Opening a calcium carbonate grinding plant requires What equipment is needed

Calcium Carbonate Grinding Union Process

With our Attritor grinders available for both dry and wet grinding processes, your calcium carbonate grinding requirements can be tailored to meet your exact specifications To determine what type of grinding process should be used, you must first consider the nature of the Wet Batch Laboratory Mills Wet Circulation Laboratory MillsChocolate Grinding Wet Grinding Laboratory MillsGrinder or grinding mill is the core equipment for calcium carbonate grinding plant, which can largely determine the fineness of the end product Daswell mainly provides ball mill combined Customize Suitable Calcium Carbonate Plant DASWELLIn calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh For processing 4 Steps to Build a Calcium Carbonate Processing Plant

How to Choose a Calcium Carbonate Grinding Mill

Before choosing a grinding mill, you need to understand how calcium carbonate is produced At present, there are two main methods, dry grinding method and wet grinding method The dry grinding method is mainly used in primary grinding, Calcium carbonate powder production line includes several machines such as crushers, dryers, grinding mills, classifiers, coating machines, and packing machines Each stage of the Calcium Carbonate Powder Production Line – Powder Equipment2023年10月10日 Calcium carbonate dry ultrafine grinding equipment mainly includes Raymond mill, vertical mill, ball mill, jet mill, stirring mill, vibration mill and various mechanical impact mills Raymond mill: used in large quantities to Typical processes and equipment for ultrafine grinding 2023年5月4日 When it comes to processing calcium carbonate, choosing the right grinding equipment is paramount to ensure efficient and effective production The demand for calcium How to choose calcium carbonate grinding equipment

CALCIUM CARBONATE (GCC) Hosokawa Alpine

Low grinding energy, very high fineness: Wet grinding systems score high points with an extremely economical micronisation technology Very steep particle size distributions are 2023年12月7日 The carbon dioxide reacts with the calcium hydroxide to form calcium carbonate Equipment The equipment used in the manufacturing process for calcium carbonate varies depending on the type of calcium carbonate What is the steps in the Calcium Carbonate 2020年1月13日 Calcium Carbonate Grinding Mill Capacity: 0430 T/H Feeding size: ≤20mm Output Size: 1503000mesh Calcium Carbonate Grinding Mill is the equipment specializing in producing fine and superfine calcium carbonate powder Product CLUM calcium carbonate ultrafine vertical roller millCalcium carbonate manufacturing plant surface modification processIn calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh4 Steps to Build a Calcium Carbonate Processing

制粉-10.25公众号.jpg)

Calcium Carbonate Grinding Production Line TAYMACHINERY

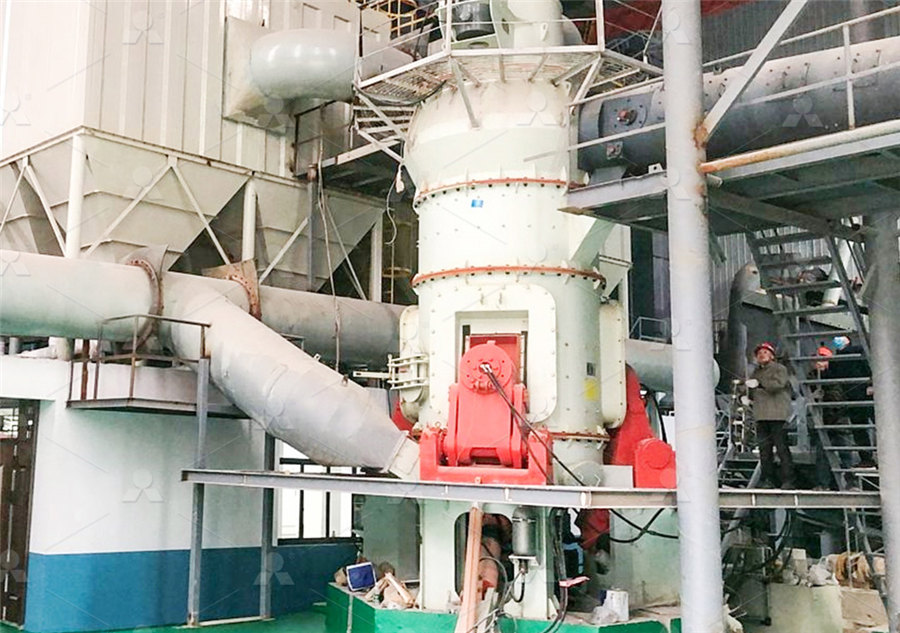

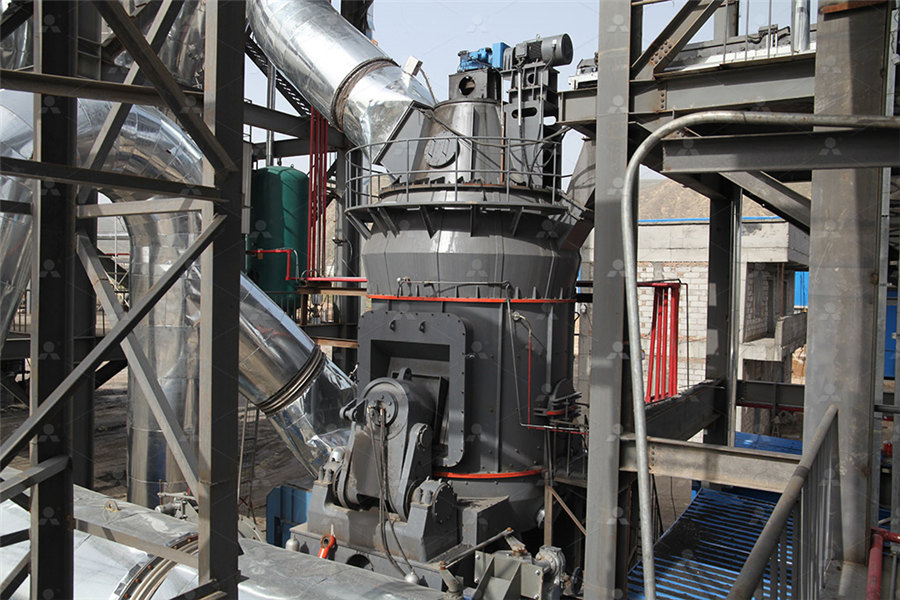

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy 2022年9月29日 In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh4 Steps To Build A Calcium Carbonate Processing Plant Zenith 2022年7月26日 The 600mesh calcium carbonate grinding mill has a small footprint and is environmentally friendly Calcium carbonate is known as “industrial monosodium glutamate” The demand in the market continues to rise, and the demand for 600mesh calcium carbonate grinding mills is also increasing 600mesh carbonic acidWhat is a 600 mesh calcium carbonate grinding mill?2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the (PDF) Effects of Grinding Aids Used in Grinding Calcium Carbonate

.jpg)

Customize Suitable Calcium Carbonate Plant DASWELL

Calcium carbonate grinding mill is the central equipment for calcium carbonate manufacturing plant And there are many kinds of calcium carbonate grinders available, such as ball mill, roller mill, vertical mill, wet grinding mill and so onCalcium carbonate functions as an agricultural amendment, raising the pH level in acidic soils and supplying calcium essential for plant growth Papermaking Calcium carbonate acts as a coating and filler agent in the paper and pulp industry, enhancing paper’s brightness, opacity, and suitability for printingCalcium Carbonate: Grinding and Applications Overviewflow chart of grinding calcium carbonate plant Raymond Grinding flow chart of grinding calcium carbonate plant BINQ provides both small ball mill and big ball mill; each new and utilized ball grinding generatorcalcium carbonate grinding plant flow charts2021年7月22日 CLIRIK calcium carbonate processing equipment, calcium carbonate production line, calcium carbonate processing equipment, calcium carbonate crushing equipment and calcium carbonate grinding equipment have been exported to many countries and regions Welcome to leave a message, online consultation or contact us via or WhatsAppWhat equipment does the calcium carbonate powder production line need?

.jpg)

Calcium Carbonate Powder Production Line – Powder Equipment

A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are available A grinder or grinding mill is the core equipment for a calcium carbonate grinding plant, which can largely determine the fineness of the end productAutomatic control of equipment operation, good stability, simple operation and easy maintenance Best calcium carbonate ball mill plant We are a calcium carbonate ball mill plant factory with over 30 years of work experience in this Calcium Carbonate Ball Mill Plant DASWELL2022年5月5日 Calcium carbonate grinding mill is an efficient industrial ultrafine powder mill It can grind calcium carbonate into fine and superfine powder(1503000mesh) SBM is China’s famous calcium carbonate grinding mill manufacturer Its selfdeveloped HGM series ultrafine grinding mills and CLUM series ultrafine vertical roller mills are the most Calcium Carbonate Grinding Mill Powder Modify SBM To build a calcium carbonate processing plant, you will need to source the right equipment and technology This includes crushers, grinders, sorters, and packaging machines It is important to choose equipment that is durable, efficient, and costeffectiveHow To Build A Calcium Carbonate Processing Plant

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Ground calcium carbonate is also called known as heavy calcium carbonate,it is made by mechanical methods (using grinding mills such as roller mill or other highpressure grinding mills) to directly crush natural calcite, limestone, chalk, shells, etc Ground calcium carbonate can be made into different particle sizes according to different usage requiresCalcium Carbonate – What Is It And How To Make ItCalcium Carbonate Formula It is a chemical compound with the chemical formula CaCO 3; It is a white insoluble powderlike substance which occurs naturally in minerals, chalk, marble, limestone, calcite, shells, pearl, etc; Medicinally, it is used as an antacid or as a Limestone: Calcium Carbonate (CaCO3) Uses, Preparation, 2023年11月21日 Ground calcium carbonate (GCC) is a type of calcium carbonate that is obtained by mechanically grinding and crushing natural calcite, limestone, chalk, marble, or other sources It is one of the most abundant minerals on Earth and has a wide range of industrial applications due to its physical and chemical propertiesGround Calcium Carbonate Production Line

