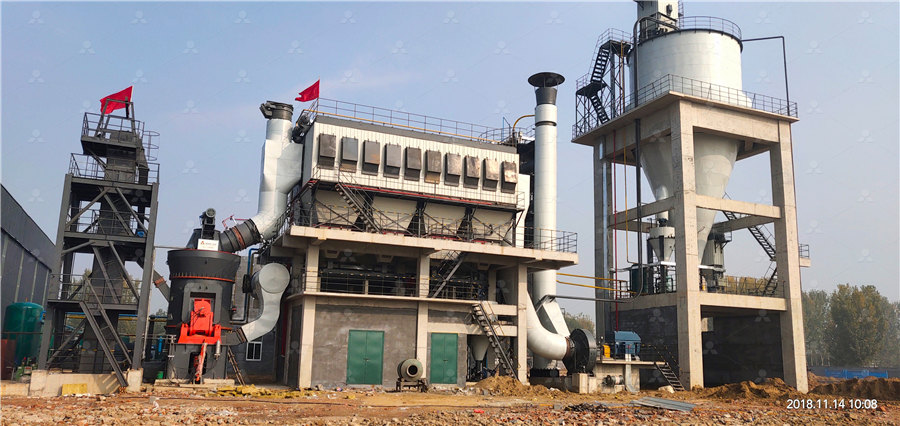

heavy medium powder processing process

.jpg)

Heavy Media Separation an overview ScienceDirect Topics

Heavy media separation (or sinkandfloat separation) is a part of the gravity separation process and uses heavy liquids in the separation operation The primer liquids for density separation include bromoform (284 g/cm 3 ) and diiodomethane (331 g/cm 3 ), where heavy particles ated material is recovered by spiral classifier and dried in a gas fired rotary dryer The final powder is obtained by milling in a ball mill in closed ci the atomizing process to the product The production, properties,andselectionof 2016年5月22日 The heavymedia separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally Heavy Media Separation Process 911MetallurgistDense medium separation (DMS), also known as dense or heavy media separation, is a beneficiation technology that has been used for many years in the processing and mining Dense Medium Separator (DMS) Sepro Mineral Systems

Physical beneficiation of heavy minerals ScienceDirect

2023年8月1日 The dense medium separation (DMS) or heavy medium separation (HMS) is a CGC process whereby HMs are separated from each other based on their SG differences There are basically two types of ferrosilicon powder available to operators of heavymedium plants in South Africa: spherical and milled grades The production processes are described, The production, properties, and selection of ferrosilicon powders 2023年6月1日 The coating significantly improved physical stability, wetting by aqueous media, dissolution rate, powder flow, and tabletability Thus, it can be seen that coating cohesive A concise summary of powder processing methodologies for flow Dense medium separation (DMS) is one of several preconcentration methods used for early waste rejection from run of mine ores at relatively coarse particle sizes prior to additional RECENT DEVELOPMENTS IN PRECONCENTRATION USING DENSE

.jpg)

Powder Processing of Bulk Components in Manufacturing

2014年1月1日 This method involves a filtration process which separates powders from the solvent using a porous medium In a typical example of this process, a suspension, usually a 2015年6月24日 Dense medium separation (or heavy medium separation (HMS), or the sinkandfloat process) is applied to the preconcentration of minerals, ie the rejection of gangue prior to grinding for final liberationDenseHeavy Medium Separation HMS / DMS ProcessThe heavy medium beneficiation process includes ore preparation, medium preparation, ore beneficiation, medium removal, and medium regeneration What mineral processing machine do we supply? 【Ore Preparation】 crushing, Dense Media Separation (DMS) Plants JXSC Machine2014年1月1日 Classification of Powder Processing Methods Methods to process powder particles can be stoneware, and heavy clayware tiles for floor, wall, and alumina This method involves a filtration process which separates powders from the solvent using a porous medium In a typical example of this process, a suspension Powder Processing of Bulk Components in Manufacturing

Bulk material feeder types and applications

2022年12月21日 Vibratory feeders can be used in light to heavyduty applications When properly calibrated, small vibratory feeders can be used to meter discrete items through a process, such as pharmaceutical tablets, while Powder metallurgy is a metal forming process in which compacted metal powders are heated to just below their melting point Although the process has been around for more than 100 years, over the past quartercentury it has been widely recognized as a superior method for making highquality parts for a variety of important applicationsWhat is Powder Metallurgy? Definition, and ProcessThis processing enables the structuring of hollow particles and a wide range of specific gravity (particle density) adjustments by modifying the surface texture d) Resin Coating Technology Particles can be coated with different types of organic resin to provide flow properties, electrical characteristics, and other functionsPowder Processing Powdertech Co,LtdDMS Powders: The use of Ferrosilicon in Diamond Processing Plants Dense / heavy medium separation also referred to as the sinkandfloat process, is widely used in mineral / diamond processing plants to effectively separate diamonds and minerals from other materialA medium is made in a gravity separator tank (Dense Media Cyclone), which is a mixture of Ferrosilicon Use of Ferrosilicon in Diamond Processing Plants DMS Powders

Processing of tungsten heavy alloy by extrusionbased additive

2023年1月1日 In the PIM process, powder(s) The asmolded parts were embedded in a wicking medium of alumina powder with a particle size of 1 μm, The solvent debinding process coupled with pre sintering and sintering has become a standard technique for the PIM processing of tungsten heavy alloys into complex near net shapes2023年8月1日 The dense medium separation (DMS) or heavy medium separation (HMS) is a CGC process whereby HMs are separated from each other based on their SG differences DMS employs the use of an aqueous or liquid suspension medium of mineral particles with predetermined density which mineral particles that are denser than the fluid/liquid medium will Physical beneficiation of heavy minerals ScienceDirect2014年12月29日 Powder metallurgy techniques can generally be classified into powder injection molding, mechanical alloying, microwave, and spark plasma sintering; these are discussed briefly in the following 22 Powder Injection Molding The powder injection molding (PIM) process is a combination of powder metallurgy and plastic injection molding technologiesRecent Progress in Processing of Tungsten Heavy Alloys2020年5月1日 The 3 mm flipflow screen dry depth screening and grading heavy medium washing process is expressed the use of coal results in serious environmental pollution due to the low utilization of clean processing technologies [[2], [3] Powder Technol, 287 (2016), pp 301307 View PDF View article View in Scopus Google Scholar [19]A novel and low cost coal separation process: Combination of

.jpg)

Powder Detergent: Ingredients Manufacturing

2021年6月21日 Powder detergent is one of the more traditional washing solutions, with two key advantages: affordability and power against heavy stains These advantages, among others, lead to the resurgent popularity of 2024年1月1日 Granulation is a process that is wellknown and widely used in various industries This is primarily used when bulk material in the form of a fine powder is considered difficult to treat and process [1]The process is designed to convert fine powders into granular materials with controlled physical properties, ie a specific shape (granule size) and a specific bulk densityPowder agglomeration processes of bulk materials – A state of 2022年2月10日 They may be employed as a preproduction step, helping to prepare material for subsequent processing, or as a postproduction step, finishing material into its final dried form They are widely used in the Relying on rotary drums for process heating and coolingasthemost suitable medium forthe heavymedium separation of ores having a specific gravity in the range ofapproximately 2,5to 4,0 Ferrosilicon has many properties essential toametal oralloy powder that istobeusei asaheavy medium, some ofthe more important being thefollowing: (a) resistance toabrasion, (b) resistance tocorrosion, (c The production, properties,andselectionof

.jpg)

Atomization FeSi Powder C60Heavy Medium Fesi Powder

Production process: electric furnace smelting / vacuum water atomization treatment / high precision screening Product shape: spherical Product use: used as heavy medium in mineral processing industry, such as: waste aluminum separation, gold ore, diamond ore, copper ore and other flotation aspects 1Chemical content:2024年2月10日 Ultimately, the interplay of engineering and chemistry is crucial in industrial powder processing Industrial powder processing plants serve a wide range of industries These include metallurgy, pharmaceuticals, food processing, and materials manufacturing Their importance lies in the ability to efficiently process raw materials into valuable Designing Industrial Powder Processing Plants2014年9月9日 The dense medium cyclone (DMC) process used in coal beneficiation plants is studied from a control system perspective Employing the dynamic model of the DMC process derived from mass flow balance Medium Density Control for Coal Washing Dense Medium Cyclone Circuits2016年1月25日 Highly efficient herbal processing and extraction technologies have been developed to obtain the optimal amounts of active ingredients from herbs and cope with the rising demands for herbal products(PDF) Herbal Processing and Extraction Technologies

.jpg)

DENSE MEDIA SEPARATION Springer

264 Mineral ProcessingDense Media Separation Chance process, patented in 1917 This is not strictly a simple DMS process, since it employs a hydraulically dilated bed of sand In 1928 Lessing re developed the use of calciumchloride solution In 1931 clay, gypsum, andProcessing of rare earth elements, eg for the production of heavyduty magnets for the IT industry pe wax Optimum processing of ultrafine PE wax at ambient temperatures sterilized powder Systems for aseptic, pharmaceutical substances achieve cGMP standards and low OEB values nutMeg Cryogenic grinding for the protection of aromasThe pursuiT of perfecTion in powder processing Hosokawaliquid test results are presented herein The use of heavy liquid for bench scale simulation and results are also discussed Bench Scale Simulation – Heavy Liquid Separation Although not economically feasible in large scale operations, bench scale heavy liquid separation (HLS) testing is an ideal preliminary step to pilot scale DMS testingRECENT DEVELOPMENTS IN PRECONCENTRATION USING DENSE MEDIA SEPARATION2014年7月1日 A pilot hydrocyclone plant was used to concentrate mediumgrade celestine ore (67% celestine) from the Montevive deposit in Granada (Spain) by using a dense media concentration (DMS) processThe art and science of dense medium selection ResearchGate

.jpg)

The StepbyStep Tea Powder Manufacturing Process

2024年6月12日 The manufacturing process of tea powder involves several essential techniques to ensure the desired flavor, aroma, and quality of the final product Let’s explore the key steps involved in the tea powder manufacturing 2022年3月24日 He has extensive industrial experience in designing and troubleshooting solids processing plants, with special expertise in pneumatic conveying, silo storage, separation, fluidization, drying, particle and powder characterization, mixing/blending, dosing, and Basic concepts in pneumatic conveying Processing Magazine2021年8月20日 Postharvest losses of mango fruit in a number of developing countries in Africa and Asia have been estimated to be as high as over 50%, especially during the main harvest season Micro, small, and medium scale food processing enterprises play an important economic role in developing economies in processing of a diversity of healthy food products as a Mango Fruit Processing: Options for SmallScale Processors inAll our jet mills feature a ceramic alumina lining to prevent iron contamination during the jet milling process Furthermore, our toll processing rooms operate under negative pressure to prevent cross contamination As an added precaution our air compressors are humidity controlled to prevent adding heat or moisture to the powder processing Toll Processing Capabilities Powder Technology

Metallurgy Powder, Process, Components Britannica

1998年10月30日 Metallurgy Powder, Process, Components: Powder metallurgy (P/M) consists of making solid parts out of metal powders The powder is mixed with a lubricant, pressed into a die to form the desired shape, and then sintered, or heated to a temperature below the melting point of the alloy where solidstate bonding of the particles takes place In the absence of any 2020年7月30日 The mechanism of droplet formation from the molten metal depends on the powder characteristics: size, shape, and structure; process parameters: molten metal properties (composition, viscosity, and surface tension), molten metal flow properties (flow path, flow rate, and flow length); type of disintegration process: melt drop process driven by capillary forces, Nanomaterials through Powder Metallurgy: Production, ProcessingWould you be a confirmed Engineer, a new graduate looking for information on the process he has 1st to work on, or a student, please access below articles on unit operations and equipment that, we hope, will be useful for you PowderProcess also hosts Process Engineer's Tools, a new online ressource for Process Engineers, not limited to Powder Processing This powderprocess Engineering resources for powder processing 2020年7月30日 Nanomaterials through Powder Metallurgy: Production, Processing, and Potential Applications toward Energy and Environment July 2020 DOI: 101007/97830301115571271Nanomaterials through Powder Metallurgy: Production, Processing

Dense Media Separation (DMS) Plants JXSC Machine

The heavy medium beneficiation process includes ore preparation, medium preparation, ore beneficiation, medium removal, and medium regeneration What mineral processing machine do we supply? 【Ore Preparation】 crushing, 2014年1月1日 Classification of Powder Processing Methods Methods to process powder particles can be stoneware, and heavy clayware tiles for floor, wall, and alumina This method involves a filtration process which separates powders from the solvent using a porous medium In a typical example of this process, a suspension Powder Processing of Bulk Components in Manufacturing2022年12月21日 Vibratory feeders can be used in light to heavyduty applications When properly calibrated, small vibratory feeders can be used to meter discrete items through a process, such as pharmaceutical tablets, while Bulk material feeder types and applicationsPowder metallurgy is a metal forming process in which compacted metal powders are heated to just below their melting point Although the process has been around for more than 100 years, over the past quartercentury it has been widely recognized as a superior method for making highquality parts for a variety of important applicationsWhat is Powder Metallurgy? Definition, and Process

Powder Processing Powdertech Co,Ltd

This processing enables the structuring of hollow particles and a wide range of specific gravity (particle density) adjustments by modifying the surface texture d) Resin Coating Technology Particles can be coated with different types of organic resin to provide flow properties, electrical characteristics, and other functionsDMS Powders: The use of Ferrosilicon in Diamond Processing Plants Dense / heavy medium separation also referred to as the sinkandfloat process, is widely used in mineral / diamond processing plants to effectively separate diamonds and minerals from other materialA medium is made in a gravity separator tank (Dense Media Cyclone), which is a mixture of Ferrosilicon Use of Ferrosilicon in Diamond Processing Plants DMS Powders2023年1月1日 In the PIM process, powder(s) The asmolded parts were embedded in a wicking medium of alumina powder with a particle size of 1 μm, The solvent debinding process coupled with pre sintering and sintering has become a standard technique for the PIM processing of tungsten heavy alloys into complex near net shapesProcessing of tungsten heavy alloy by extrusionbased additive 2023年8月1日 The dense medium separation (DMS) or heavy medium separation (HMS) is a CGC process whereby HMs are separated from each other based on their SG differences DMS employs the use of an aqueous or liquid suspension medium of mineral particles with predetermined density which mineral particles that are denser than the fluid/liquid medium will Physical beneficiation of heavy minerals ScienceDirect

.jpg)

Recent Progress in Processing of Tungsten Heavy Alloys

2014年12月29日 Powder metallurgy techniques can generally be classified into powder injection molding, mechanical alloying, microwave, and spark plasma sintering; these are discussed briefly in the following 22 Powder Injection Molding The powder injection molding (PIM) process is a combination of powder metallurgy and plastic injection molding technologies2020年5月1日 The 3 mm flipflow screen dry depth screening and grading heavy medium washing process is expressed the use of coal results in serious environmental pollution due to the low utilization of clean processing technologies [[2], [3] Powder Technol, 287 (2016), pp 301307 View PDF View article View in Scopus Google Scholar [19]A novel and low cost coal separation process: Combination of