Model parameters of Calcite European version grinding mill in Pingxiang City, Jiangxi Province

Analysis of grinding aid performance effects on dry fine milling of

2022年3月1日 Influences of different grinding aids on dry fine grinding of calcite using a laboratorytype ball mill were investigated Tested grinding aids had affected the flowability Moreover, some researchers have focused on the effects of grinding aids on the Analysis of grinding aid perfo2022年1月1日 Various factors affect grindability, which can be generally divided into three main categories such as material properties (mineralogy, physical properties, etc), machine The effects on the grinding parameters of chemical, morphological operating parameters on fine particle grinding in a vertically stirred media mill, Separation Science and Technology, 52:6, 11431152, DOI: 101080/2016 To link to this article Effect of operating parameters on fine particle grinding in a

.jpg)

The Evolution of Grinding Mill Power Models Mining,

2019年1月30日 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with HoggFuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operations Then, we show how this model was on the 2020年3月8日 The optimization of the operating parameters of a stirred media mill in the dry grinding of calcite was investigated A threelevel BoxBehnken design was used for the purpose of examining the Optimization of Operating Parameters on Dry 2016年4月30日 Identification of Optimal Mill Operating Parameters during Grinding of Quartz with the Use of Population Balance Modeling April 2016 KONA Powder and Particle Journal 2017(34)Identification of Optimal Mill Operating Parameters during Grinding 2014年10月20日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection (PDF) Population balance model approach to ball mill optimization

.jpg)

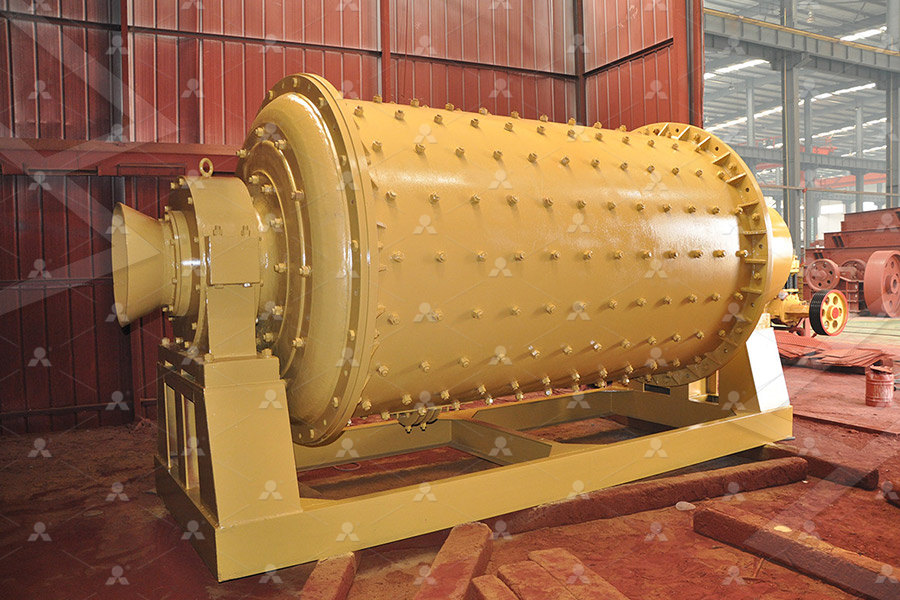

Calcite Grinding Mill

There are five models of calcite grinding mill: HGM80, HGM90, HGM100, HGM125 and HGM1680L, both ultra fine grinding mill Finished production fineness: 250meshes2500meshes, 574 micron Capacity (ton/hour): ranges from 04T/H to 30T/H Parameters of HGM series ultrafine mill; Model:2023年6月25日 Pingxiang in east China's Jiangxi Province is renowned as the "Pearl of Western Jiangxi" The city is predominantly characterized by rolling hills, but when considering the overall topography, it exhibits a complex distribution of mountains, hills and basins that all combine to create a diverse and intricate landscapePingxiang, the pearl of western Jiangxi CGTN2022年1月1日 Then, Si and Bi,j equations were determined from the size distributions at different grinding times, and the model parameters (Si, aT,α,γ, and φj) were compared for five different mill speed The effects on the grinding parameters of chemical, 2017年1月10日 This paper evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through size reduction under different Effect of operating parameters on fine particle grinding in a

