Ore grinding machine working video performance

Ball Mill the Key Equipment for Stone Ore Grinding YouTube

The robust and efficient ball mill from The Nile Machinery, designed for highperformance grinding in the mining and mineral processing industry This video 2024年5月14日 The technology excels in reducing ore size and achieving high throughput rates with a reasonable degree of process scalability and flexibility Overall, they do a 'very fine job' Higher performing liners + fast relining = higher throughputThere are a few factors that can affect ore grinding performance in ball mills Some of these factors include the size and shape of the mill balls, the type of feed material being processed, Factors affecting ores grinding performance in ball mills2017年4月1日 Within the scope of the study, ore grinding performance of the VRM was investigated via a mobile grinding plant and relationships between operational parameters Operational parameters affecting the vertical roller mill

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore Grinding mills operate on the principle of breaking down ore particles into smaller sizes through the action of abrasion The primary types of grinding mills include ball mills, rod mills, Understanding the operation of grinding mills in the mining and 2017年10月26日 Increased circulating load decreases overgrinding and provides the media with an effectively narrower size distribution to work on However, it meets with diminishing returns Factors Affecting Ball Mill Grinding Efficiency2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral Processing

Ball Mill JXSC Mineral

Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel balls, or ceramic are used in the collision Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron oreOur Dynamic HPGR Technology for Mineral Grinding Weir2018年8月17日 Further, the grinding mills can be categorized into three major types — rod mills, ball mills, and SAG mills So, which one is for you? Well, the answer essentially lies in the feed size and the Grinding Mills — Types, Working Principle Ball Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are Ball Mill Grinding Machines: Working Principle,

Surface Grinding Machine working Video Manufast

Surface Grinding Machine Working VideoManufast gives manufacturing services from prototype to mass productionvisit https://manufast/ us contact@manuThe ball mill machine is known as a ball grinding machine It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training in mining, grinding, screening, crushing plantBall Mill JXSC MineralIdeal for large quantities The Planetary Mill PULVERISETTE 5 classic line with 4 working chemical industry, etc, it has two ore grinding Compare this product common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and Ore mill, Ore grinding mill All industrial manufacturers2023年11月13日 Selecting the appropriate feeder for a mineral processing plant ensures efficient and effective operations Feeders are responsible for transferring material from storage to the processing equipment, and their performance can significantly impact the plant’s overall productivity Factors Affecting Feeder Selection: Particle size Feed rate Moisture content How to Select the Best Feeder for Your Ore Processing Plant?

Ore Grinding Machines: Ball Mill, Rod Mil Grinding Media

Ore grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;The Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and operation of grinding machines These laws include Kick's law, Bond's law, and Rittinger's lawUnderstanding the SAG Mill in Copper Ore Mining Process2020年4月16日 Hammer Mill Machine : Working Principle and Application By Senieer / April 16, 2020 Hammer Mill grinder is the most broadly utilized in grinding mills for pharmaceutical and chemical and food processing The panel has a display box through which you can monitor the performance and operation of a hammer mill 3Hammer Mill Working Principle Application SenieerChina Ore Processing Machine wholesale MiningMachinery Small Industrial Used Grinding Fine Powder in Gold Ore Processing Plant Gear Transmission Ceramic Grinding Ball Mill Milling Machine Ore Powder US$ 65008500 / Set 1 Set (MOQ) Zhengzhou Zhongjia Heavy Industry Co, Custom solutions ensure optimal performance and efficiency, Ore Processing Machine MadeinChina

Wet Pan Mill JXSC

Our wet pan mill is a popular gold and silver ore grinding machine in Africa and South America Because of its low investment, Explore Video >> Why Choose Our Wet Pan Mills Grinding Wheel Thickened grinding We design our When iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS The six main steps of iron ore processing Multotec2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant2018年10月1日 Grinding Machine Definition A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the materialIt is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece Generally, the grinding is a type of finishing operation to make sure that there is high surface quality, Grinding Machine: Types, Parts, Working Operations (With PDF)

Grinding Modeling and Energy Efficiency in Ore/Raw Material

2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration 67% and filling ratio 35% For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding 2017年2月21日 In samplingmills the shakingtray is generally used on account of the ease with which the rate of feed can be inspected, and the great facility with which such feeders can be cleaned after each lot of ore has been run For finegrinding machines, the coffeemill type still successfully holds its own against most of the newer devices, although Ore Sampling Methods: Good Proper 911Metallurgist2022年5月11日 The employees of the United Grinding Group – over 2500 strong characters with their own history – make us successful Our brands and companies make us what we are: one of the leading manufacturers of precision machines for grinding, eroding, laser machining, combination machining and measuringSix Tips for Optimizing the Performance of Your Grinding Machine2021年8月27日 The grinding wheel is the most important and unique part of the electrochemical grinding machine It is connected to the negative terminal of the power supply and acts as the cathode The grinding wheel is made of insulating materials such as diamond and aluminum oxide The wheels rotate and increase the flow of the electrolyteElectrochemical Grinding: Definition, Parts or Construction, Working

CHROME WASH PLANT Pineer Mining Machinery

Pineer mining machinery company could supply a full list of chrome wash plant machinery and help customers to install up whole wash plant Skip to content PLANT WORKING VIDEO to grinding ore into about 100200 mesh, and liberate out useful mineral ore contained by quartz2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant2024年4月26日 These mills utilize the ore itself as the grinding media, reducing the need for additional grinding media AG/SAG mills are typically used for coarse grinding, where large pieces of ore are efficiently broken down The grinding Iron Ore Processing: From Extraction to Manufacturingiii Abstract Buzwagi Gold Mine (BGM) is operated by Acacia Mining and located in the Lake Victoria Goldfields of central Tanzania The mine commenced its operation since AprilOptimization and Performance of Grinding Circuits: The Case

What is Powder Grinding Mill? JXSC Machine

2021年11月27日 The main host machine is composed of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, a cover, and a motor Auxiliary equipment includes jaw crusher, bucket elevator, electromagnetic vibrating It suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 7(the Moh’s hardness) Such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etcVertical Roller Mill SBM Ultrafine Powder TechnologyRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermillOne contribution to minimise the increase is to use more efficient comminution equipment Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented hereResearch of iron ore grinding in a verticalrollermill

.jpg)

High Performance Mineral Ore Washing Machine Log Washer

High Performance Mineral Ore Washing Machine Log Washer, Working Principle: This machine drive the spiral stirring shaft depends on speed reducer and rotate in different directions, Ltd is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, A Wet Pan Mill also known as an amalgamation grinding mill, or gold grinder mill, is a versatile ore grinding pan mill for wet materials It’s the best replacement for a mediumsmall capacity ball mill, owing to its excellent performance for wet crushing, small investment, and high outputWet Pan Mill Ore Grinding Equipment JXSC Machine2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems and been Grinding SpringerLink2012年12月28日 A comparative study was carried out to investigate the effect of highpressure grinding rolls (HPGR) comminution on agitation leaching of gold ore in comparison with the conventional jaw crusher Optimizing the performance of highpressure grinding roll based ore

.jpg)

Grinding Mills — Types, Working Principle

2018年8月17日 Further, the grinding mills can be categorized into three major types — rod mills, ball mills, and SAG mills So, which one is for you? Well, the answer essentially lies in the feed size and the Ball Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are Ball Mill Grinding Machines: Working Principle, Surface Grinding Machine Working VideoManufast gives manufacturing services from prototype to mass productionvisit https://manufast/ us contact@manuSurface Grinding Machine working Video ManufastThe ball mill machine is known as a ball grinding machine It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training in mining, grinding, screening, crushing plantBall Mill JXSC Mineral

.jpg)

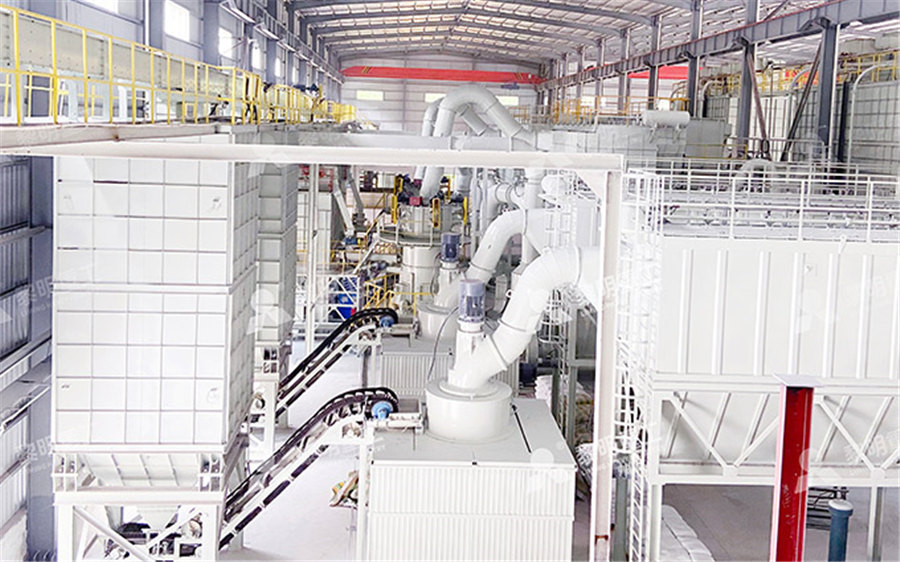

Ore mill, Ore grinding mill All industrial manufacturers

Ideal for large quantities The Planetary Mill PULVERISETTE 5 classic line with 4 working chemical industry, etc, it has two ore grinding Compare this product common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and 2023年11月13日 Selecting the appropriate feeder for a mineral processing plant ensures efficient and effective operations Feeders are responsible for transferring material from storage to the processing equipment, and their performance can significantly impact the plant’s overall productivity Factors Affecting Feeder Selection: Particle size Feed rate Moisture content How to Select the Best Feeder for Your Ore Processing Plant?Ore grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;Ore Grinding Machines: Ball Mill, Rod Mil Grinding MediaThe Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and operation of grinding machines These laws include Kick's law, Bond's law, and Rittinger's lawUnderstanding the SAG Mill in Copper Ore Mining Process

Hammer Mill Working Principle Application Senieer

2020年4月16日 Hammer Mill Machine : Working Principle and Application By Senieer / April 16, 2020 Hammer Mill grinder is the most broadly utilized in grinding mills for pharmaceutical and chemical and food processing The panel has a display box through which you can monitor the performance and operation of a hammer mill 3China Ore Processing Machine wholesale MiningMachinery Small Industrial Used Grinding Fine Powder in Gold Ore Processing Plant Gear Transmission Ceramic Grinding Ball Mill Milling Machine Ore Powder US$ 65008500 / Set 1 Set (MOQ) Zhengzhou Zhongjia Heavy Industry Co, Custom solutions ensure optimal performance and efficiency, Ore Processing Machine MadeinChina