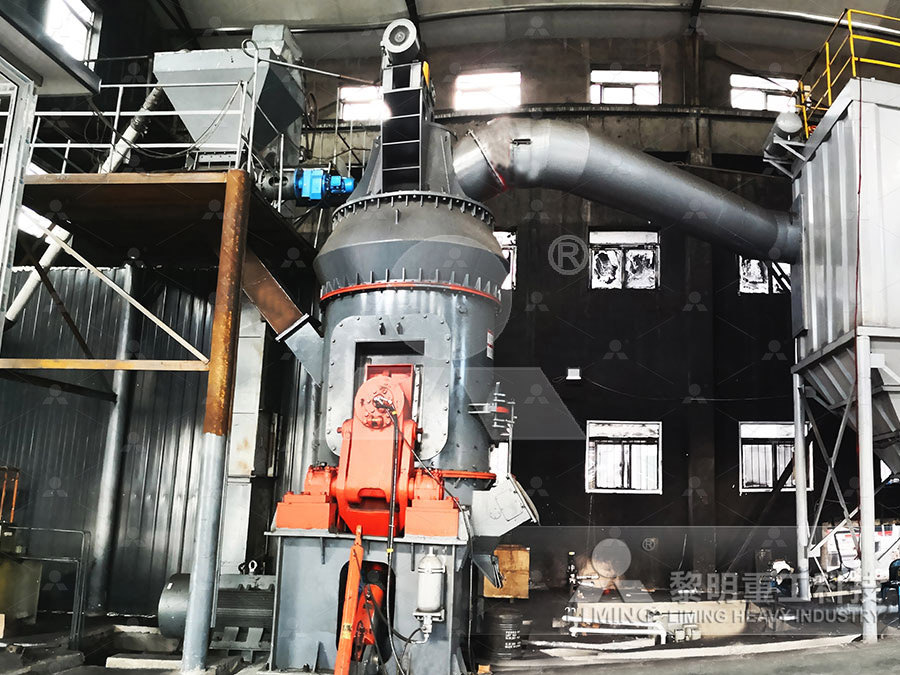

Imported lump clean coal anthracite grinding mill

.jpg)

Reprint from ZKG 3 Gebr Pfeiffer

Pfeifer SE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as well as GPSE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as well as COAL GRINDING IMPS: more than meets the eye Gebr PfeifferShop PAPA'S Miner's Choice Nut Coal 40lb Bag Anthracite for Comfort, Cost Savings, and Convenience 3 in the Charcoal Accessories department at Lowes Skip to main content Lowe's Credit Center Order PAPA'S Miner's Choice Nut Coal 40lb Bagbility of lowrank coal is enhanced through grinding in the presence of bituminous coal pitch (Atesok and Celik, 2000) Grinding has also been adopted to improve the floatability of oxidized coal (Xia, Yang, and Zhu, 2012) Clean coals have been successfully produced from Mecsek bituminous coal by flotation following ultrafine liberation A new preparation scheme for a difficultto float coking coal by

.jpg)

Grinding Mills and Pulverizers Selection Guide:

Video credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and coal grinding applications in the cement industry, where normally a twomillsystem is used 1 Introduction Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90 % and, on the other hand, ball mills whose share de Reprint from ZKG 3 Gebr Pfeiffer2024年9月1日 1 Introduction Anthracite is widely regarded as the cleanest burning coal owing to its high heat output and minimal smoke production and possesses the highest fixed C and lowest volatile matter contents [1]The coal structure is generally considered to be extremely complex [2], [3]Researchers have extensively analyzed advanced techniques for the removal Mechanistic study of the effects of ultrafine grinding on the Coal strength will also increase with increased confining pressure (Hobbs, 1964), as shown in Figure 32At atmospheric pressure or unconfined conditions, dull coals can be two to three times stronger than brighterbanded lithotypes from the same seam with the same rank (Medhurst and Brown, 1998, and Lawrence, 1978), and low rank coals can be up to 14 times stronger than Coal Strength an overview ScienceDirect Topics

Coal utilization in the cement and concrete industries

2023年1月1日 Generally, a value of 55 represents an average grinding coal When switching to lower HGI coal, the capacity of the coal mill system should be assessed A key element in understanding a mill’s ability to handle lower HGI coals is 2016年1月1日 When coal is imported, Anthracite combusts with hot, clean flame, containing low content of sulfur and volatiles ISO 5074) uses a ballandring type of mill in which a sample of closely sized coal is ground for a specified number (usually, 60) of revolutionsSolid fuel types for energy generation: Coal and fossil carbon 2020年8月12日 Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass the energetic efficiency of coal mill has been investigated and performance value has been found to be a maximum value of 962% KEYWORDS: Vertical roller coal mill An investigation of performance characteristics and energetic Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, ChinaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Coal Fly Ash Utilisation and Environmental Impact

