Ore grinding mill hammer shaft material

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL

2017年1月1日 Fitz mill in their 2011 brochure explained that a horizontally situated hopper design will expose the feed to more breakup surface area, producing a finer grind while a 2017年1月1日 A hammer mill has been designed with due considerations to standard design requirements, local content and cost The power required to crush granite with the desired Development of a Horizontal Shaft Hammer Mill Academia2015年12月18日 mentioned that a hammer mill with 16 hammers, a 458 mm screen, and an operating speed of 3600 r pm was more effective at grinding a mixture of 124 mmDESIGN AND EVALUATE OF A SMALL HAMMER MILL ResearchGatefeeding (eg, making metering into the mill difficult), grinding (eg, plugging the hammer mill screen or blocking the air classifier of a jet mill), and collection (eg, plugging the bag filters) Back to Basics Hammer Milling and Jet Milling Fundamentals

.jpg)

Development of a Horizontal Shaft Hammer Mill ResearchGate

2020年1月31日 The hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea corn and other coarse materials of Material is fed into the mill, typically by gravity Inside the grinding chamber, the material is repeatedly struck by flailing ganged hammers which are attached to a shaft that rotates at a Intro to Size Reduction Schutte HammermillThe basic design of the industrial hammer mill is really quite simple: A steel chamber containing a shaft to which rectangular steel hammers are affixed Replaceable plates lining the mill's The Industrial Hammer Mill: A Versatile WorkhorseMunson's HammerHead™ Hammer Mills reduce an exceptionally wide range of friable, nonfriable and fibrous materials into particle sizes from coarse pieces down to 200 mesh, Hammer Mills Size Reduction Equipment for Bulk Materials

Hammer Milling and Jet Milling Fundamentals AIChE

A hammer mill is typically good for grinding softer materials with Mohs hardness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10 High hardness 2020年5月8日 Hammer mills are whole purpose machines that are designed to crush, grind, and mill material As the name suggests, the purpose is served by grinding material by small hammer blows The history of hammer mills is quite Working Principal, Types and Application of Hammer There were some problems with the service life of grinding elements, especially in the case of quartzcontaining raw materials, but because of improvements in wearresistant engineering materials, the service life has been substantially increased and, depending on the abrasiveness of the raw material, values of up to 16,000 h are reported 8 These mills have rollers as shown in Grinding Mill an overview ScienceDirect Topics2016年3月11日 The screen bypasses any material fine enough to enter the grinding section and delivers the oversize to a cone crusher, the discharge of which joins the undersize of the screen and is taken by a belt conveyor to the Crushing Plant Flowsheet DesignLayout

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 This technique is employed in impact crushers, hammer crushers, sand making machines, fine crushers, and compound crushers Understanding material characteristics and defining production needs can help you choose the right crushing method, saving costs throughout the production process Types of crushersComminution of mineral insulation material waste; Design of NEUE HERBOLD hammer mills The NEUE HERBOLD hammer mills series HM are equipped with robust and highly wearresistant tools (hammers, blow bars) The outside housed in pedestal bearings rotor shaft is separated from the grinding chamber Through the solid steel weldment the hammer mill Hammer Mills Neue Herbold GmbHHammer mills operate on the basic principle that most materials will crush, shatter or pulverize upon impact This is accomplished by a simple four step process: 1 Material is fed into the mill, typically by gravity 2 Inside the grinding chamber, the material is repeatedly struck byIntro to Size Reduction Schutte Hammermill2019年3月5日 Hammer Mill Comparison Horizontal InFeed Hammer Mills The unique quality of the horizontal infeed hammer mill is that material is fed into the side of the mill, instead of the top This design makes horizontal mills ideal for long, linear, or otherwise large, geometric materials to be processed without a pre grind Horizontal in feedHAMMER MILLS: FIVE KEY STYLES

