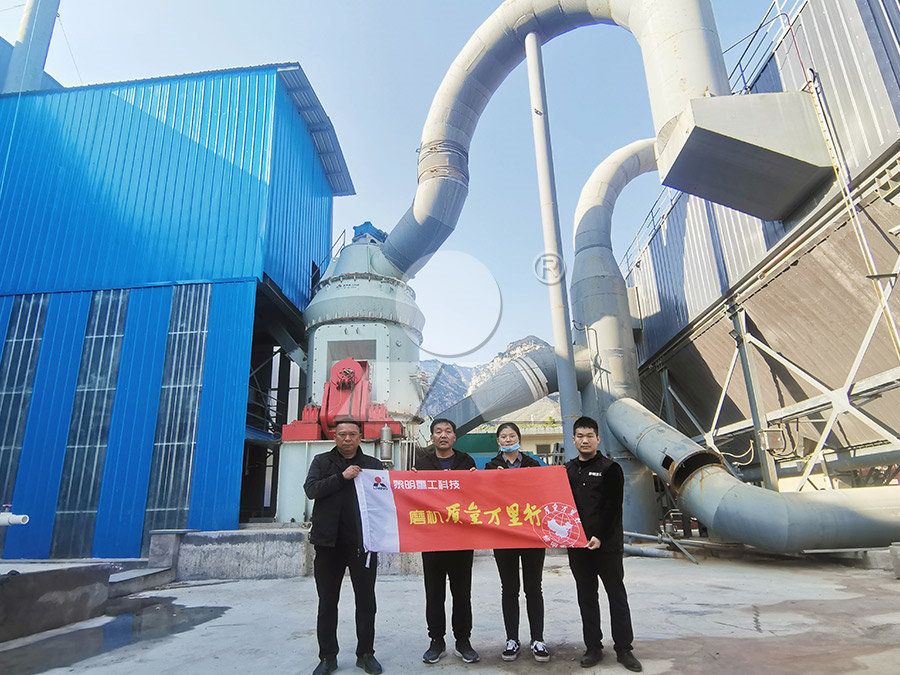

Iron ore powder processing plant renderings

Model of an iron ore sinter plant with selective waste gas

2022年3月1日 Sintering of iron ores is an enormous energyintensive and resources consuming process Introducing a selective waste gas recirculation (SWGR) to the sintering process Five iron ore agglomeration technologies can be defined: briquetting, nodulization, extrusion, pelletization and sintering Sintering and pelletization are the most important agglomerationIron Ore Agglomeration Technologies2023年10月9日 Fluidized bed technology has become a crucial method used to process iron ore powder in nonblast furnace ironmaking, such as smelting reduction and direct reduction This Development and Problems of Fluidized Bed Ironmaking Process: 2019年2月28日 There are mainly three stages in the iron ore concentrate supply chain, ie, the mining stage, the ore concentrate production stage, and the distribution stage In the mining Integrated Production and Distribution Planning for the Iron Ore

Application of deep learning in iron ore sintering process: a review

2024年3月16日 Along with the rapid development of deep learning technology, process modelling and simulation incorporating sintering theory and largescale production data 2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and Iron Ore Processing, General SpringerLink2018年8月9日 This study focussed on flowsheet simulation for mineralogicalbased approach to geometallurgy of iron ores Process unit models used were selected based on their applicability at particle level for iron ore beneficiation Process simulations in mineralogybased 2022年1月1日 Powder Xray diffraction (XRD) is increasingly being used for the characterization of iron ore, sinter, and pellets thanks to the continuing developments in its instrumentation and Quantitative XRD analysis and evaluation of iron ore, sinter, and

.jpg)

The impact of new technologies on the iron ore screening flowsheet

2024年1月16日 The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter the firing process of a pelletizing plant The particle size 2018年6月21日 Fine ore and ore powder, on the other hand, are specially processed for the blast furnace process This ore processing will be discussed in more detail in the next section Iron ore processing After the iron ore has Iron ore mining and dressing tecscience2019年6月11日 The remaining 2% of domestic iron ore was produced for nonsteel end uses Seven openpit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one direct Sintering: A Step Between Mining Iron Ore and 2017年1月1日 Therefore, the generated waste iron ore beneficiation plant tailings (IOBPT) containing 5696% Fe(T), 407% Al2O3, 723% SiO2 and 438% of LOI (contributed mainly from clay and goethite) can be Recovery and separation of iron from iron ore using

.jpg)

Iron Ore Sintering: Raw Materials and Granulation

2016年10月28日 Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slagforming elements and coke The purpose of sintering is to obtain a product with suitable 2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 11 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021)As shown in Fig 13, China is the largest iron ore importing country and imported about Introduction: Overview of the global iron ore industry2021年12月31日 In this article, an ensembled convolutional neural network (CNN)based algorithm is proposed for iron ore pellet size analysis A new customized CNN is ensembled along with VGG16, MobileNet, and Iron Ore Pellet Size Analysis: A Machine LearningBased Image 2018年5月1日 Iron oxide bearing wastes (IOBS) are produced at every part of processing stage of sinter, molten iron and steel production They are hard to handle and in many cases are stockpiled only to be a Factors Affecting Ballability of Mixture Iron Ore Concentrates and Iron

.jpg)

(PDF) Effective Processing of the Iron Ores ResearchGate

2017年1月1日 Effective technology for a complex wasteless processing of the iron ores has been designed and includes three main components (plats): comminution plant, briquette plant, pigment plant2017年10月17日 Figure 1: Steelmaking byproducts for blast furnace (BF), basic oxygen furnace (BOF) and electric arc furnace (EAF) processes Source: World Steel Association (worldsteel) The first step in the production of steel or cast iron alloys is the reduction of iron ore—which contains iron oxide and gangue or mineral impurities—to unrefined, reduced iron formFrom Ore to Iron with Smelting and Direct Iron Reduction2022年7月30日 In order to study in depth the differences in basic characteristics between iron ore fines commonly used by a steel company, and guide the sintering performance plant to choose the best ore allocation method, experimental studies on the basic characteristics of seven iron ore powders of three sizes were carried out using microsintering equipment, mainly Study on the Basic Characteristics of Iron Ore Powder with2013年8月1日 PDF Sintering is a process by which a mixture of iron ores, fl uxes and coke is agglomerated in a sinter plant to manufacture a sinter product of a Find, read and cite all the research you (PDF) Iron ore sintering Part 1 Theory and practice of

Machine Learning based Image Processing for Iron

PDF On Jan 15, 2021, Arya Jyoti Deo and others published Machine Learning based Image Processing for Iron Ore Pellet Size Analysis Find, read and cite all the research you need on ResearchGateIron ore products classification for ironmaking [3] 43 44 Iron Ores and Iron Oxide Materials Pellets produced to be used in ironmaking processes must have characteristics that meet the list of quality specifications regarding physical, Iron Ore Pelletizing Process: An OverviewOre Processing Plant, gold ore processing plant, copper ore processing plant, Iron processing plant +86371 er Follow Us : Home; About Us Profile; The ore powder discharged from the ball mill will be sent to the next procedure: classifyingOre Processing Plant2021年1月1日 Currently, approximately 14 billion tons per year of iron ore tailing wastes (IOT) are generated, mainly in Australia, Brazil, and China This work describes the characterization and application Iron Ore Tailings: Characterization and Applications

.jpg)

Recycling of steel plant mill scale via iron ore sintering plant

2012年4月1日 Request PDF Recycling of steel plant mill scale via iron ore sintering plant During the processing of steel in steel mills, iron oxides will form on the surface of the metal These oxides 2023年4月5日 The blast furnace and direct reduction processes have been the major iron production routes for various iron ores (ie goethite, hematite, magnetite, maghemite, siderite, etc) in the past few decades, but the challenges of maintaining the iron and steelmaking processes are enormous The challenges, such as cumbersome production routes, scarcity of Recent Trends in the Technologies of the Direct Reduction and 2017年3月20日 Concentrates as production of iron ore processing plants mostly has BSA in the range of 5001600 cm 2 /g so it must be re Microstructural analysis was performed on concentrate powder, Physicochemical Problems of Mineral Processing Investigation Download Table Specifications of iron ores required by steel plants for ironmaking from publication: Current strategies and future challenges on exploration, beneficiation and value addition of Specifications of iron ores required by steel plants for ironmaking

Iron Ore Processing Plant CFlo

Processing Iron Ore maximizes recovery of calibrated lumps Our wet screening technology can efficiently recover material upto minus 2mm size, with highest efficiency around the year, even during the monsoon season, which typically traditional dry screens fail to achieve2017年5月1日 General India has the fourth largest iron ore reserves in the world after Russia, Brazil, and Australia[] As per the survey conducted by the Indian Bureau of Mines (IBM) in April 2000, India had 9919 million tonnes of Hazard Identification, Risk Assessment, and Control 2005年11月1日 Request PDF Dust suppression in iron ore processing plants Handling taconite pellets produces dust As the pellets are transported, they abrade and produce a fine material that represents a Dust suppression in iron ore processing plants Request PDF2023年9月18日 This is further supported by a recent study by Higuchi, Lu and Kasai (2017) which shows that Australian ores (Pisolitic Channel Iron Deposits, Banded Iron Formation Marra Mamba and Brockman Ore Behaviour of Iron Ore Granules: Laboratory and

Mineral and Technological Features of Magnetite–Hematite Ores

2021年3月24日 Analysis of the current technical solutions for the processing of iron ores showed that the highgrade ores are directly exposed to metallurgical processing; by comparison, lowgrade ores Dry iron ore beneficiation is without doubt currently being driven forward by Vale in Brazil The company wants to increase its capacity from 340 Mta iron ore at present to 450 Mta in future, dry beneficiation is to be further increased by 10 % from 60 % at present Dry beneficiation capacity will increase by around 110 MtaDry beneficiation of iron ore Mineral Processing2023年2月15日 Hematite, also spelled haematite, is a weakly magnetic iron ore with better floatability than magnetite and wide distributionIt is one of the most important raw materials for the extraction of iron Its composition is complex In addition to containing a small amount of magnetite, the impurity embedding of haematite has uneven particle size and high content of How to Extract Iron from Hematite: Methods and PlantsEvolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2 Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processingIron Ore Pelletizing Process: An Overview IntechOpen

.jpg)

(PDF) An Study on Preparation and Utilization of Tourmaline from

2016年12月31日 Sahoo et al (1980) and Krishna et al (2013), also discussed mineralogical characteristics of some off grade Iron ore in India and the use of Heavy Medium Separation in the processing of Iron Ore 2023年9月4日 Jig machine: processing 30 (2)~05mm coarse iron ore; Shaking table: separating 2~0037mm fine iron ore particles; Spiral chute: processing 01037mm iron ore with low mud content 4 Iron ore dewatering equipment The iron ore mine dewatering operation divides into two parts: concentrate mine dewatering and tailings mine dewateringIron Ore Beneficiation Plant Equipment For Mining Processsite pilot plant tests are recommended as the process appears economically and ecologically feasible and can be retrofitted as tail piece in the existing washing plants [Key words: WHIMS, Iron ore slimes, processing] 1 Introduction Indian Iron ore occurs mostly as oxides in nature A substantial amount of this reserve is high grade hematiteFine Particle Processing Of Iron Ore Slimes From Wash Plant2018年6月21日 Fine ore and ore powder, on the other hand, are specially processed for the blast furnace process This ore processing will be discussed in more detail in the next section Iron ore processing After the iron ore has Iron ore mining and dressing tecscience

.jpg)

Sintering: A Step Between Mining Iron Ore and

2019年6月11日 The remaining 2% of domestic iron ore was produced for nonsteel end uses Seven openpit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one direct 2017年1月1日 Therefore, the generated waste iron ore beneficiation plant tailings (IOBPT) containing 5696% Fe(T), 407% Al2O3, 723% SiO2 and 438% of LOI (contributed mainly from clay and goethite) can be Recovery and separation of iron from iron ore using 2016年10月28日 Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slagforming elements and coke The purpose of sintering is to obtain a product with suitable Iron Ore Sintering: Raw Materials and Granulation2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 11 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021)As shown in Fig 13, China is the largest iron ore importing country and imported about Introduction: Overview of the global iron ore industry

Iron Ore Pellet Size Analysis: A Machine LearningBased Image

2021年12月31日 In this article, an ensembled convolutional neural network (CNN)based algorithm is proposed for iron ore pellet size analysis A new customized CNN is ensembled along with VGG16, MobileNet, and 2018年5月1日 Iron oxide bearing wastes (IOBS) are produced at every part of processing stage of sinter, molten iron and steel production They are hard to handle and in many cases are stockpiled only to be a Factors Affecting Ballability of Mixture Iron Ore Concentrates and Iron 2017年1月1日 Effective technology for a complex wasteless processing of the iron ores has been designed and includes three main components (plats): comminution plant, briquette plant, pigment plant(PDF) Effective Processing of the Iron Ores ResearchGate2017年10月17日 Figure 1: Steelmaking byproducts for blast furnace (BF), basic oxygen furnace (BOF) and electric arc furnace (EAF) processes Source: World Steel Association (worldsteel) The first step in the production of steel or cast iron alloys is the reduction of iron ore—which contains iron oxide and gangue or mineral impurities—to unrefined, reduced iron formFrom Ore to Iron with Smelting and Direct Iron Reduction

Study on the Basic Characteristics of Iron Ore Powder with

2022年7月30日 In order to study in depth the differences in basic characteristics between iron ore fines commonly used by a steel company, and guide the sintering performance plant to choose the best ore allocation method, experimental studies on the basic characteristics of seven iron ore powders of three sizes were carried out using microsintering equipment, mainly