Highfine vertical mill bearing

.jpg)

Rolling Bearings in Vertical Mills Built by Gebr Pfeiffer AG, Germany

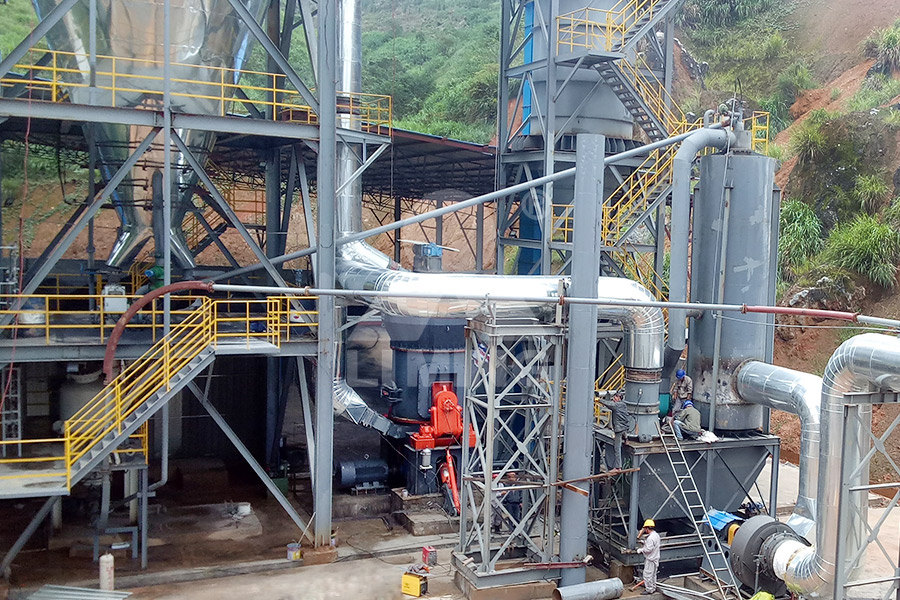

mills With the exception of coal mills, MPS mills are equipped with an external material feed system to reduce pressure losses Thanks to the optimal design of the nozzle ring, a fluidized Vertical roller mills are one of the core items in cement plants and are used in particular for high and very high throughput rates Up to six grinding rollers are suspended over a grinding plate Rolling bearings in the world’s largest vertical roller millProduct Application Of Limestone Ultrafine Vertical Mill Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6 (the Moh’s hardness), such as Limestone Ultrafine Vertical Mill2024年10月8日 To sum up, the working characteristics of highspeed rolling mill bearings are that they can work continuously, stably and reliably under highspeed, highimpact conditions, and have a long fatigue life 2 Bearing structural form Highline rolling mill bearings include fourrow tapered roller bearings and doublerow cylindrical roller bearingsHighspeed wire rod mill bearings and their applications

Barite Ultrafine Vertical Roller Mill

Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content +17 [ protected] The special sealing design of the roller bearing can prevent the infiltration of dustLM vertical mill adopts new milling devic and automatic electric control system, integrating Grinding roller bearings are lubricated with forced thin oil, longer bearing life Model Capacity (t/h) Output The collected powder is the product of the ultrafine vertical grinding RELATED CASE 30tph LM170K Vertic LM190K Vertical RolLM Vertical Roller MillGrinding mill machine, mineral mill, Bearings supporting the grinding rollers in the vertical mill Floating bearing end: Doublerow cylindrical roller bearing (series NNU41) Locating bearing end: spherical roller bearing (series 231) Fine product Feed material SLS high efficiency classifier for accurate classification Entirely closed mill housing Optimized free flow areas Rolling Bearings in Vertical Mills Built by Gebr Pfeiffer AG, Germanybearing housing, which is finally followed by the mill grinding chamber, in which the vertical agitator screw is located, together with a charge of grinding media and grinding material in slurry form Highgrowth markets in copper, ironore, gold, leadzinc ores, mineral sands and rareearth metals drive increasing demand for fine grindingEIRICH TowerMill Vertical agitated media mill

.jpg)

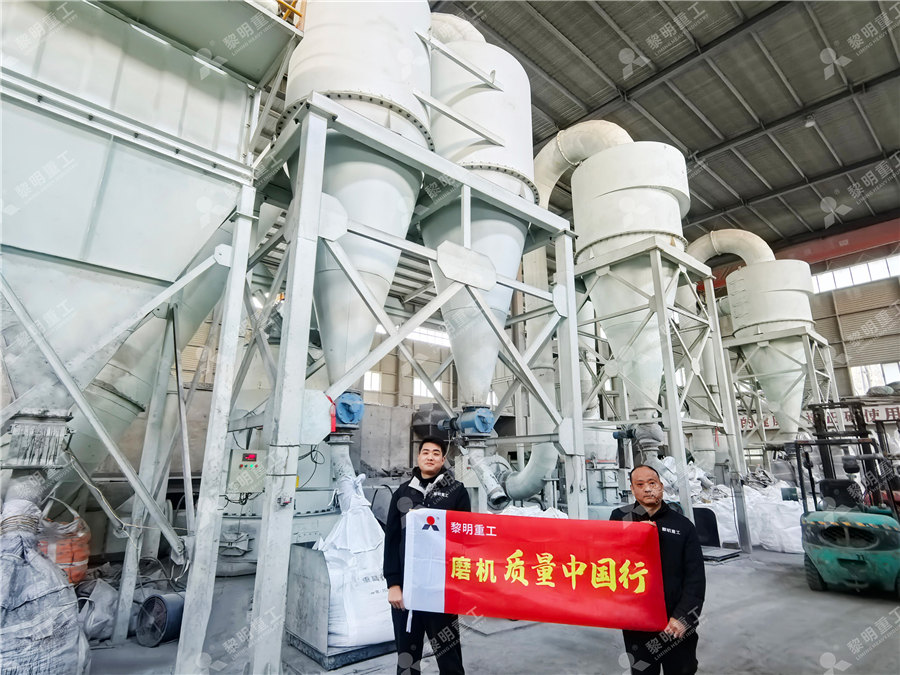

Dolomite Ultrafine Vertical Roller Mill

The ultrafine vertical mill integrates crushing, drying, grinding, and conveying, and is especially suitable for largescale production of nonmetallic mineral ultrafine powder processing Dolomite is an important resource of calcium and magnesium, and dolomite powder can be used in many industrial fields2020年6月14日 And improved filterability over gear oil, providing longer lubricant life, improved filter longevity, and again better oil flow to the bearings Maintenance Tips If high bearing operating temperatures cause the mill to trip offline, consider increasing the trip set pointsImproving Mill Shoe Bearing Reliability and ProductivityBearing arrangement of grinding rollers Extreme requirements especially on the bearings of the grinding rollers due to very high loads, vibrations and shock loads Design as locating/nonlocating bearing arrangement with double row tapered roller bearing FTR2 in X arrangement Illustration of a Pfeiffer MVR mill andRolling bearings in the world’s largest vertical roller millHigh Range rpm Main Spindle Taper Spindle Travel Quill Feed in/rev (mm/rev) Quill Diameter CONSTRUCTION AND WEIGHT Column Turret Diameter Knee Width Column Bearing Length Saddle/Table Bearing Length Ram/Turret Bearing Length Ram Length Table Load Machine Net Weight Machine Shipping Weight 9” x 49” (230 x 1245mm) 3638” (16mm) 208 VERTICAL KNEE MILLS Clausing Industrial

MACHINE TOOL SPINDLE BEARING SELECTION MOUNTING

High rigidity thrust bearings for lathe applications › Contact angles: 30˚ (BAR), 40˚ (BTR) › Ball material: steel (S type), ceramic (H type) ROBUST Series: BAR BTR Ultra HighSpeed Single Row Cylindrical Roller Bearings High performance cylindrical bearings designed for ultra highspeed applications, such as machining centre spindlesThe vertical mill is a very compact machine designed to take up less space and offer the user a high level of production capacity with reduced energy consumption The advantages of using the vertical mill in production, as Vertical hammer mill LamecBEARING FEATURES, BENEFITS AND SERVICES back of foldout CYLINDRICAL ROLLER BEARINGS EM and EW series bearings are cylindrical roller bearings capable of carrying particularly large radial loads and are suitable for highspeed applications The EW series features a pressed steel cage and the EM series features a onepiece machined brass cageBearings for Pulverizers and Vertical Rolling Mills2011年12月14日 about lubing the bearings and the preload on them They also said a good quality #2 bearing grease (like wheel bearing grease) was fine They said if the bearings were getting too hot, to reduce the preload on the bearings In my case, the preload was 5 lbs in rolling torque in the spindle bearings of my Millrite Good Luck!Blue ChipsWebbGrease for vertical mill quil bearings? The Home Machinist!

