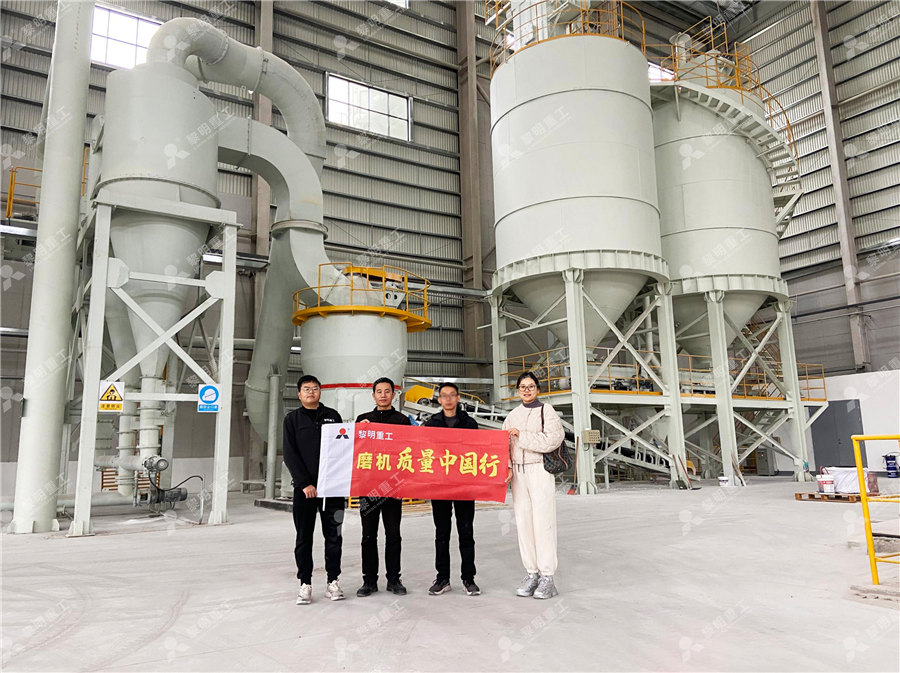

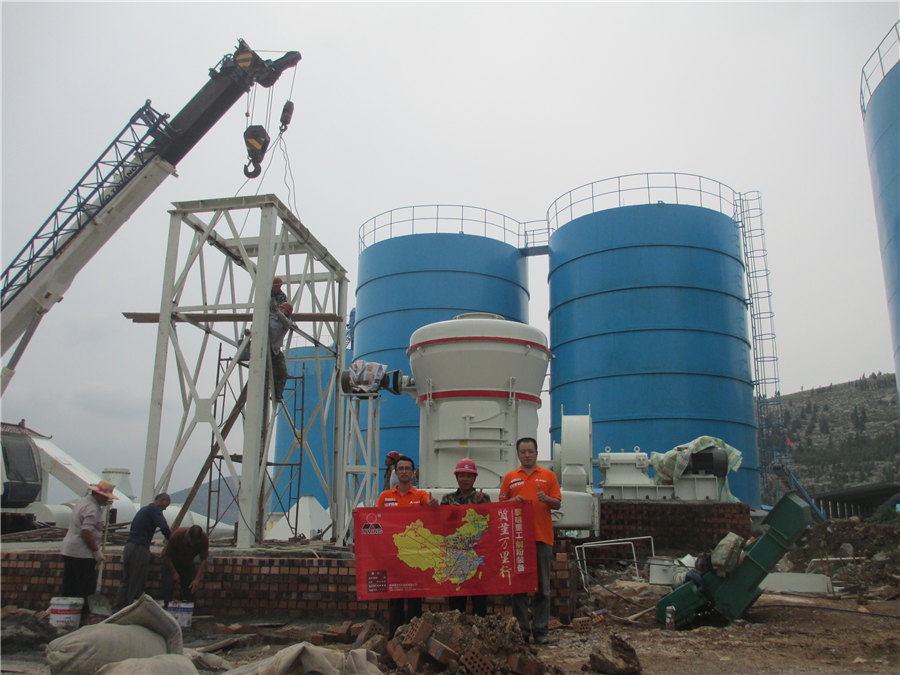

100 tons of rare earth ore grinding and powder production line

Processing the ores of rareearth elements MRS Bulletin

Most REE minerals, especially bastnäsite and monazite, must be decomposed prior to leaching Decomposition is commonly done by roasting or baking the concentrate in acidproof 展开2023年11月9日 The screened rare earth ore enters a ball mill for dry grinding, improving mineral powder fineness and uniformity Overgrinding can waste resources and reduce recovery of brittle minerals FTM Machinery offers ball Unlocking Potential: Rare Earth Elements Processing 2017年9月10日 The purpose of this paper is to comprehensively review and summarize the rare earth processing routes, the mostly employed rare earth (PDF) A Review of Rare Earth Mineral Processing 2023年6月1日 Rare earth elements resources production, consumption, and processing activities are significantly uneven around the world Global production of REOs (210,000 of Global rare earth elements projects: New developments and

A review on complex utilization of mine tailings: Recovery of rare

2024年6月1日 Mine tailings (MTs) pose a major environmental problem because of the challenges associated with their management and storage Depending on the type of ore 2024年4月1日 The proven resource reserves include 35 million tons REO (average grade = 6 wt%), 1400 million tons iron ore, 100 million tons fluorite, and 32 million tons Nb 2 O 5Journal of Rare Earths ScienceDirectA brief introduction to powder grinding production line Powder grinding production line is widely applied for grinding materials into the size of 80 to 3,000 meshes in various industries of building materials, chemical engineering, chemicals, Powder Grinding Plant with High Capacity and 2024年4月1日 The proven resource reserves include 35 million tons REO (average grade = 6 wt%), 1400 million tons iron ore, 100 million tons fluorite, and 32 million tons Nb 2 O 5 The ratio of bastnaesite to monazite in the deposit is approximately 3:1, and REEs are recycled from iron ore processing tailings 42 , 43 There are three mining areas in the Bayan Obo depositJournal of Rare Earths ScienceDirect

The Process Mineralogical Characterization of Bayan

2023年9月30日 As Bayan Obo rareearth tailings, which are generated after the production of mineral products with the raw ore from different mining areas, are considered secondary resources rich in valuable 2024年7月15日 Rare earth elements (REE) have applications in electric vehicles, wind turbines, trains, electronics, and agriculture Nevertheless, in the mining process, waste production, such as thorium and uranium, harms the wellbeing of both people and the natural environment This work provides a basis for studies that evidence research in the production chain of rare earth Life cycle assessment and circular economy in the production of rare 2022年3月31日 The demand for rare earth elements (REE) is increasing rapidly owing to the emergence of new cleanenergy and defenserelated technologies China's dominates the world production of REEDevelopment and beneficiation technology of rare earth ores in 2017年8月10日 Rare earth elements (REE) are widely used in high technologies, medical devices, and military defense systems, and are especially indispensable in emerging clean energy Along with the growing market of green energy in the next decades, global demand for REE will increase continuously, which will put great pressure on the current REE supply chain Global Potential of Rare Earth Resources and Rare Earth Demand

.jpg)

NdFeB Powder Making Process Grinding Plant JXSC Mineral

2023年12月14日 Capacity: 40,000 tons/year Finished product particle size: 300 mesh Finished product use: rare earth materials Main equipment: MTW European version mill NdFeB Grinding Production Line Production Process The onsite raw materials are transported to the European version of the primary mill via a belt conveyor for grinding and processing2014年10月29日 Rare earths are used in the renewable energy technologies such as wind turbines, batteries, catalysts and electric cars Current mining, processing and sustainability aspects have been described in this paper Rare earth availability is undergoing a temporary decline due mainly to quotas being imposed by the Chinese government on export and action Rare Earth Elements: Overview of Mining, Mineralogy, Uses 2021年12月1日 Fifteen lanthanides (atomic numbers 5771) plus two transition metal elements (scandium and yttrium) are grouped as rare earth elements (REEs) due to their similar chemical properties [1, 2]REEs are essential raw materials for numerous modern technologies, such as rechargeable batteries, electric vehicles, wind turbines, lasers, guidance and control, and The effect of mechanical grinding and thermal treatment on Refining rare earths is complex and China controls many processing technologies Still, Hanoi University of Mining and Geology says that rare earths at Dong Pao are relatively easy to mine and are mostly concentrated in bastnaesite ores These rare earth ores will then be ground into powder and processed into rareearth oxide (REO)Quality Rare Earth Polishing Powder, Rare Earth Catalyst factory, Rare

.jpg)

(PDF) Process development to recover rare earth metals from

2015年8月31日 200,000 tons in 2014 but REEs demand surpassed 200,000 tons per ionadsorbed rare earth ore is also feasible for RE recovery while bucket line and suction dredges are used for mining deeper2024年11月21日 All rareearth ores contain less than 10 percent REO and must be upgraded to about 60 percent in order to be processed further They are first ground to a powder and then separated from the other materials in the ore body by various standard processes that include magnetic and/or electrostatic separation and flotation In the case of Mountain Pass Rareearth element Processing Ores Britannica2003年1月1日 The impact of dynamic forces in rockblast fragmentation process has been the subject of investigation for years Nevertheless, while the influence of the macrofragmentation in downstream (PDF) The Effects of Blasting on Crushing and Grinding 5 Classifying – Dedusting of fine Powder mClass Highefficiency Fine Classifier ∙ The mClass Highefficiency Fine Classifier, equipped with the patented ConVor® classifier wheel, is suitable for an extremely fine classification (d 97 1 µm to 120 µm) with a closely defined sharpness of cutFine Grinding and Classifying of Rare Earth Alloys

.jpg)

Development status and research progress in rare earth industry

2007年1月1日 The production of mixed rare earth oxide powder from a thorium about 14e16 tons of residue will and they account for more than 80% of the annual global rare earth ore production2018年3月22日 Neodymium, praseodymium and dysprosium are rare earth elements often used in high performance magnets Environmental impacts during the production of 1 kg neodymium iron boron (NdFeB) magnet from Comparative Life Cycle Assessment of NdFeB Permanent Magnet Production 2023年12月29日 One of the most important and wide range of applications for rare earth (REs) containing materials is the production of permanent magnets Since the 1960s, this class of magnets has given designers and engineers the ability to increase performance, reduce the size of devices and even create applications that would not be possible with other magnet materialsRare Earth Magnets: Manufacturing and Applications2019年8月15日 The use of powderbased technologies for the production of rare earth (RE)doped fibers and preforms is discussed Although these technologies cannot compete with vaporbased technologies such as modified chemical vapor deposition (MCVD) with respect to purity of the silica material obtained, they offer a high degree of versatility with respect to the material Powder Process for Fabrication of Rare EarthDoped Fibers

.jpg)

(PDF) Economic analysis of rare earth element processing

2022年8月22日 Although rare earth deposits are found on all continents, China produces more than 90% of all globally used rare earth metals Besides its economic dominance, China has also gained a monopolistic 2015年12月25日 This chapter gives an overview of the major and minor ore minerals of the rare earths, and of the related major ore deposits and at least 48 million tons of rare earth oxides with an average grade of 6 % (Drew et al 1990) The deposit was discovered in 1927 Mining, not for REE or Nb, but for iron began in 1957 The Ore Minerals and Major Ore Deposits of the Rare EarthsGeneral Flowsheet for REE Production Igneous or sedimentary rare earth ores, (usually phosphates or carbonates) Grinding, Magnetic, Flotation, Density Separations Mixed rare earth physical concentrates Rare earth mineral cracking and chemicalpurification Individual rare earth separation by solvent extraction Precipitation, filtration Reactive Grinding of Coal Ash For Enhanced Rare Earth ExtractionTuXingSun Mining provides stateoftheart mining and mineral processing equipment for metallic and nonmetallic minerals We offer comprehensive services including ore testing laboratories, global ore trade, and turnkey mining technology solutions Our global expertise ensures efficient and sustainable mining operations for gold, copper, rare earths, and other minerals Partner TuXingSun Mining Advanced Mining and Mineral Processing

Material and Energy Requirement for Rare Earth Production

2013年8月21日 The use of rare earth metals (REMs) for new applications in renewable and communication technologies has increased concern about future supply as well as environmental burdens associated with the extraction, use, and disposal (losses) of these metals Although there are several reports describing and quantifying the production and use of REM, there is still a 2021年11月3日 Rare earth elements (REEs) are critical raw materials and are attracting interest because of their applications in novel technologies and green economy Biohydrometallurgy has been used to extract other base metals; however, bioleaching studies of REE mineral extraction from mineral ores and wastes are yet in their infancy Mineral ores have been treated with a Rare Earth Elements Biorecovery from Mineral Ores andProcessing of rare earth ores All rare earth ores contain less than 10 percent of REO and need to be upgraded to about 60 percent for further processing They are first ground to a powder and then separated from the other materials in the orebody by various standard processes, including magnetic and / or electrostatic separation and flotationRare earths Institute for Rare Earths and Metals2024年9月29日 Electronic waste (ewaste) contains valuable rare earth elements (REEs) essential for various hightech applications, making their recovery crucial for sustainable resource management This review provides an overview of the occurrence of REEs in ewaste and discusses both conventional and emerging green technologies for their recovery Conventional A Review of the Occurrence and Recovery of Rare Earth Elements

An Overview of Rare Earth Ores Beneficiation in Vietnam

2021年11月10日 Rare earth elements have unique physicochemical properties that make them essential elements in many hightech components Bastnesite (La, Ce)FCO3, monazite, (Ce, La, Y, Th)PO4, and xenotime, YPO4 2024年7月2日 Large quantities of hazardous ceriabased polishing powder waste (CPPW) are produced worldwide each year, much of which unfortunately ends up in landfills, causing waste of rareearth resources and harm to the environment This study proposes a novel mechanochemical approach for the recovery of La and Ce from CPPW and the regeneration KilogramScale Recovery of La/Ce and Regeneration of RareEarth Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, Copper Mining and Processing: Processing Copper Ores2024年8月29日 Rare earth metal production was on the rise again in 2023, jumping to 350,000 metric tons (MT) worldwide — that’s up significantly from 190,000 MT in 2018, just five years prior Demand for Top 11 Countries by Rare Earth Metal Production (Updated 2024)

Powder Grinding Plant with High Capacity and

A brief introduction to powder grinding production line Powder grinding production line is widely applied for grinding materials into the size of 80 to 3,000 meshes in various industries of building materials, chemical engineering, chemicals, 2024年4月1日 The proven resource reserves include 35 million tons REO (average grade = 6 wt%), 1400 million tons iron ore, 100 million tons fluorite, and 32 million tons Nb 2 O 5 The ratio of bastnaesite to monazite in the deposit is approximately 3:1, and REEs are recycled from iron ore processing tailings 42 , 43 There are three mining areas in the Bayan Obo depositJournal of Rare Earths ScienceDirect2023年9月30日 As Bayan Obo rareearth tailings, which are generated after the production of mineral products with the raw ore from different mining areas, are considered secondary resources rich in valuable The Process Mineralogical Characterization of Bayan 2024年7月15日 Rare earth elements (REE) have applications in electric vehicles, wind turbines, trains, electronics, and agriculture Nevertheless, in the mining process, waste production, such as thorium and uranium, harms the wellbeing of both people and the natural environment This work provides a basis for studies that evidence research in the production chain of rare earth Life cycle assessment and circular economy in the production of rare

Development and beneficiation technology of rare earth ores in

2022年3月31日 The demand for rare earth elements (REE) is increasing rapidly owing to the emergence of new cleanenergy and defenserelated technologies China's dominates the world production of REE2017年8月10日 Rare earth elements (REE) are widely used in high technologies, medical devices, and military defense systems, and are especially indispensable in emerging clean energy Along with the growing market of green energy in the next decades, global demand for REE will increase continuously, which will put great pressure on the current REE supply chain Global Potential of Rare Earth Resources and Rare Earth Demand 2023年12月14日 Capacity: 40,000 tons/year Finished product particle size: 300 mesh Finished product use: rare earth materials Main equipment: MTW European version mill NdFeB Grinding Production Line Production Process The onsite raw materials are transported to the European version of the primary mill via a belt conveyor for grinding and processingNdFeB Powder Making Process Grinding Plant JXSC Mineral2014年10月29日 Rare earths are used in the renewable energy technologies such as wind turbines, batteries, catalysts and electric cars Current mining, processing and sustainability aspects have been described in this paper Rare earth availability is undergoing a temporary decline due mainly to quotas being imposed by the Chinese government on export and action Rare Earth Elements: Overview of Mining, Mineralogy, Uses

.jpg)

The effect of mechanical grinding and thermal treatment on

2021年12月1日 Fifteen lanthanides (atomic numbers 5771) plus two transition metal elements (scandium and yttrium) are grouped as rare earth elements (REEs) due to their similar chemical properties [1, 2]REEs are essential raw materials for numerous modern technologies, such as rechargeable batteries, electric vehicles, wind turbines, lasers, guidance and control, and Refining rare earths is complex and China controls many processing technologies Still, Hanoi University of Mining and Geology says that rare earths at Dong Pao are relatively easy to mine and are mostly concentrated in bastnaesite ores These rare earth ores will then be ground into powder and processed into rareearth oxide (REO)Quality Rare Earth Polishing Powder, Rare Earth Catalyst factory, Rare