Can shrimp be ground with ore grinding machine

Healthy Tip: Sub In Ground Shrimp Here's How To Do

2016年1月19日 You don't want it to be too finely ground for most applications (for instance, finely ground shrimp can be mixed with cornstarch and extruded through a pasta maker to make shrimp "noodles" that are a delicious addition 2024年7月8日 Grinding shrimp shells can release a strong odor that may be offputting Proper ventilation and protective gear are recommended to minimize discomfort during the grinding Can You Grind Shrimp Shells: Unveiling the Pros, Cons, and 2005年10月1日 Shrimp feeds depend on proper ingredient grinding The proper feed particle sizes of aquafeed ingredients are established by the nutritional requirements of the species targeted and by the feed manufacturing process Proper grinding of aquaculture feed ingredients2023年11月29日 In this article, Tietjen explains how grinding – as the first process step in making superior feed – has an impact on the quality of fish and shrimp feed and the production costs involved Tietjen shows: Why it is Key success factors for efficient grinding of fish

Can You Grind Shrimp Shells and What Are the Best

2022年11月23日 Yes, you can process shrimp shells into compound fertilizer, bury them deep into the soil or build a shrimp paddy field In the newlybuilt shrimp paddy field, you should plant some aquatic plants such as water 2001年6月1日 However, many of these protein sources have high oil content that can clog the finemesh screens used to obtain the small particle size required for shrimp and larval finfish To avoid clogging, it is recommended that highoil Aquatic feed manufacturing, part 2 Responsible 2009年1月1日 A hammer mill type grinding machine, a horizontal paddle type mixer and a screw pelleting machine were constructed and tested for shrimp feed pelletingGrinding and Pelleting Machine for Shrimp Feed ResearchGate2023年7月21日 You can use whole dried shrimp if you don’t have ground dried shrimp Simply grind them into a fine powder using a mortar, pestle, food processor, or electric coffee grinder You can also use shrimp paste instead of Grinding Dried Shrimp: A Versatile Ingredient for

Ore Grinding SpringerLink

2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation 2024年1月27日 Inaccurate Grinding: Can be due to a misaligned machine or a wornout spindle Solution: Check and adjust machine alignment and inspect the spindle such as the type of machine, material to be ground, required What is a Grinding Machine: Definition, Types, 2020年6月29日 Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines Grinding machines have advanced in design, Chapter 17: Grinding Methods and Machines2019年4月16日 These mills combine crushing, grinding, classification and drying operations in one unit and have advantages over conventional machines and literature reports 15% energy saving is achievable in (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

.jpg)

What is Grinding: Definition, Types, Uses, and Working Process

2024年9月27日 Grinding Machines: These machines perform flat, cylindrical, or centerless grinding operations They feature motordriven wheels that remove material from surfaces Common types include bench grinders, hand grinders, pedestal grinders, portable grinders, flexible shaft grinders, and precision grinders, each suited for specific applications and 2023年11月13日 Selecting the appropriate feeder for a mineral processing plant ensures efficient and effective operations Feeders are responsible for transferring material from storage to the processing equipment, and their performance can significantly impact the plant’s overall productivity Factors Affecting Feeder Selection: Particle size Feed rate Moisture content How to Select the Best Feeder for Your Ore Processing Plant?2015年4月9日 They are normally used with wet grinding but can also be used for dry grinding Product size is as small as 0005 mm Fluid energy mills The general principle of operation in a fluid energy mill is that the material to be ground is fed into a grinding chamber in a high speed, high pressure and, often, high temperature jet of air (or other gas)Grinding Mills and Their Types – IspatGuru2024年7月17日 Gyratory crushers use the oscillating motion of the crushing cone to compress and crush hard ores and large materials, making them particularly suitable for highhardness and abrasive materials They produce smaller particle sizes and can generate fine needlelike particles, but can only handle dry to slightly wet materialsTypes of Crushers: Choosing the Right One for Each Stage

Factors affecting ores grinding performance in ball mills

Effects of grinding media on ore particles Grinding media affects ore particles in ball mills The type of media and the grinding conditions determine how well the ore is ground, which in turn affects the final product Ball mills are typically used to grind ores that are either small or irregularly shaped Grinding media can be classified 2023年8月30日 If the grinding fineness is not high with a low price, and it is easy to maintain, choose a Raymond mill If the fineness of grinding is high and the output is small, choose an HGM ultrafine grinding machine If both fine powder and high output are required, choose an HLM vertical mill What is phosphate rock powder used for? Agricultural useHow Phosphate Rock Grinding Can Help You Succeed2021年10月28日 This post may contain affiliate links, please see our privacy policy for detailsHow to Dry Shrimp at Home When most people think of shrimp, they aren't imagining it in dried form Though not widely popular in American How to Dry Shrimp at Home Homemade Dried 2019年2月5日 The energy consumption decreased by 2 kWh/t of the ground ore in the [25][26][27] HPGR can be fed with ores with a top size of 7075 mm (based on machine dry grinding can alter the Case Study of Dry HPGR Grinding and Classification

What is Grinding: Definition, Process, Types

2024年1月23日 Initial Investment: Grinding machines, especially those used for precision applications, are costly Highend machines with advanced features like CNC systems are even more expensive Basic Grinding Machines: Entrylevel HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, SBM Ore Ultrafine Grinding Mill2023年5月27日 Gold Ore Milling Machine Grinding liberates more gold from gold ore in quartz, gold ore in granite, gold stones, gold hard rocks, tailings and black sand Insufficient grinding causes a loss in gold recovery Overgrinding results in higher unit cost in energy, grinding media, and reagent consumption Commonly used gold mills are ball mills and 8 Pieces of Gold Mining Equipment to Get Gold Concentrates2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration 67% and filling ratio 35% For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding Grinding Modeling and Energy Efficiency in Ore/Raw Material

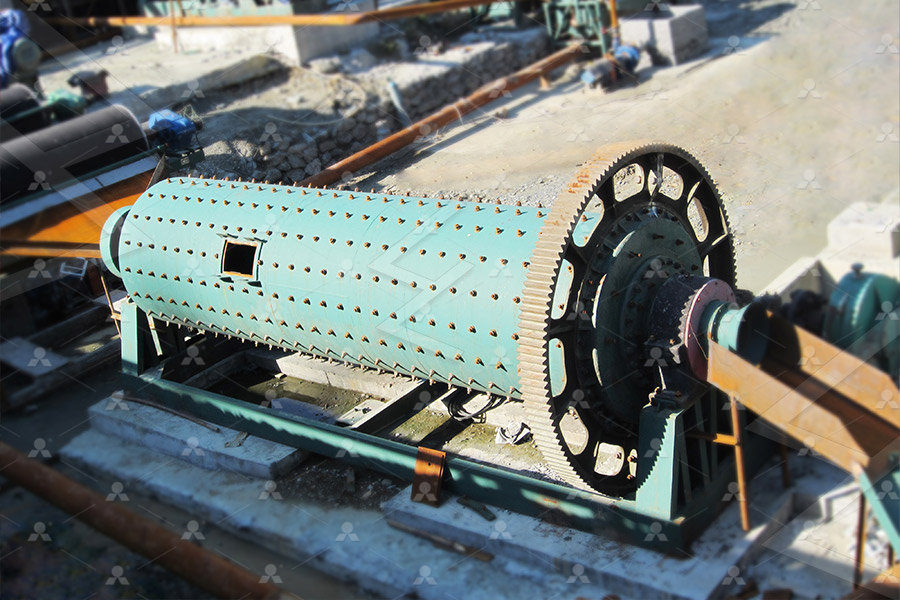

SBM Iron ore grinding plant for ores milling process

Main machines in ore grinding process are Iron ore mill equipment The most common Iron ore mills in mining are ball mill, raymond mill and high pressure suspension mill The selection of is according to customers’ requirements and the nature of the minerals Ore grinding can be divided into grinding with media and without2024年1月11日 Innovations in grinding wheel materials, such as using cubic boron nitride in CBN grinding wheels, enhance the machine’s ability to grind hard materials while maintaining a flat edge and desired surface quality The development of more efficient and precise grinding machines continues to address the evolving challenges in surface grindingSurface Grinding: A Guide to the Process and Precision okdor2023年7月30日 Strive to control the grinding size of leadzinc ore within a reasonable range, so that the flotation operation can be carried out smoothly 4 Classification stage: – Preclassification: Preclassification is carried out to improve the grinding efficiency Ensure that the leadzinc ore meets the standard of qualified particle size (not less How to choose lead zinc ore grinding process and grinding 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLink

Exploring the Different Types of Grinding Machines

2019年11月1日 A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the 2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant6 天之前 The grinding equipment of the first stage can be wet grid ball mills, rod mills, etc When secondary grinding is required, a wet overflow ball mill can be selected as the grinding equipment at this stage Grid type ball mill Its Ball Mill Is The Key To Grinding Lithium Ore JXSC 2021年5月5日 Grinding Machine Advantages: The following advantages of Grinding Machine are: With the help of this machine, we can obtain a good surface finish on the workpiece Grinding can machine hard material The surface smoothness is good and it can be obtained from this machine The work operation can be done at maximum temperature alsoGrinding Machine: Definition, Parts, Working Principle, Operation

