Principle of NdFeB rare earth ore grinding machine

.jpg)

Extraction and recovery of rare earth elements from NdFeB waste

1 天前 Bian et al [13] utilized FeO and B 2 O 3 as oxidants to selectively oxidize the REEs in NdFeB waste, achieving a conversion rate of 995% for REEs into rare earth oxides, with a purity reaching 98% Tetsuya Uda et al [14] employed FeCl 2 and activated carbon to react with 2024年4月1日 Rare earth (RE) permanent magnets are essential components for successful green and digital transition This paper extensively reviews the properties, recycling potential, An overview of NdFeB magnets recycling technologies2024年11月27日 We conducted a mechanistic and experimental study on zinc fluoride roasting for the recovery of NdFeB waste to address the difficulties faced during this pyrometallurgical Mechanism and Experimental Study on the Recovery of Rare Earth 2016年9月20日 NdFeB permanent magnets contain about 31–32 wt% of rareearth elements (REEs) Recycling of REEs contained in this type of magnets from the EndofLife (EOL) products will play an important and complementary role REE Recovery from EndofLife NdFeB Permanent

.jpg)

Energy efficient process for recovery of rare earths from spent

2021年5月1日 Rare earths from the spent NdFeB magnet were selectively recovered by roasting with 3 times stoichiometric amount of NH 4 Cl at 300 °C temperature for 3 h and subsequent 2015年6月14日 The topics covered are: world rare earth resources and production; ore processing and separation of individual rare earths; reduction, refining, and ultrapurification of Recovery of rare earth elements from NdFeB based grinding slurries2018年5月25日 Recycling rareearth elements (REEs) from NdFeB magnet waste is an important step toward building a sustainable REE supply chain In this study, we describe an Selective Extraction of RareEarth Elements from NdFeB Magnets 2023年9月30日 To address this issue, we conducted tests using a flash furnace to explore the lowtemperature reduction behavior of NdFeB magnet scraps under an H2 atmosphere based on thermodynamic calculations comparing the Separation and Recovery of Rare Earths and Iron from

.jpg)

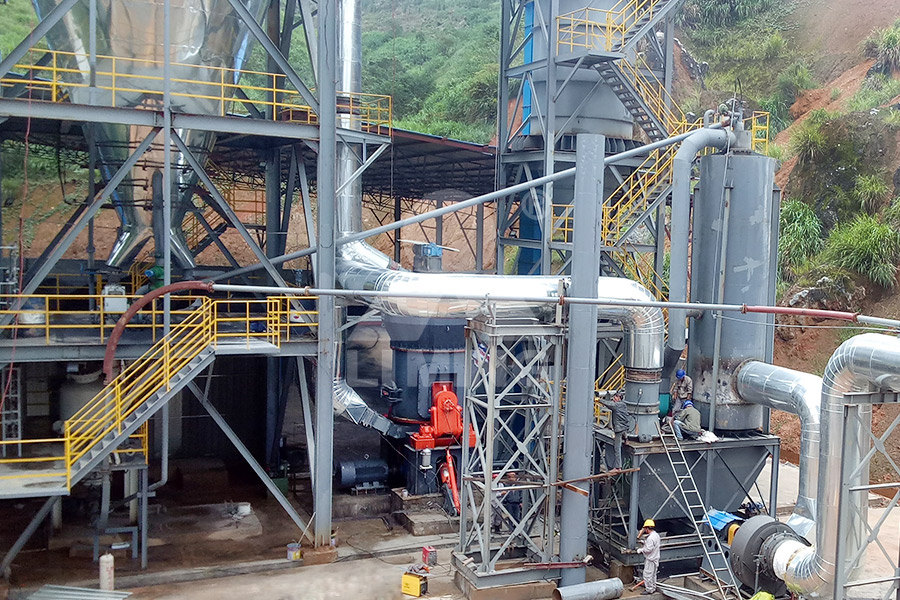

NdFeB Powder Making Process Grinding Plant

2023年12月14日 Material: NdFeB scrap Capacity: 40,000 tons/year Finished product particle size: 300 mesh Finished product use: rare earth materials Main equipment: MTW European version mill NdFeB Grinding Production Line 2024年4月1日 Rare earth (RE) permanent magnets are essential components for successful green and digital transition This paper extensively reviews the properties, recycling potential, and critical raw material stateoftheart recycling technologies of waste permanent NdFeB magnets (containing about 15–30 wt% REE with high economic value)An overview of NdFeB magnets recycling technologies2017年2月8日 Rare earth magnetsRare earth magnet recycling play an increasingly important role in high end technology, and the manufacture of rare earth magnets, such as the NdFeB type, consume a large amount of the rare earths produced Recycling of this material could provideSelective Sulfation Roasting of Rare Earths from NdFeB 2015年6月14日 A comprehensive review is presented of the extractive metallurgy of rare earths The topics covered are: world rare earth resources and production; ore processing and separation of individual rare Recovery of rare earth elements from NdFeB based grinding slurries

