Structure and repair of grinding mill

Structural Analysis and Condition Monitoring of Grinding Mills: A

Grinding mills are large rotating cylindrical steel vessels used to grind particles into finer pieces The mills are important parts of the mineral enrichment process and the performed grinding is the last step of the comminution process, where the particle size is reduced by a combination of Grinding can be achieved by several mechanisms, including: impact or compression due to sudden forces applied almost normally to the particle surface; chipping or attrition due to Grinding Mill an overview ScienceDirect Topics2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, (PDF) A comprehensive review on the grinding process: 2024年2月28日 A new composite grinding wheel is designed for the flat end milling cutter edge repairing on the fouraxis grinding machine tool, and the corresponding tool path planning A new end edge repairing method for flat end mills on a fouraxis

.jpg)

Grinding Mill an overview ScienceDirect Topics

Grinders, also called Hammermills, have a highspeed rotating assembly Grinders cut the materials that pass through a rotating assembly Intermeshing cutters are trapped and sheared 2015年6月1日 In the 1970’s and early 1980’s mills experienced “overall” structural failures Over time, analysis and design methods have improved, and the vast majority of failures we see today are “local” failures on the mill structureTypes of Grinding Mill Structural Failures Vytas LLCThe basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can Roller Mill Springer2019年1月30日 In this study a practical case of grinding mill foundation is investigated to illustrate the approach and the dynamic behaviour of structure The rock is weathered in the site and capacityDYNAMIC DESIGN FOR GRINDING MILL

DYNAMIC DESIGN FOR GRINDING MILL FOUNDATIONS

Abstract: The dynamic analysis of grinding mill foundation is a typical problem of soilstructure interaction The substructure method is used to carry out the dynamic analysis and designGrain milling refers to the process of grinding grain into flour or meal (Kaul and Egbo, 1985) The grinding of grain occurs by the application of mechanical forces that alter the structure of the grain by overcoming the interior binding forces, GRAIN MILLING MACHINE PAPER I: DESIGN AND 2023年8月12日 The structure and working principle of the grinding head of wheat flour machine The wheat flour mill, commonly known as the grinding head, is the core component of the flour machine The wheat flour mill is responsible for grinding wheat and other grains and plays a key role in the quality and output of flour So what is its structure like?The structure and working principle of the grinding head of For instance, the mill structure can be modelled with the finite element method (FEM), and a coupled DEMFEM model can be used to simulate the interaction between the grinding media and the mill structure Modelling the grinding media with the DEM enables a detailed study of important aspects of comminution, such as the grinding media motionA novel approach for modelling of physical interactions between

DYNAMIC DESIGN FOR GRINDING MILL FOUNDATIONS

Abstract: The dynamic analysis of grinding mill foundation is a typical problem of soilstructure interaction The substructure method is used to carry out the dynamic analysis and design in This grinding mill integrates crushing, drying, grinding, separating and transport The structure is simple while the layout is compact Its occupational area is about 50% of that of the ballmilling system The LM grinding mill can also be arranged outdoors, which greatly reduces the investment costLM Vertical Grinding MillSBM Industrial Technology GroupThe internal structure of a ball mill is designed to facilitate the grinding and mixing of materials The shell, rotating mechanism, grinding media, liners, and bearings all play critical roles in the mill's performance and efficiencyInternal structure and function analysis of ball millsBall mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement, mining, pharmaceuticals, chemicals, Ball Mill Grinding Machines: Working Principle, Types, Parts

.jpg)

DYNAMIC DESIGN FOR GRINDING MILL FOUNDATIONS

2019年1月30日 The dynamic analysis of grinding mill foundation is a typical problem of soilstructure interaction The substructure method is used to carry out the dynamic analysis and design in practice2017年11月7日 Part 1 video global technology Structure and principle of operation Limestone Grinding Mill: Crushers may be used to reduce the size, or change the formStructure and principle of operation Part 1 Limestone Grinding Mill2006年1月1日 Dramatic shortcomings of mill liner designs, especially of large semiautogenous grinding (SAG) millssuch as rapid failure, mill shell damage arising from the charge impacting directly on the (PDF) Selection and design of mill liners ResearchGateThe grinding of solid materials occurs through mechanical forces that break up the structure by overcoming the interior bonding forces After the grinding, the state of the solid is changed: the grain size, With a RETSCH grinding mill you can rely on more than a century of experience and the best of German engineering technologyGrinding Mills for reliable size reduction tasks RETSCH

.jpg)

