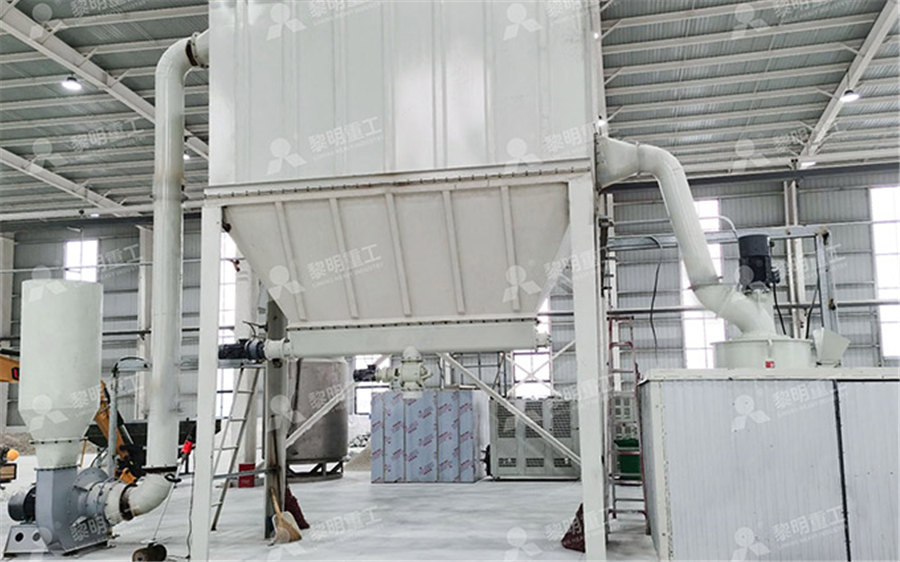

Highefficiency highpressure mill

Optimization of working parameters of highpressure roller mill

2024年11月15日 In order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is 2022年3月15日 This paper unifies highpressure grinding rolls crusher (HPGR) models of the working gap, mass flow rate, power draw, and centre and edge product particle size Unifying highpressure grinding rolls models ScienceDirectThe comminution process of High Pressure Grinding Rolls (HPGR) was discovered in the 1980s by the research work of the German Professor Schönert Its main advantage is the high Quantification of HPGR energy efficiency effects on downstream High Pressure Grinding Rolls (HPGR) technology is accepted as an energyefficient and costeffective alternative for treating specific mineral ore types HPGR technology has been A Review of the Modeling of High Pressure Grinding Rolls JSTAGE

The effect of ball size on the energy efficiency of hybrid high

1999年11月1日 There is an optimum range of energy partitioning between the highpressure roll mill and the ball mill in the hybrid system The increased efficiency of hybrid grinding is related 1997年9月1日 Other workers have reported the high pressure mill is up to five times more efficient than hall mifling for both hard minerals (quartz) and softer minerals (limestone) It is Evaluating high pressure milling for liberation enhancement and 2020年6月17日 The objective of both highspeed and highefficiency machining strategies is to improve MRR, according to Yair Bruhis, global product and application manager for YG1 Tool Co, Vernon Hills, Illinois Highefficiency Maximizing MRR with Tools for HighSpeed Milling1998年1月1日 The high pressure roll mill, HPRM, a newly invented size reduction equipment, has been recently added to the list of comminution machines and is classified as a highly efficient equipment(PDF) THE PERFORMANCE OF THE HIGH PRESSURE

Grinding technology thyssenkrupp Polysius

Costeffective, reliable and energysaving: for its high performance range of mills for the grinding of a wide variety of materials, thyssenkrupp Polysius offers solutions to suit your every need The polysius® booster mill is an additional High efficiency, large output YGM series high pressure suspension grinding mill Breaking through the bottleneck of traditional pendulum mill production capacity, enjoy the advantages of large single production capacity at home and abroad, YGM Series High Pressure Suspension Grinding MillQuality FDS High efficiency super fineness sand mill suppliers exporter all products made in China +8621 Specialized in the manufacture of chemical machinery and equipment for 20 yearsFDS High efficiency super fineness sand mill FarflyOne of the principal reasons for the outstanding success of the high pressure grinding roll in the cement industry is its low power requirement Today, this mill is employed all around the world for the grinding of cement raw material, cement polycom® high pressure grinding roll

.jpg)

EnergyEfficient Technologies in Cement Grinding IntechOpen

2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a The sepol® high efficiency separator plays a key role in grinding systems equipped with tube mills, roller mills and high pressure grinding rolls Modular Grinding Plant or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grindingGrinding technology thyssenkrupp Polysiusin combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1) The ball mill comminution process has a high electricalBALL MILLS Ball mill optimisation Holzinger Consulting2005年1月31日 Request PDF Comparison of emulsification efficiency of proteinstabilized oilinwater emulsions using jet, high pressure and colloid mill homogenization The aim of this work is to compare Comparison of emulsification efficiency of proteinstabilized

.jpg)

Comparison of emulsification efficiency of proteinstabilized

2005年1月1日 The droplets obtained with the two high pressure devices were smaller than those from rotor–stator process, in line with the difference in energy density input The high pressure jet, for low protein content, promotes the disruption of droplets into smaller ones (less than 90 nm) more than that of the microfluidizerIn order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is sought, GM160140 high Optimization of working parameters of highpressure roller mill penditure, are the defining features of the sepol ® highefficiency separator All requirements defining a futureproof system configuration are precisely fulfilled by the sepol ® highefficiency separator The separator plays a key role in grinding systems equipped with tube mills, roller mills and highpressure grinding rolls OverIndustrial Solutions sepol highefficiency separator ThyssenKruppHigh Pressure Mill High Pressure Mill is based on five years research on the traditional grinding mills, the High Pressure Mill got national patent and CE certificate, features of high efficiency and energy savingIt is suitable for grind mineral to powder, which is widely used in the fields of metallurgy, building materials, chemical and mining industry and so onHigh Pressure Mill Grinding Mill Kefid Machinery

(PDF) Efficiency Improvement in Sugar Mills; The Role

2023年5月6日 Efficiency Improvement in Sugar Mills; The Role of HighPressure Boiler Technology in Cogeneration May 2023 Conference: 1st International Conference on Modern Technologies in Mechanical and YGM85 has high crushing efficiency and stable performance; YGM95 highpressure Raymond mill is also a hotselling model, which is suitable for occasions such as 200mesh petroleum coke pulverizing production lines, with stable performance and reliable quality; YGM130 highpressure suspension roller mill is a model with superior performance YGM Grinding Mill Powder Grinding Mill Fine Grinding MillThe coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal Pulverization2005年1月1日 The droplets obtained with the two high pressure devices were smaller than those from rotor–stator process, in line with the difference in energy density input The high pressure jet, for low protein content, promotes the disruption of droplets into smaller ones (less than 90 nm) more than that of the parison of emulsification efficiency of proteinstabilized

YGM HighPressure Grinding Mill Zhengzhou Jemelon Mining

Jemelon high pressure suspension mill is a new RD mill It is designed by engineers based on many years’ industrial mill research and the needs of mill industry The adoption of world leading powder processing technology makes Jemelon high pressure suspension mill start a new era of mill industry with high efficiency and low consumption It is the ideal substitute of the traditional Shunky high pressure suspension mill is a new RD mill It is designed by engineers based on many years’ industrial mill research and the needs of mill industry The adoption of world leading powder processing technology makes Shunky high pressure suspension mill start a new era of mill industry with high efficiency and low consumptionYGM HighPressure Grinding Mill Shanky Machinery2021年8月17日 Short electric arc milling (SEAM) is an efficient electrical discharge machining method, especially for the efficient removal of difficulttomachine conductive materials with high hardness, high toughness, and wear resistance In this study, titanium alloy Ti–6Al–4V is used as the research object to conduct machining experiments The material removal mechanism of Experimental study on highefficiency DC short electric arc 2023年8月5日 High pressure roller mill is a new type of grinding equipment developed on the basis of roller press for cement in recent years Mines increase the specific surface area for fine grinding The high pressure roller mill has the characteristics of high production efficiency, large crushing ratio, low power consumption, significant energy saving and convenient maintenanceWorking principle of high pressure roller millZYmining

.jpg)

High Efficiency Milling Archives Harvey Performance Company

2020年4月17日 High Efficiency Milling (HEM) High Efficiency Milling Breaking and damaging an end mill is oftentimes an avoidable mistake that can be extremely costly for a It can be delivered as mist, flood, high pressure or minimum quantity lubricant Appropriate coolant type and delivery vary depending on your application and tool High Pressure Grinding Rolls (HPGR) are the most efficient comminution product for milling High energy efficiency reduces operating costs (SAG)–ball mill circuits They are also used as the final grinding step in producing the required ironore FLS High Pressure Grinding Rolls – Efficient grindingdesign incorporated two, known energy efficient technologies, the High Pressure Grinding Roll (HPGR) and the horizontal highspeed stirred mill, and examined the technical feasibility of a circuit operating without the need for a tumbling mill The main objectives of this research were to setup pilotscale research equipment and developA PilotScale Examination of a Novel High Pressure Grinding Roll 2022年1月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 07, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110 rpm, grinding concentration of 50%, Highefficiency and energyconservation grinding technology using

.jpg)

YGM Series High Pressure Suspension Grinding Mill

YGM Series High Pressure Suspension Grinding Mill can produce powder from various nonflammable and nonexplosive mineral materials with Mohs hardness below 93 and humidity below 6%, there are mainly applied in the industries of metallurgy, construction materials, chemical, and mining, etcHigh pressure roll mill 241 Effect of moisture on energy efficiency The reduction ratio, X80f/X80p, was used to correlate the energy efficiency as a function of feed moisture It was found that at low specific energy, the reduction ratio decreased with increasing the moisture content of the feed(PDF) The Performance of the High Pressure Roll Mill: Effect of 2022年6月1日 High pressure grinding mill is a new type of grinding machine developed on the basis of highfine powder processing, also known as highpressure roller mill +17 [ protected] the more stable the output and the higher the processing efficiency, High pressure grinding mill suspension roller mill for salequick check of catalytic efficiency; accelerated hydride formation and nanocrystallinity; Features: Continuous insitu monitoring of pressure and temperature during ball milling; p max = 150 bar of hydrogen (smaller pressure ranges with higher resolution available: up to 125102050100 bar) Operation time up to 40 hHigh Pressure Milling Vial evico magnetics

.jpg)

High Pressure Grinding Roll and Magnetic Separation for Energy

2024年5月31日 This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the thirdstage fine crushing operation to reduce the particle size of ball mill feed and improve the processing capacity of grinding operation The optimal process parameters of high pressure grinding roll and magnetic separation were Sugar mill waste could play a significant role in generating electricity due to its potential, with modified highpressure boilers, efficiency can be increased to 84% [14]Efficiency Improvement in Sugar Mills; The Role of HighPressure High Efficiency: Enhances ball mill system capacity by 2050% and reduces total energy consumption by 3050% 2 HPGM series high pressure grinding roll is a new type of energysaving grinding equipment designed by the principle of highpressure material layer pulverizationHPGM High Pressure Grinding Mill HuateHigh efficiency, large output YGM series high pressure suspension grinding mill Breaking through the bottleneck of traditional pendulum mill production capacity, enjoy the advantages of large single production capacity at home and abroad, YGM Series High Pressure Suspension Grinding Mill

FDS High efficiency super fineness sand mill Farfly

Quality FDS High efficiency super fineness sand mill suppliers exporter all products made in China +8621 Specialized in the manufacture of chemical machinery and equipment for 20 yearsOne of the principal reasons for the outstanding success of the high pressure grinding roll in the cement industry is its low power requirement Today, this mill is employed all around the world for the grinding of cement raw material, cement polycom® high pressure grinding roll2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a EnergyEfficient Technologies in Cement Grinding IntechOpenThe sepol® high efficiency separator plays a key role in grinding systems equipped with tube mills, roller mills and high pressure grinding rolls Modular Grinding Plant or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grindingGrinding technology thyssenkrupp Polysius

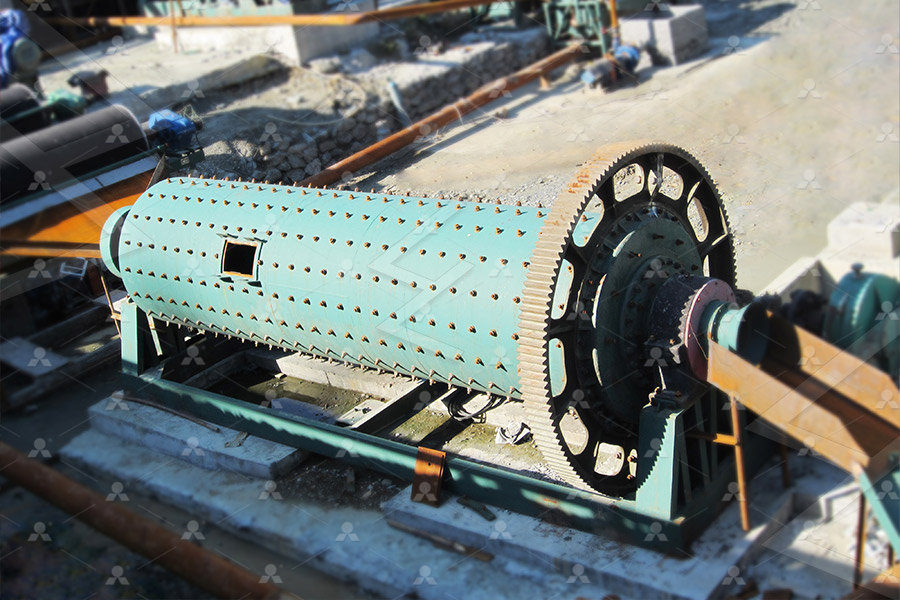

BALL MILLS Ball mill optimisation Holzinger Consulting

in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1) The ball mill comminution process has a high electrical2005年1月31日 Request PDF Comparison of emulsification efficiency of proteinstabilized oilinwater emulsions using jet, high pressure and colloid mill homogenization The aim of this work is to compare Comparison of emulsification efficiency of proteinstabilized 2005年1月1日 The droplets obtained with the two high pressure devices were smaller than those from rotor–stator process, in line with the difference in energy density input The high pressure jet, for low protein content, promotes the disruption of droplets into smaller ones (less than 90 nm) more than that of the parison of emulsification efficiency of proteinstabilized In order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is sought, GM160140 high Optimization of working parameters of highpressure roller mill

.jpg)

Industrial Solutions sepol highefficiency separator ThyssenKrupp

penditure, are the defining features of the sepol ® highefficiency separator All requirements defining a futureproof system configuration are precisely fulfilled by the sepol ® highefficiency separator The separator plays a key role in grinding systems equipped with tube mills, roller mills and highpressure grinding rolls Over