RECOVERY OF RARE EARTH ELEMENTS FROM NDFEB MAGNET

efficient lighting systems and wind turbines[1] However, the regional distribution of rare earth ores in the world is uneven Also caused by the environmental and labors cost of rare earth ore mining, production of the permanent magnet, including smelting, smashing and grinding, 30%40% of NdFeB alloys was wasted as useless materials[10]2023年9月30日 NdFeB magnet scraps contain large amounts of iron, which poses challenges in recycling and greatly hinders the recovery of rare earths through direct hydrometallurgical treatment To address this issue, we conducted tests using a flash furnace to explore the lowtemperature reduction behavior of NdFeB magnet scraps under an H2 atmosphere based on Separation and Recovery of Rare Earths and Iron from NdFeB2024年9月29日 Electronic waste (ewaste) contains valuable rare earth elements (REEs) essential for various hightech applications, making their recovery crucial for sustainable resource management This review provides an overview of the occurrence of REEs in ewaste and discusses both conventional and emerging green technologies for their recovery Conventional A Review of the Occurrence and Recovery of Rare Earth Elements 2020年4月26日 Rare Earth Elements (REEs) are used in many technological applications since their chemical and physical properties allow them to obtain more efficient products, which is especially true for green Recycling Processes for the Recovery of RareEarth Magnets of

REE Recovery from EndofLife NdFeB Permanent Magnet Scrap

2016年9月20日 NdFeB Magnet Production and Market Demand The global annual REE production remained rather constant at about 120,000 tons (counted as oxidesREOs) during 2005–2015, except for two peak years of 2006 and 2009 (~137,000 tons) according to the USGS Minerals Yearbook for Rare Earths published annually during 2010–2016 []Although very little 2023年12月29日 One of the most important and wide range of applications for rare earth (REs) containing materials is the production of permanent magnets Since the 1960s, this class of magnets has given designers and engineers the ability to increase performance, reduce the size of devices and even create applications that would not be possible with other magnet materialsRare Earth Magnets: Manufacturing and ApplicationsNdFeB permanent magnet scrap is regarded as an important secondary resource which contains rare earth elements (REEs) such as Nd, Pr and Dy Recovering these valuable REEs from the NdFeB permanent magnet scrap not only (PDF) Hydrometallurgical Recovery of Rare Earth 2023年2月14日 A sustainable separation concept for largescale recycling of NdFeB magnets under atmospheric pressure was developed by utilizing a combination of two separation concepts known from the literature: (I) selective Recovery of Rare Earth Elements from NdFeB

.jpg)

Hydrometallurgical Recovery of Rare Earth Elements from NdFeB

About 20–30 wt% scrap is generated during the NdFeB magnets cutting and grinding for extraction of rare earths from primary ores Many process steps required2014年11月14日 PDF A chemical process which consumes a minimum amount of chemicals to recover rareearth metals from NdFeB magnets was developed The recovery of Find, read and cite all the research you (PDF) From NdFeB magnets towards the rareearth oxides: A 2023年11月13日 Rare earth is a crucial mineral resource that has significant applications in the electronic device industry In recent years, with the continuous improvement and updating of various electronic devices, electric vehicles have been promoted globally The excellent properties of rare earth fluorescent materials have made rare earthcontaining electronic devices widely Recycling NdFeB Magnets and Rare Earth Fluorescent Materials Metals 2020, 10, 841 5 of 34 Figure 4 NdFeB demand and net supply from EndofLife (EOL) magnets (losses during collection and disassembly have been subtracted) [41]; published by Elsevier, 2016Hydrometallurgical Recovery of Rare Earth Elements from NdFeB

.jpg)

Life Cycle Assessment studies of rare earths production

2021年6月1日 By expanding gravimetric separation to finegrained ore and to sediment systems (loess deposits, shallow to deep marine muds), the grain size of the tailings can be still in the medium silt to 2020年3月1日 Makarova et al (2020), studied the electrochemical leaching of Fe and rare earths from NdFeB magnets, using sulfuric acid as a leaching agent and oxalic acid to precipitate the REEElectrochemical leaching of rareearth elements from spent NdFeB 2014年2月27日 Permanent magnets from NdFeB, with a typical chemical formula of Nd 2 Fe 14 B, are widely used for wind turbines, electric vehicles, robotics, and hard disk drives (ISO, 2020)Life Cycle Inventory of the Production of Rare Earths and the 2017年9月10日 p>The recent technological advancement has made the rare earth elements (REEs) more significant and they in turn have facilitated the culmination of more new technological applications owing to (PDF) A Review of Rare Earth Mineral Processing

.jpg)

