carried out in various types of The mini ball mill is a type of smallscale ball mill, suitable for trial production and small batch production AGICO offers highefficiency mini ball mills at a competitive price Material: quartz, iron ore, aluminum powder, slag, fly ash, Mini Ball Mill – Mineral Grinding Small Ball Mill For 2023年11月22日 Precision Grinding Excellence: Quartz Grinding Ball Mill by SBM 🌐 Project Background: In the thriving landscape, where mineral processing plays a pivotal role in various industries, we are quartz grinding ball mill manufacturarThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates metal oxides, minerals, ores, paints and lacquers, paper, pigments, plant materials, polymers, quartz, seeds, semiprecious stones, sewage sludge, slag, soils, tissue, tobacco, waste samples Planetary Ball Mill PM 100 RETSCH highest fineness

.jpg)

The Advantages of Using Quartz Ball Mill in Mineral Processing

The use of quartz ball mills in mineral processing applications has gained popularity due to their high efficiency and costeffectiveness Understanding Quartz Ball Mills A quartz ball mill is a type of ball mill that uses quartz as the grinding media The grinding media is the balls, which may be made of steel, stainless steel, ceramic, or 2019年12月5日 Quartz ball mill is a special type of ball mill machine series, it is named after the material quartz, but not limited to grinding quartz It can also grind other ore similar to the physical and chemical properties of quartz, such as feldspar, sandstone, dolomite, shaleQuartz Sand Wet Grinding Ball Mill JXSC MachineManufacturer of Ball Mill Machine Quartz Ball Mill Plant And Machinery, QuartzBall Mill, Use Ball Mill In Rajasthan offered by Shree Ji Engineering Works, Beawar, Rajasthan X Shree Ji Engineering Works Mahavir Colony, Beawar, Ajmer, Rajasthan GST 08FAPPB9539H1Z6 is a member of IndiaMARTBall Mill Machine Quartz Ball Mill Plant And Machinery EPIC’s ball mill classification production line, Jet mill, air classifier, etc, are widely used in the fine processing of silica powder, greatly promoting the application field expansion, technical progress, and industrial upgrading of ultrafine quartz and related productsQuartz ultrafine grinding machine EPIC Powder Machinery

.jpg)

Bond Work Index FormulaEquation 911Metallurgist

2013年7月15日 The sample was received crushed appropriately for the ball mill test Ball Mill Grindability Test was conducted by standard practice using 100mesh (150 pm) closing screens The ball mill work index is shown below BM This website is dedicated to the introduction of China's ultrafine ball mill machines, including various types of ball mills, cases of ball crushers, and the latest information about ball mill machines Quartz Ball Mill Lime Planetary Leading Manufacturer Of ultrafine ball millChina Ball 2024年9月23日 Quartz sand ball mill is the key equipment for crushing materials after they are crushed, applicable to quartz sand purification, nonmetallic mineral processing and glass ceramics and other industriesIt can be dry or wet grinding of Dry or Wet Grinding Ball Mill for Quartz Sand JXSC Mineral2024年4月28日 A ball mill is a kind of grinder that grinds and blends materials for the purpose of mineral processing, paint production, pyrotechnics, In the ceramic industry, ball mills are utilized to grind and mix raw materials, ie clays, feldspar, What is a Ball Mill Explained: InDepth Guide JXSC

Grinding Media in Ball Mills for Mineral Processing

2023年11月24日 The ball mill is a rotating cylindrical vessel with grinding media inside, Quartz is one of the most pervasive abrasive materials in mineral processing The chemical composition, microstructure and hardness of grinding media influence Use it as a Lab Ball Mill if you like overgrinding or a Rod Mill if you prefer selective milling 911 Metallurgist is a trusted resource for practical insights, The mill employed grinding quartz had four times as much capacity to produce finished minus65 mesh product as it had to produce finished minus250 mesh sandLABORATORY BALL MILL – (BALL OR ROD) 911Metallurgist2023年1月12日 In this study, silica nanoparticles (SiO2 NPs) were fabricated using a handmade ball mill as a novel, simple, rapid, costeffective, and green approach The sol–gel method was also used to produce these NPs as a comparative method The SiO2 NPs produced by both methods were characterized using highresolution transmission electron microscopy Facile, fast, and green preparation of highpurity and quality silica 2020年5月15日 This study investigates particle size reduction and interparticle agglomeration in clear and milky quartz ground in a planetary ball mill for up to 32 h Particle size distribution and specific surface area were assessed using laser scattering and nitrogen physisorption methodsEvaluation of particle size reduction and agglomeration in dry

Quartz Ball Mill, Ball Mill Grinding Plant zoneding

2017年9月8日 : l Mill: zoneding/products/beneficiation/BallMillhtmlBall mill is working in quartz sand production line Zonedin2014年1月15日 A planetary ball mill (QM3SP2, Nanjing University Instrument, China) was used in all experiments A stainless 80 mL vial was filled with stainless balls in diameter of between 5 mm and 10 mm, which serve as the milling mediumZerovalent metal (Al, Zn, Fe) and quartz sand were individually added as reactive chemicals during ball milling of DPEffects of zerovalent metals together with quartz sand on the This paper covers theoretical and experimental explorations for the sake of determining the optimal ball charge in mills In the first part of the paper, on the basis of the theoretical analysis of the energygeometric correlations, which THE OPTIMAL BALL DIAMETER IN A MILLConsider the characteristics of your material, your desired particle size, and your production capacity to determine the ideal size and capacity of ball mill for quartz grinding Types of Ball Mills Available There are several types of ball mills available, including batch, continuous, and planetary ball millsHow to Choose the Right Size and Capacity of Ball Mill for Quartz

.jpg)

How to Prevent Common Problems and Safety Hazards ball mills

Quartz grinding ball mills are subject to wear and tear over time, which can lead to reduced equipment life and increased maintenance requirements This can be exacerbated by a number of factors, such as poor quality grinding media or insufficient lubrication Dust Exposure2020年7月15日 A quartz ball mill classification production line is a process that uses ball mills to grind and classify quartz particles The equipment used in this process includes a ball mill, a classifier, a dust collector, and other auxiliary equipmentA Comprehensive Guide to Understanding Quartz Ball Mill 2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside diameter and Ball Mills 911Metallurgist2023年4月23日 One of the most used tumbling mills is the ball mill inders and balls of equivalent volume and a 95% calcite feed combined with a 5% quartz, ball load, density and shape (PDF) Grinding Media in Ball MillsA Review ResearchGate

The energy efficiency of ball milling in comminution

2002年11月1日 Review of the energy to produce new surface of quartz shows comminution efficiency ranging from about 01% to 10%, A ball mill employs steel balls to generate a grinding action, 2020年5月15日 This study investigates particle size reduction and interparticle agglomeration in clear and milky quartz ground in a planetary ball mill for up to 32 h Particle size distribution and specific surface area were assessed using laser scattering and nitrogen physisorption methodsEvaluation of particle size reduction and agglomeration in dry 2017年1月1日 Ball mills have been the most common equipments used for comminution of ores in mineral industries due to their flexibility and versatility in reducing minerals to smaller sizes [1], [2], A typical study of grinding was carried out by Venkataraman and Fuerstenau [12] using a 1:l mix of calcite and quartz in a tumbling ball millGrinding kinetics of quartz and chlorite in wet ball millingContinuous Ball Mill is useful for grinding coarse feed to get fine powder in single continuous operationIt used is for grinding Feldspar, Quartz, iron ore, manganese ore, Zircon, steatite, Ceramics, Cement, Pencil, Paint, Chemical, Ink, Marble, Coal, any types of minerals etcBall Mill Shalimar Engineering