Heavy calcium crushing feed volume is 36 mechanical equipment

Calcium carbonate milling process SBM Ultrafine

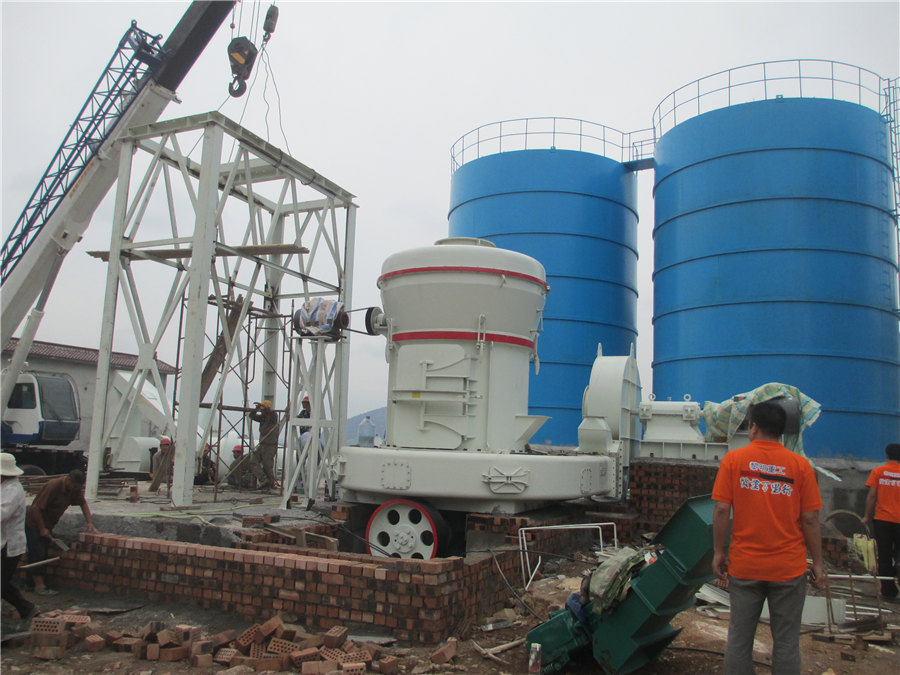

2023年9月19日 Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production Large unobstructed feed opening, heavyduty breaker plates and heavy rotor are designed to accept big feed size for high production These features maximise loading, and with a bigger MEKA CRUSHING SCREENING AND CONCRETE BATCHING 2020年3月19日 A crusher that is too small will fail to produce the desired tonnages, thereby limiting yields and profits and capping the growth potential of the organisation A machine that Selecting the right crusher for your operations QuarryMechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are CRUSHERS

.jpg)

Crushing equipment Komatsu

Efficiency and productivity in sizing and feeding can unlock production growth for your operation and we offer material handling systems and expertise to help you do that Our crushing 2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers Types of Crushers: Choosing the Right One for Each Stagethyssenkrupp jaw crushers are mainly designed to crush mediumhard to very hard materials When it comes to the crunch, crushing systems from thyssenkrupp Industrial Solutions offer Industrial Solutions Jaw crushers ThyssenKrupp2016年4月7日 Most crushers used for aggregate production can be categorised as one of three main types: Compression crushers – which squeeze the material until it breaks Impact Selecting the right type of crushing equipment Quarry

.jpg)

Feeders MEKA

MEKA Apron Feeders provide reliable means of controlling the feed rate to prevent surge loads to the Primary Crusher or other plant equipment An Apron Feeder is run at very low speeds and 2015年10月28日 Singletoggle jaw crushers have better feed acceptance capability than the corresponding doubletoggle crushers Jaw crushers are reliable, robust machines, offering a Selecting the Right Crushing Equipment AggNetIS 3612 : 1994 Indian Standard CRUSHING AND GRINDING EQUIPMENT CLASSIFICATION AND METHODSFOR b MEASURINGCAPACITY ( First Revision ) UDC 621*925/*926 : 66012~4IS 3612 (1994): Crushing and grinding equipment Classification 2024年10月28日 The most common heavy equipment types and uses, 36 Heavy Equipment Types (and Uses) With Names Pictures By Rhett C Updated on October 28, 2024 Boom pumps are used in large construction projects 36 Heavy Equipment Types (and Uses) With Names

concrete crushing Heavy Equipment Forums

2011年2月6日 To start the process your gonna need an excavator with a thumb to feed the crushing spread Then the next piece in the lineup would be a primary jaw crusher, which at the least should be 22x34 Next would come a magnet to remove the iron from your concreteThis document provides an overview of crushing in metalliferous mining processing It discusses crushing theory, including definitions of comminution, work index, and specific energy input It also outlines the three main mechanisms of particle fracture: abrasion, cleavage, and shatter The document reviews common types of crushing equipment like jaw crushers and cone crushers Crushing Handbook PDF Mill (Grinding) Belt (Mechanical)Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the Detailed explanation of calcium powder processing machinery and equipment: Ordinary heavy calcium carbonate with d97≥5μm is mainly produced by dry method The News Calcium powder processing machinery and equipment 2023年11月21日 This information holds a significant value for equipment health monitoring, fault diagnosis, and predictive maintenance 21 Specific features and patterns embedded in the mechanical vibration signals, such as frequency, amplitude, and phase, can be linked to specific fault modes or the health status of equipment 26 This association furnishes a potent tool, Advances in vibration analysis and modeling of large rotating

Mechanical Equipment an overview ScienceDirect Topics

Role of image feature enhancement in intelligent fault diagnosis for mechanical equipment: A review Yongjian Sun, Wei Wang, in Engineering Failure Analysis, 2024 Abstract In the modern manufacturing industry, mechanical equipment plays a crucial role Equipment working in harsh environments for a long time is more likely to break down, which can lead to economic losses 2016年2月28日 For heavyduty quarry or openpit mining operations the heavyduty steel apron feeder is the most practical type It can be made in any length to fit in with any type and size of transportation equipment and crusher house arrangement It hasCrushing Equipment Selection 911Metallurgist2024年6月28日 The results demonstrate that the crushing efficiencies of ore crushing particles, raw material crushing particles, and cement crushing particles can respectively reach 807%, 7015%, and 8027% Energy Efficiency Measurement of Mechanical Crushing Based on There are many kinds of grinding and processing equipment for heavy calcium in China Generally, they can achieve the effect of ultrafine production by combining with ultrafine classifier to form an ultrafine processing system However, which production process and equipment is more reasonable needs to objectively evaluate various processes and equipment How To Select The Dry Process Production Line For Heavy Calcium

17 Types of Heavy Equipment Commonly Used in

2020年4月8日 Construction projects typically rely on several types of heavy equipment to get the job done in a timely, safe, and costeffective manner Depending on the size and scope of the construction project, you’ll probably Sale and rental et location Crushers, Conveyors, Screeners, Trommels Exclusive McCloskey heavy equipment distributor in QuebecAULT Heavy equipment distributor Quebec, Ontario HUGE FEED OPENING with MASSIVE HP in a COMPACT PACKAGE! Quiet and Burns LESS FUEL A “SWISS ARMY KNIFE CONCEPT” LOADED with FEATURES! ABLE to TACKLE ANY JOB! DESIGNED from Customer INPUT Rebel Crusher For Sale Rebel Concrete Crusher RR2023年5月15日 Two types of nonspherical particle units are used in the numerical simulation: (1) particle clumps and (2) particle clusters 33A particle clump can simulate irregular granular materialsMechanical behavior and particle crushing of irregular granular

Heavy Media Separation Process 911Metallurgist

2016年5月22日 The heavymedia feed, crushed to the proper size, is screened, washed and drained on the Vibrating Screen to eliminate as much of the fines as possible The fines removed will usually range from ¼” to 10mesh and be reserved for separate processing by gravity or flotation methodsIt is therefore extremely important to consider all individual milling parameters in order to make an informed choice: material properties, feed size and volume of the sample, grinding time and desired final particle size, any abrasion of the grinding parts ‘ all these factors are significantCrushers, Pulverizers, Grinders Lavallab2018年11月19日 PDF The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Generally, the ability of Find, read and cite all the research you need (PDF) Comminution in mineral processing ResearchGateHeavy calcium carbonate (commonly known as heavy calcium) is the first filler in the world coating industry, it is not only cheap, can greatly reduce the production cost of coating, as one of the functional fillers, it can affect many properties of the coating, such as changing the mechanical strength of the coating, improve the water resistance, resistance to powder and so on4 Steps to Build a Calcium Carbonate Processing Plant Zenith

43.jpg)

Crushing Energy Work of Crushing Machines 911Metallurgist

2016年3月5日 while the 5stamp mill has an output of 225 tons with 336 estimated hp, or 25,916 x 2¼/336 = 17,300 units of reduction The mechanical efficiencies are then as 1:059 in favor of the Nissen stamp The compiler of the figures stated that the power consumption was 50% less for the Nissen stamp The above figures more than bear this out2017年3月4日 A simplified model (kinematic diagram) of the mechanism of the double buckling jaw crusher is shown in Fig 20 The mechanism in question is a six membered mechanism formed by attaching a binary SIZE REDUCTION BY CRUSHING METHODS ResearchGateproduction and heavy duty build, packaged for efficiency and mobility Specifications Engine 166 kW (225 Hp) Feed Opening** 1016mm (40") x 610mm (24") Crusher Speed 300 rpm Grizzly Feeder 950mm (374") x 3840mm (12'7") Hopper Volume 54m3 (74 yd3) Stockpile Height Main Conveyor 3458mm (11'42") Stockpile Height Side Conveyor 2500mm (8'2 CRUSHING SCREENING STACKING WASHING RECYCLING2024年1月12日 Today’s Techni Waterjet Manufacturing Manager, Jonathan Schlick, has over 20 years experience in the field of industrial machinery After a 12 year career in laser machinery, he moved to waterjets where he’s grown Machines Used in Manufacturing: Full List of

Crushing Principles of Mechanical Crushing 911 Metallurgist

• More crushing in the upper part of the chamber • Less crushing pressure in the lower part of the crusher • Lower forces in the crushing chamber • Gentle crushing without increasing CSS Mantle Geometry 年11月18日 Top 10 Stone Crusher Manufacturers in the World Overview of the Stone Crusher Industry The stone crusher industry is integral to the global construction and mining sectors, contributing significantly to the production of essential materials used in infrastructure development and various industrial applicationsThe 10 Best Crusher Manufacturers Brands in 年6月30日 Research the modelling and automation of crushing equipment Develop a mathematical model of a cone crusher Identify the effect of plant capacity on the crusher’s current and drive powerModeling and Improving the Efficiency of Crushing EquipmentThis is why we explain the basics of crushing equipment Find Us On: 6102732066 About Why Kemper; Our Mission; Our Team; Careers; Equipment Most crushing equipment is designed with heavy plates or jaws used to apply pressure to whatever material have been fed into the Split Feed Crushers; Glass Crushers; Gyratory Crushers Crushing Equipment 101

Crushing Plant Flowsheet DesignLayout 911Metallurgist

2016年3月11日 Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushing In the majority of cases, the last crushing stage is closed circuited using anywhere from 10MM (3/8″) square to 14MM (9/16″) slotted openings on the sizing deck2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder Kemper Equipment's aggregate conveyors help we recommended a REMCO 4060 ST/AR VSI, with a 36" feed conveyor The producer is so confident in the profitability of to make up for lost production Kemper got to work quickly, installing a NEW 2 phase plant that utilizes Terex MPS crushing and screening equipment, a Kemper custom 80 Aggregate Conveyor Systems Kemper Equipment2023年12月16日 The complexity of coal and gas outburst as mine disasters is immense, and they pose a severe threat to the safety of underground employees and inflict significant damage to coal mine production (Dennis, 2019; Hou, 2021; Zhang et al, 2023a, c)China has attached great importance to coal mine safety and has achieved remarkable results, effectively reducing the Energy Evolution and Coal Crushing Mechanisms Involved in Coal

IS 3612 (1994): Crushing and grinding equipment Classification

IS 3612 : 1994 Indian Standard CRUSHING AND GRINDING EQUIPMENT CLASSIFICATION AND METHODSFOR b MEASURINGCAPACITY ( First Revision ) UDC 621*925/*926 : 66012~42024年10月28日 The most common heavy equipment types and uses, 36 Heavy Equipment Types (and Uses) With Names Pictures By Rhett C Updated on October 28, 2024 Boom pumps are used in large construction projects 36 Heavy Equipment Types (and Uses) With Names2011年2月6日 To start the process your gonna need an excavator with a thumb to feed the crushing spread Then the next piece in the lineup would be a primary jaw crusher, which at the least should be 22x34 Next would come a magnet to remove the iron from your concreteconcrete crushing Heavy Equipment ForumsThis document provides an overview of crushing in metalliferous mining processing It discusses crushing theory, including definitions of comminution, work index, and specific energy input It also outlines the three main mechanisms of particle fracture: abrasion, cleavage, and shatter The document reviews common types of crushing equipment like jaw crushers and cone crushers Crushing Handbook PDF Mill (Grinding) Belt (Mechanical)

News Calcium powder processing machinery and equipment

Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the Detailed explanation of calcium powder processing machinery and equipment: Ordinary heavy calcium carbonate with d97≥5μm is mainly produced by dry method The 2023年11月21日 This information holds a significant value for equipment health monitoring, fault diagnosis, and predictive maintenance 21 Specific features and patterns embedded in the mechanical vibration signals, such as frequency, amplitude, and phase, can be linked to specific fault modes or the health status of equipment 26 This association furnishes a potent tool, Advances in vibration analysis and modeling of large rotating Role of image feature enhancement in intelligent fault diagnosis for mechanical equipment: A review Yongjian Sun, Wei Wang, in Engineering Failure Analysis, 2024 Abstract In the modern manufacturing industry, mechanical equipment plays a crucial role Equipment working in harsh environments for a long time is more likely to break down, which can lead to economic losses Mechanical Equipment an overview ScienceDirect Topics2016年2月28日 For heavyduty quarry or openpit mining operations the heavyduty steel apron feeder is the most practical type It can be made in any length to fit in with any type and size of transportation equipment and crusher house arrangement It hasCrushing Equipment Selection 911Metallurgist

Energy Efficiency Measurement of Mechanical Crushing Based on

2024年6月28日 The results demonstrate that the crushing efficiencies of ore crushing particles, raw material crushing particles, and cement crushing particles can respectively reach 807%, 7015%, and 8027% There are many kinds of grinding and processing equipment for heavy calcium in China Generally, they can achieve the effect of ultrafine production by combining with ultrafine classifier to form an ultrafine processing system However, which production process and equipment is more reasonable needs to objectively evaluate various processes and equipment How To Select The Dry Process Production Line For Heavy Calcium