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

A Comparative study on a vertical stirred mill agitator design for fine

2015年7月16日 Grinding experiments were conducted in a laboratoryscale stirred mill on a lowgrade PGE bearing chromite ore HighPressure Grinding Rolls (HPGR) product of −1 mm was used as feed material to Thrust bearings TMP cylindrical thrust bearings are produced with ultra clean steel to extend bearing life up to 80% They are capable of carrying high axial loads and are offered in several styles Tapered roller bearings NSK offers 2 and 4 row versions of tapered roller bearings to support axial loads in either directionBearings for Pulverizers and Vertical Rolling MillsHighquality ultra fine powder vertical roller mill manufacturer Tongli Ultrafine Powder Vertical Mill is particularly suitable for ultrafine grinding of nonmetallic minerals, including ultrafine calcium carbonate powder (fineness can reach 25 microns), limestone, barite, calcite, kaolin, gypsum, bauxite and graphite Its production capacity can reach 1030 tons per hour to meet the Ultra fine Vertical Roller Mill CEMENTLTapered roller bearings 7 Sphericalroller bearings 9 Tapered roller thrustbearings for screwdown mechanisms 9 Calculation ofbearing load 10 Selfaligning chocks 10 Strip rolling 10 Groove rolling 11 Rigid chocks 12 Cantilevered stands 13 Calculation ofrolldeflection 14 Dimensioning 18 Staticallystressed bearings 18 Dynamicallystressed bearings 18FAG Rolling Bearings for Rolling Mill Applications

.jpg)

Atlas Vertical Roller Mill NETZSCH Grinding Dispersing PDF

Consult NETZSCH Grinding Dispersing's entire Atlas Vertical Roller Mill catalogue on DirectIndustry Page: 1/4 Exhibit This enables an operation with a standard design gearbox instead of the typical gearboxes with integrated bearing section with long NETZSCH Highefficiency Fine Classifier CFS/HDS 8 Pages NETZSCH Fine Classifier CFS2020年7月23日 The depletion of highgrade ores has forced the utilization of lowgrade ores The small liberation sizes in the lowgrade ores require fine grinding which is an energy intensive operationOptimization of stirred mill parameters for fine grinding of PGE bearing housing, which is finally followed by the mill grinding chamber, in which the vertical agitator screw is located, together with a charge of grinding media and grinding material in slurry form Highgrowth markets in copper, ironore, gold, leadzinc ores, mineral sands and rareearth metals drive increasing demand for fine grindingEIRICH TowerMill Vertical agitated media millIn a vertical fine grinding mill, material is fed from the top and ground by the action of grinding media, such as steel or ceramic balls The grinding media is agitated by either a slowspeed rotating agitator (as in the Tower Mill) or a highspeed impeller (as in the VXPmill)Vertical mills for fine grinding – FLS

HGM80 ultra fine mill, HGM80 ultra fine grinder

HGM80 ultra fine mill, Performance and features of HGM80 ultra fine mill, HGM80 ultra fine grinder: 1 High efficiency about 25 times as long as that of vertical shaft impact crusher and turbomill Especially when handling calcium carbonate and Raymond vertical mill is also called calcite milling machine It is suitable for all kinds of mineral powder preparation, coal powder preparation, such as fine powder processing of raw material mine, gypsum mine, coal and other materials Now with the development of the mining industry, there are many types of grinding equipment in the mine development site to process oreSuggested collection, causes and solutions for overheating of mill bearingsFlying chips present an eye injury hazard Fine dust can be a respiratory hazard Mills can also be very PV1 Factory 6Speed Tapered Roller Bearing Kit Installation Instructions bakerdrivetrain PV1 and cut gears, threads, and slots The vertical mill, or “column and knee” mill, is the most common milling machine Bridgeport Vertical Mill Manual DocsLibProduct advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, greatly improving the added value of finished products and application areas 2Talc Powder Ultrafine Vertical Roller Mill

Vibrations of tandem cold rolling mill: coupled excitation of rolling

2023年1月22日 Vibration issues of a fivestand tandem cold rolling mill were found in the steel production practice, and the experimental observation and numerical analysis indicated that the vibrations were related to the backup roll bearing The results were validated by replacing the backup roll bearing with the new bearing resulting in 30% decline in vibration amplitude 2021年6月15日 Too much powdery material forms an unstable material layer, the pressure difference inside the mill rises, and the vertical mill vibrates; The grinding performance is poor, the speed of the separator is too high, and the fine powder returning to the grinding disc is too much, causing the material layer to be unstable, the pressure difference in Characteristics and Cause Analysis of Vibration in Vertical MillG0667X 9" x 48" 3 HP HighPrecision VariableSpeed Vertical Mill A highperformance and precisioncontrolled Grizzly mill The G0667X 9" x 48" 3 HP HighPrecision VariableSpeed Vertical Mill is used to remove material from metal workpieces to form complex shapes Attention to detail is evident by the use of highclass spindle bearings, hardened and ground leadscrews 9" x 48" 3 HP High Precision VariableSpeed Vertical MillCement vertical roller mill Raw Material Vertical Roller Mill Coal vertical roller mill Medium speed coal pulverizer Ultra fine vertical roller mill Pre grinding vertical roller mill Slag vertical roller mill Water slag vertical roller mill Steel slag vertical roller mill Manganese slag vertical roller mill Nickel slag vertical roller Ball Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli

.jpg)

Limestone Ultrafine Vertical Mill

Product Application Of Limestone Ultrafine Vertical Mill Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6 (the Moh’s hardness), such as 2024年10月8日 To sum up, the working characteristics of highspeed rolling mill bearings are that they can work continuously, stably and reliably under highspeed, highimpact conditions, and have a long fatigue life 2 Bearing structural form Highline rolling mill bearings include fourrow tapered roller bearings and doublerow cylindrical roller bearingsHighspeed wire rod mill bearings and their applicationsBarite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content +17 [ protected] The special sealing design of the roller bearing can prevent the infiltration of dustBarite Ultrafine Vertical Roller MillLM vertical mill adopts new milling devic and automatic electric control system, integrating Grinding roller bearings are lubricated with forced thin oil, longer bearing life Model Capacity (t/h) Output The collected powder is the product of the ultrafine vertical grinding RELATED CASE 30tph LM170K Vertic LM190K Vertical RolLM Vertical Roller MillGrinding mill machine, mineral mill,

Rolling Bearings in Vertical Mills Built by Gebr Pfeiffer AG, Germany

Bearings supporting the grinding rollers in the vertical mill Floating bearing end: Doublerow cylindrical roller bearing (series NNU41) Locating bearing end: spherical roller bearing (series 231) Fine product Feed material SLS high efficiency classifier for accurate classification Entirely closed mill housing Optimized free flow areas bearing housing, which is finally followed by the mill grinding chamber, in which the vertical agitator screw is located, together with a charge of grinding media and grinding material in slurry form Highgrowth markets in copper, ironore, gold, leadzinc ores, mineral sands and rareearth metals drive increasing demand for fine grindingEIRICH TowerMill Vertical agitated media millThe ultrafine vertical mill integrates crushing, drying, grinding, and conveying, and is especially suitable for largescale production of nonmetallic mineral ultrafine powder processing Dolomite is an important resource of calcium and magnesium, and dolomite powder can be used in many industrial fieldsDolomite Ultrafine Vertical Roller Mill2020年6月14日 And improved filterability over gear oil, providing longer lubricant life, improved filter longevity, and again better oil flow to the bearings Maintenance Tips If high bearing operating temperatures cause the mill to trip offline, consider increasing the trip set pointsImproving Mill Shoe Bearing Reliability and Productivity

Rolling bearings in the world’s largest vertical roller mill

Bearing arrangement of grinding rollers Extreme requirements especially on the bearings of the grinding rollers due to very high loads, vibrations and shock loads Design as locating/nonlocating bearing arrangement with double row tapered roller bearing FTR2 in X arrangement Illustration of a Pfeiffer MVR mill andHigh Range rpm Main Spindle Taper Spindle Travel Quill Feed in/rev (mm/rev) Quill Diameter CONSTRUCTION AND WEIGHT Column Turret Diameter Knee Width Column Bearing Length Saddle/Table Bearing Length Ram/Turret Bearing Length Ram Length Table Load Machine Net Weight Machine Shipping Weight 9” x 49” (230 x 1245mm) 3638” (16mm) 208 VERTICAL KNEE MILLS Clausing Industrial