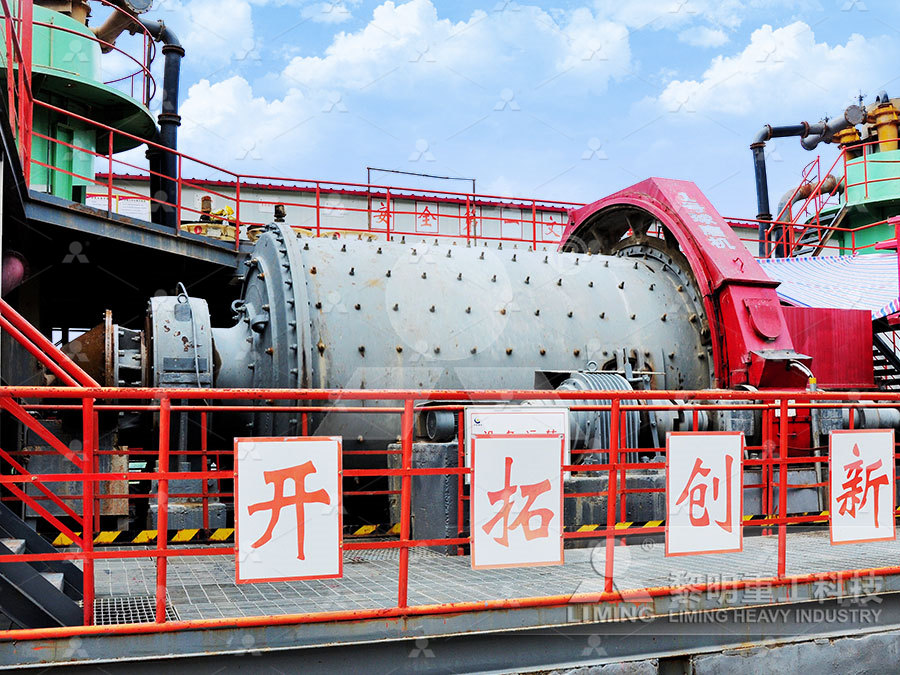

Single bin grinding quicklime

.jpg)

Quicklime preparation Gebr Pfeiffer

We have innovative processes for limestone grinding and separating as well as for lime hydration with Pfeiffer mills, hydrators, high efficiency separators, and distribution table separatorsBiolime 90 is a fine, white calcium oxide powder that is made by crushing and screening quicklime It has been s pecifically developed for sludge treatmentQuicklime Singleton BirchQuicklime milling is generally divided into four types: coarse powder processing (03mm), fine powder processing (20 mesh400 mesh), ultrafine powder processing (400 mesh1250 mesh) quicklime processing plant, quicklime grinding machine, quicklime 2023年2月4日 In the process of agglomeration and granulation, lime is used as a binder in the agglomeration of many raw materials, but due to the reaction between lime and water, Lime/quicklime for metallurgy – how producing and briquetting

PFEIFFER SOLUTIONS FOR THE MINERAL INDUSTRIES

Grinding and hydrating to obtain fi ne white lime and hydrated lime //Quicklime lumps are ground and separated in Pfeiffer MPS vertical roller mills The fineness of the fine white limes can be Graymont can supply both crushed and pebble high calcium quicklime from various sites that is suitable for either subsequent further processing and slaking or direct slaking Some of the High Calcium Quicklime GraymontLIMESTONE GRINDING QUICKLIME SLAKING PLANT Case Study: Due to limited resources in getting quicklime the client had to import limestone and mix it with quicklime in order for the Case Study: LIMESTONE GRINDING QUICKLIME SLAKING PLANT As one of the basic raw materials, quicklime has a growing demand for its powder formHow to grind quicklime into powder efficiently and finely has become the focus of attention of many What machine is good for quicklime grinding?

QUICKLIME SLAKING PLANT FOR WORLD’S LARGEST COPPER

The quicklime is delivered in 1 or 2t Bulk Bags and is lifted into any of the three bag breakers and then lowered onto their spike via the hoists The quicklime is transferred via a common screw mounted ball mills suitable for quicklime slaking and regrind applications The mills range from 600mm diameter for laboratory batch testing applications through to the largest mill currently available of 23m diameter with an effective grinding length of 46m SEW Eurodrive geared reducers are used exclusively on Lime SystemsCOMPLETE PLANT CAPABILITY LIME SYSTEMS LTD2023年10月27日 Quicklime is an alkaline substance produced from heating limestone in specialized kilns Humans have used quicklime since antiquity for construction, agriculture and metalwork applications It is still used in all of Quicklime: A PrimerI understand how quicklime takes forever to make, and you really should consider running many firepits at the sane time to get around your problem Also consider using coal or charcoal for your fuel so you get longer burntime However, may I ask why you need so much quicklime?Quicklime mass production? : r/VintageStory Reddit

.jpg)

The 8 Best SingleDose Espresso Grinders Reviewed

2023年7月18日 Brand: Baratza Color/s: Black and silver Material: Stainless steel Designed for coffee aficionados, the Baratza Sette 30 Conical Burr Grinder is a standout among the best singledose espresso grinders on the marketWith accolades from the Specialty Coffee Association, this grinder is favored by professionals and home baristas alike2022年12月22日 Scope of application: It is suitable for quicklime grinding and processing, requiring large output, low energy consumption, low operating cost, single machine processing capacity up to 60T/H, economical investment; ③ Thin oil lubrication system: The main engine drive and fan drive system are all lubricated with thin oil, Type Selection of Quicklime Deep Processing EquipmentTurning limestone into quicklime industrially The next video shows a modern industrial plant for producing quicklime, calcium oxide It carries far more information than you need, and you really only need to concentrate on what happens in the kiln itself (starting just after 2 minutes) This is where the limestone is heated and quicklime is limestone, quicklime and slaked lime chemguide2017年1月1日 The paper presents a study of chip formation in single grain grinding using a convenient FEM formulation, the Smooth Particle Hydrodynamics (SPH) methodSPH Simulation of single grain action in grinding ResearchGate

.jpg)

LIME SLAKING SYSTEMS Bulk Handling Technologies Australia

Quicklime Slaking/ Grinding Benefits and Features Lime slaking systems comprise multiple components, each specifically designed to form part of the lime slaking system Correct design ensures the reliable production of a MOL slurry at the specified rate and with the required concentration of solids2022年2月28日 Introduction of grinding technology in lime industry Quicklime, whose main component is calcium oxide, is usually prepared by calcining natural rock whose main component is calcium carbonate at high temperature to decompose into carbon dioxide and calcium oxide (chemical formula: CaO, namely quicklime, also known as marble)How to do a good job of grinding in the lime industry?2001年4月1日 This study has examined the effects of limestone characteristics (microstructure and texture) and calcination temperature on the reactivity of the produced quicklime(PDF) The Effects of Limestone Characteristics and Calcination 2023年10月29日 This step involves the removal of residual moisture content, ensuring the quicklime achieves the desired level of dryness for effective utilization 4 Grinding and Sizing Depending on the intended application, the What is Quicklime Drying? Vulcan® Drying Systems

.jpg)

Quicklime preparation Gebr Pfeiffer

For fine grinding lime hydrate lumps, grinding circuits comprising ball mills and separators are provided Instead of separators, screening machines are used in case of coarse grinding The fineness of the products can be set within wide The quality of the quicklime is largely dependent on the efficiency of the grinding process, which is where the vertical mill comes into play The vertical mill, also known as the vertical roller mill, has emerged as a leading piece of equipment for the production of quicklime due to its advanced technology and operational excellenceVertical mill: The preferred equipment for quicklime production%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources2024年11月8日 quicklime (CaO), compound of one atom of calcium and one atom of oxygen that is a white or grayish white solid produced in large quantities by roasting calcium carbonate so as to drive off carbon dioxideAt room temperature, CaO will spontaneously absorb carbon dioxide from the atmosphere, reversing the reactionIt will also absorb water, converting itself into Quicklime Formula, Uses, Definition Britannica

.jpg)

Grinding, drying, classifying Gebr Pfeiffer

From raw material grinding to hydrating: we have the optimum solution when it comes to efficient material preparation with our Pfeiffer products you can produce pulverized limestone and crushed limestone in a single process Find out more Quicklime and lime hydrate Pfeiffer solutions for quicklime preparation: 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder 1998年5月14日 Summary This chapter contains sections titled: Processing Production of Ground Quicklime Storage, Handling and Transport ReferencesProcessing Storage and Transport of QuicklimeSinglepiece welded silo construction (12’0” in diameter) Ships preassembled limiting the amount of onsite construction needed: Lowprofile, top access, bin vent filter dust collector mounted on roof: Removes particles from the air minimizing dust emissions improving air quality and employee safetyStandard Quicklime Feed System in a Box Carmeuse Systems

Singlegrain cutting based modeling of abrasive belt wear in

2019年6月4日 A systematic wear model of the cylindrical grinding process with an alumina abrasive belt from the perspective of single grain sliding wear was established in this study2021年8月7日 Typical forcetime profiles from breakage of single particles of 12590 mm iron ore pellets and their fragments in an impact Copper ore Bin gham Canyon, Ut ah 283 961 117 1 26 0 25 (PDF) Review and Further Validation of a Practical Quicklime Slaking Plant Year: 2006 Scope of Project: Due to Transmin’s broad base the silo into the ball mill using bin activator, screw feeder, and vibrating conveyor AFRICA Benefits: The benefits of using lime processing plants: Processing Slaking and grinding mills of the roller mounted or vertical typeQUICKLIME SLAKING PLANT FOR WORLD’S LARGEST COPPER 2012年1月1日 Purity – The purer the quicklime, the faster the rate of hydration If there are a large amount of impurities, pores can be blocked and the product will be less impervious MgO content – MgO has a retarding effect on the process Size of quicklime – The smaller the size of the quicklime lumps, the more rapid the rate of hydrationThe Effect of Calcination Time upon the Slaking Properties of Quicklime

Quicklime powder processed by vertical grinding mill YouTube

2024年10月25日 Quicklime powder processed by vertical grinding millHigh calcium quicklime is available from all regions we operate in including North America, the East coast of Australia including Tasmania, New Zealand, Malaysia and the Philippines These products can also be exported further afield SDS High Calcium Quicklime, MLYHigh Calcium Quicklime Graymont2017年10月15日 During the dissolution of quicklime used in the actual operation, quicklime emits CO2 gas twice, and the second gas formation effectively enhances the dissolution rate(PDF) Effect of CO2 Content in Quicklime on Dissolution Rate of Quicklime grinding mill#liming #limingmill #grindingmill #verticalmill #quicklimemillNO33 Quicklime grinding mill YouTube

The Right Grinding Machines for Your Quicklime Industry

Quicklime is indispensable in so many areas Without it, we would have no homes for a start, because there would be no mortar We would have to travel on rough tracks instead of roads, and the manufacture of glass and paper would be impossible, as would the production of iron and therefore the manufacture of toolsmounted ball mills suitable for quicklime slaking and regrind applications The mills range from 600mm diameter for laboratory batch testing applications through to the largest mill currently available of 23m diameter with an effective grinding length of 46m SEW Eurodrive geared reducers are used exclusively on Lime SystemsCOMPLETE PLANT CAPABILITY LIME SYSTEMS LTDDOI: 101007/S001700182719X Corpus ID: ; A force model in single grain grinding of long fiber reinforced woven composite @article{Wei2018AFM, title={A force model in single grain grinding of long fiber reinforced woven composite}, author={Jin Hua Wei and Haoji Wang and Bin Lin and Tianyi Sui and Feifei Zhao and Sheng Fang}, journal={The International A force model in single grain grinding of long fiber reinforced mounted ball mills suitable for quicklime slaking and regrind applications The mills range from 600mm diameter for laboratory batch testing applications through to the largest mill currently available of 23m diameter with an effective grinding length of 46m SEW Eurodrive geared reducers are used exclusively on Lime SystemsCOMPLETE PLANT CAPABILITY LIME SYSTEMS LTD

.jpg)

Quicklime: A Primer

2023年10月27日 Quicklime is an alkaline substance produced from heating limestone in specialized kilns Humans have used quicklime since antiquity for construction, agriculture and metalwork applications It is still used in all of I understand how quicklime takes forever to make, and you really should consider running many firepits at the sane time to get around your problem Also consider using coal or charcoal for your fuel so you get longer burntime However, may I ask why you need so much quicklime?Quicklime mass production? : r/VintageStory Reddit2023年7月18日 Brand: Baratza Color/s: Black and silver Material: Stainless steel Designed for coffee aficionados, the Baratza Sette 30 Conical Burr Grinder is a standout among the best singledose espresso grinders on the marketWith accolades from the Specialty Coffee Association, this grinder is favored by professionals and home baristas alikeThe 8 Best SingleDose Espresso Grinders Reviewed2022年12月22日 Scope of application: It is suitable for quicklime grinding and processing, requiring large output, low energy consumption, low operating cost, single machine processing capacity up to 60T/H, economical investment; ③ Thin oil lubrication system: The main engine drive and fan drive system are all lubricated with thin oil, Type Selection of Quicklime Deep Processing Equipment

limestone, quicklime and slaked lime chemguide

Turning limestone into quicklime industrially The next video shows a modern industrial plant for producing quicklime, calcium oxide It carries far more information than you need, and you really only need to concentrate on what happens in the kiln itself (starting just after 2 minutes) This is where the limestone is heated and quicklime is 2017年1月1日 The paper presents a study of chip formation in single grain grinding using a convenient FEM formulation, the Smooth Particle Hydrodynamics (SPH) methodSPH Simulation of single grain action in grinding ResearchGateQuicklime Slaking/ Grinding Benefits and Features Lime slaking systems comprise multiple components, each specifically designed to form part of the lime slaking system Correct design ensures the reliable production of a MOL slurry at the specified rate and with the required concentration of solidsLIME SLAKING SYSTEMS Bulk Handling Technologies Australia2022年2月28日 Introduction of grinding technology in lime industry Quicklime, whose main component is calcium oxide, is usually prepared by calcining natural rock whose main component is calcium carbonate at high temperature to decompose into carbon dioxide and calcium oxide (chemical formula: CaO, namely quicklime, also known as marble)How to do a good job of grinding in the lime industry?

.jpg)

(PDF) The Effects of Limestone Characteristics and Calcination

2001年4月1日 This study has examined the effects of limestone characteristics (microstructure and texture) and calcination temperature on the reactivity of the produced quicklime