.jpg)

Calcium Carbonate (GCC) Hosokawa Alpine

In the production of ultrafine calcium carbonate additives, various aspects must be considered when selecting and deciding among available types of processing systems: Fineness range, annual output (uncoated and coated GCC), dry or wet grinding, specific energy consumption, investment costs, plant engineering, running costs and logistical aspects2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone Mining 2024年9月23日 Why Start a Calcium Carbonate Business? Establishing a calcium carbonate production line has a range of perks associated with it: Board application: Calcium carbonate can be found in various fields such as construction, pharmacy, food and agriculture Constantly Growing Marketplace: According to projections, the global calcium carbonate market is likely How to Start a Calcium Carbonate Manufacturing IndustryLimestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin as is the case with travertineLimestone Quarrying and Processing: A LifeCycle Inventory

46.jpg)

How Much Does It Cost to Invest a Small Calcium Carbonate Processing Plant

2018年9月25日 Recommend Calcium Carbonate Grinding Mill Capacity: 0430 T/H Feeding size: ≤20mm Output Size: 1503000mesh Calcium Carbonate Grinding Mill is the equipment specializing in producing fine and superfine calcium carbonate powder2024年6月14日 GCC VS PCC and Calcium Carbonate Grinding Mills ; CLUM Series Mill: EcoFriendly and EnergySaving, Leading UltraFine Powder Production to New Height ; Efficient Grinding Of Calcium Carbonate Calcium Oxide: HGM125 Ultrafine Grinding Mill in Liaoning Ground Calcium Carbonate Production Plant In Sichuan27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM 2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on Precipitated Calcium carbonate production, synthesis and properties

(PDF) Calcium Carbonate Synthesis, Optimization and Characterization

2020年7月30日 In this study, to determine the calcium carbonate availability in eggshells waste and factors those affect its extraction The parameters like temperature, the size of the eggshell powder and the Calcium carbonate (CaCO 3) is a substance widely used for various purposes, for example, as a filler and pigment material not only in paper, plastics, rubbers, paints, and inks but also in pharmaceutics, cosmetics, construction materials, and asphalts and as a nutritional supplement in animal foods (1)Besides the socalled ground calcium carbonate (GCC), which is milled from Calcium Carbonate an overview ScienceDirect Topics2024年6月7日 Today we will take you to visit one ground calcium carbonate/GCC plant in Sichuan Province, China See how ground calcium carbonate is produced +17 [ protected] The plant uses advanced grinding equipment, including HGM ultrafine mills and CLUM ultrafine vertical millsGCC Ultrafine Grinding Mill Plant Factory Tour2023年12月7日 The carbon dioxide reacts with the calcium hydroxide to form calcium carbonate Equipment The equipment used in the manufacturing process for calcium carbonate varies depending on the type of calcium carbonate What is the steps in the Calcium Carbonate

Calcium carbonate manufacturing plant surface modification process

2020年1月13日 Calcium Carbonate Grinding Mill Capacity: 0430 T/H Feeding size: ≤20mm Output Size: 1503000mesh Calcium Carbonate Grinding Mill is the equipment specializing in producing fine and superfine calcium carbonate powder Product CLUM calcium carbonate ultrafine vertical roller millIn calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh4 Steps to Build a Calcium Carbonate Processing The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2022年9月29日 In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh4 Steps To Build A Calcium Carbonate Processing Plant Zenith

.jpg)

What is a 600 mesh calcium carbonate grinding mill?

2022年7月26日 The 600mesh calcium carbonate grinding mill has a small footprint and is environmentally friendly Calcium carbonate is known as “industrial monosodium glutamate” The demand in the market continues to rise, and the demand for 600mesh calcium carbonate grinding mills is also increasing 600mesh carbonic acid2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the (PDF) Effects of Grinding Aids Used in Grinding Calcium Carbonate Calcium carbonate grinding mill is the central equipment for calcium carbonate manufacturing plant And there are many kinds of calcium carbonate grinders available, such as ball mill, roller mill, vertical mill, wet grinding mill and so onCustomize Suitable Calcium Carbonate Plant DASWELLCalcium carbonate functions as an agricultural amendment, raising the pH level in acidic soils and supplying calcium essential for plant growth Papermaking Calcium carbonate acts as a coating and filler agent in the paper and pulp industry, enhancing paper’s brightness, opacity, and suitability for printingCalcium Carbonate: Grinding and Applications Overview

calcium carbonate grinding plant flow charts

flow chart of grinding calcium carbonate plant Raymond Grinding flow chart of grinding calcium carbonate plant BINQ provides both small ball mill and big ball mill; each new and utilized ball grinding generator