Porcelain clay high pressure roller mill

Clay mills for all requirements Gebr Pfeiffer

Lumpsize ceramic raw materials of low to medium abrasiveness are ground, classified, and dried in Pfeiffer MPS vertical roller mills The fineness of the finished products can be set within wide 2022年2月10日 HRC™ Series high pressure grinding rolls (HPGR) are most often utilized when the processed material is hard rock However, they can also refine softer materials like Highpressure mill HRC™ Metso Corporation roller / Realtime monitoring of the clay, coupled with our patented vacuum deairing design, makes this machine the most capable studio processor available today FEATURES Stainless Steel: VPM20 Pug Mill Specifications The Ceramic ShopUnder the performance of highpressure springs, the rollers grinding pressure on raw materials can be raised by 1500kgf All the mineral materials with Mohs hardness below 93 can be Highpressure Suspension Mill

High Pressure Roll Mill / RHP 16Lab Minerali Engineering

The RHP 16Lab is a roller mill built to simplify the grinding treatment in laboratories, specially dedicated to hard minerals The RHP 16Lab was designed after the multiyear of experience HRC™ 8 and HRC™ 800 are based on a highpressure grinding roll (HPGR) technology and are optimized for the demanding requirements of high quality manufactured sand and aggregates High pressure grinding rolls HRC™ 8 HRC™ 800 Metsopolycom® high pressure grinding roll One of the principal reasons for the outstanding success of the high pressure grinding roll in the cement industry is its low power requirement Today, this polycom® high pressure grinding roll thyssenkrupp Polysius2019年4月12日 Based on the current research results and industrial data, this paper compares the process flow of highpressure roller mill in metal mine and pellet pretreatment industry, as 高压辊磨机在金属矿选矿与球团预处理领域的工艺和

Our Dynamic HPGR Technology for Mineral Grinding Weir

Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron oreAs the acknowledged leader in fluid bed roller mill design, Williams Roller Mills provide years of reliable, consistent, and efficient operation However, what truly sets our equipment apart is their ease of use and maintenance Learn more Industrial Roller Mills Williams Crusher2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10] Now a days Ball mills and HPGR are installed together as a common unitReview on vertical roller mill in cement industry its Raymond roller grinding mill is mainly applicable to the grinding and coal, coking coal, lignite, Lingmei sand, chromium oxide green, gold mine, red mud, clay, kaolin Coke, coal gangue, porcelain clay, kyanite, fluorite, bentonite, Raymond Roller Grinding Mill

.jpg)

Mining Roller Mill MadeinChina

China Mining Roller Mill wholesale Select 2024 high quality Mining Roller Mill products in best price from certified Chinese Mining High Pressure Roller Mill Voltage: 380V Weight: 2T Material Stone Micronized Aluminium Powder Grinding Mill Bentonite Clay Vertical Roller Mill for Aluminum Ore Powder US$ 16500 2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a EnergyEfficient Technologies in Cement Grinding IntechOpenIn ceramics, ball mills are used to grind down materials into very fine particles Materials such as clay and glaze components can be broken down in a ball mill by getting placed into rotating or rolling jars with porcelain balls inside themBall Mills The Ceramic ShopHigh Pressure Roller Mills are used in the cases of mediumfine crushing of hard materials such as ceramics, minerals from 5 up to 9 on the MOHS hardness scale, metals and metal alloys High Pressure Roller Mills ECP are used in continuous operation or in a closed circuit with screening machines or classifiersHighPressure Roller Mill ECP Hosokawa Alpine

.jpg)

High Pressure Grinding Roll Grinding Mill Supplier CITIC HIC

GM14060 High Pressure Grinding Roll The project was being retrofitted in 2010 The type of ore has mineral hardness of f=1416, silicon content of approximately 48%, and is strongly abrasive The high pressure roller mill was put into operation in August 2011, the roller surface has been subjected to continuous improvements1998年1月1日 The high pressure roll mill, HPRM, a newly invented size reduction equipment, has been recently added to the list of comminution machines and is classified as a highly efficient equipment(PDF) THE PERFORMANCE OF THE HIGH PRESSURE ROLL MILLRaymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materialsRAYMOND® ROLLER MILLS ThomasnetAdvantages at a glance: Modular design and small footprint enable integration in existing grinding plants Production increase in range of 1020 %, depending on the fineness, especially for smaller ball mill systems up to 100 tph Quality polysius® booster mill

