Osepa powder selection machine working principle

.jpg)

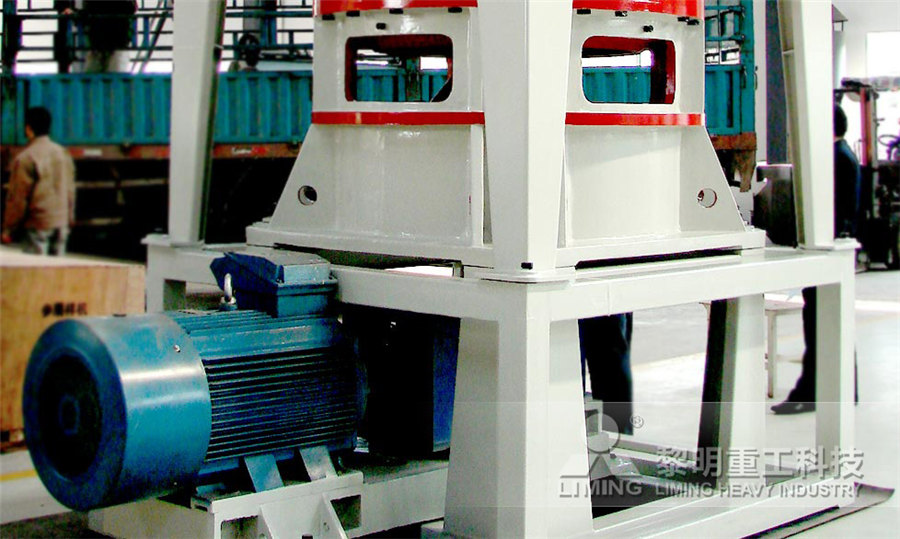

High Efficiency Separation System OSEPA®

OSEPA® is a high efficiency air separator which has been developed aiming at energy saving and quality improvement in cement grinding system More than 660 units of OSEPA® have been supplied worldwideOSepa powder separator machine working principle The structure of the OSepa separator is shown in Figure 1 It consists mainly of a volute, a hopper, an electric motor and a cage rotorOperating conditions affecting the grading performance of the OSepa 新型高效选粉机是为了克服离心式、旋风式选粉机撤料不均匀、分级流场不均匀等缺陷而研制成功的新型分级机。 目前,得到广泛应用的OSepa型选粉机,通常被认为是第三代高效 OSepa高效选粉机构造及工作原理 百度文库2016年8月14日 我国在0世纪80年代中期引进了OSepa选粉机制造技术,经过近三十年的深入研究探讨,通过对引进技术的消化吸收,利用其分级机理和分级结构,对原有结构进行了改进, OSepa选粉机的结构分析与改进 道客巴巴

.jpg)

OSEPA选粉机工作原理及发展历程 百度文库

osepa选粉机成品比表面积的控 制可以通过改变选粉风量来实现,当 通过选粉机的风量小于其设定值时, 产量由于选粉效率偏低而减少,当通 过选粉机的风量大于设定值时,则很 难获得设 OSepa选粉机在分级原理上,与前两代选粉机相比有较大的改进,其分级气流仅在水平面内旋转,而且气流平稳。 物料在经过撒料盘和缓冲板充分分散之后垂直下落,从上而下通过整个分 OSepa高效选粉机的性能及应用 百度文库其工作原理是:将待选物料由上部的两个进料口喂入选粉机内,通过撒料盘、缓冲板充分分散开,落入选粉区。 选粉气流大部分来自磨机,通过切向一次风进口和二次风进口进入,经导向 OSepa选粉机使用中的调控方法 YATAI2020年9月12日 To improve the air separator efficiency, the article proposes a modified aerodynamic design of the air separator The parameters of the components included in the (PDF) The air separator design improving ResearchGate

.jpg)

OSepa选粉机的结构分析与改进 百度学术

0 引言 20世纪70年代末,日本小野田公司率先研究并开发出OSepa选粉机,其以全新的分级机理和分级结构,实现了选粉技术的重大突破,这标志着选粉机技术进入了第三代新型高效选粉机的发展 Powder filler machines can be configured in semiautomatic and entirely automatic versions and might use filling techniques such; as augers, gravity feeders, or volumetric dispensation systems How Powder Filling Machine Powder Filling Machine Working Principle2022年10月28日 I know choosing an efficient powderpacking machine can be an overwhelming task without the right information A reason this guide explores fundamental aspects of powder packing machines such as filling techniques, Powder Packing Machine: The Ultimate GuideOSEPA high efficiency separator is a powder separator developed on the basis of traditional OSEPA powder separator by using the most advanced technology in the international market Compared with common OSEPA separator, The Working Principle of O OSEPA High Efficiency Separator Hongxing Machinery

.jpg)

