Safety system of industrial grinding mill manufacturers

American National Standard Safety Requirements for Grinding

By approving this American National Standard, the ANSI Board of Standards Review confirms that the requirements for due process, consensus, balance and openness have been met by B11 Standards, Inc, (the ANSIaccredited standards developing organization) American National Mill Control System This system provides all control functions required for the safe operation of grinding mills and their associated ancillary equipment It enables the opportunity to implement Grinding mill solutions Mill Control System2023年10月11日 In this article, we will explain what grinding safety precautions are and how they can be identified and implemented using a grinding risk assessment and provide you with grinding safety tips to keep your workers Grinding Safety Precautions and Control MeasuresThe Environmental, Health, and Safety (EHS) Guidelines are technical reference documents with general and industry specific examples of Good International Industry Pract iceFinal Integrated Steel Mills International Finance Corporation

PeerReviewed Working Safely With Grinders American Society

safety needs greater attention from OSH professionals and employers •This article presents 10 best practices for grinder use that are based on several years of practice as a safety profes Our roller mills are designed for the highest operational safety They also have special sampling points, where you can take samples safely How can we help? Bühler roller mills consistently and safely grind wheat, corn, rye, barley, spelt Roller Mills Milling Bühler GroupBühler offers the full package for grinding lines for any situation From sieving, conveying, storage, hoppers, gates, feeders, automation, fans, filters and safety equipment, we have you covered We have industryleading experience in Horizontal Hammer Mill Grinding System Bühler GroupSKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills The solutions are designed to protect pinions and trunnions Grinding mills SKF

Safety in Grinding SpringerLink

2017年9月27日 Safety regulations for grinding prepared by a number of national and international bodies are reviewed, and factors affecting safety in grinding are presented, The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine Grinding mill Palamatic ProcessWilliams roller mills boast nearly infinite turn down while maintaining product size The mill grinding rate is adjusted as a direct function of control system demand The mill capacity is modulated by varying mill speed Mill Speed Mill speed Industrial Roller Mills Williams CrusherThe Metso Outotec® Open Ended Discharge Grinding Mill (OED Mill) EverRoast industrial grinder is produced to meet mass coffee grinding need of companies and it is perfect grinding from raw materials roughing to transport to the milling to packaging, forming an independent production system Working principle The complete Raymond Mill Large mill, Large grinding mill All industrial manufacturers

.jpg)

Laboratory mill, Laboratory grinding mill All industrial

Output: 4 g/s Motor power: 600 W Machine width: 317 mm The CT 293 Cyclotec™ laboratory mill is ideal for rapid and flexible preparation of a wide variety of feeds, grains, leaves and more for NIR or reference analysis Excellent for all types of sample preparation In coal combustion, the efficiency and safety of the process are paramount Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing This article explores the components, advantages, and operational considerations of indirect firing cIndirect Firing Coal Grinding Systems: Enhancing Efficiency and Safety More Pulverizer Manufacturers Pulverizers deliver material size reduction services for various purposes, such as producing fine powder for pharmaceuticals, creating pulp for paper manufacturing, grinding grain for food production, shredding and recycling tires, breaking down construction materials, turning soil, crushing vehicles for scrap, and grinding rock samplesPulverizer Manufacturers Pulverizer SuppliersRotational speed: 120 rpm 240 rpm Output: 400 kg/h 30,000 kg/h Machine length: 13,900, 14,700 mm inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose highspeed impeller will screen the airflow: the unqualified particle size will fall and return Glass mill, Glass grinding mill All industrial manufacturers

.jpg)