.jpg)

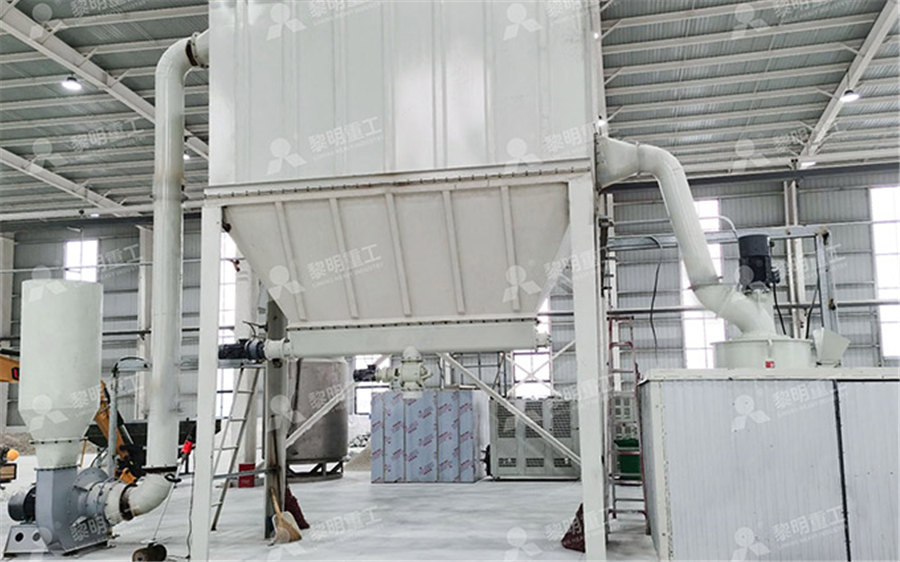

YGM High Pressure Grinding Mill

High pressure grinding mill, also known as high pressure roller mill, can grind nonflammable and explosive materials with Mohs hardness not greater than 93 and humidity below 6%Its main components include main engine, reducer, 2016年7月14日 Thus, some of the finish grinding work is handled by the highpressure grinding roll The throughput of the existing grinding system can be increased by 50 to 70%, while power consumption can be cut by 20 to 30% HPGR 911MetallurgistThe RHP 16Lab is a roller mill built to simplify the grinding treatment in laboratories, specially dedicated to hard minerals The RHP 16Lab was designed after the multiyear of experience of Minerali Industriali in the field of highpressure roller mill, from which inherit all the main advantages: low energy consumption, easyHigh Pressure Roll Mill / RHP 16Lab Minerali EngineeringShop online for best discount prices on Pugmills, Pugmill/Mixers, Clay Mixers, and Clay Mixer Dust Hoods Blend your clay perfectly, and save money by recycling clay scrap Studio and University models Bailey has excellent technical advise on the use and maintenance of pugmills, clay mixers, and ventilationBuy Pugmills, Puggers Clay Mixers Bailey Ceramic Supply

New Technology Big Capacity Sodium Silicate European Mill High Pressure

New Technology Big Capacity Sodium Silicate European Mill High Pressure Grinding 3 Roller Raymond fertilizer, fly ash, bituminous coal, coking coal,lignite, magnesite sand, chromium oxide green, gold ore, red mud, clay, kaolin, coke, coal gangue, porcelain clay, kyanite,fluorspar, bentonite, medical stone rhyolite rocks, muddy green rock 2021年10月23日 Natural moisture content of brick clays is around 10–25%, the refractoriness 1150–1250 ℃, and the sintering temperature (up to 5% of water absorption) close to 1100–1150 ℃ []Because of the high impurity content, fluxes are not necessary and the body can be fired at a relatively low temperatureTraditional Ceramics Manufacturing SpringerLink2024年10月22日 Milled clay that turns into fine material can absorb the water easily, thus becomes very homogenous to facilitate the extrusion and removes the defects of the clay The difference in the running speed of the rollers provides a plastered grinding of the raw material The roller shells are manufactured with spheroidal castiron of high hardnessROLLER MILL Arsan Makina2013年8月1日 For the effect of application in nonferrous and ferrous ores, the high pressure roller mill will be widely applied in the future Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 222,534,667 papers A Review on the Development of High Pressure Roller Mill