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

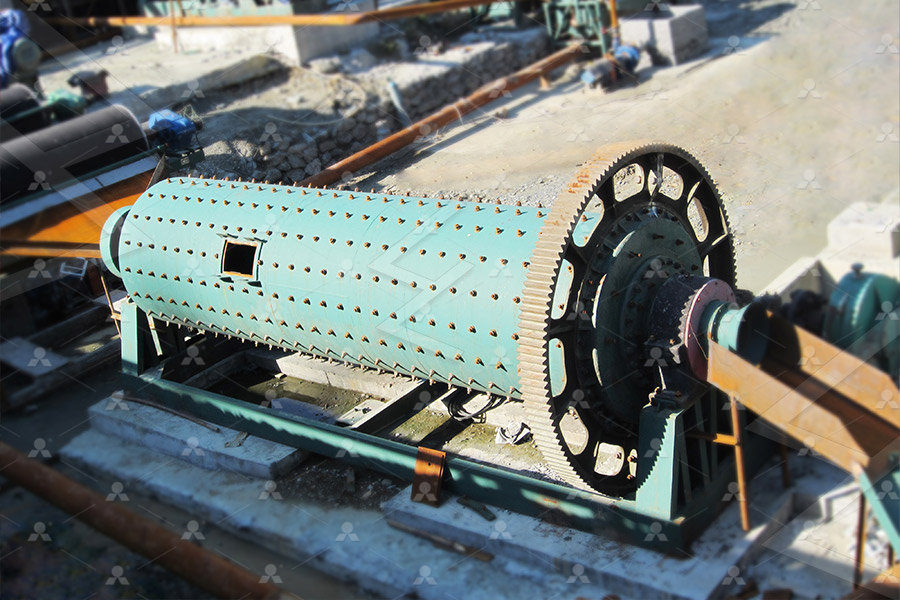

2019年12月23日 A hammer mill has been designed with due considerations to standard design requirements and cost to cater to this need The power required to deliver the through put efficiency of the machine was 2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Grinding Mill Design Ball Mill Grinding Mill Design Ball Mill Manufacturer 911Metallurgist2024年4月19日 Hammer Mill: Consists of a series of hammers mounted on a rotating shaft that strike and break material against a screen or plate: Suitable for softer materials, produces finer particle sizes: 50500 mm: 0120 mm: Low to moderate: Produces finer particle sizes, handles softer materials well: Higher wear on hammers, not suitable for highly Types of Crushers Explained: Everything You Need to Know JXSCA mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are Mill (grinding) Wikipedia

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

The material is contained within a crushing chamber, with openings of the product screen size to allow crushed material to escape when the desired size is achieved (Sidhartha Biswajit, 2007) 2331 Horizontal Shaft Impact crushers / Hammer mill The horizontal shaft impact crushers shatter materials by impactOre grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their Ore Grinding Machines: Ball Mill, Rod Mil Grinding Types of Grinding Mills Grinding mills play a crucial role in the mining process, as they are responsible for reducing large chunks of ore into smaller particles that can be further processed There are various types of grinding mills available, each designed to meet specific requirements based on the material being ground and the desired outputUnderstanding the SAG Mill in Copper Ore Mining Process2023年4月12日 Let’s first take a close look at this equipment in order to select a suitable hammer mill stone crusher How does a hammer mill stone crusher work? In a hammer crusher, multiple hammers mounted on a rotating shaft repeatedly strike material entering the machine The hammers in the crusher’s cylindrical chamber swing in a circular motion What Kind Of Hammer Mill Stone Crusher Do You Need?

Optimum Design of Hammer Mill for Grinding Leonardite

2023年1月16日 The objective of this research is to design and construct a hammer mill for grinding leonardite charcoal (Lignite, class J) The conditions for the design and construction of the grinder are A hopper leads the sample material into the grinding chamber of the hammer mill The HM 200 is equipped with a horizontal rotating shaft on which 10 freely swinging hammers are mounted Those hammers crush the material at high speed inside the grinding chamberHammer Mill HM 200: For Laboratory Pilot Plant RETSCH2017年6月2日 Pebble mills use rock pebbles as the grinding media to cause friction and attrition between the pebbles and ore material Pebble mills may be used when metal balls must be avoided Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the Vertical shaft mills work on the same principal How it Works: Crushers, Grinding Mills and Pulverizers2024年6月17日 Hammer mills have numerous uses While use varies depending on the type of hammer mill used and the industry, common hammer mill applications include: Food product grinding: One common application of hammer mills is food product grinding You can use this hammer mill to grind several varieties of legumes, such as groundnuts, soya nutshells and Hammer Mill Types Explained Pulva Corporation

Grinding Mills Common Types 911Metallurgist

2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of drum ranging from about 15 in to 55 in2023年4月23日 grinding media in a grinding mill with about 2630 wt% chrome by Chen et al [37] using a phosphate ore in a modified ball laboratory ball mill whose electrochemical potential could be controlled(PDF) Grinding Media in Ball MillsA ReviewThis document summarizes research on improving the design, construction, and testing of a hammer mill Key points: 1) The researchers redesigned and constructed the hammer mill beater, chamber, and shaft They incorporated a Hammer Mill 1 PDF PDF Mill (Grinding) Bending2016年2月26日 Operational Characteristics: The method of operation has a considerable effect upon the nature of the productWhen minimum fines are a requirement, the hammer mill should always he operated in closed circuit with a screen, or screens; the circulating load should be fairly high; speed should be as low as is consistent with physical structure of the material; and Hammer Mill Operating Principle 911Metallurgist

