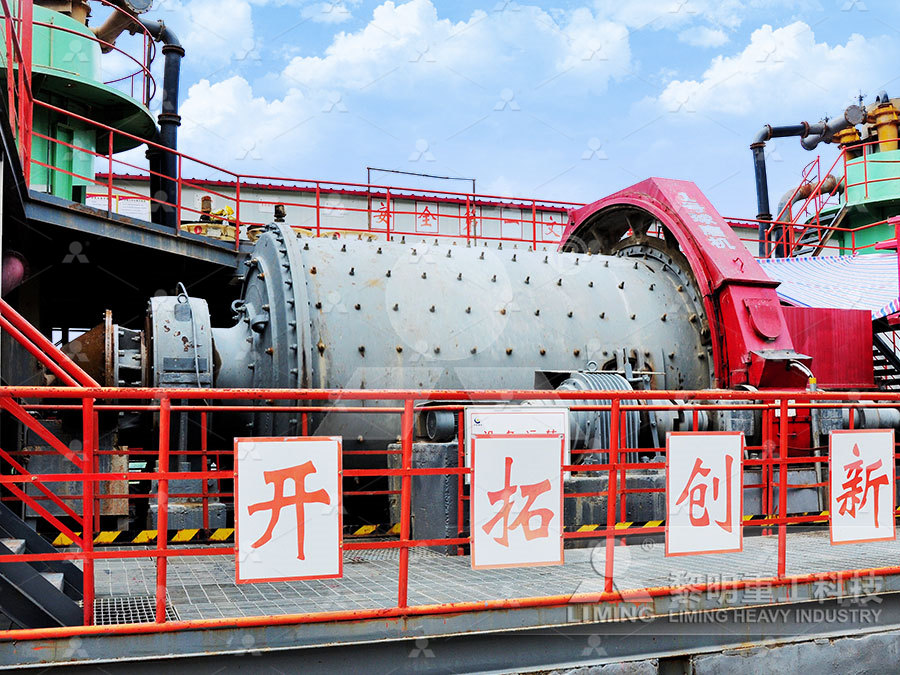

800*400 type silica grinding mill

.jpg)

Silica mill All industrial manufacturers

Output: 400 kg/h 10,000 kg/h • High energy utilization rate, low operating cost, grinding particle size range D50: 0510μm • The revolution of dry milling technology, the milled particle size Horizontal Silica Sand Grinding Mill Machine, Find Details and Price about Silica Sand Grinding Mill Sand Mill from Horizontal Silica Sand Grinding Mill Machine Zhengzhou Hengxing Heavy Horizontal Silica Sand Grinding Mill MachineBrowse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills Grinding mills for mining and minerals processing MetsoFor over 60 years, CITIC HIC has focused on providing global customers with reliable, energysaving and highefficiency mineral grinding mills, such as AG mills, SAG mills and overflow Grinding Mills Mineral Processing Equipment CITIC HIC

HIGmill high intensity grinding mill Metso

The Metso HIGmill™ is an advanced, energyefficient fine and ultrafine grinding solution that utilizes proven technology With the tall, narrow, vertical body arrangement, grinding media is Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Grinding Metso is the ideal Variable Speed Rotor Mill for comminution at pilot plantscale in the plastics industry Two Mills in one instrument: With the cutting rotor you turn the PULVERISETTE 14 Powder mill, Powder grinding mill All industrial manufacturersThe PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml It processes up to 8 samples simultaneously which Planetary Ball Mill PM 400 RETSCH powerful and quick grinding

.jpg)

SPEX™ SamplePrep Geno/Grinder™ Accessory, Grinding Mill

Acid washed silica grinding beads; Bead size ranges from 8001000μm; Specifications Product Type: Silica Grinding Beads: For Use With (Equipment) Titer plates and vial sets of Geno/Grinder: Particle Size: 400 to 600 μm: For Use With Accessory, Grinding Mill at Fishersci Test Order Status; Quick Order; Support; Sign In 1) Ball mill is an efficient tool for grinding many materials into fine powder 2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine 3) Ball mill is widely used in building material, and chemical industry 4) Selling Silica Sand Grinding Raw Mill MachineLimestone/ Cacium/ Raymond Type Roller Grinding Mill Limestone Powder Making Machine FOB Price : US $ PE 400*600 Jaw Crusher Line with Low Price for Ballast/Rock Gold/Dolomite Sand/Dolomite/Diamond Waste/Copper is professional in manufacturing the crusher and grinding mill over 15 years since 2005, which located in Hightech Crusher; Grinding Mill; Rotary Dryer Manufacturer, Cone Crusher, Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with a capacity range of 11000tph There are two types of feeding opening designs, rectangular and square Jaw Crusher JXSC Machinery

Newtype Pneumatic Ultra Fine Grinding Mill (Jet Mill) Cross Jet Mill

Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse Grinding Mill Rod Mill; New Type of Fine Particles Classifier Sharp Cut Separator2023 low price silica grinding ball mill easy operate way from Henan Hongxing $14,50000 Min Order: 1 set Previous slide Next slide Quartz Silica Sand Powder Grinding Machine Kaolin Clay Ceramic Ball Mill for clays $5,00000 Min Order: 1 set Previous slide Next slideSilica grinding ball mill2021年4月21日 The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable laboratory batch type stirred mill The experimental results were evaluated using stress intensity analysis The performance was also compared in terms of mill orientation The results showed that the d50 values decreased with The Influence of Stirred Mill Orientation on Calcite Grinding2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding

INBEST Ceramic

Maintain the media charge at 48%~55% of total mill volume in batchtype mills and 38%42% in continuous mills We recommends 55% to 65% of critical mill speed for optimum grinding performance [100% Critical mill speed=423/D,D=inside diameter(m)] Dry grinding requiress faste mill speeds than wet grindingSilica Grinding Beads (US ENG) SDSpdf (1817 KB) 800 micron Low Binding Silica Beads Low Binding Beads are chemically treated so they bind less solutes liberated from homogenized samples Untreated silica and zirconium beads have surface chemistries that bind DNA, RNA, and proteins upon 800 micron Low Binding Silica Beads OPS Diagnostics LLCCylindrical grinding, Centreless grinding, Internal grinding, Surface grinding , Tool and Cutter grinding, Thread grinding, Crankshaft and Camshaft grinding A Grinding Wheel is basically a precision tool composed of abrasive grains held together by a bonding material or ' bond' The abrasive grains provide the wheel with its cutting points , whichGrinding Wheels Master AbrasivesSilica sand ball mill is a professional ball mill equipment for grinding silica sand In some areas, it is also called silica sand grinding mill or silica sand grinding machineSilica sand is a chemically stable silicate mineral with particle size Wet Dry Silica Sand Ball Mill for Silica Sand Grinding

Silica sand Ball millSinonine

Silica sand ball mill is a new type of dry ball mill Features and technology advantages of silica sand ball mill 1 The lining board and grinding medium of the ball mill are made of nonmetal wearresistant materials to avoid iron pollution; Silica Sand Plant Mineral Ore Ball Mill Grinding For Gold Ore Mining, New Type Limestone Ball Grinding Mill Suppliers Raw Gold Ore Grinding Ball Mill Suppliers Mining Grate Ball Mill Horizontal Ball Grinding Mill/Continuous Ball Mill for Silica Sand, Gypsum, Minerals Grinding $4,00100 $4,21000Silica Sand Plant Mineral Ore Ball Mill Grinding For Gold Ore The Metso Outotec® Open Ended Discharge Grinding Mill (OED Mill) Final grain size: 20 µm 400 µm Output: 50 kg/h 30,000 kg/h Motor power: 11, 22, 45, 90, 160 kW The universal impact mills type “P IMPACT MILLS TYPE “P – D – PC” are specially used for: Powder mill, Powder grinding mill All industrial manufacturersBuy ColeParmer SamplePrep BM400230 Mixer/Mill® SingleClamp HighEnergy Ball Mill; Adjustable clamp accepts vials in various materials to effectively grind all sample types and to avoid contamination from specific ColeParmer SamplePrep 2160 Acid Washed Silica Grinding Beads, 800 to 1,000 µm; 200 g Bottle UX0457547 $19740 USD ColeParmer SamplePrep BM400230 Mixer/Mill® SingleClamp

.jpg)

Silica Powder Grinding Mill Machines

2024年2月22日 Here are some common types of silica grinding mill machines: 1 Ball Mill: A traditional cylindricalshaped mill rotating on its axis, containing steel balls as grinding media Silica is fed into the mill along with the balls, and as the mill rotates, the grinding media crushes the silica particles into finer powdersThe BM400 Mixer/Mill (part #8000M), is a highenergy ball mill that grinds up to 02 10 grams of dry, brittle samples (2162) LOW BINDING SILICA GRINDING BEADS (800 UM) View Details: 2165 (2165) SILICA GRINDING BEADS (400600 UM) View Details: 2166 (2166) SILICA GRINDING BEADS MOLECULAR BIOLOGY GRADE: View Details:BM400 Mixer/Mill ® (part # 8000M) HighEnergy Ball MillWith our manufactured Horizontal Grinding Mills, we ensure a cost effective grinding in many industries, be it small scale or large scale The grinding mills supports technically advanced functionality ensuring high quality nutritional flour with a very fine textureDanish Type / 3 Leg Horizontal Flour Mill ADINATH STONESFinal grain size: 74 µm 400 µm Rotational speed: 21 rpm Output: 16 t/h 50 t/h Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which is widely used Mill, Grinding mill All industrial manufacturers

.jpg)

Grinding Jars for Mixer Mill MM 400 Lab Unlimited

High quality range of Grinding Jars for Mixer Mill MM 400 products available at low cost with Free Delivery available (Terms and Conditions apply) To view pricing in Pounds Sterling(£) visit: labunlimitedcouk XBuy ColeParmer SamplePrep BM400115 Mixer/Mill® SingleClamp HighEnergy Ball Mill; Adjustable clamp accepts vials in various materials to effectively grind all sample types and to avoid contamination from specific ColeParmer SamplePrep 2160 Acid Washed Silica Grinding Beads, 800 to 1,000 µm; 200 g Bottle UX0457547 $19740 USD ColeParmer SamplePrep BM400115 Mixer/Mill® SingleClamp Models: HGM80, HGM90, HGM100, HGM100A, HGM125 and HGM1680 Power: 1233444 kw Finished size: 325~3000 meshes, 547 micron HGM Micro Powder Grinding Mill is the new type mining equipment for making micro powders, fine powders,which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, Grinding MillThe company′s main products are: Wet ball mill (grinding) production line, dry ball mill with sorting machine production line, high purity stone English system sand machine, air classifier, the board type magnetic separator, quartz pickling equipment, drum washing machine, vertical ring high gradient magnetic separation machine, hydraulic classifier, scrubbing machine, dryer, Silica Sand Processing Equipment Micron Grinding Ball Mill Air

Knee Type Universal Mill UK800 Coastal Engineering Supplies

Knee Type Universal Mills UK800 ISO50 Spindle Taper 22 / 4kw Spindle Motors 1320 X 320/360mm Tables Price Ex VAT Ex our stores: 0400 mm Table swivel: None Ram travel: 500 mm Main motor: 22 kw Dimension (L x W x H) MT800 Gear Type Twin Spindle Mill With Turret Type Head ISO40/ISO50 Spindle Taper; 22/4KW Spindle Motor;Ball mill is widely used in silica sand grinding process Vertical mill is also widely used in silica sand grinding process Both ball mill and vertical mill have their own advantages and disadvantages Here we will analyze the advantages and disadvantages of ball mill and vertical mill to help you choose the best silica sand grinding mill for What is the best for grinding silica sand ball mill or vertical mill1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control system, including automatic start and stop, adjustment of grinding speed and addition of grinding media to improve the convenience of operation;Ball Mill Mining Grinding Mill JXSC MachineryIn this study, we ground (a) one type of silica sand and (b) four different types of slag sands from various steel plants For all grinding trials we used the milling and pelletizing machine of the type HPMP (Herzog, Germany) The HPMP was equipped with the standard TCM module for the evaluation of grinding performanceAssessment of grinding power in silica and slag sands by using a

.jpg)

Contraplex Pin Mills, C CW Hosokawa Micron Ltd

Tailormade for your specific needs and the requirements of your industry – including the stringent standards of the food and pharmaceutical sectors and European safety guidelines – the Contraplex CW II fine impact mill range is currently available in four sizes (250 CW II, 400 CW II, 630 CW II and 800 CW II) and can be manufactured with special design features, if requiredAcid washed silica grinding beads; Bead size ranges from 8001000μm; Specifications Product Type: Silica Grinding Beads: For Use With (Equipment) Titer plates and vial sets of Geno/Grinder: Particle Size: 400 to 600 μm: For Use With Accessory, Grinding Mill at Fishersci Test Order Status; Quick Order; Support; Sign In SPEX™ SamplePrep Geno/Grinder™ Accessory, Grinding Mill1) Ball mill is an efficient tool for grinding many materials into fine powder 2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine 3) Ball mill is widely used in building material, and chemical industry 4) Selling Silica Sand Grinding Raw Mill MachineLimestone/ Cacium/ Raymond Type Roller Grinding Mill Limestone Powder Making Machine FOB Price : US $ PE 400*600 Jaw Crusher Line with Low Price for Ballast/Rock Gold/Dolomite Sand/Dolomite/Diamond Waste/Copper is professional in manufacturing the crusher and grinding mill over 15 years since 2005, which located in Hightech Crusher; Grinding Mill; Rotary Dryer Manufacturer, Cone Crusher,

Jaw Crusher JXSC Machinery

Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with a capacity range of 11000tph There are two types of feeding opening designs, rectangular and square Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse Grinding Mill Rod Mill; New Type of Fine Particles Classifier Sharp Cut SeparatorNewtype Pneumatic Ultra Fine Grinding Mill (Jet Mill) Cross Jet Mill2023 low price silica grinding ball mill easy operate way from Henan Hongxing $14,50000 Min Order: 1 set Previous slide Next slide Quartz Silica Sand Powder Grinding Machine Kaolin Clay Ceramic Ball Mill for clays $5,00000 Min Order: 1 set Previous slide Next slideSilica grinding ball mill2021年4月21日 The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable laboratory batch type stirred mill The experimental results were evaluated using stress intensity analysis The performance was also compared in terms of mill orientation The results showed that the d50 values decreased with The Influence of Stirred Mill Orientation on Calcite Grinding

.jpg)

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Maintain the media charge at 48%~55% of total mill volume in batchtype mills and 38%42% in continuous mills We recommends 55% to 65% of critical mill speed for optimum grinding performance [100% Critical mill speed=423/D,D=inside diameter(m)] Dry grinding requiress faste mill speeds than wet grindingINBEST CeramicSilica Grinding Beads (US ENG) SDSpdf (1817 KB) 800 micron Low Binding Silica Beads Low Binding Beads are chemically treated so they bind less solutes liberated from homogenized samples Untreated silica and zirconium beads have surface chemistries that bind DNA, RNA, and proteins upon 800 micron Low Binding Silica Beads OPS Diagnostics LLC