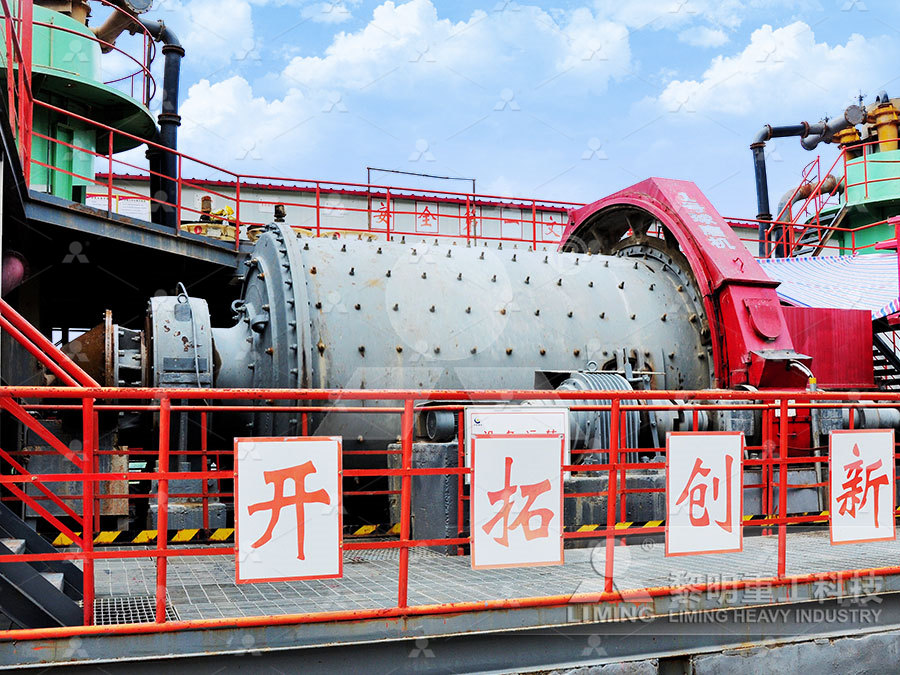

Guangyi grinding Phosphate rock

.jpg)

Phosphate Rock Processing: 6 Useful Ways and 4 Stages

Commercial phosphorus is obtained from phosphate rock, which is beneficiated after mining There are eight main ways for phosphate processing, which are suitable for different types of phosphate rock, to improve the grade and quality of phosphate rock 展开摘要: 以无机、有机材料为活化剂,用振动磨湿法研磨和连续提取的方法,研究了不同活化剂对磷矿粉的超微细活化作用及磷素动态释放特性。 结果表明,添加活化剂能够显著提高磷矿粉的 磷矿粉的超微细活化及磷释放动态研究2023年8月30日 From fertilizing phosphate fields to promoting industrial progress, phosphate rock powder grinding technology is the key The phosphate rock is crushed, screened, ground, How Phosphate Rock Grinding Can Help You Succeed2021年10月28日 Grinding and pulverizing mills are the furthest upstream process in phosphate fertilizer manufacturing The continuous crushing of phosphate rock to meet particle size The Essentials of Phosphate Milling for Fertilizer Manufacturing

The importance of phosphate milling Bradley Pulverizer

Simply stated, the role of the mill in fertilizer processing is to crush/grind/pulverise the raw phosphate rock Typically, the aim is to reduce quarter inchsize crushed rock into fine 2020年6月26日 Planetary ball mill was used for ultrafine grinding of phosphate rock powder with P 2 O 5 content of 2707% The influences of pulp concentration and grinding time on particle 湿式粉磨提高某磷矿粉释磷特性研究2008年1月31日 Techniques for beneficiation of phosphate rocks depend on the type of the phosphate deposit, the phosphate minerals existing in the ore as well as the associated non Physical and thermal treatment of phosphate ores — An overview2022年9月15日 There are similarities and differences between the mills that are most commonly used for commercial phosphate grinding The following insight into the performance variables A Comparison of Mills Used for Phosphate Rock Grinding