Tin Ore Processing 911Metallurgist

2017年2月16日 The crusher discharges to a travelling belt conveyor, which distributes the ore over the whole length of the secondary bins; from these, which have a capacity of 120 tons, or roughly, 20 hours’ supply of hard ore, the material is fed 6 天之前 Overflow ball mills are mainly suitable for grinding finer minerals in lithium ore dressing plants, and are mostly used in the second stage or concentrate grinding operations Additionally, the ball mill ’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium oreBall Mill Is The Key To Grinding Lithium Ore JXSC Machinery2013年7月15日 What is the Bond Work Index FormulaEquation? In case you had forgotten, here is a classic: You can read all the details of this now “Biblical” grinding power requirement calculation formula in Fred Bond’s original paper You can also review the stepbystep Bond Work Index Test Procedure I posted here See this useful summary Table of Bond Work Bond Work Index FormulaEquation 911MetallurgistCLRM series Raymond mill Discharge fineness: 80500 mesh Feed size: 35 mm Output: 135 t/h Materials: Quartz, feldspar, barite, carbonate calcite, limestone, talc, ceramics, iron ore, emery, bauxite, phosphate rock, coal and other materials, a total of about 400 kinds of materialsCLRM series Raymond mill SBM Ultrafine Powder Technology

.jpg)

Small Hammer Mill JXSC Machine

JXSC small hammer mill for small grinding capacity, especially for laboratory use the broken material been repeatedly conflict, the bigger particle materials hammer again on the screen bars by grinding, squeezing and crushing, the rotor includes shaft, pins and small hammers Hammer grinder with Intelligent PLC control, At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where technology and excellence converge Ore Crushing, Sand Making, Grinding Machinery Bellian Mining 2024年11月24日 Vertical Hammer Mills: Commonly used in agriculture and pharmaceuticals, vertical hammer mills use gravity to feed the material through the milling chamber The vertical orientation allows for a more straightforward design and costeffective operation, making it suitable for materials that are not excessively abrasiveA Guide to Different Hammer Mill Parts Midwest Hardfacing2020年5月8日 Hammer mills are whole purpose machines that are designed to crush, grind, and mill material As the name suggests, the purpose is served by grinding material by small hammer blows The history of hammer mills is quite Working Principal, Types and Application of Hammer

Grinding Mill an overview ScienceDirect Topics

There were some problems with the service life of grinding elements, especially in the case of quartzcontaining raw materials, but because of improvements in wearresistant engineering materials, the service life has been substantially increased and, depending on the abrasiveness of the raw material, values of up to 16,000 h are reported 8 These mills have rollers as shown in 2016年3月11日 The screen bypasses any material fine enough to enter the grinding section and delivers the oversize to a cone crusher, the discharge of which joins the undersize of the screen and is taken by a belt conveyor to the Crushing Plant Flowsheet DesignLayout2024年7月17日 This technique is employed in impact crushers, hammer crushers, sand making machines, fine crushers, and compound crushers Understanding material characteristics and defining production needs can help you choose the right crushing method, saving costs throughout the production process Types of crushersTypes of Crushers: Choosing the Right One for Each StageComminution of mineral insulation material waste; Design of NEUE HERBOLD hammer mills The NEUE HERBOLD hammer mills series HM are equipped with robust and highly wearresistant tools (hammers, blow bars) The outside housed in pedestal bearings rotor shaft is separated from the grinding chamber Through the solid steel weldment the hammer mill Hammer Mills Neue Herbold GmbH

.jpg)

Intro to Size Reduction Schutte Hammermill

Hammer mills operate on the basic principle that most materials will crush, shatter or pulverize upon impact This is accomplished by a simple four step process: 1 Material is fed into the mill, typically by gravity 2 Inside the grinding chamber, the material is repeatedly struck by2019年3月5日 Hammer Mill Comparison Horizontal InFeed Hammer Mills The unique quality of the horizontal infeed hammer mill is that material is fed into the side of the mill, instead of the top This design makes horizontal mills ideal for long, linear, or otherwise large, geometric materials to be processed without a pre grind Horizontal in feedHAMMER MILLS: FIVE KEY STYLES2019年12月23日 A hammer mill has been designed with due considerations to standard design requirements and cost to cater to this need The power required to deliver the through put efficiency of the machine was DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER 2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Grinding Mill Design Ball Mill Grinding Mill Design Ball Mill Manufacturer 911Metallurgist

.jpg)

Types of Crushers Explained: Everything You Need to Know JXSC

2024年4月19日 Hammer Mill: Consists of a series of hammers mounted on a rotating shaft that strike and break material against a screen or plate: Suitable for softer materials, produces finer particle sizes: 50500 mm: 0120 mm: Low to moderate: Produces finer particle sizes, handles softer materials well: Higher wear on hammers, not suitable for highly