.jpg)

Roller Roller Mill MadeinChina

China Roller Roller Mill wholesale Select 2024 high quality Roller Roller Mill products in best price from certified Chinese Rice Mill manufacturers, High Pressure Roller Mill Voltage: 380V Weight: 2T Material: Stainless Steel Roller Mill for Clay Brick Manufacturing Roller Crusher US$ 2000 / Set 1 Set YGM high pressure micro powder mill is referred to as micro powder mill or super barite, marble, limestone, carbon black and clay The fineness is between 80 mesh (019mm) and 425 mesh (0033mm), and the finest the grinding force of YGM high pressure ultrafine grinder’s roller to material is increased by 8001200 kg under the YGM High Pressure Grinding Mill vanguardtecMSE Supplies offers a wide selection of roller jar mills for efficient The ceramics industry uses them to grind clay and glaze materials They're leveraged in materials science efficiency, and versatility with our highperforming roller jar mills at MSE Supplies We provide topquality roller milling equipment and expert service at Roller Jar Mills and Roller Milling Equipment MSE Supplies LLC2023年10月3日 Rocker Arms: The function of the rocker arm device of the cement vertical roller mill is to transmit the pressure provided by the hydraulic cylinder to the grinding roller, so that it can be transformed into the grinding force act on the material bed The rocker arm device is mainly composed of upper rocker arm, lower rocker arm, rocker arm shaft, bearing and What is a vertical roller mill (VRM)? A Comprehensive Guide to

Roller mills: Precisely reducing particle size with greater efficiency

roller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2Product introduction:YGM high pressure micro powder mill is referred to as micro powder mill or super fine grinding mill The high pressure micro grinder is mainly used for the ultrafine powder processing of more than 500 kinds of materials such as feldspar talc barite marble limestone carbon black and clayYGM High Pressure Grinding MillVanguard MachineryThe High Pressure Roller Mill (HPRM) stands out as an efficient and energysaving crushing device that plays a crucial role in mineral processing, industrial, and cement production Its high crushing ratio, low energy consumption, and broad applicability make it an ideal choice for meeting various crushing needsHigh Pressure Roller Mill huashengmingFind your ceramic and pottery supply needs at Axner We manufacture the Pacifica Pottery Wheel and Laguna Ceramic Clays We also carry or dropship a wide selection of Ceramic Equipment, Pottery Supplies, Tools, Raw Materials, Glazes and more! Find Electric and Gas Kilns, Raku Kilns, Slab Rollers, Extruders, Pugmills, Ware Carts, Clay Mixers, Kiln Furniture Laguna Clay Company FL Axner High Porcelain

.jpg)

高压辊磨机在金属矿选矿与球团预处理领域的工艺和

2019年4月12日 高压辊磨机能量利用率高,目前已在水泥行业、金属矿山、冶金球团等领域广泛应用。结合当前研究成果及工业现场数据,本文对比了高压辊磨机在金属矿山和球团预处理行业中的工艺流程,以及辊面比压力、辊面线速度、辊缝几个工艺参数,为高压辊磨机在金属矿山和球团预处理应用中工艺参数的 By means of the roller swingout device, the grinding rollers can be turned out of the mill, which is in favor of maintenance 5 The limit mechanism avoids the fiction and crash of metals between grinding roller and grinding plate, increasing the rotating stability and securityVertical Roller Mill,Vertical Roller Mill of features,Vertical Roller uses the testroller mill Atrol (throughput approx 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills Roller mill for granulated blast furnace slag grinding in China Roller mill for cement raw material grinding in China Roller mill for cement clinker grinding in Mexico Coal grinding plant in PolandPolysius Roller Mills For grindingAs the acknowledged leader in fluid bed roller mill design, Williams Roller Mills provide years of reliable, consistent, and efficient operation However, what truly sets our equipment apart is their ease of use and maintenance Learn more Industrial Roller Mills Williams Crusher

Review on vertical roller mill in cement industry its

2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10] Now a days Ball mills and HPGR are installed together as a common unitRaymond roller grinding mill is mainly applicable to the grinding and coal, coking coal, lignite, Lingmei sand, chromium oxide green, gold mine, red mud, clay, kaolin Coke, coal gangue, porcelain clay, kyanite, fluorite, bentonite, Raymond Roller Grinding MillChina Mining Roller Mill wholesale Select 2024 high quality Mining Roller Mill products in best price from certified Chinese Mining High Pressure Roller Mill Voltage: 380V Weight: 2T Material Stone Micronized Aluminium Powder Grinding Mill Bentonite Clay Vertical Roller Mill for Aluminum Ore Powder US$ 16500 Mining Roller Mill MadeinChina2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a EnergyEfficient Technologies in Cement Grinding IntechOpen

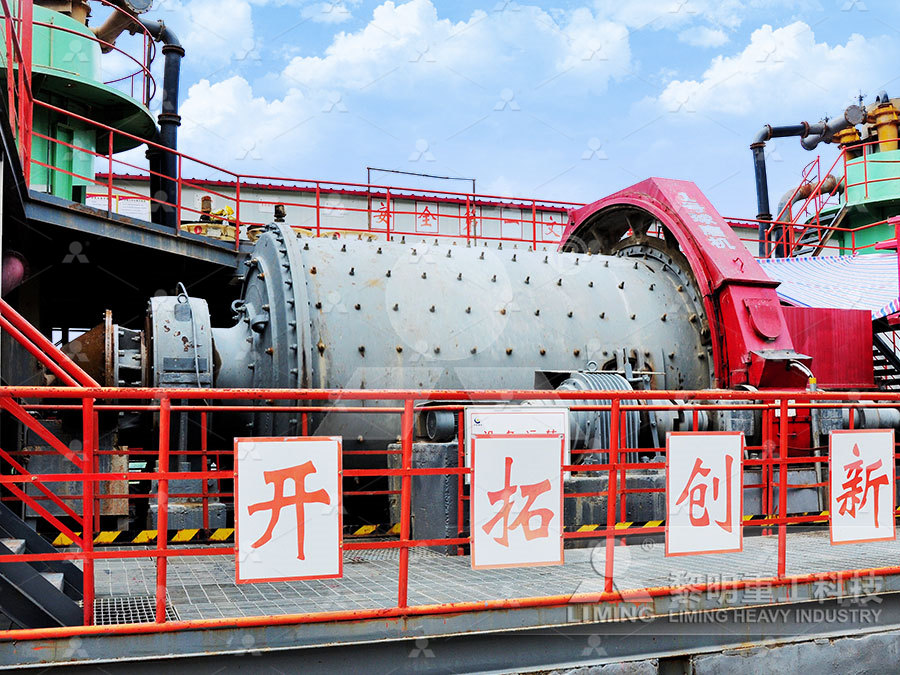

Ball Mills The Ceramic Shop

In ceramics, ball mills are used to grind down materials into very fine particles Materials such as clay and glaze components can be broken down in a ball mill by getting placed into rotating or rolling jars with porcelain balls inside themHigh Pressure Roller Mills are used in the cases of mediumfine crushing of hard materials such as ceramics, minerals from 5 up to 9 on the MOHS hardness scale, metals and metal alloys High Pressure Roller Mills ECP are used in continuous operation or in a closed circuit with screening machines or classifiersHighPressure Roller Mill ECP Hosokawa AlpineGM14060 High Pressure Grinding Roll The project was being retrofitted in 2010 The type of ore has mineral hardness of f=1416, silicon content of approximately 48%, and is strongly abrasive The high pressure roller mill was put into operation in August 2011, the roller surface has been subjected to continuous improvementsHigh Pressure Grinding Roll Grinding Mill Supplier CITIC HIC1998年1月1日 The high pressure roll mill, HPRM, a newly invented size reduction equipment, has been recently added to the list of comminution machines and is classified as a highly efficient equipment(PDF) THE PERFORMANCE OF THE HIGH PRESSURE ROLL MILL

.jpg)

RAYMOND® ROLLER MILLS Thomasnet

Raymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materials