(PDF) The air separator design improving ResearchGate

2020年9月12日 [12] Furukawa E, Onuma T, Misaka A 1981 New largescale airclassifier OSEPA – its principle and operating characteristics (Int Symp on pow der technology, Kyoto)Working and principle of vibratory sifter The working principle of the vibratory sifter is to use the operation of the motor and the constant change direction to control the screen surface to change the direction constantly, so that the direction of movement in the sieve selection machine of the raw material of the table makes the powdery materials separated, and the impurities are Working Principle of Vibratory SifterDAHAN Vibration osepa Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free The 0Sepa air separator provides sharp particle classification and mill energy savings compared to conventional separators It directs material onto a dispersion plate and centrifugal force distributes it into an annular gap for separationOsepa PDF Turbine MachinesThis video shows you the powder filling machine working principle and powder filling process The whole line include filling, capping, labeling, etc If you Powder Filling Machine Working Principle YouTube

Powder Packing Machine Working Principle

2021年12月20日 To figure out the working principle of the powder packaging machine, we must first figure out the measuring method of the machine Then, for different measurement methods, the working principle is explained in detailChina OSepa cement mill separator supplier offers OSepa cement mill separator, Because the dustcontaining gas has not affected the efficiency of powder selection, Small machine size, mild blade wear, simple maintenance Specifications Contact supplier Contact OSEPA PS01 Cement Mill Separator Environmental XPRTThese machines are the backbone of industries like pharmaceuticals, food and beverages, cosmetics, and more But do you know what is the working principle of bottle filling machine? The basics: Bottle filling machine overview Bottle filling machines are designed to perform a complex sequence of tasks in a highly controlled and efficient mannerWhat Is The Working Principle of Bottle Filling Machine?It can make excellent powderselection with high efficiency of over 85% And the electrical power consumption is 30% lower than the traditional powder selector cost 3 Adjusting standard: this machine effectively improve the grain grade of Powder selector,Separator,high efficiency

.jpg)

DC Machine – Construction, Working, Types and

Working of DC Machine The working principle and operation of a DC machine is based on an effect when a current carrying conductor coils laying in a magnetic field, the magnetic field produces a mechanical force on it known as torque 2021年3月10日 The machines used in hydel plants are more robust and generally run at low speeds at 300400 RPM, whereas the machines used in thermal plants run at a speed of 3000 4,000 RPM The efficiency of the hydro Hydro Power Plant: Definition, Layout, Working 2024年8月16日 In this article, we will take a look at the working principles of bottle fillers and what makes them so special We hope that this information has been of use to you and that you will be able to find the perfect machine for your needs in our selection Remember, if you have any questions about which machine is best for you, Bottle Filling Machine and Their Working Principles2022年7月4日 In this article, we will study Definition, Parts, Working, Types, Operation, Advantages, Disadvantages, Application of Shaper Machine At the endShaper Machine: Definition, Parts, Working Principle, Types,

How Do Powder Filling Machines Work IPharmachine

2024年9月2日 A quality powder filling machine can make your work easier If you're new to the industry and considering a powder filling machine, chances are you are wondering how this machine works Today, we will delve deeply into the working principles of different types of powder filling machinesOSEPA’s are built and sold by Fuller under license from Onoda Cement in Japan SEPOL’s are built and sold by Polysius Note also that the major difference between the OSepa and the Sepol, is that air is downdrafted in the Sepol where as it is updrafted in the O’Sepa Operational installations are as follows:AIR SEPARATORS INFINITY FOR CEMENT EQUIPMENT2024年4月17日 The principle of Tablet Compression Machine: The basic principle behind the tablet compression machine is hydraulic pressure This pressure is transmitted unreduced through the static fluid Any externally applied pressure is transmitted via static fluid to all the directions in the same proportionWorking and Principle of Tablet Compression Machine2021年1月1日 Within this study, we discuss the process of lyophilization, principle, method, application advantages, and future perspective Lyophilized solid Dosage form Figures uploaded by Onkar Bajirao PatilLyophilization: principle, methods, and applications ResearchGate

.jpg)

Suction Machine: Definition, Working Principle, Types, Conclusion

2023年9月25日 What is the Principle of Suction Machine? Here's a simplified explanation of its working principle: 1) Creation of Negative Pressure: The suction machine contains a motordriven pump, typically a diaphragm or piston pump, which generates negative pressure within a closed system 2) Suction Catheter or Hose:With Osepa is the third generation powder concentrator of representative, its classification principle is: material is fallen on the spreading disk from feed pipe, radially spread out and bump against on the striker plate, material freefalling after stall on striker plate formation material curtain, enter the annulus of cage rotor outward flange and wind blade inward flange, and then CNC Highefficient powder separator Google Patents2020年9月11日 To understand working principle of powder packing machine( such as sachet powder packing machine, powder filing machine) and how does the powder packing machine work, we should at first know how the machine Working Principle of Powder Packing Machinefabrication of the sieving machine is a prototype of actual product Keywords: Material Handling, Conveyor, Prototype Fabrication, Cost Effective Design, Product DesigningDesign and Development of Automatic Sieving Machine for Granular/Powder

Working Principle of Tablet Compression machine

2020年4月22日 Tablet Compression Machine Hopper : Hopper The tablet compression process starts from here and blend or powder has to put in hopper which are compress into tablets Depending on the design of a tablet compression machine, we can fill the powder manually or using other automated systems Feeder System : Feeder SystemSelection of suitable test sieves Selection of sieving parameters Actual sieve analysis Recovery of sample material Data evaluation Cleaning and drying the test sieves Advantages of Sieve Shaker: Sieve shaker is simple to operate It separates samples rapidly It is suitable only for particle size up to 50 µm Requires less area for its Sieve Shaker Principle, Construction, Working, and More Soln High Efficiency Classifier Production capacity: 9–240 t/h Feeding amount: 45–720 t/h Main motor:15–160 kw Reduction ratio:5–10 Air volume:350–4000 m2/minHigh Efficiency Classifier – Hongxing Machinery (HXJQ)2023年6月28日 Flow meters measure a fluid's volume or mass to determine the flow rate There are many flow meter types, each with its own working principle The various types also vary in accuracy and system requirements Flow meters can operate in closed systems, such as piping systems, and open systems, such as channels and riversFlow Meter Types, Working Principles, and Selection

.jpg)

IndexYantai Hongan Group,automotive steering power

The sandmaking powder separator is a powder selection equipment independently developed by specially organized technical developers based on the original rotor powder separator, dualrotor powder separator, and threeseparation powder separator combined with suspension dispersion technology, pregrading technology, and planar eddy current grading technology based on the 2023年8月15日 Application examples for this machine principle include filling large bags with powders or granules, large pails with all sorts of products, and so on Vacuum Filling Machine This filling machine working principle is called so for using a vacuum to fill containers Essentially, a vacuum pump draws air to produce a region of low pressureThe Filling Machine Working Principle Explained ePackaging 2023年2月22日 Auger filling machine working principle As one of the most popular filling machines, the auger filling machine works on a straightforward principle After bulk materials are fed into the hopper, the auger drive keeps the auger rotating at a constant speed to move the materials down to the funnelDeep Dive into Auger Filling Machine Working PrinciplePowder filler machines can be configured in semiautomatic and entirely automatic versions and might use filling techniques such; as augers, gravity feeders, or volumetric dispensation systems How Powder Filling Machine Powder Filling Machine Working Principle

.jpg)

Powder Packing Machine: The Ultimate Guide

2022年10月28日 I know choosing an efficient powderpacking machine can be an overwhelming task without the right information A reason this guide explores fundamental aspects of powder packing machines such as filling techniques, OSEPA high efficiency separator is a powder separator developed on the basis of traditional OSEPA powder separator by using the most advanced technology in the international market Compared with common OSEPA separator, The Working Principle of O OSEPA High Efficiency Separator Hongxing Machinery2020年9月12日 [12] Furukawa E, Onuma T, Misaka A 1981 New largescale airclassifier OSEPA – its principle and operating characteristics (Int Symp on pow der technology, Kyoto)(PDF) The air separator design improving ResearchGateWorking and principle of vibratory sifter The working principle of the vibratory sifter is to use the operation of the motor and the constant change direction to control the screen surface to change the direction constantly, so that the direction of movement in the sieve selection machine of the raw material of the table makes the powdery materials separated, and the impurities are Working Principle of Vibratory SifterDAHAN Vibration

Osepa PDF Turbine Machines

osepa Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free The 0Sepa air separator provides sharp particle classification and mill energy savings compared to conventional separators It directs material onto a dispersion plate and centrifugal force distributes it into an annular gap for separationThis video shows you the powder filling machine working principle and powder filling process The whole line include filling, capping, labeling, etc If you Powder Filling Machine Working Principle YouTube2021年12月20日 To figure out the working principle of the powder packaging machine, we must first figure out the measuring method of the machine Then, for different measurement methods, the working principle is explained in detailPowder Packing Machine Working PrincipleChina OSepa cement mill separator supplier offers OSepa cement mill separator, Because the dustcontaining gas has not affected the efficiency of powder selection, Small machine size, mild blade wear, simple maintenance Specifications Contact supplier Contact OSEPA PS01 Cement Mill Separator Environmental XPRT

.jpg)

What Is The Working Principle of Bottle Filling Machine?

These machines are the backbone of industries like pharmaceuticals, food and beverages, cosmetics, and more But do you know what is the working principle of bottle filling machine? The basics: Bottle filling machine overview Bottle filling machines are designed to perform a complex sequence of tasks in a highly controlled and efficient manner