.jpg)

Phosphate Mining Arroyo Process Equipment

Optimize the extraction processes with equipment that ensures precise crushing, controlled grinding, efficient separation, and effective flotation, resulting in improved phosphate recovery 2023年12月26日 摘要: 本文采用行星式球磨机对河北省某地磷矿粉进行干式粉磨,考察了不同磨矿时间条件下粉磨产品的颗粒形貌、结晶程度、比表面积以及表面自由能,系统分析了超细粉 超细粉磨活化河北某磷矿粉机理研究2022年12月25日 Phosphorus (phôs: light and phoros: bearer in Greek), which is an essential element for all life forms, is a major and vital nonrenewable resource (Elbendary et al, 2019; Sis and Chander, 2003)Phosphorus was discovered by Henning Brand in 1669 (Huminicki and Hawthorne, 2002)Phosphate rock is mainly used as a raw material for fertilizer manufacturing Waste rock reprocessing to enhance the sustainability of phosphate 2022年4月2日 Selecting phosphate rock Selecting source of sulfuric acid Receiving and storing raw materials Grinding and otherwise preparing the rock Reacting the phosphate rock and sulfuric acid Filtering to separate The Dihydrate Process FerTech Inform

.jpg)

Phosphate Rock Beneficiation Process JXSC Machinery

The degree of grinding depends on the particle size of phosphorus minerals and impurity minerals 2 Separation process of phosphate rock usually adopts the flotation machine Usually, phosphate rock contains recyclable iron ore and 2019年4月25日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to Review on Beneficiation Techniques and Reagents Used for Phosphate 2022年5月22日 Using gamma spectrometry, the activity concentrations of natural radionuclides (Ra226, Th232 and K40) were measured in phosphate rock samples collected from phosphate mines located in El The Phosphate Mining in Egypt: Geology and Sustainable 1121 Phosphate Rock Processing 11211 Process Description15 The separation of phosphate rock from impurities and nonphosphate materials for use in fertilizer manufacture consists of beneficiation, drying or calcining at some operations, and grinding The Standard Industrial Classification (SIC) code for phosphate rock processing is 1475 The 1121 Phosphate Rock Processing US Environmental Protection

.jpg)

Wet grinding method for crude phosphate rock Google Patents

This application discloses a method of wet grinding crude phosphate rock containing clay minerals and the like impurities The procedures of the invention produce a rock slurry of enhanced fluidity and a desired degree of economy; and the principles of the invention may be applied to rock slurries after sizereduction The method of the invention contemplates introducing coarsely basic phosphate deposit, crushing, grinding, scrubbing, and flotation associated with other steps such as magnetic and or gravity separation is proved to be successful in upgrading this type of UPGRADING OF PHOSPHATE ORES – A REVIEW ResearchGateThe optimization tests demonstrated improved performance for both test feeds; however, acceptable quality phosphate rock was not obtained from pebble 3 at satisfactory P 2 0 5 recovery Test results for the blended phosphate rock sample are given below FEED STOCK CONCENTRATE % P 2766 2895 % CaO 4388 4346 % MgO 129 062Phosphate Rock Treatment for Waste Reduction2015年1月1日 Rock grinding Until 1973, most phosphate was ground dry in roller or ball mills In that year, Agrico, at South Pierce, Florida, converted one of its dry mills to wet slurry grinding and proved that the plant water balance could manage the rock at a 65–68 percent solids slurryPhosphorus and Phosphates SpringerLink

.jpg)

A Comparison of Mills Used for Phosphate Rock

2022年9月15日 There are similarities and differences between the mills that are most commonly used for commercial phosphate grinding The following insight into the performance variables across the mill types helps to determine which 2019年2月18日 Enhanced Phosphorus Release from Phosphate Rock Activated with Lignite by Mechanical Microcrystallization: Effects of Several Typical Grinding Parameters February 2019 Sustainability 11(4):1068Enhanced Phosphorus Release from Phosphate Rock Activated 2017年8月2日 Rock Grinding Until 1973, most phosphate was ground dry in roller or ball mills In that year, Agrico, at South Pierce, Florida, converted one of its dry mills to wet slurry grinding and proved that the plant water balance could manage the rock at a 65–68% solids slurryPhosphorus and Phosphates SpringerLink2021年10月28日 Part 1 of a 5part blog series: “The Importance of Phosphate Milling” Bradley Pulverizer’s Ian Hancock, VP of Sales Operations, discusses the importance of a holistic understanding of the phosphate milling process to ensure maximum plant uptime, the highest process efficiencies and profitabilityClick HereThe Essentials of Phosphate Milling for Fertilizer Manufacturing

Phosphate Rock: Origin, Importance, Environmental Impacts and

2016年6月24日 Phosphate rock (PR) is an important mineral resource with numerous uses and applications in agriculture and the environment PR is used in the manufacture of detergents, animal feed, and phosphate resource for phosphorus However, highgrade phosphate rock reserves take millions of years to form via the decomposition of (marine) organisms, and with the current mine production, significantly more is being consumed than is geologically replaced Currently, it is uncertain how large the global phosphate rock reserves are,Chapter 5 Phosphorus: Reserves, Production, and Applications2024年8月19日 Zhang, XM et al Enhanced phosphorus release from phosphate rock activated with lignite by mechanical microcrystallization: Effects of several typical grinding parameters Sustainability 11 , prehensive insights into phosphorus solubility and organic Currently in the EU, phosphate rock mining is only carried out in Finland which covers just about 10% of EU's P demand and remaining 90% is imported [3]Dependence of particle size (P80, µm) on grinding time (min)

.jpg)

Phosphorus and Phosphates SpringerLink

2012年11月19日 Rock grinding Until 1973, most phosphate was ground dry in roller or ball mills In that year, Agrico, at South Pierce, Florida, converted one of its dry mills to wet slurry grinding and proved that the plant water balance could manage the rock at a Grinding size: Finer grinding improves the solubility and availability of phosphorus in P Call us at 1300 761 423 or visit our contact page to learn how rock phosphate fertiliser can benefit your soil and crops Soil Conditioners; Fertilisers; Liquid Fertilisers Trace Elements;Rock Phosphate Premium Soil Conditioners Fertilisers2021年9月1日 Estonia holds the largest unexploited sedimentary phosphate rock reserves in the EU Compared to other sedimentary and also igneous phosphate rocks the Estonian phosphorite is particularly Evaluation of Estonian phosphate rock by flotation2003年10月1日 As outlined by various authors for rock phosphate based fertilizers, grinding can improve solubility and plant availability of phosphorus (eg Sander and Eghball, 1988; Beneficiation of rock phosphate fertilisers by mechanomilling

Influence of measuring process properties on phosphate rock

Keywords: phosphate rock, grinding, concentration, rheological properties, apparent viscosity 1 Introduction Phosphate rock is a nonrenewable resource As an important chemical raw material extracted from phosphate rock, phosphorus is mainly used to produce phosphate fertilizer, phosphate and phosphoricSP, Brazil) Western phosphate rock, SRM 694, and trace elements in multinutrient fertilizer, SRM 695, from the National Institute of Standards and Technology (NIST, Gaithersburg, MD, USA) were the CRMs used to accuracy evaluation For the QCM production, 10 kg of phosphate rock (apatite) from Morocco, a commercial product purchasedPreparation and characterization of phosphate rock as quality 2004年12月1日 The dolomite is more friable than phosphate rock Thus, dolomite can be separated from phosphate by discarding the fine fraction (mainly dolomite) by scrubbing or sizingSeparating dolomite from phosphate rock by reactive flotation 2019年1月30日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to the low grade of P2O5 and high content of impurities In order to obtain a qualified phosphate concentrate, the beneficiation of the lowgrade phosphate ore is, Review on Beneficiation Techniques and Reagents Used for Phosphate

Managing Phosphate Rock to Improve Nutrient Uptake, Phosphorus Use

2020年4月14日 Managing Phosphate Rock to Improve Nutrient Uptake, Phosphorus Use Efficiency, and Carrot Yields grinding it and combining with compost (Nis hanth and Biswas 20 08)o rm a n u r e(Z a f a rChappar Grinding Mill is one of the major companies producing phosphate rock in Pakistan with production capacity of around 25000 Tons a year from one of the biggest reserves of “Tarnoi” located in the city of Abbottabad Skip to content Chappar Grinding Mill Home;Home Chappar Grinding Mill2018年1月30日 Recent advances in wet grinding technology (eg US Patents A, US B2) Minjingu phosphate rock combined with either manure or Tithonia diversifolia led to a significant increase (PDF) In Situ Acidulation of Rock Phosphate ResearchGate2022年12月25日 Phosphorus (phôs: light and phoros: bearer in Greek), which is an essential element for all life forms, is a major and vital nonrenewable resource (Elbendary et al, 2019; Sis and Chander, 2003)Phosphorus was discovered by Henning Brand in 1669 (Huminicki and Hawthorne, 2002)Phosphate rock is mainly used as a raw material for fertilizer manufacturing Waste rock reprocessing to enhance the sustainability of phosphate

The Dihydrate Process FerTech Inform

2022年4月2日 Selecting phosphate rock Selecting source of sulfuric acid Receiving and storing raw materials Grinding and otherwise preparing the rock Reacting the phosphate rock and sulfuric acid Filtering to separate The degree of grinding depends on the particle size of phosphorus minerals and impurity minerals 2 Separation process of phosphate rock usually adopts the flotation machine Usually, phosphate rock contains recyclable iron ore and Phosphate Rock Beneficiation Process JXSC Machinery2019年4月25日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to Review on Beneficiation Techniques and Reagents Used for Phosphate 2022年5月22日 Using gamma spectrometry, the activity concentrations of natural radionuclides (Ra226, Th232 and K40) were measured in phosphate rock samples collected from phosphate mines located in El The Phosphate Mining in Egypt: Geology and Sustainable

1121 Phosphate Rock Processing US Environmental Protection

1121 Phosphate Rock Processing 11211 Process Description15 The separation of phosphate rock from impurities and nonphosphate materials for use in fertilizer manufacture consists of beneficiation, drying or calcining at some operations, and grinding The Standard Industrial Classification (SIC) code for phosphate rock processing is 1475 The This application discloses a method of wet grinding crude phosphate rock containing clay minerals and the like impurities The procedures of the invention produce a rock slurry of enhanced fluidity and a desired degree of economy; and the principles of the invention may be applied to rock slurries after sizereduction The method of the invention contemplates introducing coarsely Wet grinding method for crude phosphate rock Google Patentsbasic phosphate deposit, crushing, grinding, scrubbing, and flotation associated with other steps such as magnetic and or gravity separation is proved to be successful in upgrading this type of UPGRADING OF PHOSPHATE ORES – A REVIEW ResearchGateThe optimization tests demonstrated improved performance for both test feeds; however, acceptable quality phosphate rock was not obtained from pebble 3 at satisfactory P 2 0 5 recovery Test results for the blended phosphate rock sample are given below FEED STOCK CONCENTRATE % P 2766 2895 % CaO 4388 4346 % MgO 129 062Phosphate Rock Treatment for Waste Reduction

Phosphorus and Phosphates SpringerLink

2015年1月1日 Rock grinding Until 1973, most phosphate was ground dry in roller or ball mills In that year, Agrico, at South Pierce, Florida, converted one of its dry mills to wet slurry grinding and proved that the plant water balance could manage the rock at a 65–68 percent solids slurry