Sustainable Recycling of RareEarth Elements from NdFeB

2021年11月17日 The rare earth content (about 30 wt%) of these magnet scraps is generally higher than that of raw ore, and the recovery of rare earth elements from them helps to stabilize the global rare earth Therefore, rare earths recovered from waste residue would reduce the demand of rare earth elements from primary sources In this study, the feasibility of recycling rare earths through a hydrometallurgical process was investigated The selective leaching of Nd from grinding sludge can successfully raise the rare earths concentration to 70% TheSelective Extraction and Recovery of Rare Earth Metals (REMs)2018年8月9日 p>Sintered NdFeB as a thirdgeneration rare earth permanent magnet material, has been in rapid development since 1980’s due to its broad industrial applications and high electromagnetic performanceNew Technology of Making NdFeB by Sintering ResearchGate2012年1月1日 Hightechnology rare earth elements comprising of the 15 lanthanides (La–Lu), yttrium (Y), and scandium (Sc) are widely used in hightechnology industrial and consumer productsReview of methods for the rare earth metals recycling Annual

.jpg)

Separation and Recovery of Rare Earths and Iron from NdFeB

2023年9月30日 PDF NdFeB magnet scraps contain large amounts of iron, which poses challenges in recycling and greatly hinders the recovery of rare earths through Find, read and cite all the research you NdFeB Magnet Supplier, Rare Earth Magnet, Permanent Magnet Manufacturers/ Suppliers Nanjing Huajin Magnet Co, Ltd Menu Sign In Join Free Our production line also contains centerless grinding machines, ultrasonic punch and linear cutting machine all of which make us capable of machining very special shapes of magnet, and NdFeB Magnet Manufacturer, Rare Earth Magnet, Permanent 2018年11月7日 A new recycling process for the extraction of rare earths from neodymium–iron–boron (NdFeB) magnet scrap is being developed, based on the direct extraction of rare earths from endoflife (PDF) An Exante LCA Study of Rare Earth Extraction from NdFeB 2022年9月27日 China's dominance in rare earth production and supply along with an increase in the available NdFeB magnets in the market [1], strongly motivates the recovery of rare earth elements from secondary (PDF) Recovery of Rare Earth Elements from Spent NdFeB

Mineral Processing and Extractive Metallurgy of the Rare Earths

2015年12月25日 In Chap 2, the most important occurrences of the rare earths were describedThis chapter will deal with what happens when the rare earths have been mined It answers the question: how are the ores processed? Mineral processing (sometimes called mineral dressing or ore dressing) is the preparation of ore from the stage that the material is 2023年12月14日 Material: NdFeB scrap Capacity: 40,000 tons/year Finished product particle size: 300 mesh Finished product use: rare earth materials Main equipment: MTW European version mill NdFeB Grinding Production Line NdFeB Powder Making Process Grinding Plant2024年4月1日 Rare earth (RE) permanent magnets are essential components for successful green and digital transition This paper extensively reviews the properties, recycling potential, and critical raw material stateoftheart recycling technologies of waste permanent NdFeB magnets (containing about 15–30 wt% REE with high economic value)An overview of NdFeB magnets recycling technologies2017年2月8日 Rare earth magnetsRare earth magnet recycling play an increasingly important role in high end technology, and the manufacture of rare earth magnets, such as the NdFeB type, consume a large amount of the rare earths produced Recycling of this material could provideSelective Sulfation Roasting of Rare Earths from NdFeB

Recovery of rare earth elements from NdFeB based grinding slurries

2015年6月14日 A comprehensive review is presented of the extractive metallurgy of rare earths The topics covered are: world rare earth resources and production; ore processing and separation of individual rare efficient lighting systems and wind turbines[1] However, the regional distribution of rare earth ores in the world is uneven Also caused by the environmental and labors cost of rare earth ore mining, production of the permanent magnet, including smelting, smashing and grinding, 30%40% of NdFeB alloys was wasted as useless materials[10]RECOVERY OF RARE EARTH ELEMENTS FROM NDFEB MAGNET 2023年9月30日 NdFeB magnet scraps contain large amounts of iron, which poses challenges in recycling and greatly hinders the recovery of rare earths through direct hydrometallurgical treatment To address this issue, we conducted tests using a flash furnace to explore the lowtemperature reduction behavior of NdFeB magnet scraps under an H2 atmosphere based on Separation and Recovery of Rare Earths and Iron from NdFeB2024年9月29日 Electronic waste (ewaste) contains valuable rare earth elements (REEs) essential for various hightech applications, making their recovery crucial for sustainable resource management This review provides an overview of the occurrence of REEs in ewaste and discusses both conventional and emerging green technologies for their recovery Conventional A Review of the Occurrence and Recovery of Rare Earth Elements

.jpg)

Recycling Processes for the Recovery of RareEarth Magnets of

2020年4月26日 Rare Earth Elements (REEs) are used in many technological applications since their chemical and physical properties allow them to obtain more efficient products, which is especially true for green 2016年9月20日 NdFeB Magnet Production and Market Demand The global annual REE production remained rather constant at about 120,000 tons (counted as oxidesREOs) during 2005–2015, except for two peak years of 2006 and 2009 (~137,000 tons) according to the USGS Minerals Yearbook for Rare Earths published annually during 2010–2016 []Although very little REE Recovery from EndofLife NdFeB Permanent Magnet Scrap