Ore mill SG grinding lime 0

SAG Mill Grinding Circuit Design 911Metallurgist

The design of large mills has become increasingly more complicated as the size has increased and there is little doubt that without sophisticated design procedures such as the use of the Finite Element method the required factors of safety would make large mills prohibitively expensive In the past the design of small mills, 展开An autogenous mill of ID 67 m and an effective grinding length of 21 m was fed with ore of SG 38 to 20% of its volume The mill was operated continuously 24 hours per day at 1200 t per Semi Autogenous Grinding Mill an overview ScienceDirect2019年11月1日 Primary grinding – Lime is often added into the semiautogenous (SAG) mill together with the ore feed and process water Sulfide minerals are, by nature, acid to varying Lime use and functionality in sulphide mineral flotation: A review2021年1月11日 the correct power required to grind ore in a SAG mill, by developing ore hardness variability functions for the ore body to be mined This paper describes the next step Choosing a SAG Mill to Achieve Design Performance

.jpg)

SAG Mill Testing Test Procedures to Characterize Ore Grindability

Several grindability tests were developed over the years to design grinding circuits or optimize existing operations Each test has its own strengths and weaknesses and it is imperative to • Specific Gravity (SG) of the ore in situ • Bulk Density of the blasted or excavated ore • Abrasion Index Bauxite ore typically falls into the lower UCS ranges and therefore lends itself to various Physical Bauxite Processing: Crushing and Grinding of Bauxite2013年12月18日 Fine grinding, to P80 sizes as low as 7 μ m, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred Energy Use of Fine Grinding in Mineral Processing2017年9月1日 The objective of this work is to assess the influence of fine grinding in ball mills and stirred mills on valuable mineral liberation and particle shape characteristics of UG2 ore, a Fine grinding: How mill type affects particle shape characteristics

.jpg)

Ore Grinding SpringerLink

2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Mill2016年7月1日 Five classes with different sizes (668 × 472 mm, 236 × 167 mm, 118 × 083 mm, 0 recently demonstrated the ability of the population balance model to predict size reduction in an industrial ball mill grinding iron ore pellet feed on the basis of batch grinding dataSimulation and optimization of a twostage ball mill grinding SBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Our main products include ultrafine vertical roller mill, ultrafine grinding mill, CLUM Series Ultrafine Vertical Roller Mill Fineness:1503000mesh Yield:02 SBM Ultrafine Powder Technology Industrial

(PDF) Optimization of inmill ball loading and slurry solids

2012年12月1日 Optimization of inmill ball loading and slurry solids concentration in grinding of UG2 ores: A statistical experimental design approach December 2012 Minerals Engineering 39:149155The results of the analyses clearly shows that using a sieve of +180µm and its bottom 180µm, the best time for grinding 05kg of Itakpe iron ore with 3kg of grinding media and a mill speed of 92 rpm is 8 minutes, yielding 1710% fines and 8290% coarse, 08 mill critical speed measured 1520% fines and 8480% coarseProcessing of Magnetite Iron Ores–Comparing Grinding OptionsRefractory Gold Ores S Ellis Kalgoorlie Consolidated Gold Mines Kalgoorlie, WA Figure 2 compares the power consumption of a laboratory ball mill to a UFG mill in grinding KCGM concentrate industries for high value products 0 20 40 60 80 100 120 140 0 1020 60 70 80 90 100 110 Grind Product P80 microns Net Energy kWh/t Ball Ultra Fine Grinding A Practical Alternative to Oxidative 2022年4月20日 Lime is divided into quick lime and slaked lime HGM Series Ultrafine Grinding Mill – 150~2500 mesh YGM Series Raymond Mill – 80~600 mesh Share this article What processing equipment is required for rectorite grinding? Kalium ore powder grinding mill machine Hot News PEX Jaw Crusher; Ultra Fine Powder Mill; Vertical Limestone crushing and grinding production line SBM Ultrafine

Table of Bond Work Index by Minerals 911Metallurgist

2015年6月19日 This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on 'around the world sample' You can find the SG of each mineral samples on the 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Table of Bond Work Index by 2024年4月26日 These mills utilize the ore itself as the grinding media, reducing the need for additional grinding media AG/SAG mills are typically used for coarse grinding, where large pieces of ore are efficiently broken down The grinding process reduces the ore size, which enhances the efficiency of subsequent beneficiation processes by increasing the Iron Ore Processing: From Extraction to Manufacturing911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911Metallurgistindicated an optimum range of stress intensity of (08−2)×10−3 Nm for all power inputs Key words: refractory ore tailings; stirred media mill; ultra fine grinding; experimental design; Box−Behnken design; stress intensity ® 1 Introduction Refractory ores yield low Ultra fine grinding of silver plant tailings of refractory ore using

How to choose a limestone grinding mill SANDMINE

2024年1月18日 How to choose a limestone grinding mill limestone has a long history of quarrying Limestone is the primary raw material for manufacturing cement, lime, and carbide and is an essential flux limestone 2019年3月1日 Grinding has become one of the most important unitary operations for producing pellet feed for direct reduction from lowgrade ores and small liberation size, such as compact itabiritesEvaluation of grinding circuits for iron ore ResearchGateVarious magnetite ore grinding flowsheets have been implemented in the past, consisting of an AG mill followed by cobber magnetic separation of pebbles, Concentrate SG = 084 Reducing Grinding Energy and Cost Magnetite Iron Ore2019年12月5日 The lime ball mill can superfinely grind lime or coal ash, consists of feeding part, which increases the contact surface of the ball ore, strengthens the grinding effect, 0075089: 0652: 185: 585: Ф900×3000: 36: 27: ≤20: 0075089: 11 Lime Ball Mill JXSC Machine

.jpg)

A developed approach based on grinding time to determine ore

2013年12月31日 The grinding process for all the three iron ores is carried out individually in Bond’s ball mill and the total retention time taken by each iron ore sample is calculated2018年7月21日 Based upon the results of the pilot plant test work, a decision was made to conduct a full scale test in 1990 utilizing one of the ten (10) primary mill lines at the National Steel Pellet Plant Primary Mill Line No 10 would be converted to a fully autogenous grinding mill with pebble extraction and crushingPebble Crushing in SAG Mill Circuit 911Metallurgist2021年1月14日 sg water displacement 276 282 254 281 275 282 291 277 Revolutions (to achieve T 80 17mm) 450 449 302 260 229 465 574 390 Weight of ore in mill, grams 6739 6608 6921 7359 7087 6634 6889 6891 Pinion kWh/t to T 80 17mm 339 343 224 185 167 355 427 291 Bond BM Wi, kWht (SAG ground ore) 891 1133 761 777 946 1175 832 931Comparison of Ore Hardness Measurements for Grinding Mill 2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeA guide to SAG Mill management

.jpg)

The effects of ore blending on comminution behaviour and

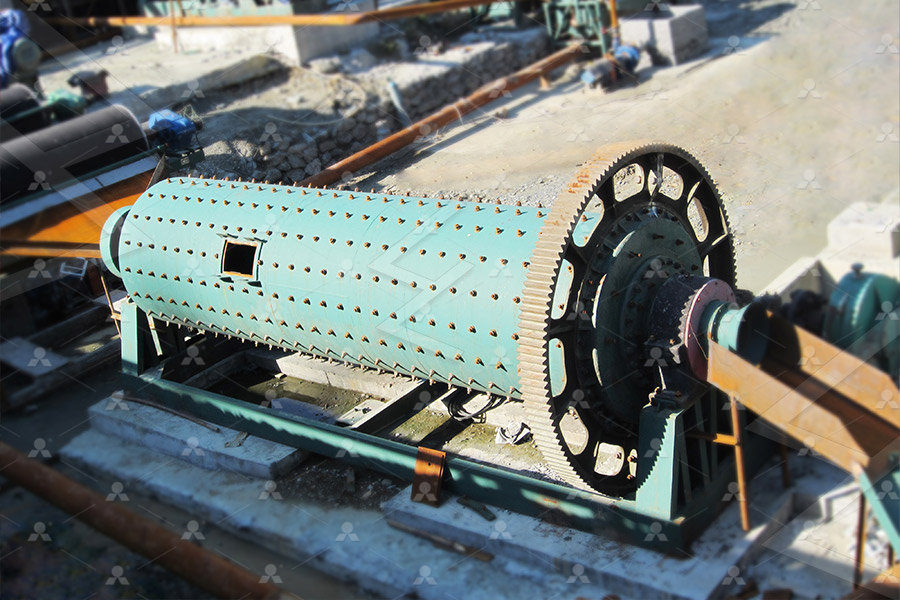

2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The company's metallurgical beneficiation ball mill has six specifications from Φ750×750 (mm) to Φ1830×6400 (mm), which can meet the grinding and beneficiation of 01815 t/h minerals Ore ball mill is used to separate and screening different ore minerals, separate ore tailingore ball mill, ore grinding mill, ore grinding2013年4月1日 A simple and novel nonlinear model of a runofmine ore grinding mill circuit, developed for process control and estimation purposes, is validatedAnalysis and validation of a runofmine ore grinding mill circuit 2016年10月12日 Because of the responsibilities assigned to grinding it becomes essential that a grinding mill accepts a certain required tonnage of ore per day while Stockpiling of ore ahead of the mill can aid in smoothing out some of Closed Circuit Grinding VS Open Circuit Grinding