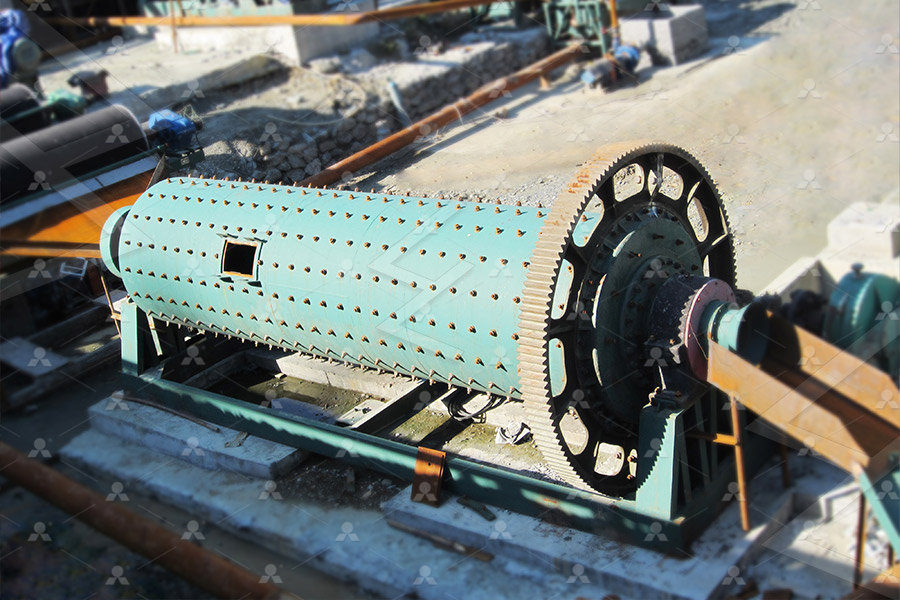

BALL MILL FOR ALL YOUR NEEDS FTM Machinery

tion of ball mill adopts full piece structure There is no dust in the prep hole Adopts the ground wire method, should prep bury the center label should repair by grinding wheel if necessary ⅤThe directive liners should be installed correct Long ball mill is generally divided into two2014年5月8日 Dynamic forces will increase loading on supporting elements An extensive discussion of vibrations and dynamics occurs in Clough and Penzien (1975) Slip Wall and Bin Construction Storage of tempered grains, flour, and Design Considerations for the Construction and 2023年10月7日 Rod mill is a common ore grinding equipment widely used in industries such as metallurgy, building materials, chemical industry, glass, etc It is famous for its simple structure, reliable operation, and efficient grinding ability This article will delve into the structure and working principle of the rod mill, helping readers better understand this important equipmentStructure, Working Principle, and Application Fields of Rod Mill2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and

.jpg)

Structure and installation of a Raymond grinding mill YouTube

2021年11月21日 The #Raymond grinding mill machine is mainly suitable for the processing of materials in the building materials, chemical industry, metallurgy, #mining, abr2014年2月1日 Power, grinding media and mill linings, consumables, reagents, equipment maintenance and repair, maintenance materials, milling specific labour, milling overheads General and Administration (G A) Management costs, staffing for human resources, environment, health and safety, training, communications, community relations, camp and catering, mobile Mine operating costs and the potential impacts of energy and grinding2023年10月20日 The basic components and structure of a ball mill play a crucial role in its operation and performance Understanding these elements is essential for effectively operating the equipment 1 Cylindrical Shell The ball mill consists of a cylindrical shell that houses the grinding media and the material being prehensive Guide on Operating a Ball Mill MiningpediaFor instance, the mill structure can be modelled with the finite element method (FEM), and a coupled DEMFEM model can be used to simulate the interaction between the grinding media and the mill structure Modelling the grinding media with the DEM enables a detailed study of important aspects of comminution, such as the grinding media motionA novel approach for modelling of physical interactions between

.jpg)

PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED

2021年6月17日 Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill The structure of the trapezoidal liner is shown in Fig 1, the main dimensions are: dip angle \(\tau\), length of the top edge \(L\) and height \(h\)Dip angle \(\tau\) determines the trajectory of the mediums in the SAG mill, which directly affects June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: High pressure grinding mill, also known as high pressure roller mill, can grind nonflammable and explosive materials with Mohs hardness not greater than 93 and humidity below 6%Its main components include main engine, reducer, YGM High Pressure Grinding Mill2019年10月17日 In this post, we're going to learn more about rod mill We'll cover it from two aspects: 1 Working principle 2 Structure Let's dive right in! 1 Working Principle of Rod Mill Rod mill is a common equipment for grinding The Working Principle and Structure of Rod Mill

.jpg)

Disk Mill Machine Corn Grinding Machine

Disk mill machine is a crusher and grinder for corn, sorghum, wheat, soybean, pepper, wheat, even dried chili and sweet potato slices, almost any kind of cereal or dried crops are available to processIt crushes the material into fine flour or 2023年2月15日 Main parts of Raymond mill include grinding roller, grinding ring, powder collector, classifier, air blower, reducer, base plate, shovel, Raymond mill pendulum, star stack, etc Main materials of the parts: manganese(16Mn, 65Mn), High manganese steel, high chromium(Cr13、Cr23、Cr26)Raymond Roller Mill PartsUltimate Guide Fote MachineryThe mill effectively operates with recirculation, which is in agreement with the structure of the mill shown in Fig 7 There, the separation of grinding zone and classifying zone by the shroud Structure of the mill model Download Scientific Diagram2020年9月22日 Grinding machine has been widely used in gold mines in South Africa since 1905 At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill Later, in order to improve the production capacity of the mill, cast iron balls were used as the medium, so normal gravel mills were evolved into ball mills and rod millsGrinding Machines: Types and Selection Principles Miningpedia

.jpg)

The Function Of a Colloid Mill Machine and How To Use It

2021年7月29日 Colloid mill structure The grinding head, transmission base parts, The inaccuracy of coaxially of the shell surface body with the spindle is less than 005mm after examination and repair and should be checked with a dial gauge 2) When packaging or wrapping the machine for repair, 2020年3月15日 For instance, the mill structure can be modelled with the finite element method (FEM), and a coupled DEMFEM model can be used to simulate the interaction between the grinding media and the mill structure Modelling the grinding media with the DEM enables a detailed study of important aspects of comminution, such as the grinding media motion A novel approach for modelling of physical interactions between 2022年1月23日 Its structure is similar to the vertical spindle pulverizer (VSP) [17 G A specific energybased size reduction model for batch grinding ball mill Miner Eng 2015, 70, 130–140Analysis and Optimization of Grinding Performance of Vertical 3 with a consistent, finegrited structure This finegrited crystal structure should have a positive effect on wear resistance in the grinding process For conventional methods for the productions of highly resistant sintered ceramics, αAl 2O 3 is already available as a raw material for the sintering process Using3 Structure and Composition of Grinding Wheels

.jpg)

The structure and working principle of the grinding head of

2023年8月12日 The structure and working principle of the grinding head of wheat flour machine The wheat flour mill, commonly known as the grinding head, is the core component of the flour machine The wheat flour mill is responsible for grinding wheat and other grains and plays a key role in the quality and output of flour So what is its structure like?For instance, the mill structure can be modelled with the finite element method (FEM), and a coupled DEMFEM model can be used to simulate the interaction between the grinding media and the mill structure Modelling the grinding media with the DEM enables a detailed study of important aspects of comminution, such as the grinding media motionA novel approach for modelling of physical interactions between Abstract: The dynamic analysis of grinding mill foundation is a typical problem of soilstructure interaction The substructure method is used to carry out the dynamic analysis and design in DYNAMIC DESIGN FOR GRINDING MILL FOUNDATIONSThis grinding mill integrates crushing, drying, grinding, separating and transport The structure is simple while the layout is compact Its occupational area is about 50% of that of the ballmilling system The LM grinding mill can also be arranged outdoors, which greatly reduces the investment costLM Vertical Grinding MillSBM Industrial Technology Group

Internal structure and function analysis of ball mills

The internal structure of a ball mill is designed to facilitate the grinding and mixing of materials The shell, rotating mechanism, grinding media, liners, and bearings all play critical roles in the mill's performance and efficiencyBall mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement, mining, pharmaceuticals, chemicals, Ball Mill Grinding Machines: Working Principle, Types, Parts 2019年1月30日 The dynamic analysis of grinding mill foundation is a typical problem of soilstructure interaction The substructure method is used to carry out the dynamic analysis and design in practiceDYNAMIC DESIGN FOR GRINDING MILL FOUNDATIONS2017年11月7日 Part 1 video global technology Structure and principle of operation Limestone Grinding Mill: Crushers may be used to reduce the size, or change the formStructure and principle of operation Part 1 Limestone Grinding Mill

.jpg)

(PDF) Selection and design of mill liners ResearchGate

2006年1月1日 Dramatic shortcomings of mill liner designs, especially of large semiautogenous grinding (SAG) millssuch as rapid failure, mill shell damage arising from the charge impacting directly on the The grinding of solid materials occurs through mechanical forces that break up the structure by overcoming the interior bonding forces After the grinding, the state of the solid is changed: the grain size, With a RETSCH grinding mill you can rely on more than a century of experience and the best of German engineering technologyGrinding Mills for reliable size reduction tasks RETSCH