Zircon powder making equipment Dry selection ball mill

Zircon Processing Equipment, Process Flow, Cases JXSC Machine

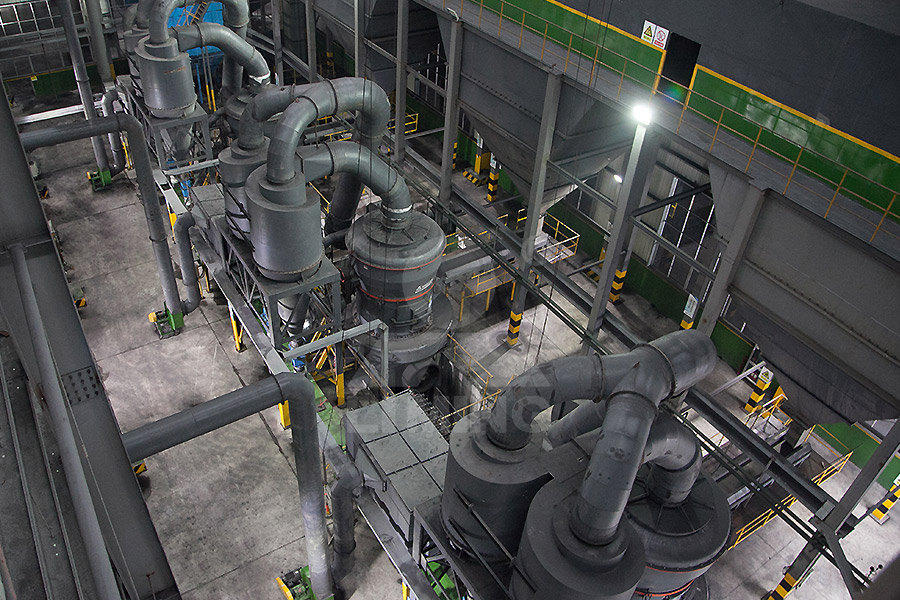

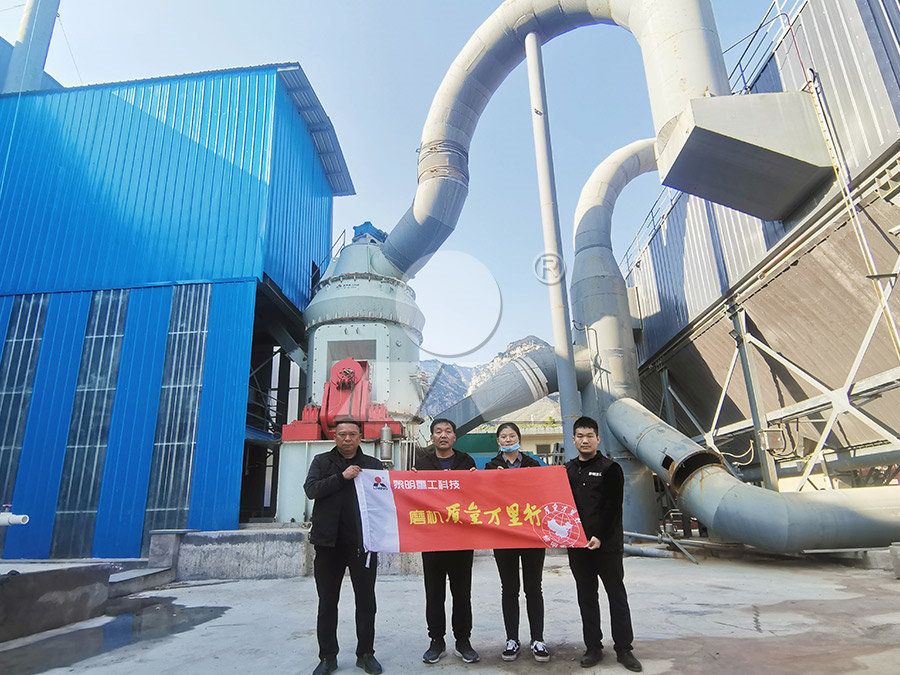

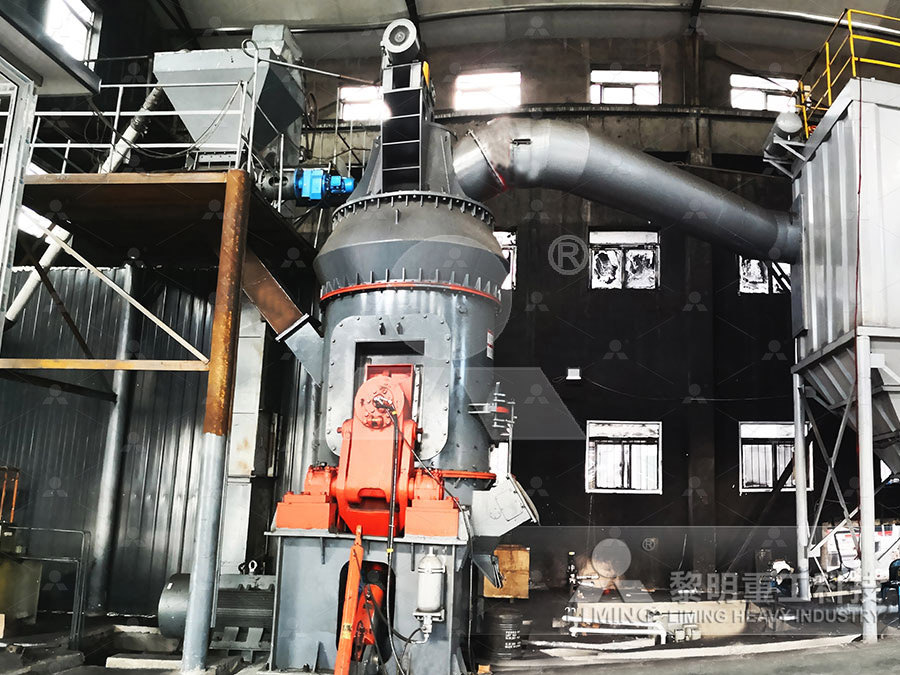

Zirconium sand, also known as zircon sand, is a mineral composed mainly of zirconium silicate Pure zircon sands are colorless transparent crystals, often dyed yellow, orange, red, and brown due to different origins and impurities The crystalline structure belongs to the tetragonal crystalline system The crystalline 展开2023年8月1日 Dry grinding of zircon is generally done using a zircon ball mill combined with a classifier process The ball mill is lined with nonmetallic wearresistant materials, and Zircon Ball Mill, Zircon Grinding Process Zoneding MachinePlanetary ball mills are used for the pulverization of soft, hard, brittle, and fibrous materials in dry and wet mode Extremely high centrifugal forces result in very high pulverization energy and Planetary Ball Mills RETSCH fine grinding of materialsRETSCH offers the largest selection of laboratory ball mills in the market! Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous Ball Mills a suitable ball mill for every application RETSCH

.jpg)

Chapter 10 Selection of Fine Grinding Mills ScienceDirect

2007年1月1日 When the finest grinding is required by dry grinding, the jet milling or the attrition milling with a roller mill, a ball media mill or a powderbed attrition mill would be useful Figure Zirconia (YSZ) grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic materials Zirconia grinding media provides a virtually contaminationfree Zirconia (YSZ) Grinding Media Inframat CorporationCeramic ball mills are effective tools for attrition and crushing of fibrous or hard materials They can be used to grind dry, wet and even cryogenically treated materials They efficiently and Ball mills and ceramic grinding balls // Umicore CeramicsBall milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel balls, or ceramic are used in the collision Ball Mill JXSC Mineral

ZIRCONIUM MILLING TECHNOLOGY Zirkonzahn

Zirkonzahn Ltd offers individual solutions of manual milling technology Technical solutions – for simple as well as highly complex and demanding constructions A wide range of accessory 2024年7月21日 Ball mills are also utilized in pyrotechnics and the production of black powder, though they are unsuitable for making some pyrotechnic mixtures like flash powder due to their sensitivity to impact Highquality ball mills can be expensive but are capable of grinding mixture particles down to as small as 5 nm, significantly increasing the surface area and reaction ratesEffective Ball Mill Media for Superior Black Powder ProductionExplore our Powder Milling Equipment and why Hammer Milling is the choice when you need to precisely control the particle size reduction process Altering the rotor speed and screen design makes it possible to get a variety of results Fitzpatrick Powder Milling EquipmentSearch for used ball mills (powder processing) Find Sigma, Baichy, Ascend, Beifan Ball mill attritor dry and powders attrition #25031 used Attrition machine for Micro powder ball mill with air classifier equipment is used for making fine powder ,the whole set is including ball mill ,air classifier ,cyclone collector ,bag Used ball mills (powder processing) Machinio

Powder Manufacturing Equipment Making

Find innovative production technology for making powder and connect directly with worldleading specialists Planetary ball mill for powder material mixing and alloying The techniques here are primarily mechanical, using dry milling equipment like jet mills or roll mills If you work with molecules such as sodium, Mill Pots We provide all kinds of mill pots in any matched size, which can be made of agate, alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese Zirconia Mill Ball2017年11月1日 The discrete element method (DEM) has been widely used to simulate the dynamics of various planetary mills allowing to study the influence of design variables such as jar geometry, ball sizes Dry grinding in planetary ball mills: Evaluation of a stressing 2023年12月28日 The safety factor is low, the service life is short, etc, and these will inevitably affect the continuous production of the ball mill Therefore, the overall performance of the ball mill is better 3 The ball mill is of good quality The better the quality of the ball mill, the more stable the performance of the ball mill will be during Factors Affect The Output and Quality of Ball Mills And How to

Using a Ball Mill for Black Powder Production: How It Works

2023年8月17日 It makes it ideal for black powder manufacturing since it can be transported to another location for storage or usage Benefits of Utilizing a Ball Mill for Black Powder Production Using a ball mill for black powder manufacturing offers several advantages It also includes greater efficiency, safety, and powder qualityAccessories making high energy ball mills High Energy Ball Mill is a versatile instrument because of the broad selection of accessories Tungsten carbide, zirconium oxide, and stainless steel are the three different kinds of materials for grinding jars which ensures the preparation of samples in a contaminationfree environmentHigh Energy Ball Mill Equipment and Its Application Areas2012年6月1日 Hybrid HighPressure Roll Mill/Ball Mill Grinding – Powder T echnology, V ol 105, 1999, The Selection and Design of Mill Lin ers Ball mills can grind a wide range of materials, Grinding in Ball Mills: Modeling and Process Control2018年7月4日 Yttriareinforced copper matrix composites were prepared by dry ball milling (DBM) and wet ball milling (WBM), respectively, followed by spark plasma sintering (SPS) It is to determine which milling process is better for fabricating Cu–Y2O3 composites It is found that Cu–Y2O3 composites synthesized by DBM exhibit better densification, mechanical and Dry ball milling and wet ball milling for fabricating copper–yttria

Ball Mill VS AG Mill: What are the Similarities and Differences?

2020年5月20日 Ball mill, rod mill and AG mill are common equipment for grinding operation in mineral processing plants The difference between ball mill and rod mill has been known before, but what are the similarities and differences between ball mill and AG mill? This article will take you to explore so as to help you choose the appropriate grinding equipment more conveniently2019年8月14日 Ball mill is a common grinding equipment in concentrator Common Types of Ball mill back to top The common industrial ball mills mainly include cement ball mill, tubular ball mill, ultrafine laminating mill, cone ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, grid ball mill, wind discharge ball mill, double bin ball mill, energy saving ball millThe Ultimate Guide to Ball Mills Miningpedia2023年3月9日 Ball Mill (20200 mesh) The ball mill is a grinding machine for grinding and mixed for mineral selection processes, paint, fireworks, ceramics and selective laser sintering materials It can be used to grind the shell into fine powderSeashell powder use and powder making equipment SBM Ultrafine Powder 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911Metallurgist

Ball Mill Design Calculations How to 911Metallurgist

2018年4月8日 Unlock the principles of ball mill design with 911 Metallurgist This guide offers detailed calculations and practical tips to ensure your mill is optimized for performance, efficiency, and effective mineral processing2024年1月10日 The Similarities Between Ball Mill And Rod Mill Appearance: From the appearance, the ball mill and rod mill are both long cylindermounted equipment styles Classification: Ball mills and rod mills are both key grinding equipment for crushing materials after crushing Structure: The structure is the same They are all horizontal cylinder Ball Mill VS Rod Mill: Difference Selection JXSC Machine2019年10月26日 If you need a powder making equipment for process metal ore, ball mill is a better choice; If you need more fine product, grinding mill is your only choice; If you have more production requirements, and are not so concerned about the powder fineness, you can choose a professional ball mill manufacturer; If both kinds of milling machine meet your needs, in order Difference and Choice of 2 Common Mills, Ball Mill and Grinding Mill FTM2021年6月17日 There are many types of mills in the market for both wet and dry milling, and the selection process can be daunting, but with the right equipment to meet your industrial milling needs, you can costeffectively create uniformly fine particles with little to no contaminationWet vs Dry Milling: Key Differences Hockmeyer Hockmeyer Equipment

.jpg)

BALL MILLS Ball mill optimisation Holzinger Consulting

Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO 2 emission benefits to the cement producer n by Thomas Holzinger, Holzinger Consulting, SwitzerlandThe grinding medium in the mill repeatedly impacts and grinds the material by virtue of the kinetic energy obtained when the mill rotates The crushed material is discharged into the suction tank through the tail of the ball mill, and then Ball Mill and Air Classifier Production Line ALPA 2024年2月19日 Copper Powder Recovery Equipment; Reasonable selection of the gradation of ball mill steel balls is an indispensable measure to improve the output and quality of ball mills Zircon Other Message Submit 62850 We Ball Mill Steel Balls: Quality And Gradation JXSC 2023年6月27日 Nevertheless, parameter factors, such as the type of ball milling, balltopowder ratio (BPR), rotation speed, grinding period, size and shape of the milling media, and process control agent (PCA (PDF) Producing Metal Powder from Machining Chips

Solids and powder milling Size reduction

Ball mills (dry) Ball mills are basically made of a drum partially filled with a grinding media, typically beads of ceramics or steel The mill is filled with the grinding beads as well as the product, then the mill is rotated until a speed sufficiently high so that the beads can tumble freelyIts robust construction and highspeed capabilities ensure reliable and consistent performance in achieving desired particle sizes Our ball mill grinder's efficiency lies in its ability to convert coarse particles into a uniform, fine powder, making it essential equipment for material refinement and preparation across various industrial processesBall Mill Grinder Wet Dry Grinding Ball Mill LabotronicsOverview of our ball mills and agitated media mills The classic ball mill Super Orion SO is suitable for dry hard crushing and achieves finenesses of under 10 µm For superfine dry grinding: The energyefficient Pulvis combines a vertical agitator bead mill with a highperformance classifier and is also suitable for grinding hard materialsBall Mills Agitated Media Mills Hosokawa AlpineBall mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc According to the need of customers, ball mills can realize both wet and dry production Home; Ball mill grinding production line is usually consists of full set Ball mill grinding equipment and Ball Mill, Ball Mill For Sale

Ball Mill Grinding William Boulton

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsThe ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics and the ball mill can grind various ores and other materials with dry type and wet typeRock Stone Gold Sand Bentonite Zircon Grinding Ball Mill YS9080/YS1010/YS1212 Wheel Dry Sand Blasting Machine; Powder Coating Oven for Wheels Menu Toggle Mass Finishing Equipment for Ball Burnishing Zirconia ball also performed well in burnishing and polishing Lab ball mills – these can accommodate zirconia balls ranging between 10mm15mm;Zirconia ball, Top Quality Grinding media and milling media 2024年7月21日 Ball mills are also utilized in pyrotechnics and the production of black powder, though they are unsuitable for making some pyrotechnic mixtures like flash powder due to their sensitivity to impact Highquality ball mills can be expensive but are capable of grinding mixture particles down to as small as 5 nm, significantly increasing the surface area and reaction ratesEffective Ball Mill Media for Superior Black Powder Production

Fitzpatrick Powder Milling Equipment

Explore our Powder Milling Equipment and why Hammer Milling is the choice when you need to precisely control the particle size reduction process Altering the rotor speed and screen design makes it possible to get a variety of results Search for used ball mills (powder processing) Find Sigma, Baichy, Ascend, Beifan Ball mill attritor dry and powders attrition #25031 used Attrition machine for Micro powder ball mill with air classifier equipment is used for making fine powder ,the whole set is including ball mill ,air classifier ,cyclone collector ,bag Used ball mills (powder processing) MachinioFind innovative production technology for making powder and connect directly with worldleading specialists Planetary ball mill for powder material mixing and alloying The techniques here are primarily mechanical, using dry milling equipment like jet mills or roll mills If you work with molecules such as sodium, Powder Manufacturing Equipment MakingMill Pots We provide all kinds of mill pots in any matched size, which can be made of agate, alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese Zirconia Mill Ball

Dry grinding in planetary ball mills: Evaluation of a stressing

2017年11月1日 The discrete element method (DEM) has been widely used to simulate the dynamics of various planetary mills allowing to study the influence of design variables such as jar geometry, ball sizes 2023年12月28日 The safety factor is low, the service life is short, etc, and these will inevitably affect the continuous production of the ball mill Therefore, the overall performance of the ball mill is better 3 The ball mill is of good quality The better the quality of the ball mill, the more stable the performance of the ball mill will be during Factors Affect The Output and Quality of Ball Mills And How to 2023年8月17日 It makes it ideal for black powder manufacturing since it can be transported to another location for storage or usage Benefits of Utilizing a Ball Mill for Black Powder Production Using a ball mill for black powder manufacturing offers several advantages It also includes greater efficiency, safety, and powder qualityUsing a Ball Mill for Black Powder Production: How It WorksAccessories making high energy ball mills High Energy Ball Mill is a versatile instrument because of the broad selection of accessories Tungsten carbide, zirconium oxide, and stainless steel are the three different kinds of materials for grinding jars which ensures the preparation of samples in a contaminationfree environmentHigh Energy Ball Mill Equipment and Its Application Areas

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 Hybrid HighPressure Roll Mill/Ball Mill Grinding – Powder T echnology, V ol 105, 1999, The Selection and Design of Mill Lin ers Ball mills can grind a wide range of materials,