Grinding technology of ore gypsum mine

.jpg)

An experimental study on the ultrafine grinding of gypsum ore in

2015年12月1日 We determined the properties of the micronized gypsum products obtained in optimal grinding conditions, and the results showed that the dry ball mill grinding process can 2016年4月1日 In the present study, the effect of grinding media shape on breakage parameters was investigated Balls and cylpebs were used as the grinding media It was observed that the An experimental study on the ultrafine grinding of gypsum ore in 2024年5月20日 In this study, the effects of truncated ellipsoids and cubes on the particle size distribution of a UG2 ore were compared to the spheres using the response surface Effect of grinding media shape on the particle size distribution of 2020年7月1日 Grinding aids (GAs) have been an important advent in the comminution circuits Over the last few decades, in order to address the high energy consumption and scarcity of A critical review on the mechanisms of chemical additives used in

Ore Grinding SpringerLink

2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding Gypsum grinding / calcining mills with throughput capacities from 10100t/hr are successfully in operation Mills for much higher throughputs are also available GG: How are your gypsum GLOBAL GYPSUM: GRINDING Gebr PfeifferAn experimental study on the ultrafine grinding of gypsum ore in a dry ball mill Powder Technology, 291, 186–192 doi:101016/jpowtec201512027 101016/jpowtec201512027SciHub An experimental study on the ultrafine grinding of Fine grinding, in particular in the zinc retreatment circuit requiring a milled product P80 of 7 micron, is essential to treat the ores from the Mount Isa Mines depositsISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

An experimental study on the ultrafine grinding of gypsum ore

2016年4月1日 Gypsum has been known for centuries as a building material The earliest known use of gypsum as a building material was in Anatolia, approximately 6000 BC Gypsum has been found on the interiors of the great pyramids in Egypt, which were erected in approximately 3700 BC Gypsum is found on every continent in the world and is among the most widely used Grinding Natural Gypsum Preparation Gypsum Connecting Science and Technology ( Recentlyed No results foundGrinding Natural Gypsum Preparation Gypsum Connecting The preparation of natural and synthetic gypsum prior to calcination, such as drying and grinding The various calcination methods for βhemihydrate and αhemihydrate are reviewed, such as batch kettle, continuous kettle, submerged Calcination Processes Gypsum: Connecting Science gypsum sector, supplying its fi rst mills to the sector in 1963 It is one of the technical leaders in this fi eld, introducing its gypsum grinding and calcining mills in the late 1990s Th ere are 49 MPS VRMs references for gypsum grinding and drying, plus 30 MPS VRMs for gypsum calcining Th ey are very fl exible, whichGLOBAL GYPSUM: GRINDING Gebr Pfeiffer

Ore Pretreatment Methods for Grinding: Journey and Prospects

2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 2022年12月30日 Purpose The purpose of this paper is to evaluate the efficiency of grinding operations in terms of how mechanical properties (eg, strength properties and ore texture) affect the Bond Work Index(PDF) Evaluation of gold ore properties and their impact on grinding 2024年9月13日 The way gypsum is mined depends on the hardness of the gypsum and the size and depth of the deposit If the gypsum is located close to the surface and the deposit is small, simple strip mining technology is employed In strip mining, overburden is removed from above the gypsum layer by large trucks equipped with shovelsHow is Gypsum Mined and Processed? Rock Mineral2013年5月21日 The EM mill has been installed in more than 100 gypsum applications and is a wellknown machine for plaster production This experience is the basis of the state of the art grinding and calcining technology The processes of grinding, drying, calcining and classifying are all executed in one single machineInnovative gypsum processing at GIPS AD

.jpg)

ISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

then at MIM’s McArthur River Mine in 1995 These IsaMills have been used to liberate sphalerite and galena at Mount Isa and silica at McArthur River by grinding to less than 7 micron This paper discusses the IsaMill Technology and reports on the metallurgical performance of the2009年1月1日 Ore from a location, which by the mine is characterised as “hard to drill”, has the lowest resistance to breakage, and the surrounding rock is clearly harder than the magnetite oreProcessing of Magnetite Iron Ores–Comparing Grinding Options2022年10月13日 Grinding plays an important role in mining, construction, metallurgy, chemical, coal and other basic industries In terms of beneficiation, grinding is the most energy consuming operation So, reasonable grinding Research on Grinding Law and Grinding Parameters 2023年1月4日 In this paper, taking the goaf of the gypsum mine in Diaodao District, Jingmen City as an example, through the investigation of the overall structure and distribution characteristics of the gypsum (PDF) Research on monitoring and stability evaluation

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Gypsum Powder Grinding And Processing Plant

