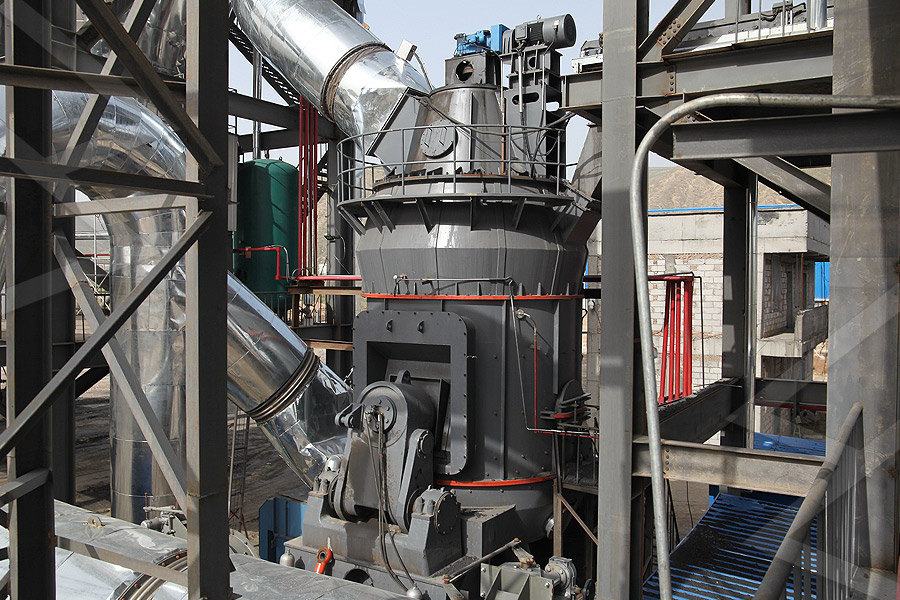

Vertical mill pulverized coal manufacturer

.jpg)

Reliable Coal Pulverizers and Mills » Babcock Wilcox

From our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifierVertical pulverized coal mill integrates grinding, homogenization, drying, powder selection and conveying functions Due to its simple structure, easy operation As a manufacturer of vertical pulverized coal mills,HCM Machinery will What is the process flow of vertical mill to produce The coal vertical mill adopts the temperature detection device, An explosion proof valve is arranged on the upper shell to prevent the explosion of the pulverized coal in the mill and ensure the safe use of the equipment In the nearly 60 years of largescale grinding equipment manufacturing experience, COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

.jpg)

Coal Pulverizer – Power Plant Pall Corporation

Power generation industry studies have shown that pulverized coal power plants are an area where improved equipment Vertical Roller Mills This mill uses hydraulically loaded vertical rollers resembling large tires to pulverize raw with 70% of these particles smaller than 10µm Ingression rates vary with manufacturer Vertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etc Material can be pulverized into 80400Mesh with this millLM Vertical Roller Mill, Vertical Mill ManufacturerThe pulverized coal is then conveyed by air to centrifugal classifiers Figure 5 shows the installation of a vertical roller mill in a typical pulverized fuel system These mills are designed for pressurized operation since primary air fans are located upstream of the millA Comparison of Three Types of Coal Pulverizers Babcock PowerThe coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal Pulverization

Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

A coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production processA coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production processCoal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillReliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldReliable Coal Pulverizers and Mills » Babcock WilcoxInBuilt Reliability for Cement Plant Application: Raw Material, Cement, Slag, Coal and Minerals In May 2019, AMCL signed an exclusive Licensing Agreement for the design, manufacture, erection, commissioning and after sales service with VRM – AMCL Machinery Limited

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, Vertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etc Material can be pulverized into 80400Mesh with this millLM Vertical Roller Mill, Vertical Mill ManufacturerCan GE service my boiler mills? YES Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacitiesWe provide customized maintenance solutions, and offer a full spectrum of highquality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutionsThis is the Power of YesBoiler Mill and Coal Pulverizer Performance GE Steam Power2022年2月24日 Production of clean pulverized coal for boiler combustion heating and power supply Fineness: 200 mesh, D8090, according to the needs of backend combustion Suitable coal types: bituminous coal, anthracite, blue carbon, etc The production of clean pulverized coal is used for boiler combustion heating and power supply to improve the operating efficiency of How is pulverized coal processed? SBM Ultrafine Powder

Coal Crushers Coal Pulverizers Mills Williams Crusher

Coal is crushed to desired fineness between spheres or cylindrical rollers After that, air from the boiler is heated to around 330°C (650°F) The raw coal is then fed into the pulverizer where it is ground into fine coal particles What are the Advantages of Pulverized Coal? Pulverized coal produces a larger amount of heat than traditional coal2003年10月1日 BALANCING OF PULVERIZED COAL FLOWS TO BURNERS IN BOILERS WITH PRESSURIZED VERTICAL SPINDLE MILLS FINAL REPORT FOR THE PERIOD October 1, 2003 to March 31, 2005 by Harun Bilirgen Report Issued June 2005 DOE Award Number DEFC2603NT41867 Energy Research Center Lehigh University 117 ATLSS Drive Bethlehem, BALANCING OF PULVERIZED COAL FLOWS TO BURNERS IN 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic Pulverized Coal Injection 2 Coal Preparation and Pulverized Coal Injection Equipment in Main Structure MAIN BAGFILTERS RAW COAL STORAGE BIN VERTICAL ROLLER MILL VERTICAL ROLLER MILL DYNAMIC CLASSIFIER MILL CHARGING CONVEYOR RAWC OAL STORAGE BIN SIEVING MACHINE ROTARY VALVE RAWC OAL MAIN BAGFILTER Pulverized Coal Injection Paul Wurth

.jpg)

Vertical Coal Mill Manufacturer Cloud Computing at ETW

The vertical coal mill makes use of hot air for coal powder drying and delivering Through a nozzle ring, the hot air is uniformly distributed around the grinding wheel, responsible for drying the pulverized coal and delivering the material to the separator at the upper part of the machineSince the first application using an MPS mill to process pulverized coal in Germany in the mid 1960s, there have been over 2,000 different MPS mill installations operating in coalfired power plants worldwide As one of the most popular coal pulverizers in the utility industry, the MPS mill was first introduced into the US in the early 1970sCoal Pulverizer Design Upgrades to Meet the Demands of Low Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields Its special design structure and production process creates the higher production Vertical Coal Mill Great WallThe pulverized coal screw conveyor is widely used in coal pulverized transportation scenarios in coal industry, electric power industry, chemical industry and other fields Specific application scenarios include: 1 Pulverized coal transportation links such as ash storage, coal mill, pulverized coal incineration system, etc 2Pulverized Coal Screw Conveyor Dahan Conveyor Manufacturer

.jpg)

How Does a Vertical Coal Mill Work

2024年3月16日 A vertical coal mill is a type of industrial milling equipment used to crush and grind coal into powder for use in thermal power the pulverized coal is carried upward by a highspeed airflow generated by the rotating table and directed towards a classifier following the manufacturer’s recommendations for lubrication LM series Large Vertical Roller Mill comes into being The system of blast furnace pulverized coal has been widely used in Electric Power, Steel and Metallurgical industry etc In the whole system, the preparation of pulverized coal is the most important step Common mill can’t satisfy the needs of pulverized coal due to its high demand and Large Pulverized Coal Preparation System, Coal Grinder Milling Mill Vertical Coal Mill is specially used for ultrafine grinding of raw coal and bituminous coal An explosion proof valve is arranged on the upper shell to prevent the explosion of the pulverized coal in the mill and ensure the safe use of the equipment In the nearly 60 years of largescale grinding equipment manufacturing experience, coal grinding machine CHAENGFuel: gas, pulverized coal, gas coal cofiring, and other fuels Activity degree : more than 320 ml Double beam lime kiln saves energy and require lower investment, it is applied for steel, power and papermaking, etcVertical Lime Kiln Lime Kiln Manufacturer Output: 501200TPD

How to Process Coal into Pulverized Coal in 5 Steps?

2024年1月11日 With a vertical roller mill (VRM) VRMs consist of a rotating table or bowl and rollers 1 To grind the coal, feed raw or initially crushed coal into the mill which is then ground between the rotating components; 2 Finally, hot air removes moisture, carries the pulverized coal out, and a classifier segregates the particles; Here is all you need to know about the VRM:Pulverized Coal Vertical Mill For Metallurgy Manufacturers, Suppliers, Factory from China The business keeps to the operation concept "scientific management, premium quality and efficiency primacy, customer supreme for Pulverized Coal Vertical Mill For Metallurgy, Pendulum Roller Mill , Ygm 130 , Illite Ultrafine Mill , China Grinder Pulverized Coal Vertical Mill For Metallurgy Manufacturers, Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifierVertical pulverized coal mill integrates grinding, homogenization, drying, powder selection and conveying functions Due to its simple structure, easy operation As a manufacturer of vertical pulverized coal mills,HCM Machinery will What is the process flow of vertical mill to produce

COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

The coal vertical mill adopts the temperature detection device, An explosion proof valve is arranged on the upper shell to prevent the explosion of the pulverized coal in the mill and ensure the safe use of the equipment In the nearly 60 years of largescale grinding equipment manufacturing experience, Power generation industry studies have shown that pulverized coal power plants are an area where improved equipment Vertical Roller Mills This mill uses hydraulically loaded vertical rollers resembling large tires to pulverize raw with 70% of these particles smaller than 10µm Ingression rates vary with manufacturer Coal Pulverizer – Power Plant Pall CorporationVertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etc Material can be pulverized into 80400Mesh with this millLM Vertical Roller Mill, Vertical Mill ManufacturerThe pulverized coal is then conveyed by air to centrifugal classifiers Figure 5 shows the installation of a vertical roller mill in a typical pulverized fuel system These mills are designed for pressurized operation since primary air fans are located upstream of the millA Comparison of Three Types of Coal Pulverizers Babcock Power

HighEfficiency Vertical Coal Mill Enhancing Coal Pulverization

The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresA coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production processCoal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillA coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production processCoal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillReliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldReliable Coal Pulverizers and Mills » Babcock Wilcox