Industrial Grinder Manufacturers Suppliers in India

Find here Industrial Grinder manufacturers OEM manufacturers in India Automatic SODIUM SULPHATE GRINDING MACHINE, AIR CLASSIFYING MILL ₹ 10,00,000/ Unit Get Latest Price Capacity 100 Kg/hr Type of Machine AIR CLASSIFYING MILL Operation Mode Automatic Electricity ConnectionManufacturers B; BEIJING POWER EQUIPMENT GROUP CO LTD (1) C; CEMTEC (1) Cepi Spa (1) F; of advanced technologies of famous international corporations and 30 years’ experience in grinding mill production, energy saving and environment friendly grinding equipment specially for cement raw material grinding system Vertical roller mill, Vertical roller grinding mill All industrial Find Industrial Grinding Machine manufacturers, bank transfer, credit card, ewallet, online payment systems etc Eco Friendly 5Hp Sonar Multipurpose Grinding Machine Price: 7550000 INR/Piece Get Best Quote Product Type Grinding Mill Usage Industrial Equipment Type Grinding Mill More details Kaps EngineersIndustrial Grinding Machine Manufacturers, Suppliers, Dealers Rotational speed: 980 rpm Output: 420 kg/h 500 kg/h Motor power: 132 kW Scrap Tyre Rubber Crushing Mill In Waste Tire Recycling Line is mainly used to grinding waste rubber, tir , tube, flap and break the raw rubber materials Finally the steel wire Plastic mill, Plastic pulverizer All industrial manufacturers

Grinding Safety Precautions Hazards Control

2023年10月11日 Grinding Safety Tips Control measures must be put in place to manage the risks posed by grinding to the health and safety of workers The following list outlines some health and safety control measures that can be put Depending on your choice, the particles will be more or less refined These brands also allow grinding more humid, pasty mixtures or liquids, as the BEPEX brand wet grinding mill manufacturer confirms What applications are there for industrial mills? All these types of industrial mills can serve you in several areas, namely: Food The different types of industrial mills and their applicationsFinal grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L welded mechanic, it is intended for the small installations of grinding in laboratory Mill for the food industry, Grinding mill for the food industry All Final grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L welded mechanic, it is intended for the small installations of grinding in laboratory Dry milling mill, Dry milling grinding mill All industrial manufacturers

.jpg)

Impact mill, Impact grinding mill All industrial manufacturers

Rotational speed: 7,500, 5,550, 12,000 rpm Output: 5 kg/h 500 kg/h Motor power: 3 kW 15 kWPrinciple Advantages The material is evenly sent to the grinding chamber by the feeding system, and receives the strong impact of the highspeed rotating grinding movable disk At the same time, it receives the action 2023年3月15日 Richland Hills, Texas, September 12, 2024 AML, a USbased manufacturer of barcode data collection products, announces the launch of its latest Android ® product, the StrikerX mobile computer StrikerX is the evolution of its predecessor, the Striker, but comes equipped with the most powerful processing architecture available for devices in its class, the The Evolution and Importance of Grinding Mills in Modern IndustryProduction of industrial and professional stone mills for industrial mills Industrial production processes are increasingly required to meet a wide variety of requests from customers and thus from final consumers, who are now demanding different food products to suit today’s major changes in lifestyle The BioStoneMill industrial and professional electric stone mill is able to Industrial Electric Stone Grinding Mill Manufacturer BioStoneMillPDF On Jan 16, 2013, Gheorghe Voicu and others published Grinding Characteristics of Wheat in Industrial Mills Find, read and cite all the research you need on ResearchGateGrinding Characteristics of Wheat in Industrial Mills

.jpg)

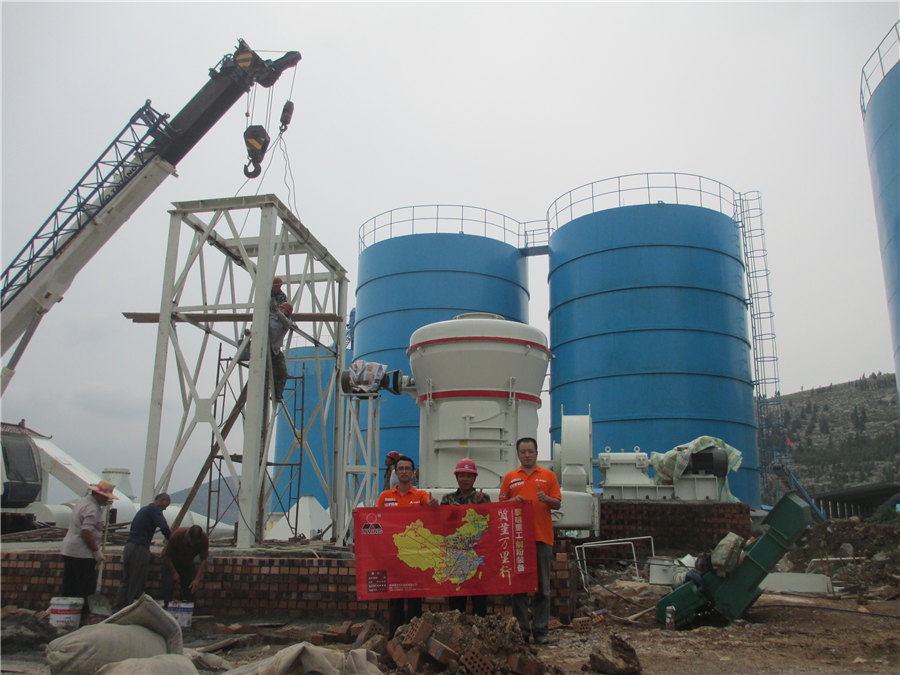

Barite Industrial Ultrafine Grinding Mill SBM

2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest NEUMAN ESSER – Grinding and Classifying Systems The product program comprises today of impact classifier mills, pendulum roller mills as well as cyclone collectors and air separators for coarse and fine classification The pendulum mill PM, a type of roller mill, is applied when grinding minerals, clays, pigments and chemical productsNEUMAN ESSER Grinding and Classifying Systems BulkInside2024年5月15日 If you’re tempted to modify or remove a guard, consult the manufacturer first Only proceed if they advise you to do so Other Essential Safety Measures Guarding is, of course, only one component of machine Using Machine Guards to Improve Industrial China Grinding Mill System wholesale Select 2024 high quality Grinding Mill System products in best price from certified Chinese Professional System manufacturers, Automatic System suppliers, wholesalers and factory on MadeinChinaGrinding Mill System MadeinChina

.jpg)

Grinding machines safe operation and inspection tips Safety Bag

2023年7月6日 Hydraulic System Some grinding machines use hydraulic systems to control the movement of the grinding wheel and workpiece The hydraulic system should be inspected regularly to ensure that it is functioning properly Check the hydraulic fluid level and make sure there are no leaks in the systemBy continuously classifying out fines and returning oversize material to the mill, such systems can very efficiently provide sharp particlesizedistribution grinds As a rule of thumb, dry grinding generally will achieve particle sizes of 3–5 microns To Solids Choose the Right Grinding Mill Chemical ProcessingOur sand milling machines grind materials into fine particles suited for a wide array of industrial applications Before customizing, we consider the environment and ambient temperature where our machines will be installed to ensure safer operations As wet grinding requirements differ with every industry, we, as a bead mill manufacturer, are able to apply different materials for the Bead (Sand) Mill Machines for Wet Grinding, priceFinal grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L welded mechanic, it is intended for the small installations of grinding in laboratory Coarse powder mill, Coarse powder grinding mill All industrial

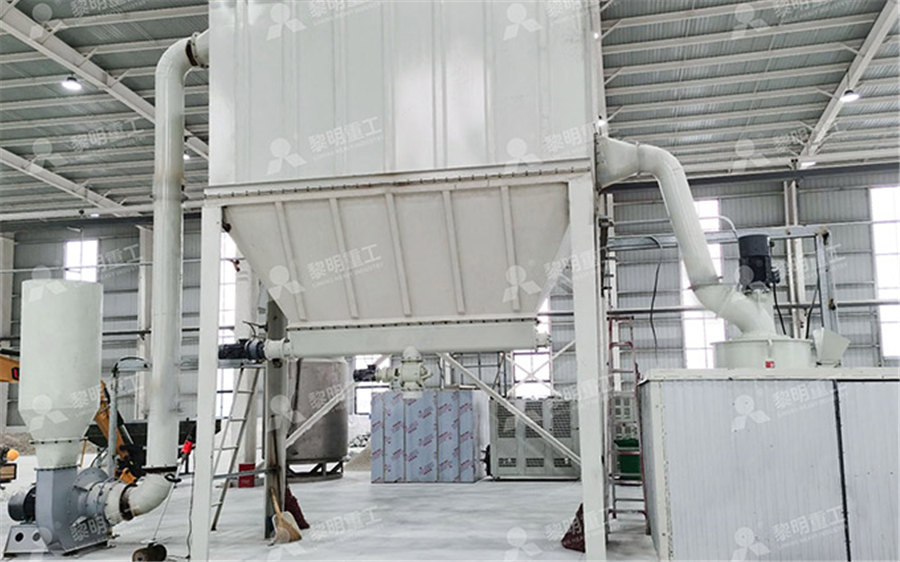

Horizontal Hammer Mill Grinding System Bühler Group

Bühler’s horizontal hammer mill is for pregrinding and postgrinding in animal feed production, including pet foods and fish feed, as well as grain milling and other storage, hoppers, gates, feeders, automation, fans, filters and safety equipment, we have you covered We have industryleading experience in design, installation and Final grain size: 100 µm 100 µm Output: 60,000 kg/h 480,000 kg/h Motor power: 2,200, 4,000, 3,000 W The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under waterAutomatic mill, Automatic grinding mill All industrial manufacturersThe industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine Grinding mill Palamatic ProcessWilliams roller mills boast nearly infinite turn down while maintaining product size The mill grinding rate is adjusted as a direct function of control system demand The mill capacity is modulated by varying mill speed Mill Speed Mill speed Industrial Roller Mills Williams Crusher

.jpg)

Large mill, Large grinding mill All industrial manufacturers

The Metso Outotec® Open Ended Discharge Grinding Mill (OED Mill) EverRoast industrial grinder is produced to meet mass coffee grinding need of companies and it is perfect grinding from raw materials roughing to transport to the milling to packaging, forming an independent production system Working principle The complete Raymond Mill Output: 4 g/s Motor power: 600 W Machine width: 317 mm The CT 293 Cyclotec™ laboratory mill is ideal for rapid and flexible preparation of a wide variety of feeds, grains, leaves and more for NIR or reference analysis Excellent for all types of sample preparation Laboratory mill, Laboratory grinding mill All industrial In coal combustion, the efficiency and safety of the process are paramount Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing This article explores the components, advantages, and operational considerations of indirect firing cIndirect Firing Coal Grinding Systems: Enhancing Efficiency and Safety More Pulverizer Manufacturers Pulverizers deliver material size reduction services for various purposes, such as producing fine powder for pharmaceuticals, creating pulp for paper manufacturing, grinding grain for food production, shredding and recycling tires, breaking down construction materials, turning soil, crushing vehicles for scrap, and grinding rock samplesPulverizer Manufacturers Pulverizer Suppliers

Glass mill, Glass grinding mill All industrial manufacturers

Rotational speed: 120 rpm 240 rpm Output: 400 kg/h 30,000 kg/h Machine length: 13,900, 14,700 mm inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose highspeed impeller will screen the airflow: the unqualified particle size will fall and return Find here Industrial Grinder manufacturers OEM manufacturers in India Automatic SODIUM SULPHATE GRINDING MACHINE, AIR CLASSIFYING MILL ₹ 10,00,000/ Unit Get Latest Price Capacity 100 Kg/hr Type of Machine AIR CLASSIFYING MILL Operation Mode Automatic Electricity ConnectionIndustrial Grinder Manufacturers Suppliers in IndiaManufacturers B; BEIJING POWER EQUIPMENT GROUP CO LTD (1) C; CEMTEC (1) Cepi Spa (1) F; of advanced technologies of famous international corporations and 30 years’ experience in grinding mill production, energy saving and environment friendly grinding equipment specially for cement raw material grinding system Vertical roller mill, Vertical roller grinding mill All industrial Find Industrial Grinding Machine manufacturers, bank transfer, credit card, ewallet, online payment systems etc Eco Friendly 5Hp Sonar Multipurpose Grinding Machine Price: 7550000 INR/Piece Get Best Quote Product Type Grinding Mill Usage Industrial Equipment Type Grinding Mill More details Kaps EngineersIndustrial Grinding Machine Manufacturers, Suppliers, Dealers