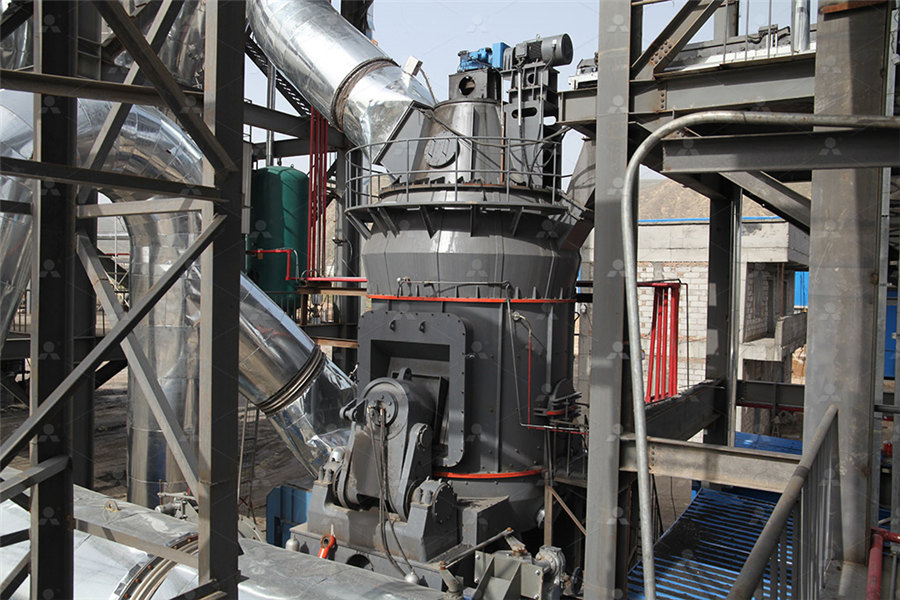

Fine crushing and powder making process

.jpg)

Making Metal Powder MPIF

In this process, molten metal is separated into small droplets and frozen rapidly before the drops come into contact with each other or with a solid surface Typically, a thin stream of molten metal is disintegrated by subjecting it to the impact of highenergy jets of gas or liquid In principle, the technique is applicable to 展开Methods for making powders – Atomization : Produces powders of both ferrous and nonferrous powders like stainless steel, superalloys, Ti alloy powders; Reduction of compounds : Powder metallurgy – basics applications IIT GuwahatiPowder metallurgy – P/M is a highly developed method of manufacturing reliable ferrous and nonferrous parts Made by mixing elemental or alloy powders and compacting the mixture in a Powder metallurgy P/M University of Technology, IraqThere are many ways in which metals may be produced in powder form, comminution of solid metal precipitation from solution of a salt; thermal decomposition of a chemical compound; Powder Metallurgy – Powder Processes (Solid State Reduction

.jpg)

Metal Powder Preparation Methods and Principles: A

2023年9月5日 What if the key to creating the perfect metal powder lay in the methods used to produce it? This article dives into various metal powder preparation techniques, from reduction and electrolysis to atomization and 2023年2月22日 4 Steps in the Powder Metallurgy Process The powder metallurgy (PM) process is more complex than 5,000 years ago Still, it can be broken down into four steps: Powder production; Mixing and blending; Powder Metallurgy Process: Steps, ApplicationsThe pulverizer, doubleroller, and jaw crusher can make large particles, and then a further finedown process is required to make the powders into porous metal Much finer powders can be Powder Preparation an overview ScienceDirect Topics2014年1月1日 Coarse comminution (cold stream) processing (Fig 12) is recommended in the case of large brittle material feed (≈ 20 mm max) that needs to be reduced to as fine as 30 Powder Processing of Bulk Components in Manufacturing

.jpg)

Mechanical Preparation Techniques SpringerLink

2010年1月1日 Crushing is used to very quickly produce a fine powder from a bulk material or fine particle using mechanical crushing This technique is essentially used to investigate 2023年6月27日 This review found that ball milling is the best tool for reducing the particle size of recycled metal chips and creating new metal powders to enhance mechanical properties and novelty for mold additive manufacturing Producing Metal Powder from Machining Chips Using 2022年8月29日 Production Process The processing of dolomite can be divided into four production processes: coarse crushing by jaw crusher, medium and fine crushing by crusher (fine jaw crusher, impact crusher, etc) and sand shaping Dolomite crushing and sand making production line2023年9月5日 The resulting powder is extremely fine and pure, but the process is costly Industrially, it’s primarily used to produce fine and ultrafine powders of nickel and iron, as well as alloy powders of FeNi, FeCo, NiCo, and others Metal Powder Preparation Methods and Principles: A

.jpg)