2024年1月23日 Gypsum powder is a particle obtained from natural gypsum through crushing, grinding, and calcination It has a wide It has a wide range of applications with the advantages of good market prospects, simple processing The European Commission (EC) maintains the consideration of tungsten as a critical raw material for the European industry, being the comminution stage of tungstenbearing minerals an essential step in the tungsten concentration process Comminution operations involve approximately 3–4% of worldwide energy consumption; therefore, grinding optimization should be a priority In this Grinding Kinetics Study of Tungsten Ore MDPIThe gypsum mine is the main raw material to produce gypsum binder and gypsum building products and the retarder of portland cement After calcining under 600~800°C and adding little catalyst Jaw crusher is used to crush gypsum ore into small size less than 8 mm in the primary crushing processGypsum Ore Crushing Solutions DSMACSBM has been focusing on the field of mining ore crushing and grinding machinery for many years Our grinding equipment can grind 100+ kinds of nonmetallic SBM has rich production experience and mature technology Mine waste rock Sand and gravel aggregate Limestone Ceramic raw materials Slag Send us an InquiryProcessing Materials SBM Ultrafine Powder Technology

HIGH PRESSURE GRINDING ROLLS—A PROMISING AND COST

Technology and technics of ore preparation processes 14 EURASIAN MINING • 1 2015 These grinding rolls exhibited higher capacity and lower energy consumption than was expected A single Polycom24/17 treated over 3 thousand tons of goldbearing copper ore per hour Cerro Verde mine HPGHR grinds 120 thouUnder the background of increasingly scarce ore worldwide and increasingly fierce market competition, developing the mining industry could be strongly restricted Intelligent ore sorting equipment not only improves ore use and enhances the economic benefits of enterprises but also increases the ore grade and lessens the grinding cost and tailings production However, long A review of intelligent ore sorting technology and equipment Invited Review A review of intelligent ore sorting technology and equipment development Xianping Luo1,2,3), , Kunzhong He3), Yan Zhang3), Pengyu He2), and Yongbing Zhang3) 1) Jiangxi Key Laboratory of Highefficiency Development and Application of Tungsten Resources, Jiangxi University of Science and Technology, GanzhouA review of intelligent ore sorting technology and equipment 2023年4月25日 12 Coppernickel sulfide ore grinding stage Adopt a twostage closedcircuit grinding process ① Use a gridtype ball mill for rough grinding And the grinding particle size range is 02~03mm ② Use an overflowtype ball mill for fine grinding And the grinding particle size is less than 5~10μm2 Types of Nickel Ore: Processing Methods and Equipment

.jpg)

A review of intelligent ore sorting technology and equipment

Invited Review A review of intelligent ore sorting technology and equipment development Xianping Luo1,2,3), , Kunzhong He3), Yan Zhang3), Pengyu He2), and Yongbing Zhang3) 1) Jiangxi Key Laboratory of Highefficiency Development and Application of Tungsten Resources, Jiangxi University of Science and Technology, GanzhouFigure 4 : Breakage Rates in Different Grinding Devices V PIN MILLS 7 9 Steel Media Size (mm) 08 16 9 12 6 8 Media Material Various Steel Power Usage to 15 µm (kWh/t) 174 596 375 390 Residence Time to 15 µm (min) 06 154 Grinding Intensity (kW/L) 054 0005 015 018 TOWER ERTICALIMPROVING FINES RECOVERY BY GRINDING FINER Glencore Technology2019年12月15日 However, the demand for finer grinding has set new challenges for grinding technology; new technological advancements in mineral processing, including stirred milling, have opened the door for many new opportunities Lowergrade ore and finely distributed ore require finer grinding than the traditional mill circuit product size (P80) of 75 μmBeneficiation of Gold and Silver Ores SpringerLinkSince SAG mills use ore as part of the grinding media, regular monitoring and control of the ore feed size distribution is recommended as the change in feed size distribution normally results to corresponding changes in the grinding media size distribution, which has further impact on power and throughputAssessment of the Performance of Grinding Circuit for Buzwagi Gold Mine

