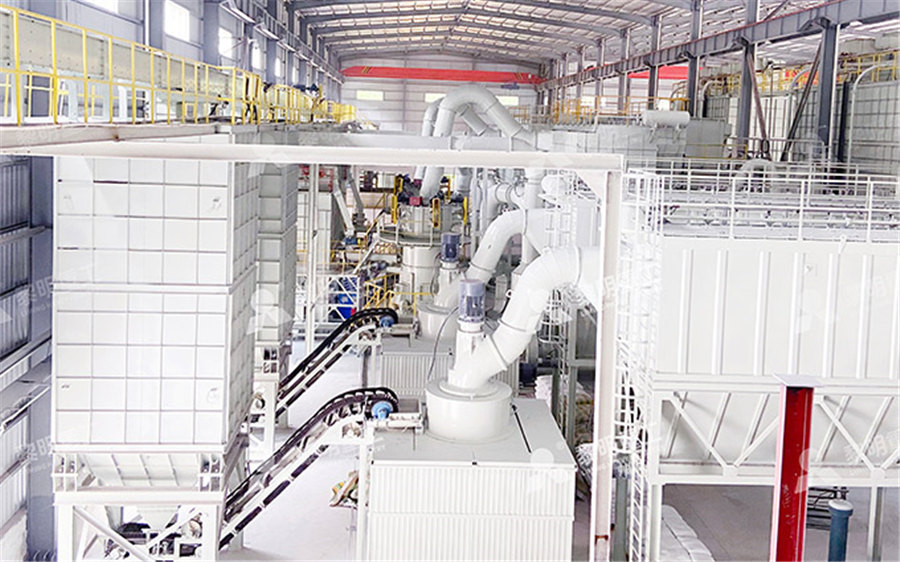

Steel slag mill for slate steelmaking plant

.jpg)

(PDF) Iron and Steel Slags ResearchGate

2017年3月5日 The physicochemical properties of four different types of iron and steel slags, including blast furnace slag, basic oxygen furnace slag, electric arc furnace slag, and ladle furnaceSteel Slag Grinding Plant Materials: Steel slag Main equipment: GRMSS Steel Slag Vertical Mill Applications: Roads, building materials, soil amendments, sewage treatmentSteel Slag Grinding Plant CHAENG2019年7月1日 Large volumes of slags are formed as byproducts during the refinement of pig iron by basic oxygen steelmaking or electric arc furnace steelmaking In order to lower the The recycling and reuse of steelmaking slags — A review2020年10月15日 Capturing CO 2 by steel slag (SS) via mineralization is regarded to be an excellent choice due to the high basicity of the slag In this paper, recent research on the steel slagbased carbon capture and storage Cotreatment of Waste From Steelmaking Processes:

Processing and Reusing Technologies for Steelmaking Slag

steel slag originates from veinstone that is contained in the raw ma terials (iron ore, coal, coke, etc) and the flux that is added in the steelmaking refining process for removal of impurities (Si, 2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants Steel slag in China: Treatment, recycling, and management2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking Research on the Properties of Steel Slag with Different 2019年10月29日 Study has reported that the addition of converter slag (a type of steelmaking slag) could increase pH of acidic soils and the concentration of the available iron, P, and Mn in soil for plants (rice, maize, and tea) growth (Ali The potential utilization of slag generated from iron

.jpg)

Slag Recycling and Metal Recovery MEKA

As a result of growing environmental awareness, steel slag is now highly regarded as a recycled material that can reduce environmental impact due to its resourceconservation and energysaving properties MEKA is designing and Table – 1 : Plantwise Capacity of Ir on and Steel Slag in the Countr y Steel Plant Capacity for granulation ('000 tpy) Bhilai Steel Plant, Durg, Chhattisgarh 2675 Bokaro Steel Plant, Bokaro, Jharkhand 7884 Rourkela Steel Plant, Rourkela, Odisha 1570 Durgapur Steel Plant, Durgapur, West Bengal 566 IISCO Steel Plant, Burnpur , West Bengal 400 SlagIron and Steel 2017 (2) IBM2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking Research on the Properties of Steel Slag with Different There are lack of guidelines for use of steel slag as replacement of natural aggregates in construction activities and roadmaking Use of aggregates in Rail Ballast is governed by RDSO standards However, the RDSO standards do not presently allow use of iron and steel slag Steel industry is pursuing the matter with RDSOEnergy Environment Management in Steel Sector

.jpg)

Steel Production American Iron and Steel Institute

Steel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace The blast furnace is the first step in producing steel from iron oxides The first blast furnaces appeared in the 14th century and produced one ton per day2012年2月8日 Slag accounts for most of the residuals or byproducts of the steel manufacturing process and represents a not inconsiderable amount of energy waste and CO2 emissions Energy recovery from steel mill slags is not actually performed because of the difficulty of the industrial implementation, but the actual demand and the incentives for new electricity generation plants Steel mill slags energy potential: the case of the steel factory of 2017年3月5日 steelmaking plants Worldwide iron slag production in 2014 was estimated on the order of 310 could be quite signi fi cant for an individual steel mill [84] References 1(PDF) Iron and Steel Slags ResearchGate2023年11月17日 The growth of electric arc furnace (EAF) steelmaking in North America has occurred mainly in the past 40 years due to low electricity prices, an abundance of steel scrap (especially near large population centers), and the development of mini and macro steel mills based on metal recycling Scrap availability and price has made steel produced by remelting in Electric Arc Furnace Steelmaking and Slag Formation,

Steel plant slag dumps: A potential source of groundwater

2022年2月3日 Abstract The metallurgical processes in production of iron and steel from ores produce slags (blast furnace slag and basic oxygen furnace slag), which is usually dumped as solid waste by various steel plants around the world The present study assessed and estimated the impact of slag dump piling up for the last 60 years on the hydrogeological environment in Table – 1 : Plantwise Capacity of Iron and Steel Slag in the Country Steel Plant Capacity ('000 tpy) Bhilai Steel Plant, Durg, Chhattisgarh 2675 Bokaro Steel Plant, Bokaro, Jharkhand 7884 Rourkela Steel Plant, Rourkela, Odisha 1570 Durgapur Steel Plant, Durgapur, West Bengal 566 IISCO Steel Plant, Burnpur, West Bengal 400 kg/THM*SLAG IRON AND STEEL IBM2016年1月21日 Slag, also known as steel aggregate, is the primary byproduct of steelmaking The residue is comprised of minerals such as silica, alumina and titanium from ironsand, as well as other combinations of calcium and magnesium oxides derived from other raw materialsSteel Slag: The Incredible, Upcycable Byproduct of Steelmaking Steelmaking slag, or steel slag, is a byproduct from the production of steel during the conversion of hot metal to crude steel in a basic oxygen furnace, or during the melting of scrap in an EAFThe slag is generated as a melt and is a complex solution of silicates and oxides that solidify upon cooling 11 Depending on the specific steel production process, three different types of steel Steelmaking Slag an overview ScienceDirect Topics

.jpg)

Heavy duty industrial conveyor for steelmaking plants

Magaldi heavyduty conveyors for the steel industry deliver exceptional reliability and performance even in extreme Steelmaking plants The Superbelt® HD conveyor automates the scrap handling process Ladle slag conveyor 2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimizationSlag Availability Use the map below to find slag near you!Slag Availability National Slag AssociationDoc No: SG/39, Rev no: 00 Page 4 of 32 35 Auxiliary units: 351 Ladle preparation of all steel HM ladles minor, major repairs, Preheating preparation activities done to smooth batch process of steel making 352 Slag yard: All BOF Secondary steel slag handling in liquid condition 353 Scrap yard: Receiving Preparing of various scrap kinds to feed BOFRECOMMENDED GUIDELINES FOR IRON STEEL SECTOR MINISTRY OF STEEL, STEEL

.jpg)

Converter steelmaking for carbon steel SMS group GmbH

In view of the expected rising costs for CO 2 emissions, large price fluctuations of the charge materials for the BOF converter process and the increased scrap availability to be expected in the future, SMS group has developed a new primary smelter named CONPRO The CONPRO makes use of the proven BOF converter and electric arc furnace technologies, offering the 2014年1月1日 The ferrous slag is able to be recycled in internal recycling (reutilization in steel plants), civil construction, agriculture, etc Internal recycling of slag after magnetic separation in iron Steelmaking Slag Beneficiation by Magnetic Separator and 2021年9月24日 During steel production, the impurities in the hot metal react with the fluxes forming the steel slag Chemical constituents of this steel slag (SS) are relevant to iron/steelmaking or blended cement manufacture Harmful impurities present in it, however, limit its recycling to these applications Japan, Europe, and the US consume a significant amount of BOF Steel Slag: Critical Assessment and Integrated Approach for Table – 1 : Plantwise Capacity of Ir on and Steel Slag in the Countr y Steel Plant Capacity ('000 tpy) Bhilai Steel Plant, Durg, Chhattisgarh 2675 Bokaro Steel Plant, Bokaro, Jharkhand 7884 Rourkela Steel Plant, Rourkela, Odisha 1570 Durgapur Steel Plant, Durgapur, West Bengal 566 IISCO Steel Plant, Burnpur , West Bengal 400 kg/THM*SLAG IRON AND STEEL Indian Minerals Yearbook 2018 IBM

Flowchart of slag production in a modern steel plant

Table 1 summarizes the chemical composition of LD slag (Singh et al , 2013; Das et al , 2007; Waligora et al , 2010), Table 2 depicts the chemical composition and major phases of typical LD 1 Introduction The basic oxygen steelmaking (BOS) process produced over 70% of the global crude steel in 2018, [] generating 100 to 150 kg of slag (“BOS slag”) for every tonne of crude steel produced BOS slag, a product of hot metal Basic Oxygen Steelmaking Slag: Formation, Reaction, 2 Production Structure of No2 Steelmaking Plant at Kimitsu Works and Its Problem Figure 1 shows the steel manufacturing process at Kimitsu Works, which has two steelmaking plants The No 1 Steelmaking plant produces blooms for wire rod mill and shape mill The No 2 Steelmaking plant has three lines of convertervacuumImprovement of Productivity at Kimitsu No 2 Steelmaking Plant*1As a result of growing environmental awareness, steel slag is now highly regarded as a recycled material that can reduce environmental impact due to its resourceconservation and energysaving properties MEKA is designing and Slag Recycling and Metal Recovery MEKA

Pelletizing steel mill desulfurization slag ScienceDirect

2002年7月1日 Steel mills produce two types of slags called ironmaking slag and steelmaking slag Slags operate as an efficient medium for metallurgical reactions and are then subjected to a suitable treatment for end use, such as cooling or quenching Initially, at a steel mill, iron ore, flux, and fuel (coke) are added into an oxygen blast furnace2019年7月1日 Around 20 million tons of slag is produced annually in Europe, half of which is produced is BOS slag (Liu et al, 2016), meaning that large quantities of industrial byproducts are produced each yearOne obvious alternative to landfilling such byproducts would be to reutilize the slag in steelmaking or use for secondary applications (Joulazadeh and Joulazadeh, 2010)The recycling and reuse of steelmaking slags — A review2010年2月17日 And, as has been mentioned, there are lots of switching opportunities with a steel plant, including raw materialin (ore, coal, limestone, refractory materials, machinery, moulds and stools, skids for coil shipment in boxcars, etc), productout (coils, plates, fasteners, fencing, slag, chemicals from coke oven byproducts), plus in plant movements from process to processsteel mill arrangement Model Railroader Magazine Model The purified steel slag tailings has an iron content of less than 2% and a fineness of less than 10mm The metal material can be recycled back to the steel plant for sintering and steelmaking Steel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller millSteel Slag Grinding Plant CHAENG

.jpg)

Steel Slag Utilization — Overview in Indian Perspective

2016年8月31日 Current total productions of steel slag in India, are around 12 million tonnes per annum (Indian Minerals Yearbook, May 2016), which is far behind the developed countries2019年5月23日 Field experimentation was made in the first and second steelmaking plants of the Anshan Iron and Steel Group Corp, and effects such as fast slagging velocity, saving flux, The yield of the mill ground steel slag that is 100% not treated via magnetic separation is 1998% lower than that which is 100% treated via magnetic prehensive Utilization Technology of Steel Slag2021年6月28日 Blast Oxygen Furnace (BOF) slag represents one of the largest waste fractions from steelmaking Therefore, slag valorisation technologies are of high importance regarding the use of slag as a (PDF) Comprehensive Analysis of Steel Slag as Aggregate for Table – 1 : Plantwise Capacity of Ir on and Steel Slag in the Countr y Steel Plant Capacity for granulation ('000 tpy) Bhilai Steel Plant, Durg, Chhattisgarh 2675 Bokaro Steel Plant, Bokaro, Jharkhand 7884 Rourkela Steel Plant, Rourkela, Odisha 1570 Durgapur Steel Plant, Durgapur, West Bengal 566 IISCO Steel Plant, Burnpur , West Bengal 400 SlagIron and Steel 2017 (2) IBM

Research on the Properties of Steel Slag with Different

2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking There are lack of guidelines for use of steel slag as replacement of natural aggregates in construction activities and roadmaking Use of aggregates in Rail Ballast is governed by RDSO standards However, the RDSO standards do not presently allow use of iron and steel slag Steel industry is pursuing the matter with RDSOEnergy Environment Management in Steel SectorSteel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace The blast furnace is the first step in producing steel from iron oxides The first blast furnaces appeared in the 14th century and produced one ton per daySteel Production American Iron and Steel Institute2012年2月8日 Slag accounts for most of the residuals or byproducts of the steel manufacturing process and represents a not inconsiderable amount of energy waste and CO2 emissions Energy recovery from steel mill slags is not actually performed because of the difficulty of the industrial implementation, but the actual demand and the incentives for new electricity generation plants Steel mill slags energy potential: the case of the steel factory of

(PDF) Iron and Steel Slags ResearchGate

2017年3月5日 steelmaking plants Worldwide iron slag production in 2014 was estimated on the order of 310 could be quite signi fi cant for an individual steel mill [84] References 12023年11月17日 The growth of electric arc furnace (EAF) steelmaking in North America has occurred mainly in the past 40 years due to low electricity prices, an abundance of steel scrap (especially near large population centers), and the development of mini and macro steel mills based on metal recycling Scrap availability and price has made steel produced by remelting in Electric Arc Furnace Steelmaking and Slag Formation, 2022年2月3日 Abstract The metallurgical processes in production of iron and steel from ores produce slags (blast furnace slag and basic oxygen furnace slag), which is usually dumped as solid waste by various steel plants around the world The present study assessed and estimated the impact of slag dump piling up for the last 60 years on the hydrogeological environment in Steel plant slag dumps: A potential source of groundwaterTable – 1 : Plantwise Capacity of Iron and Steel Slag in the Country Steel Plant Capacity ('000 tpy) Bhilai Steel Plant, Durg, Chhattisgarh 2675 Bokaro Steel Plant, Bokaro, Jharkhand 7884 Rourkela Steel Plant, Rourkela, Odisha 1570 Durgapur Steel Plant, Durgapur, West Bengal 566 IISCO Steel Plant, Burnpur, West Bengal 400 kg/THM*SLAG IRON AND STEEL IBM

.jpg)

Steel Slag: The Incredible, Upcycable Byproduct of Steelmaking

2016年1月21日 Slag, also known as steel aggregate, is the primary byproduct of steelmaking The residue is comprised of minerals such as silica, alumina and titanium from ironsand, as well as other combinations of calcium and magnesium oxides derived from other raw materials