Limestone crushing, sand making and grinding process

2022年7月20日 Introduction of limestone crushing, sand making and grinding process The particle size of limestone mined by excavation and blasting is generally about 80 cm to 1 m2 If you want to process it into sand and lime Jaw crusher (coarse crushing), cone crusher (secondary crushing), vertical shaft impact crusher (fine crushing and sand making), which can form a threestage crushing and sand making plant 425mesh, 800mesh and 1250mesh To process dolomite into powder with suitable fineness, we need dolomite grinding plant A complete dolomite grinding How to Process Dolomite: Dolomite Crushing And Grinding Plant2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for industries such as airport construction, water conservancy power stations, tall buildings, concrete mixing plants, etcLimestone Crushing And SandMaking Plant Eastman Rock 2024年8月26日 Producing basalt rock powder involves several types of machines for crushing, grinding, and classifying the rock into a fine powder Here is a list of the essential machinery used in this process: ESSENTIAL MACHINERY: Primary Crusher: Jaw Crusher: Suitable for primary crushing of large basalt rocks Gyratory Crusher: An alternative for primary crushing, offering Basalt Rock Powder Making Machines Vertical Roller Grinding

Powder Metallurgy Process: Steps, Applications Limitations

2023年2月22日 4 Steps in the Powder Metallurgy Process The powder metallurgy (PM) process is more complex than 5,000 years ago Still, it can be broken down into four steps: Powder production; Mixing and blending; Compacting; Sintering; 1 Powder Production Metal powder is the raw material of the PM process, produced by grinding, crushing, atomization, or 2024年9月6日 Many crushing equipment do not work well when facing highhumidity materials, but the doubleroll crusher is suitable The unique design makes it less prone to clogging when handling wet and sticky materials The environmental performance of roller crushers is good The dust and noise generated during the crushing process are relatively lowDouble Roller Crusher Machine For Sand MakingFind innovative production technology for making powder and connect directly with worldleading specialists When you need to produce ultrafine powders, the milling and drying process emp After crushing and drying mined bentonite, Powder Manufacturing Equipment Making2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica

.jpg)

How Cement is Made Portland Cement Association

Chunks are then ground into a fine powder Site A Sustainable Future Roadmap to Carbon Crushing After quarrying, which uses heat generated by the plant to start chemical reactions between the components—making the Crushing process— for making fermented cow dung into fine and uniform powder The role of crushing process is to deal with potential caking in fermented cow dung Because the longtime stacking of cow dung during composting will Cow dung powder making machine manure The quartz sand making process is divided into three stages: coarse fine crushing, sand making screening, and sand washing recycling The first stage: coarse fine crushing The materials are uniformly fed by the vibrating Quartz Crushing Solution Eastman Rock Crusher2024年4月22日 Its function is to crush the bentonite stone material Then the crushed materials enter the sandmaking machine for sandmaking treatment Sandmaking machine Because bentonite cannot meet the actual needs of users after rough and fine crushing processing It will adopt a vertical shaft impact sandmaking machine forBentonite Processing Plant And Grinding Machine

Small Wood Powder Machine For Making Fine Wood Flour

2023年6月16日 The main unit crushing chamber adopts a 7type knife, 1type knife, and centrifugal knife There are coarse crushing, fine crushing, and centrifugal complex crushing wood powder processing Working principle of wood flour machine2023年3月9日 Use industrial crushing and grinding equipment to crush and grind shells into fine powder Shell powder contains 95% calcium carbonate and has a wide range of uses +17Seashell powder use and powder making equipment SBM Ultrafine Powder 2022年5月7日 A complete waste glass processing production line requires auxiliary equipment such as glass crushers, glass powder making machine and conveyor belts The glass particles obtained by crushing can be used in the building material industry, and the glass fine powder obtained by grinding can be used in coatings, ceramics and other industriesGlass Recycling Powder Making Machine2022年4月20日 Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industries Limestone crushing process The particle size of limestone crushing is very small after coarse crushing and medium and fine crushing If sand making or grinding is required, Limestone crushing and grinding production line SBM Ultrafine Powder

How to Process Dolomite Rock and What Is It Used for?

2024年10月14日 Remark: For conversion from millimeter to mesh, please refer to mm to mesh Process 3: Calcinating dolomite rock The crushed dolomite is calcined in a rotary kiln, which is used for producing refractory materials, magnesium alloys, cement, etc Dolomite is calcined at 1500°C to obtain magnesiacalcium raw materials, such as dolomite sand, magnesiacalcium 2024年1月11日 The coal pulverization process involves a precise sequence of steps Each is systematically designed to convert raw coal into a fine, efficient powder But you have to start by prepping up the coal rock before the grinding process Step 1: Crush the coal rock The coal pulverization steps begin with an initial crushingHow to Process Coal into Pulverized Coal in 5 Steps?2021年9月6日 2 Wheel sand washer + fine sand recycling machine After the materials are crushed for sand making, we can arrange wheel sand washer equipment at the lower section of the sand making machineThe wheel sand Separation and Recovery of Stone Powder in Machine After the manure composting process for cmmercial fertilizer powder making Generally, after the composting, the manure composts will be suitable for fertilizing While, for selling organic fertilizers, it is a good choice for you to Manure Grinder Fine Powder Making Features

.jpg)

7 Best Methods of Metal 3D Printing Powder Making

2021年1月28日 Solid metal mechanical crushing method is an independent powder making method and can be used as a complementary process to some powder making methods Relying on the role The final degree of crushing can be divided into two categories: coarse crushing and fine crushing To further reduce or increase the size of the powder 2019年10月31日 Journal of the Society of Powder Technology Vol 22, No 6, 7176 (1985) (*5) BSI Institute website “Fertilization Engineering” – Grinding (*6) Tsutomu Nakayama: Bead mill for making ultrafine particles and nanoparticles, p2328, p29, p3435 (*7) Powder Terms Pocket Book, Association of Powder Process Industry and Engineering, JapanPulverization 1: Definition and purpose THINKY MIXER2023年3月2日 The process of the stone crushing plant is rough: (warehouse) — Vibrating feederjaw crusher — impact crusher — circular vibrating screen — sand making machine — The sand washing machinefine sand recycling machine —Final product All the equipment will be connected by several belt conveyors The finished sandstone gravel will gradually screened Getting To Know The Complete Set Stone Crushing Plant2023年2月15日 Talc powder processing: 1 Coarse crushing: First, the talc ore is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing; 2 Drying: Then the crushed ore is sent to a dryer through a bucket elevator for dying; 3 Further crushing: After drying, talc ore is sent to a hammer crusher for medium and fine crushing;How to Process Talc (the Softest Mineral)? FTM Machinery

.jpg)

Gypsum Powder Grinding And Processing Plant Equipment

2024年1月23日 Gypsum powder is formed by a series of treatments on a large bulk of gypsum, with a finished particle size usually around 80325 mesh In terms of the entire production process of gypsum grinding, the equipment required mainly includes jaw crushers, Raymond grinders, etc2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine Powder In the field of powder and particle processing, achieving mediumfine crushing of hard materials like ceramics and minerals is essential Finding a method that combines energy efficiency with precise size reduction is key to optimizing your production processHighpressure roller mill for mediumfine crushing MakingPowder metallurgy – basics applications Powder metallurgy – science of producing metal powders and making finished /semifinished objects from mixed or alloyed powders with or without the addition of nonmetallic constituents Steps in powder metallurgy:Powder production, Compaction, Sintering, Secondary operations Powder production:Powder metallurgy – basics applications IIT Guwahati

Dolomite crushing and sand making production line

2022年8月29日 Production Process The processing of dolomite can be divided into four production processes: coarse crushing by jaw crusher, medium and fine crushing by crusher (fine jaw crusher, impact crusher, etc) and sand shaping 2023年9月5日 The resulting powder is extremely fine and pure, but the process is costly Industrially, it’s primarily used to produce fine and ultrafine powders of nickel and iron, as well as alloy powders of FeNi, FeCo, NiCo, and others Metal Powder Preparation Methods and Principles: A 2022年7月20日 Introduction of limestone crushing, sand making and grinding process The particle size of limestone mined by excavation and blasting is generally about 80 cm to 1 m2 If you want to process it into sand and lime Limestone crushing, sand making and grinding processJaw crusher (coarse crushing), cone crusher (secondary crushing), vertical shaft impact crusher (fine crushing and sand making), which can form a threestage crushing and sand making plant 425mesh, 800mesh and 1250mesh To process dolomite into powder with suitable fineness, we need dolomite grinding plant A complete dolomite grinding How to Process Dolomite: Dolomite Crushing And Grinding Plant

.jpg)

Limestone Crushing And SandMaking Plant Eastman Rock

2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for industries such as airport construction, water conservancy power stations, tall buildings, concrete mixing plants, etc2024年8月26日 Producing basalt rock powder involves several types of machines for crushing, grinding, and classifying the rock into a fine powder Here is a list of the essential machinery used in this process: ESSENTIAL MACHINERY: Primary Crusher: Jaw Crusher: Suitable for primary crushing of large basalt rocks Gyratory Crusher: An alternative for primary crushing, offering Basalt Rock Powder Making Machines Vertical Roller Grinding 2023年2月22日 4 Steps in the Powder Metallurgy Process The powder metallurgy (PM) process is more complex than 5,000 years ago Still, it can be broken down into four steps: Powder production; Mixing and blending; Compacting; Sintering; 1 Powder Production Metal powder is the raw material of the PM process, produced by grinding, crushing, atomization, or Powder Metallurgy Process: Steps, Applications Limitations2024年9月6日 Many crushing equipment do not work well when facing highhumidity materials, but the doubleroll crusher is suitable The unique design makes it less prone to clogging when handling wet and sticky materials The environmental performance of roller crushers is good The dust and noise generated during the crushing process are relatively lowDouble Roller Crusher Machine For Sand Making

Powder Manufacturing Equipment Making

Find innovative production technology for making powder and connect directly with worldleading specialists When you need to produce ultrafine powders, the milling and drying process emp After crushing and drying mined bentonite, 2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica