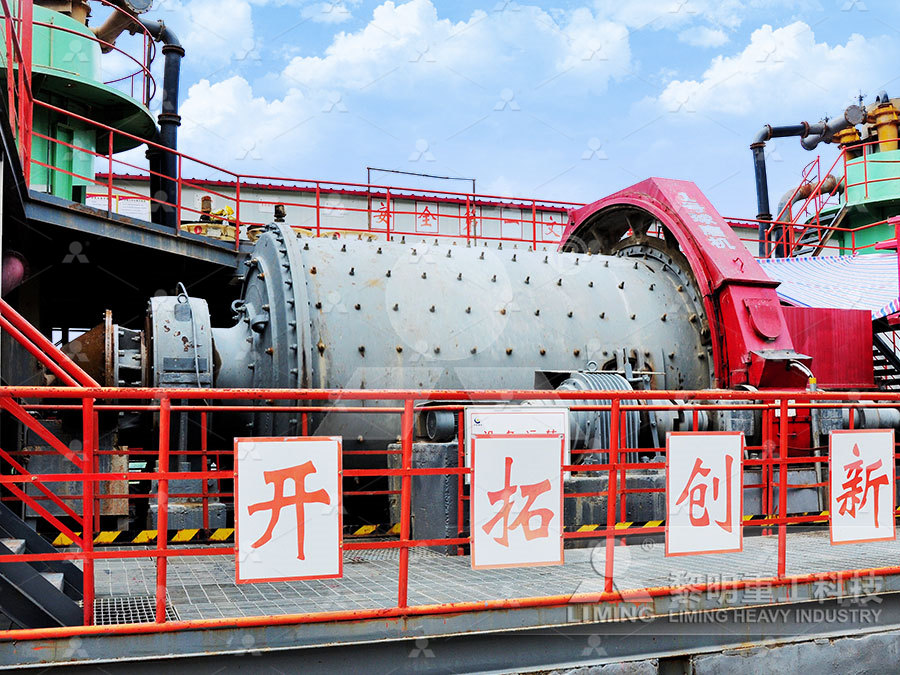

3 meters 2 13 ball mill

.jpg)

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator

Size rated as diameter x length Feed System 1 One hopper feed 2 Diameter 40 – 100 cm at 30 ° to 60 ° 3 Top of feed hopper at least 15 meter above the center line of the mill Feeder 1 Single or double helical scoop feeder or a spout feeder 2 Double helical feeders used in closedcircuit with classifiers 3 Spout feeders 展开2015年6月19日 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators In extracting from Nordberg Process Ball Mill Design/Power Calculation 911Metallurgist2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911MetallurgistBall Mill In Cement Plant is an important piece of equipment for grinding cement raw materials into proper particle size, The disc of this type of Ball Mill is usually located below ground and its diameter is usually between 1 and 3 Ball Mill In Cement Plant Selling Various Types Of

Ball Mills 911Metallurgist

2017年2月13日 Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ size a 30″ or 36″, for the 5′ a 36″ or 42″, Ball milling – a ball mill with a diameter of 244 meters, inside new liners, grinding (Fig 3) [15] Mill the first stage has a size of 6×35 m, power consumption 2020 kW and operates in a closed circuit with a vibrating screen with a mesh size of 2 mm Mill of the second stage measuring 48×132 m working with two centrifugal separators with a diameter of 67 m for receiving the cyclones, the installedAnalysis of the efficiency of the process in closed circuit ball millsLaboratory Ball Mills 2kg to 20Kg Manufacturer Supplier India Laboratory Ball Mill; The ultimate solution for the requirements of your lab Laboratory Ball mills are the tools which play a very important role in a lab and these are applied in wide range of areas like experimentation, progression and quality assuranceLaboratory Ball Mill 2, 3, 5, 10 to 20 Kg Manufacturer IndiaPipettes Glass 13; Test Tube Glass 4; Watch Glasses 7; Hardware 2 Bowl 2; Labware 49 Ceramic Buchner Funnel 8; Laboratory Furnaces 3; Meters 34 Meter Electrodes 7; Meter Spares and Accessories 1; pH Meters 8; Refractometers 5; Spectrometers 3; F C BOND LABORATORY BALL MILL 126 380 V/3 Ph/50 Milling and Leaching, Ball Mill Ball Mill Archives Effective Lab

.jpg)

Ball Mill Batch Ball Mill Manufacturer from Jodhpur

Manufacturer of Ball Mill Batch Ball Mill, Laboratory Ball Mill, Ball Grinding Mill and Ceramic Ball Mill Machine offered by Laxmi Engineers, Jodhpur, Rajasthan Dia (12 to 28 meters) x Long (3 to 14 meters) Brand: Laxmi: Drive: TEFC SLPR Motor Through Double Stage Helical Gear Box: Feed Size: 15 mm: Output Size:2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you Grinding in Ball Mills: Modeling and Process Control2017年7月26日 We will consider an ore with a ball mill work index varying between 16 and 13, feeding into a single stage ball mill operation with one million kilowatts per day consumed power For the particular mill configuration, a performance graph, Fig (21), has been constructed according to Bond’s methodsHow Ball Mill Ore Feed Size Affects Tonnage Capacity2016年1月5日 162 WAVE BALL MILL SHELL LINERS; 163 WEDGE SHELL MILL LINERS; 164 Grinding Mill SPIRAL SHELL LINERS; An incidental merit claimed for these liners is that the high bearing pressure between the balls Ball Mill Liner Design 911Metallurgist

How to Size Design a Regrind Ball Mill

2018年4月8日 305 x 191 – 583 meters (191 feet) Therefore, use one 305 meter (100 foot) diameter inside shell 289 meter (95 foot) diameter inside new liners by 579 meter (190 foot) long overflow ball mill with a 40 percent by Cubic Boron Nitride Ball End Mills for Tool Steel and Hardened Steel Make finishing cuts in tool steel and hardened steel with these cubic boron nitride (CBN) end mills Harder than carbide end mills, they’re better for making small, precise cuts and last more than five times as longBallNose End Mills McMasterCarr2021年1月1日 32 The power of the ball mill According to the calculation of the ball mill power at home and abroad, the correction formula of the former Soviet Union’s Tovalov formula is adopted:(PDF) Design of Threechamber Ball Mill ResearchGateMachinery and Equipment Company buys and sells used Ball Mills our inventory and request a quote Buy Equipment; Sell Equipment; Can't Find? Meters 14 Mezzanines 2 Mixers 256 Motors 36 Outserters 1 Ovens 27 Oxidizers 1 Packing Stations 1 Pallet Racks 1 Unused Outotec Ball Mill, 86' x 135', 450 HP Request a Quote Ball Mills For Sale Machinery Equipment Co

.jpg)

Rod Mill Design Calculations 911Metallurgist

2018年4月5日 Wf = 132 W = 10 x 132/√1,200 – 10 x 132/√18,000 = 283 kwh/s ton Efficiency Factors: EF1 does not apply EF2 does not apply EF3 determine after power calculations is completed EF4 Feed size is coarser than 16,000 micrometers, EF5 does not apply EF6 will not apply as ratio of reduction will be within Rro ±2 Rro determined after Mils = 254 Meters: 7 Mils = 0 Meters: 250 Mils = 00064 Meters: Mils = 635 Meters: 8 Mils = 0 Meters: 500 Mils = 00127 Meters: Mils = 127 Meters: 9 Mils = 0 Meters: 1000 Mils = 00254 Meters: Mils = 254 Meters: Embed this unit converter in your page or blog, by copying the following HTML code:Convert Mils to Meters (mil → m)MSC Direct offers quality Ball End Mills at a great value Find premium products to last a lifetime! Help Help 24/7 Customer Care 18006457270; Live Chat; Help Center; About Us; Give Feedback; Help 18006457270; $1319 / ea Quantity Add to Cart Compare AccuproBall End MillsHighSpeed Steel Ball End Mills Ball Cut Style 2 Flute Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel They have a ball end for milling rounded slots, slopes, and contours 13/16 " 3/4 " 2" 4 1/4 " Equal: 30 13/16" End Mills McMasterCarr

.jpg)

Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan Fungsinya

2022年10月5日 Ball Mill adalah mesin yang berbentuk silinder dan berfungsi untuk menggiling material kasar menjadi halus Bagian komponen, prinsip kerja ball mill (13) Central liners (16) Bearing inner sleeve (17) Ring gear (18) Pinion (19) Transmission shaft (20) Coupling Joint Download Table Ball mill characteristics and test conditions Mill Diameter, D (cm) 204 Length, L (cm) 166 Volume, V (cm 3 ) 5,423 Operational speed, Ν (rpm) 66 from publication Ball mill characteristics and test conditions Mill 2016年6月6日 Used in conjunction with Grade 5 (highstrength) bolts, this assembly is generally applied to rod mills over 100′ in diameter and ball and autogenous mills greater than 135″ in diameter Metal tometal contact (nut SAG Mill Liner Design 911Metallurgist2016年10月20日 Concrete may be made up in different mixtures having different proportions of sand and aggregate These are expressed in parts – for example a 1:2:4 mixture indicates one bag of cement, 2 cubic feet of sand, and 4 cubic Ball Mill Maintenance Installation Procedure

Grinding Media ball mills supplier

Falling Ball Impact Fatigue Life (height 35 meters) Low Chromium Grinding Balls (LCCB) ZQCR1, ZQCR2, ZQCR3: 4550: 4549: SGFB3: φ40φ50: 6065: 5964: 6065: ≥13: M+B+C: 80≤φ≤150: ≥10000: φ60φ80: 6065: 5863: 6065: φ90: 5964: 5963: 5963: φ100φ120: As a ball mills supplier with 22 years of experience in the 2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Ball Mill Critical Speed 911Metallurgist3522 Ball Mills The ball mill accepts the SAG or AG mill product Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore Today, the largest ball mill in operation is 853 m diameter and 1341 Ball Mill an overview ScienceDirect TopicsCement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich experience in the designing and Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill

.jpg)

Effect of ball size and powder loading on the milling SeoulTech

Keywords: Ball size; Particle size; Powder loading; Rotation speed; Wet ball mill 1 Introduction Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry [1–3] The ball mill process is very complicated process governed by many parameters, such asA ball end mill is often referred to as a ball nose end mill The end geometry is ground with a full corner radius equal to half of the tool diameter, and the edges are center cutting They can be made from solid carbide or various compositions of cobalt or high speed steelBall Nose End Mills or Ball End Mills 6G Tools2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911MetallurgistBall Mill In Cement Plant is an important piece of equipment for grinding cement raw materials into proper particle size, The disc of this type of Ball Mill is usually located below ground and its diameter is usually between 1 and 3 Ball Mill In Cement Plant Selling Various Types Of

.jpg)

Ball Mills 911Metallurgist

2017年2月13日 Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ size a 30″ or 36″, for the 5′ a 36″ or 42″, Ball milling – a ball mill with a diameter of 244 meters, inside new liners, grinding (Fig 3) [15] Mill the first stage has a size of 6×35 m, power consumption 2020 kW and operates in a closed circuit with a vibrating screen with a mesh size of 2 mm Mill of the second stage measuring 48×132 m working with two centrifugal separators with a diameter of 67 m for receiving the cyclones, the installedAnalysis of the efficiency of the process in closed circuit ball millsLaboratory Ball Mills 2kg to 20Kg Manufacturer Supplier India Laboratory Ball Mill; The ultimate solution for the requirements of your lab Laboratory Ball mills are the tools which play a very important role in a lab and these are applied in wide range of areas like experimentation, progression and quality assuranceLaboratory Ball Mill 2, 3, 5, 10 to 20 Kg Manufacturer IndiaPipettes Glass 13; Test Tube Glass 4; Watch Glasses 7; Hardware 2 Bowl 2; Labware 49 Ceramic Buchner Funnel 8; Laboratory Furnaces 3; Meters 34 Meter Electrodes 7; Meter Spares and Accessories 1; pH Meters 8; Refractometers 5; Spectrometers 3; F C BOND LABORATORY BALL MILL 126 380 V/3 Ph/50 Milling and Leaching, Ball Mill Ball Mill Archives Effective Lab

Ball Mill Batch Ball Mill Manufacturer from Jodhpur

Manufacturer of Ball Mill Batch Ball Mill, Laboratory Ball Mill, Ball Grinding Mill and Ceramic Ball Mill Machine offered by Laxmi Engineers, Jodhpur, Rajasthan Dia (12 to 28 meters) x Long (3 to 14 meters) Brand: Laxmi: Drive: TEFC SLPR Motor Through Double Stage Helical Gear Box: Feed Size: 15 mm: Output Size:2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you Grinding in Ball Mills: Modeling and Process Control2017年7月26日 We will consider an ore with a ball mill work index varying between 16 and 13, feeding into a single stage ball mill operation with one million kilowatts per day consumed power For the particular mill configuration, a performance graph, Fig (21), has been constructed according to Bond’s methodsHow Ball Mill Ore Feed Size Affects Tonnage Capacity