.jpg)

Calcite Ultrafine Grinding Mill

Calcite ultrafine grinding mill machine is a highefficiency, energysaving, stable, and environmentally friendly industrial ultra fine grinding mill equipment +17 [ protected] language Parameters of HGM series ultrafine 2021年4月1日 The results also found that the Kwade stress energy model is applicable to this mill and The paper is aimed to investigate the influence of operating parameters on dry fine grinding of calcite The Influence of Stirred Mill Orientation on Calcite GrindingCLIRIK is China processional industrial grinding mill manufacturer, has established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, vertical roller mill, Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and soonClirik calcite powder makingDue to complex dynamic characteristics of the ball mill system, it is difficult to measure load parameters inside the ball mill It has been noticed that the traditional singlemodel and ensemblemodel based soft sensor approaches demonstrate weak generalization power Also, mill motor current, feature subsets of the shell vibration and acoustical frequency spectra contain Modeling Load Parameters of Ball Mill in Grinding Process Based

PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED

2021年6月17日 Abstract The authors analyze the influence of the semiautogenous (SAG) mill parameters on the mill grinding efficiency, energy consumption and the tangential cumulative contact energy This paper provides a new liner parameter design and optimization method, which offers theoretical guidance for the optimization design of liner parameters2016年10月22日 Based on the energy balance calculation of heterogeneous grinding, energy split factors (ESFs) of components in the ballandrace mill at different grinding time are firstly computed These two energies are calculated by the modified model with parameters in the mixture and single breakage, respectivelyInvestigation of Energy Consumed Characterization of Mixture Grinding 2020年3月9日 The impacts of grinding on the structural characteristics of calcite particles were characterized by XRD analysis XRD measurements indicated that no change was observed in the peak areas of ground calcite specimens compared to the untreated calcite specimen Keywords: dry grinding; operating parameters; calcite; experimental design Grinding of Calcite in a Stirred Media Mill Using the Box 2012年8月17日 Pingxiang Mining Area in Jiangxi Province is one of the major coalproducing areas and is prone to serious coal and gas outburst, therefore, it is of significance to research on gas geological features and its controlling factors Based on the analysis of gas data collected from geological exploration and coal mining, the research reveals that the features of gas Features of gas geology and its main controlling factors in Pingxiang

Optimization of Wet Grinding Parameters of Calcite Ore in Stirred Ball Mill

Çukurova Üniversitesi Mühendislik Mimarlık Fakültesi Dergisi, 33(3), ss 225236, Eylül 2018 Çukurova University Journal of the Faculty of Engineering and Architecture, 33(3), pp 225236, September 2018 ÇÜ Müh Mim Fak Dergisi, 33(3), Eylül 2018 225 Optimization of Wet Grinding Parameters of Calcite Ore in Stirred2017年1月1日 In this study, series of dry grinding tests were performed in a prototype horizontal stirred mill (42 L) to investigate the effects of operating parameters such as stirrer speed, feed rate, media The Effect of Stirred Mill Orientation on Calcite GrindingChina Grinding Mill wholesale Select 2024 high quality Grinding Mill products in best price from certified Chinese Mining Machine manufacturers, China Crusher suppliers, wholesalers and factory on MadeinChinaGrinding Mill MadeinChinaPhase one: raw material crushing Calcite blocks will be crushed to 15mm50mm by crusher Phase two: grinding Crushed calcite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground Calcite Grinding Mill Calcite Powder Processing Solution

.jpg)

Dry Fine Grinding of Calcite Powder by Stirred Mill

2012年1月1日 In this study, the effects of various operating parameters, such as grinding time (minute), stirrer speed (rpm), feed quantity (% of ball weight), ball filling ratio (%) on fine grinding of 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of 2015年12月31日 This work investigated the size reduction process of calcined black talc using a high energy CJXXM planetary mill The grinding effects of two different grinding media, aluminia and zirconia, and Research on Superfine Grinding Process and Kinetics of 2017年9月11日 The results of the grinding tests on cement material together with its breakage results obtained from 2 cm and 4 cm diameter beds were used in the model fitting of the mill by using perfect mixing (PDF) Performance Evaluation of Vertical Roller Mill in Cement Grinding

.jpg)

The Evolution of Grinding Mill Power Models Request PDF

2019年1月30日 Request PDF The Evolution of Grinding Mill Power Models Model parameters required for scaleup have been estimated in a 380mmdiam (15in diam) batch mill2022年1月1日 Calcite, in other words, calcium carbonate (CaCO 3), is a glassy shimmer, transparent, easily breakable, large crystal marble mineralIts Mohs hardness is 3 and specific gravity is in the range of 26–28 It is micronized by grinding then classification processes are applied, and offered to the user as natural ground or ground and coated calcite according to The effects on the grinding parameters of chemical, 2011年1月31日 An experimental study on the fine grinding of calcite powder (d50=6216μm) using a 075l laboratory stirred ball mill has been carried out The effects of various operating factors, such as A study on the effect of process parameters in stirred ball mill2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid mass fraction, grinding media size, media filling ratio, and grinding time have been investigated using a vertical type stirred media mill The results are evaluated on the basis of mean particle Effect of Operating Parameters on the Breakage Process of Calcite

.jpg)

(PDF) Matrix Model Simulation of a Vertical Roller Mill with High

2014年5月1日 Onsite operational tests were performed in OMYA's limestone processing plant in Eger, Hungary, on a technology with Pfeiffer's 2800 C vertical roller grinding mill The matrix model of the operating parameters on fine particle grinding in a vertically stirred media mill, Separation Science and Technology, 52:6, 11431152, DOI: 101080/2016 To link to this article Effect of operating parameters on fine particle grinding in a 2019年1月30日 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with HoggFuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operations Then, we show how this model was on the The Evolution of Grinding Mill Power Models Mining, 2020年3月8日 The optimization of the operating parameters of a stirred media mill in the dry grinding of calcite was investigated A threelevel BoxBehnken design was used for the purpose of examining the Optimization of Operating Parameters on Dry

Identification of Optimal Mill Operating Parameters during Grinding

2016年4月30日 Identification of Optimal Mill Operating Parameters during Grinding of Quartz with the Use of Population Balance Modeling April 2016 KONA Powder and Particle Journal 2017(34)2014年10月20日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection (PDF) Population balance model approach to ball mill optimization There are five models of calcite grinding mill: HGM80, HGM90, HGM100, HGM125 and HGM1680L, both ultra fine grinding mill Finished production fineness: 250meshes2500meshes, 574 micron Capacity (ton/hour): ranges from 04T/H to 30T/H Parameters of HGM series ultrafine mill; Model:Calcite Grinding Mill2023年6月25日 Pingxiang in east China's Jiangxi Province is renowned as the "Pearl of Western Jiangxi" The city is predominantly characterized by rolling hills, but when considering the overall topography, it exhibits a complex distribution of mountains, hills and basins that all combine to create a diverse and intricate landscapePingxiang, the pearl of western Jiangxi CGTN

The effects on the grinding parameters of chemical,

2022年1月1日 Then, Si and Bi,j equations were determined from the size distributions at different grinding times, and the model parameters (Si, aT,α,γ, and φj) were compared for five different mill speed 2017年1月10日 This paper evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through size reduction under different Effect of operating parameters on fine particle grinding in a Calcite ultrafine grinding mill machine is a highefficiency, energysaving, stable, and environmentally friendly industrial ultra fine grinding mill equipment +17 [ protected] language Parameters of HGM series ultrafine Calcite Ultrafine Grinding Mill