.jpg)

Grinding Modeling and Energy Efficiency in Ore/Raw Material

2022年8月31日 In addition, the sphalerite had a more prominent effect on the grinding characteristics of the ore The grinding speed of ore and its component minerals decreased exponentially with the grinding time, and the instantaneous grinding speed of 0 min was negatively correlated with the feed sizes2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Limestone Grinding Mill That You Need To Know Mortar Plant2019年4月16日 for grinding lime stone or ores go up to over 1800 t/h depending on material and target product size In the ore industry, compressive comminution is mainly known fr om high pressure grinding(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2017年9月1日 With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which has led to an increase in the prevalence of fine grinding (Sinnott et al, 2006)This has been evident in the platinum group element (PGE) industry in South Africa, where the Bushveld Complex hosts 70% of global Fine grinding: How mill type affects particle shape characteristics

.jpg)

Grinding Metso

Metso has experience with over 8,000 grinding mill installations globally, including manufacturing and delivering the largest SAG/AG mills in the world Global expertise, local presence +100 years of experience in minerals processing Professionals in over 50 countries around the worldGold Ore Stone Mining Lime Kaolin Mill Grinder Bentonite Zircon Sand Stone Grinding Mill For Sale $30,00000$50,00000 Min Order: 1 set Previous slide Next slide YGM 160 r6 grinding mill lime stone 8tph limestone grinding raymond mill $9,00000$9,50000 Min Order: 1 setSimple Ore Extraction: Choose A Wholesale lime stone grinding mill The results of the analyses clearly shows that using a sieve of +180µm and its bottom 180µm, the best time for grinding 05kg of Itakpe iron ore with 3kg of grinding media and a mill speed of 92 rpm is 8 minutes, yielding 1710% fines and 8290% coarse, 08 mill critical speed measured 1520% fines and 8480% coarse(PDF) Reducing Grinding Energy and Cost Magnetite Iron Ore HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Mill

.jpg)

Simulation and optimization of a twostage ball mill grinding

2016年7月1日 Five classes with different sizes (668 × 472 mm, 236 × 167 mm, 118 × 083 mm, 0 recently demonstrated the ability of the population balance model to predict size reduction in an industrial ball mill grinding iron ore pellet feed on the basis of batch grinding dataSBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Our main products include ultrafine vertical roller mill, ultrafine grinding mill, CLUM Series Ultrafine Vertical Roller Mill Fineness:1503000mesh Yield:02 SBM Ultrafine Powder Technology Industrial 2012年12月1日 Optimization of inmill ball loading and slurry solids concentration in grinding of UG2 ores: A statistical experimental design approach December 2012 Minerals Engineering 39:149155(PDF) Optimization of inmill ball loading and slurry solids The results of the analyses clearly shows that using a sieve of +180µm and its bottom 180µm, the best time for grinding 05kg of Itakpe iron ore with 3kg of grinding media and a mill speed of 92 rpm is 8 minutes, yielding 1710% fines and 8290% coarse, 08 mill critical speed measured 1520% fines and 8480% coarseProcessing of Magnetite Iron Ores–Comparing Grinding Options

Ultra Fine Grinding A Practical Alternative to Oxidative

Refractory Gold Ores S Ellis Kalgoorlie Consolidated Gold Mines Kalgoorlie, WA Figure 2 compares the power consumption of a laboratory ball mill to a UFG mill in grinding KCGM concentrate industries for high value products 0 20 40 60 80 100 120 140 0 1020 60 70 80 90 100 110 Grind Product P80 microns Net Energy kWh/t Ball 2022年4月20日 Lime is divided into quick lime and slaked lime HGM Series Ultrafine Grinding Mill – 150~2500 mesh YGM Series Raymond Mill – 80~600 mesh Share this article What processing equipment is required for rectorite grinding? Kalium ore powder grinding mill machine Hot News PEX Jaw Crusher; Ultra Fine Powder Mill; Vertical Limestone crushing and grinding production line SBM Ultrafine 2015年6月19日 This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on 'around the world sample' You can find the SG of each mineral samples on the 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Table of Bond Work Index by Table of Bond Work Index by Minerals 911Metallurgist2024年4月26日 These mills utilize the ore itself as the grinding media, reducing the need for additional grinding media AG/SAG mills are typically used for coarse grinding, where large pieces of ore are efficiently broken down The grinding process reduces the ore size, which enhances the efficiency of subsequent beneficiation processes by increasing the Iron Ore Processing: From Extraction to Manufacturing

.jpg)

Metallurgists Mineral Processing Engineers 911Metallurgist

911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables