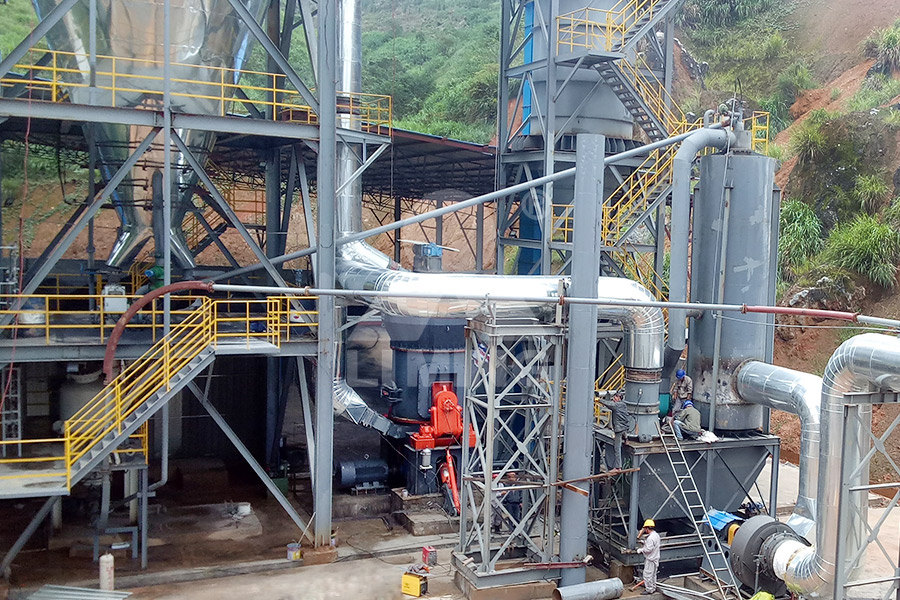

Design of a 300ton potassium feldspar ore powder processing plant

.jpg)

1127 Feldspar Processing

Feldsparsilica mixtures can occur naturally, such as in sand deposits, or can be obtained from flotation of mined and crushed rock Conventional openpit mining methods including removal Feldspar is an aluminosilicate mineral that bears potassium in the interstitial sites To unlock the potassium from the interstitial sites, it was roasted with calcium chloride prepared by mixing Sustainable Process for the Extraction of Potassium from Feldspar 2020年6月16日 Feldspar is an aluminosilicate mineral that bears potassium in the interstitial sites To unlock the potassium from the interstitial sites, it was roasted with calcium chloride Sustainable Process for the Extraction of Potassium from Feldspar 2021年12月3日 In this study, potassium extraction from Kfeldspar ore with an 842% K2O content was studied using chloridizing (CaCl2) roasting followed by water leaching Initially, to (PDF) Extraction of Potassium from Feldspar by Roasting with

.jpg)

Sustainable Process for the Extraction of Potassium from Feldspar

In this study, potassium extraction from a feldspar ore, which contained microcline, albite, muscovite, and quartz, was studied using chloridizing (CaCl2) roasting followed by leaching 2018年4月1日 The low temperature molten salt method was used to extract potassium from Kfeldspar ore, and some related factors including mass ratio between NaNO 3, NaOH, H 2 O The extraction of potassium from Kfeldspar ore by low Processes for potassium extraction from abundant Kfeldspar have recently attracted interest to ensure potash selfsu ciency for developing countries Concurrently, distiller waste and sodaLaboratory and Pilot Scale Studies of Potassium Extraction from K 2016年5月15日 An efficient millingassisted technology to use Kfeldspar and mineralize CO 2 Facilitation the potassium extraction under mild conditions (eg 30–40 °C) A maximum An efficient millingassisted technology for Kfeldspar processing

.jpg)

Systematic review of feldspar beneficiation and its comprehensive

2018年11月1日 The current paper aims to review the research conducted on the equipment of magnetic and flotation as well as collectors in feldspar beneficiation process The main factors Potassium is one of the three most important plant nutri ent elements, which is involved in enzyme activation, pho tosynthesis and protein metabolism (Pi et al , 2014)Laboratory and Pilot Scale Studies of Potassium Extraction from K 2019年6月1日 Potassium chloride (KCl) is widely used in many fields of the processing industry The application in the food industry, as well the one in the pharmaceutic sector, requires very pure KCl crystals (PDF) Production of Potassium Chloride from K 2017年9月25日 To make potassium accessible to agricultural application from Ksilicates, processing on potassic syenite powder under mild alkaline hydrothermal conditions was conducted, as a result of which Potassium fertilizer: Via hydrothermal alteration of Kfeldspar ore

.jpg)

Fertilizing Properties of Potassium Feldspar Altered Hydrothermally

2019年1月22日 Request PDF Fertilizing Properties of Potassium Feldspar Altered Hydrothermally The material obtained through hydrothermal alteration of Kfeldspar rock in alkaline conditions is a potential 2018年1月1日 Advances on thermal decomposition of potassium feldspar with flux agents are reviewed Thermodynamic calculation shows that the temperature range of the thermal decomposition of potassium feldspar Quantitative Assessment of Potassium from kFeldspar ore by Kfeldspar processing for direct powder application (stonemeal) requires only mechanical operations such as comminution and sieving, eliminating the need for water and relatively complex recrystallization units which are necessary for refining sylvinite ore5,18,19 The average potassium content in ultrapotassicMIT Open Access Articles Potassium fertilizer via hydrothermal 2017年9月1日 The low temperature molten salt method was used to extract potassium from Kfeldspar ore, and some related factors including mass ratio between NaNO3, NaOH, H2O and Kfeldspar ore, particle size The extraction of potassium from Kfeldspar ore by low

.jpg)

Engineered feldsparbased ceramics: A review of their potential in

2021年10月1日 Mechanical properties for different feldsparbased materials of literature, indicating the type of material; glass (G), glassceramic (GC) or ceramic (C) and the evaluated property: flexural Serdengeçti et al [15] investigated the production of KCl from a potassium feldspar ore containing 969% K2 O and succeeded in dissolving 998% of potassium through water leaching (a 60 C temperature and a 120 min leaching time) Minerals 2021, 11, 1369 3 of 13 following the roasting process (1:15 potassium feldspar—CaCl2 ratio, 850 C of temperature, and 60 min of roasting Extraction of Potassium from Feldspar by Roasting with CaCl2 2024年2月4日 The Kfeldspar mineral is an insoluble potassium resource with a high potassium content and the most extensive and abundant reserves To address the insufficient supply of soluble potassium fertilizers in China, the application of appropriate processing methods to extract potassium from Kfeldspar and transform it into a soluble potassium fertilizer is of great Review on KFeldspar Mineral Processing for Extracting Metallic 2015年6月17日 The extraction of potassium from Kfeldspar via a calcium chloride calcination route was studied with a focus on the effects of the calcination atmosphere, calcination temperature and time, mass Extraction of potassium from Kfeldspar via the CaCl2

Feldspar Processing Plant Zoneding Machine

Potassium feldspar with finegrained or ironstained refractory impurities requires combined processes such as flotationmagnetic separation or scrubbingmagnetic separationflotation Feldspar Processing Plant 1 Feldspar Flotation + Fuel consumption on container ship powered by Heavy Fuel Oil (HFO) is 0006 kgfuel t1 km1 (global value) at emission factor of 342 kg CO2e kg1 fuel (global value) Fuel consumption on 40t/Class 8 ambient temperature truck by diesel is 0023 kgfuel t1 km1 (EU value) at emission factor of 390 kg CO2e kg1 fuel (EU value) Under this second hypothesis, the total CO2e ELECTRONIC SUPPLEMENTARY INFORMATION (ESI) Potassium 2013年8月1日 had pioneered the process of by burning Sulfur with saltpeter (potassium nitrate) in the 17 th Design of a plant to manufacture Sulfuric acid fro m Sulfur 5 12 CAPACITY LIMITATIONS Design of a Plant to Manufacture Sulfuric Acid from SulfurAlong with potassium feldspar ore reducing, quality down, the requirement of product increasing and mine comprehensive recovery development, introduce gravity separation, flotation, highgradient separation, etc complex selection process to remove quartz, mica, ironbearing titanium, etc associated mineral potassium feldspar is mainly the orthoclase, microcline, perthite, etc, Potassium feldspar process flowsheet Yantai Jinpeng Mining

.jpg)

A Comparative Study of Quartz and Potassium Feldspar Flotation

2024年2月4日 An improved method for producing highpurity quartz (Qtz) and potassium feldspar (Kfs) concentrates was developed using various chemical reagents Froth flotation experiments on a Qtz–Kfs mixture showed that quartz could be selectively floated from Kfs in diluted hydrofluoric acid (HF) using a frother Similarly, feldspar could be selectively floated 2019年8月1日 To make potassium accessible to agricultural application from Ksilicates, processing on potassic syenite powder under mild alkaline hydrothermal conditions was conducted, as a result of which (PDF) Hydrothermal processing on potassic syenite powder: To recover potassium from feldspar, a biowaste, ie, eggshell, was used The chief composition of eggshells is calcite As it is a rich source of Ca, hence it is used with HCl to produce calcium chloride Feldspar is an aluminosilicate mineral that bears potassium in the interstitial sites To unlock the potassium from the interstitial sites, it was roasted with calcium chloride prepared by Sustainable Process for the Extraction of Potassium from Feldspar 2020年3月31日 Consequently, flotation pilot plant testing allows a digital twin (DT) to be generated by combining ore characteristics, process information, and a digital architectural platform(PDF) Pilot Plant for the Processing of a Complex Tin Ore: A

Flotation Reagents: Uses and Advantages in Ore Processing

2016年6月8日 This data on chemicals, and mixtures of chemicals, commonly known as reagents, is presented for the purpose of acquainting those interested in froth flotation with some of the more common reagents and their various uses Flotation as a concentration process has been extensively used for a number of years However, little is known of it as an exact 2005年6月1日 Request PDF Production of potassium feldspar concentrate from a lowgrade pegmatitic ore in Turkey This paper describes the possibility of producing various grade feldspar concentrates by Production of potassium feldspar concentrate from a low 2019年8月26日 Potassium processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Gold Mining Equipment Chat on Potassium Processing Equipment, Process Flow, DOI: 101016/JCJCHE201709006 Corpus ID: ; The extraction of potassium from Kfeldspar ore by low temperature molten salt method @article{Wang2017TheEO, title={The extraction of potassium from Kfeldspar ore by low temperature molten salt method}, author={Zhao Wang and Zhang Quanyou and Ying Yao and Yongzhong Jia and Bin Xie}, The extraction of potassium from Kfeldspar ore by low

Potassium solubilizing bacteria (KSB): Mechanisms, promotion of plant

2017年7月26日 Potassium (K) is considered as an essential nutrient and a major constituent within all living cells Naturally, soils contain K in larger amounts than any other nutrients; however most of the K 2020年4月1日 On the other hand, since most plants are optimized for a specific size fraction (≥ 75 µm) and the tailings of chromite plants are generally characterized by fine particles, a recurring problem Process optimization of a chrome ore gravity concentration plant In this paper Potassium Feldspar powder is going to be used along with flyash Potassium Feldspar powder (PFP) is used as raw material in ceramic and glass industries Potassium Feldspar powder has high silica and alumina content and can be used as one of the source materials to develop Geopolymer concreteStrength and Durability Studies of Flyash and Potassium Feldspar Powder 2023年10月20日 The recovery of KCl from feldspar, by assaying its 721% K2O, was carried out using a 1:125:15 ratio of feldspar:CaSO4:NaCl at 1000 °C for 60 min, followed by leaching, to obtain KCl with 961% Extraction of KCl from Potassium Feldspar by Various Inorganic

.jpg)

Effect of manganese salts on recovery of potassium from Kfeldspar

2019年10月9日 Potassium feldspar is a typical insoluble potassium ore with enormous deposits in China Its industrial utilization has not been developed yet because of high costs and technological difficulties2017年10月30日 Fertilizers ensure the necessary agricultural yields to feed an increasing world population Augmenting fertilizer use conflicts with environmental concerns such as eutrophication and soil pollution, as well as with limited availability of fertilizers in the Global South Currently, potassium fertilizers are soluble salts such as KCl, which are mined in the northern Potassium fertilizer via hydrothermal alteration of Kfeldspar oreSustainable Process for the Extraction of Potassium from Feldspar Using Eggshell Powder Jayashree Vol 43, No 4, pp 825 832 [2018] Quantitative Assessment of Potassium from kFeldspar ore by Roastleaching Process I K AYINLA1*, A A BABA1, M A RAJI1, C D UZONDU1, A A Power Plant Design Nicole Smirnoff download Download Quantitative Assessment of Potassium from kFeldspar ore by Potassium is one of the three most important plant nutri ent elements, which is involved in enzyme activation, pho tosynthesis and protein metabolism (Pi et al , 2014)Laboratory and Pilot Scale Studies of Potassium Extraction from K

.jpg)

(PDF) Production of Potassium Chloride from K

2019年6月1日 Potassium chloride (KCl) is widely used in many fields of the processing industry The application in the food industry, as well the one in the pharmaceutic sector, requires very pure KCl crystals 2017年9月25日 To make potassium accessible to agricultural application from Ksilicates, processing on potassic syenite powder under mild alkaline hydrothermal conditions was conducted, as a result of which Potassium fertilizer: Via hydrothermal alteration of Kfeldspar ore2019年1月22日 Request PDF Fertilizing Properties of Potassium Feldspar Altered Hydrothermally The material obtained through hydrothermal alteration of Kfeldspar rock in alkaline conditions is a potential Fertilizing Properties of Potassium Feldspar Altered Hydrothermally2018年1月1日 Advances on thermal decomposition of potassium feldspar with flux agents are reviewed Thermodynamic calculation shows that the temperature range of the thermal decomposition of potassium feldspar Quantitative Assessment of Potassium from kFeldspar ore by

.jpg)

MIT Open Access Articles Potassium fertilizer via hydrothermal

Kfeldspar processing for direct powder application (stonemeal) requires only mechanical operations such as comminution and sieving, eliminating the need for water and relatively complex recrystallization units which are necessary for refining sylvinite ore5,18,19 The average potassium content in ultrapotassic2017年9月1日 The low temperature molten salt method was used to extract potassium from Kfeldspar ore, and some related factors including mass ratio between NaNO3, NaOH, H2O and Kfeldspar ore, particle size The extraction of potassium from Kfeldspar ore by low 2021年10月1日 Mechanical properties for different feldsparbased materials of literature, indicating the type of material; glass (G), glassceramic (GC) or ceramic (C) and the evaluated property: flexural Engineered feldsparbased ceramics: A review of their potential in Serdengeçti et al [15] investigated the production of KCl from a potassium feldspar ore containing 969% K2 O and succeeded in dissolving 998% of potassium through water leaching (a 60 C temperature and a 120 min leaching time) Minerals 2021, 11, 1369 3 of 13 following the roasting process (1:15 potassium feldspar—CaCl2 ratio, 850 C of temperature, and 60 min of roasting Extraction of Potassium from Feldspar by Roasting with CaCl2

Review on KFeldspar Mineral Processing for Extracting Metallic

2024年2月4日 The Kfeldspar mineral is an insoluble potassium resource with a high potassium content and the most extensive and abundant reserves To address the insufficient supply of soluble potassium fertilizers in China, the application of appropriate processing methods to extract potassium from Kfeldspar and transform it into a soluble potassium fertilizer is of great