Gypsum Powder Ultrafine Grinding Mill

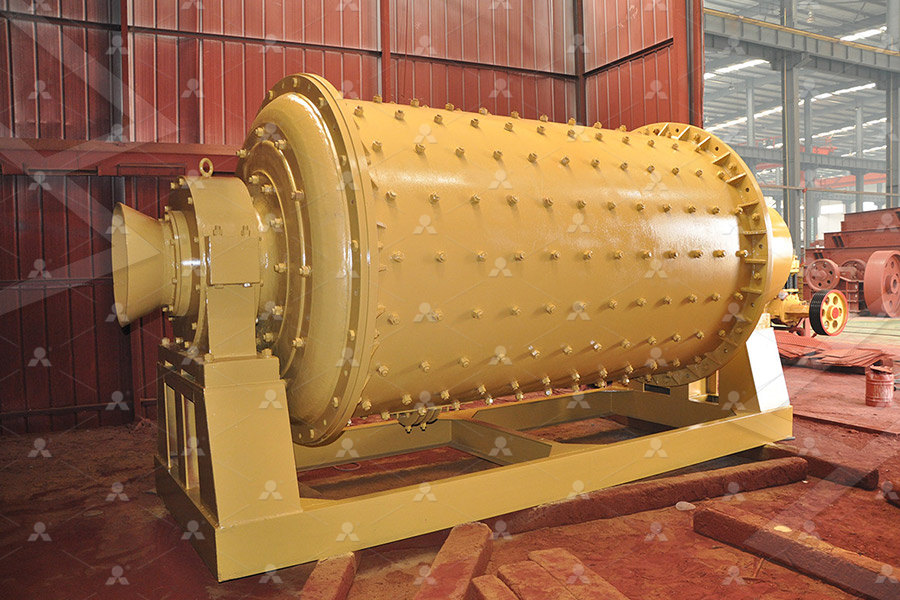

In the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle size requirements of the mill; then use the ultrafine mill for grinding treatment; then enter the boiling furnace for heating treatment, and finally do store 2020年5月17日 Commencing its first mine (Mine No1) in 1955, the company changed its name in 1956 to reflect its overall commitment to the mineral Along with a familyoriented approach to business, Harrison Gypsum believes pursuit of consistent quality leads to cost effective mining and operational efficienciesThe World of Gypsum Mining Digital600X1800, 900X1800, 900X2100, 900X3000 Small Good Grinding Ball Mill for Gold, Mine, Stone, Gypsum Price, Find Details and Price about 600X1800 Ball Mill Grinding Equipment from 600X1800, 900X1800, 900X2100, 900X3000 Small Good Grinding Ball Mill for Gold, Mine, Stone, Gypsum Price Henan Xingyang Mining Machinery Manufactory600X1800, 900X1800, 900X2100, 900X3000 Small Good Grinding 2020年1月16日 Buzwagi Gold Mine (BGM) is operated by Acacia Mining and located in the Lake Victoria Goldfields of central Tanzania The mine commenced its operation since April 2009 and treats a sulphide copper (PDF) Optimization and performance of grinding circuits: the

.jpg)

Gypsum powder processing: The role of grinding mills

Increased Surface Area: By grinding gypsum ore into a fine powder, the surface area increases, which enhances its reactivity and usability in various applications 4 Removal of Impurities: The grinding process helps in separating impurities from the gypsum ore, resulting in a purer final product Types of Grinding Mills for Gypsum Powder The hammer mill, being a shorttime calcining system, grinds, dries, calcines and classifies the raw gypsum in a single step The resulting stucco is suitable for the production of plasterboard, gypsum fiberboard and gypsum wall blocks A hammer mill can process 100% moist FGD gypsum, 100% precrushed natural gypsum, or a mixture of bothCalcining processes for natural and synthetic gypsum Grenzebach2016年4月1日 Gypsum has been known for centuries as a building material The earliest known use of gypsum as a building material was in Anatolia, approximately 6000 BC Gypsum has been found on the interiors of the great pyramids in Egypt, which were erected in approximately 3700 BC Gypsum is found on every continent in the world and is among the most widely used An experimental study on the ultrafine grinding of gypsum ore Grinding Natural Gypsum Preparation Gypsum Connecting Science and Technology ( Recentlyed No results foundGrinding Natural Gypsum Preparation Gypsum Connecting

.jpg)

Calcination Processes Gypsum: Connecting Science

The preparation of natural and synthetic gypsum prior to calcination, such as drying and grinding The various calcination methods for βhemihydrate and αhemihydrate are reviewed, such as batch kettle, continuous kettle, submerged gypsum sector, supplying its fi rst mills to the sector in 1963 It is one of the technical leaders in this fi eld, introducing its gypsum grinding and calcining mills in the late 1990s Th ere are 49 MPS VRMs references for gypsum grinding and drying, plus 30 MPS VRMs for gypsum calcining Th ey are very fl exible, whichGLOBAL GYPSUM: GRINDING Gebr Pfeiffer2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 Ore Pretreatment Methods for Grinding: Journey and Prospects2022年12月30日 Purpose The purpose of this paper is to evaluate the efficiency of grinding operations in terms of how mechanical properties (eg, strength properties and ore texture) affect the Bond Work Index(PDF) Evaluation of gold ore properties and their impact on grinding

How is Gypsum Mined and Processed? Rock Mineral

2024年9月13日 The way gypsum is mined depends on the hardness of the gypsum and the size and depth of the deposit If the gypsum is located close to the surface and the deposit is small, simple strip mining technology is employed In strip mining, overburden is removed from above the gypsum layer by large trucks equipped with shovels2013年5月21日 The EM mill has been installed in more than 100 gypsum applications and is a wellknown machine for plaster production This experience is the basis of the state of the art grinding and calcining technology The processes of grinding, drying, calcining and classifying are all executed in one single machineInnovative gypsum processing at GIPS ADthen at MIM’s McArthur River Mine in 1995 These IsaMills have been used to liberate sphalerite and galena at Mount Isa and silica at McArthur River by grinding to less than 7 micron This paper discusses the IsaMill Technology and reports on the metallurgical performance of theISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL 2009年1月1日 Ore from a location, which by the mine is characterised as “hard to drill”, has the lowest resistance to breakage, and the surrounding rock is clearly harder than the magnetite oreProcessing of Magnetite Iron Ores–Comparing Grinding Options