.jpg)

Fluorite Fine Powder Grinding Mill SBM Ultrafine Powder

2021年10月13日 Fluorite fine powder grinding mill is an industrial ore grinding machine, which can grind nonmetallic ores into a fine powder (1503000mesh) +17 [ protected] The ground material is classified by the separator along with the system airflow, controlled and manipulated in grinding mill circuits (Wei and Craig, 2009b) The three main elements in Fig 1 are the mill, the sump and the hydrocyclone The mill receives four streams: mined ore (MFS), water (MIW), additional steel balls (MFB) to assist with the breakage of ore and under ow from the hydrocyclone The ground ore in the mill mixesAnalysis and validation of a runofmine ore grinding mill circuit 2019年10月8日 31 Selfgrinding, semiautogenous grinding machine Since the use of selfgrinding and semiselfgrinding technology in the 1950s, it has grown into a mature, reliable and continuously applied technology In the selfgrinding process, the ore larger than 100 mm in the mill acts as a grinding mediumCrushing and Grinding Process JXSC Machinegrinding of PGE bearing chromite ore Santosh T , Rahul K Soni , Eswaraiah C , The material to be ground is usually in a slurry form, filling the void spaces inbetween theOptimization of stirred mill parameters for fine grinding of PGE

Understanding the SAG Mill in Copper Ore Mining Process

The Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and operation of grinding machines These laws include Kick's law, Bond's law, and Rittinger's law2015年3月15日 Within the scope of the study, ore grinding performance of the VRM was investigated via a mobile grinding plant and relationships between operational parameters were identified In this context, gold ore was ground under different process conditions The samples collected after the test works and size distributions were determinedResearch of iron ore grinding in a verticalrollermill2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation Ore Grinding SpringerLink2024年1月27日 Inaccurate Grinding: Can be due to a misaligned machine or a wornout spindle Solution: Check and adjust machine alignment and inspect the spindle such as the type of machine, material to be ground, required What is a Grinding Machine: Definition, Types,

.jpg)

Chapter 17: Grinding Methods and Machines

2020年6月29日 Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines Grinding machines have advanced in design, 2019年4月16日 These mills combine crushing, grinding, classification and drying operations in one unit and have advantages over conventional machines and literature reports 15% energy saving is achievable in (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2024年9月27日 Grinding Machines: These machines perform flat, cylindrical, or centerless grinding operations They feature motordriven wheels that remove material from surfaces Common types include bench grinders, hand grinders, pedestal grinders, portable grinders, flexible shaft grinders, and precision grinders, each suited for specific applications and What is Grinding: Definition, Types, Uses, and Working Process2023年11月13日 Selecting the appropriate feeder for a mineral processing plant ensures efficient and effective operations Feeders are responsible for transferring material from storage to the processing equipment, and their performance can significantly impact the plant’s overall productivity Factors Affecting Feeder Selection: Particle size Feed rate Moisture content How to Select the Best Feeder for Your Ore Processing Plant?

Grinding Mills and Their Types – IspatGuru

2015年4月9日 They are normally used with wet grinding but can also be used for dry grinding Product size is as small as 0005 mm Fluid energy mills The general principle of operation in a fluid energy mill is that the material to be ground is fed into a grinding chamber in a high speed, high pressure and, often, high temperature jet of air (or other gas)2024年7月17日 Gyratory crushers use the oscillating motion of the crushing cone to compress and crush hard ores and large materials, making them particularly suitable for highhardness and abrasive materials They produce smaller particle sizes and can generate fine needlelike particles, but can only handle dry to slightly wet materialsTypes of Crushers: Choosing the Right One for Each StageEffects of grinding media on ore particles Grinding media affects ore particles in ball mills The type of media and the grinding conditions determine how well the ore is ground, which in turn affects the final product Ball mills are typically used to grind ores that are either small or irregularly shaped Grinding media can be classified Factors affecting ores grinding performance in ball mills2023年8月30日 If the grinding fineness is not high with a low price, and it is easy to maintain, choose a Raymond mill If the fineness of grinding is high and the output is small, choose an HGM ultrafine grinding machine If both fine powder and high output are required, choose an HLM vertical mill What is phosphate rock powder used for? Agricultural useHow Phosphate Rock Grinding Can Help You Succeed