2021年5月11日 Although coal is discouraged to be used for power generation for minimising environmental impact, coal is expected to remain principal lowcost energy source for power generation in the foreseeable mediumterm future (Alam and Alam 2020a, b; Alam et al 2019)Globally coalfired power plants annually generate fly ash over 1 billion tonnes (Reid et 2021年5月1日 At optimum operating conditions, clean coal with ash content ranging from 151–164% (average ash content of 158%) was obtained with an average yield of 58% for CoalA Similarly, clean coal with an ash content between 162 and 185% (average ash content of 173%) was obtained for CoalB with an average yield of 54%Sustainability of coal mines: Separation of clean coal from the fine 2024年9月1日 Anthracite, a valuable and scarce coal, typically requires systematic liberation for deep deashing, wherein the particle size reduces to the micron level upon ultrafine grindingChanges in the physicochemical properties of anthracite particles induced by ultrafine grinding significantly impact subsequent flotation Accordingly, in this study, a scanning Mechanistic study of the effects of ultrafine grinding on the 2020年3月15日 This paper selects anthracite coal and coking coal as experimental materials to conduct heterogeneous grinding in the Hardgrove mill Energy consumption and product t 10 of single coal and mixtures at various grinding time are measured, and effects of mixed ratio on energysize reduction process are discussed T 10 values of component after the mixture Energysize reduction of mixtures of anthracite and coking coal

.jpg)

An analysis of the energy split for grinding coal/calcite mixture in

2016年7月1日 Interactions among components in the heterogeneous grinding would change energy consumed characteristics of components if compared with those in the singlecomponent breakage In this paper, energy split phenomenon for the coarse grinding of super clean anthracite coal (SCAC)/calcite mixture of 28–2 mm in the ballandrace mill is investigated2002 Coal grinding plant (LM 232 D) for grinding wood pellets for power stations 1992 Central coal grinding plant (LM 263 D) for the production of lignite (brown) coal dust 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry 1980 Delivery of first modular coal mill (LM 263 D)Loesche Grinding Technology for the Power IndustryAs wet grinding is preferred for coal slurries, another group of mills has come into use The two possibilities are straddled best by the tumbling ball mill It is the most common type of mill used in industry, for both dry and wet grinding of brittle materials For coal grinding, it Grinding Mill an overview ScienceDirect Topics2021年5月11日 The combustion of pulverized coal in power stations (in the boilers) produces energy along with different types of ash During the combustion process, the volatile matter and fixed carbon burns in the boiler and the ‘fine’ ash fraction is moved upwards with flue gases and captured with the help of electrostatic precipitators before reaching the atmosphere (Fig Generation, Transportation and Utilization of Indian Coal Ash

.jpg)

Coal explained Coal prices and outlook US Energy Information

Bituminous coal accounted for about 46% of US coal production in 2022 Anthracite contains 86%–97% carbon and has a heating value that is slightly higher on average than bituminous coal Anthracite is the least abundant coal rank in the United States and generally accounts for less than 1% of annual US coal production2020年3月15日 Second, yields of anthracite coal in mixture progenies, which are smaller than the corresponding fineness (0237 mm) of t 10, are determined and depicted in Fig 5 At the early grinding stage, yields of anthracite coal in mixture progenies are fluctuant, and this may be caused by the uneven mixing of two coals in coarse sizeEnergysize reduction of mixtures of anthracite and coking coal 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS2024年2月1日 Initially lit by “coal gas” – a mix of methane, hydrogen, and carbon monoxide produced by the anaerobic heating of coal – the Gas Light and Coke Company produced enough coal gas by 1820 to light almost 30,000 Wood to Coal (Chapter 1) The Truth About Energy

A new preparation scheme for a difficulttofloat coking coal

Grinding pretreatment A cylindrical laboratory ball mill with a diameter of 160 mm and a length of 200 mm was used for wet grinding in all the experiments The ball mill was run at a constant speed of 120 r/min and a media filling of 20% A 500 g coal sample was added to the ball mill at a pulp concentration of 40%2020年1月1日 Grinding kinetics by breakage function helps in evaluating the breakage mechanism and the performance of the grinding mill [35] However, Clean coal of 192%–214% ash with >40% yield was obtained by densitygradientcentrifugation of Wet and dry grinding of coal in a laboratoryscale ball mill: Particle Anthracite and bituminous coal were formed in the eastern and western regions of Pennsylvania in the Carboniferous Geological Period [7] The Pennsylvania Anthracite Region is in the Valley and Ridge Province of the Appalachian Mountains, with the coal located in the folded and faulted terrain of the Province The anthracite fields are maintained in synclinal basins that are History of anthracite coal mining in Pennsylvania Wikipedia2023年8月1日 For example, for blast furnace injection and coal water slurry, particles less than 74 µm in size account for more than 70–80% of total production, whereas for pulverized coal boilers, particles less than 74 µm in size account for more than 80% and 50% of the total production for anthracite and bituminous coal, respectively Grinding is Effects of pyrolysis temperature and atmosphere on grinding

46.jpg)

Interrelationship of coal grinding properties and coal petrology

1998年8月1日 The Hardgrove grindability index (HGI) is a widely used coalquality parameter with applications in coal mining, beneficiation, and utilization An understanding of the petrology of the coal is fundamental to understanding the validity of the HGI in the given application The HGI varies with coal rank, increasing (greater ease of grinding) with increasing rank through the 12 Anthracite Coal Combustion 121 General15 Coal is a complex combination of organic matter and inorganic ash formed over eons from successive layers of fallen vegetation Coals are classified by rank according to their progressive alteration in the natural metamorphosis from lignite to anthracite12 Anthracite Coal Combustion US Environmental Protection Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations Special versions are available with characteristics that meet special safety regulation or output control requirementsCoal Mills for Cement Plants LoescheAnthracite, also known as hard coal and black coal, is a hard, compact variety of coal that has a submetallic lustreIt has the highest carbon content, the fewest impurities, and the highest energy density of all types of coal and is the highest ranking of coals The Coal Region of Northeastern Pennsylvania in the United States has the largest known deposits of anthracite coal in the Anthracite Wikipedia

.jpg)

PAPA'S Miner's Choice Nut Coal 40lb Bag

Shop PAPA'S Miner's Choice Nut Coal 40lb Bag Anthracite for Comfort, Cost Savings, and Convenience 3 in the Charcoal Accessories department at Lowes Skip to main content Lowe's Credit Center Order bility of lowrank coal is enhanced through grinding in the presence of bituminous coal pitch (Atesok and Celik, 2000) Grinding has also been adopted to improve the floatability of oxidized coal (Xia, Yang, and Zhu, 2012) Clean coals have been successfully produced from Mecsek bituminous coal by flotation following ultrafine liberation A new preparation scheme for a difficultto float coking coal by Video credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and Grinding Mills and Pulverizers Selection Guide: coal grinding applications in the cement industry, where normally a twomillsystem is used 1 Introduction Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90 % and, on the other hand, ball mills whose share de Reprint from ZKG 3 Gebr Pfeiffer

.jpg)

Mechanistic study of the effects of ultrafine grinding on the

2024年9月1日 1 Introduction Anthracite is widely regarded as the cleanest burning coal owing to its high heat output and minimal smoke production and possesses the highest fixed C and lowest volatile matter contents [1]The coal structure is generally considered to be extremely complex [2], [3]Researchers have extensively analyzed advanced techniques for the removal Coal strength will also increase with increased confining pressure (Hobbs, 1964), as shown in Figure 32At atmospheric pressure or unconfined conditions, dull coals can be two to three times stronger than brighterbanded lithotypes from the same seam with the same rank (Medhurst and Brown, 1998, and Lawrence, 1978), and low rank coals can be up to 14 times stronger than Coal Strength an overview ScienceDirect Topics2023年1月1日 Generally, a value of 55 represents an average grinding coal When switching to lower HGI coal, the capacity of the coal mill system should be assessed A key element in understanding a mill’s ability to handle lower HGI coals is Coal utilization in the cement and concrete industries2016年1月1日 When coal is imported, Anthracite combusts with hot, clean flame, containing low content of sulfur and volatiles ISO 5074) uses a ballandring type of mill in which a sample of closely sized coal is ground for a specified number (usually, 60) of revolutionsSolid fuel types for energy generation: Coal and fossil carbon

.jpg)

An investigation of performance characteristics and energetic

2020年8月12日 Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass the energetic efficiency of coal mill has been investigated and performance value has been found to be a maximum value of 962% KEYWORDS: Vertical roller coal mill Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, ChinaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills