Calcium carbonate powder manufacturing process

.jpg)

Calcium Carbonate Manufacturing Process and Equipment

Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years) Chalk occurs as a microcrystalline material and has 展开2023年6月13日 The manufacturing process of calcium carbonate involves several essential steps, starting from raw material preparation to packaging and distribution Each stage contributes to the production of highquality calcium How is calcium carbonate manufactured? Sudarshan This video shows calcium carbonate powder manufacturing process of Praveen Mineral Chemical (PMC) The process describes how PMC offers calcium powder thatCalcium Carbonate Powder Manufacturing Process2023年3月7日 The manufacturing process for calcium carbonate powder involves several steps, including: Limestone Quarrying: The raw material used to make calcium carbonate powder is calcium carbonate powder manufacturing process LinkedIn

.jpg)

How Calcium Carbonate is

Calcium carbonate is divided into two industrial categories: Ground Calcium Carbonate (GCC) and precipitated calcium carbonate (PCC) The two categories use different manufacturing methods GCC is manufactured by physically 2024年10月1日 In this article, we will explore the process of making calcium carbonate, including its sources, methods of production, and applications Understanding Calcium Carbonate Calcium carbonate (CaCO₃) is a white, how to make calcium carbonate Sudarshan GroupCalcium Carbonate (GCC) produced from chalk, limestone, calcite or marble have developed in recent years from just being a simple cheap filler to highest quality functional additives GCC is used as dry powder or slurry in many industrial Calcium Carbonate (GCC) Hosokawa AlpineCaCl 2 solution and Ca (OH) 2 slurry, both prepared from marble waste (MARWAS), were carbonated with CO 2 gas in the presence of CTAB, SDS, Teepol610s, TritonX, and Tween a Flow chart for the synthesis of PCC by carbonation process, b

Production of precipitated calcium carbonate from calcium

2005年11月1日 Precipitated calcium carbonate can currently be produced by three different processes: a lime soda process, a calcium chloride process and a carbonation process In the Hosokawa Alpine provides the perfect process technology for every demand and covers all areas of (fineness) ranges, capacity and logistical aspects in a customerspecific and costeffective CALCIUM CARBONATE (GCC) Hosokawa AlpineE3 Beaters for powder coating manufacturing process: energyefficient high troughput ZPS: Calcium Carbonate (GCC) produced from chalk, limestone, calcite or marble have developed in recent years from just being a simple Calcium Carbonate (GCC) Hosokawa AlpineIn terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, How to Choose a Calcium Carbonate Grinding Mill

.jpg)

Customize Suitable Calcium Carbonate Plant DASWELL

With versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate powder of various particle sizes is in great demand around the world As the result, more and more shrewd businessmen want to build or expand their calcium carbonate powder processing plant all over the worldRSC Manufacturing sodium carbonate an overview for teachers Sodium carbonate (Na,CO,) is used by many different industries as a raw material, and about one million tonnes is produced each year in the UK all of it by the Brunner Mond Company in Northwich, CheshireAlso produced in smaller quantities is sodium hydrogencarbonate (NaHCO,) as well as calcium Part 1 Manufacturing sodium carbonate RSC EducationGrinding and Classifying System for Calcium CarbonateThe plant consists of an ALTAI pendular roller mill, a TAURUS ball mill, a SCIROCCO air classifier for fProcessing Plant for Calcium Carbonate YouTubeCalcium carbonate (CaCO 3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other industries In the present paper, precipitated calcium carbonate (PCC) has been produced from waste marble powder (WMP) by the CalcinationDissolutionPrecipitation (CDP) methodPRECIPITATED CALCIUM CARBONATE PRODUCTION, SYNTHESIS

.jpg)

Calcium Carbonate Palamatic Process

These fillers can be used in the manufacturing process of many products such as: paper, plastics, paints or rubber In all these processes, Calcium carbonate powder can also be conveyed by specific pneumatic conveying systems under pressure, such as our VFlow PRECIPITATED CALCIUM CARBONATE Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, there are several points in the PCC process where the calcium carbonate can be cubes, prisms, rhombohedrons—have different physical properties such as powder density, surface area and oil Project Report on PRECIPITATED CALCIUM CARBONATE Manufacturing Find here Calcium Carbonate Powder, Calcium Carbonate Drilling Additives manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Calcium Carbonate Powder, Calcium Carbonate Drilling Additives across IndiaCalcium Carbonate Powder Calcium Carbonate Drilling 2019年12月9日 Precipitated calcium carbonate manufacturing process Posted: Precipitated calcium carbonate/light calcium carbonate is a kind of calcium carbonate Precipitated calcium carbonate powders with a fineness of 125 mesh, 200 mesh, 225 mesh, 300 mesh, 600 mesh, 800 mesh, and 1250 mesh are obtained through precipitated calcium Precipitated calcium carbonate manufacturing process

Calcium Carbonate an overview ScienceDirect Topics

Calcium carbonate nanocomposites Y Lin, CM Chan, in Advances in Polymer Nanocomposites, 2012 31 Introduction: applications of calcium carbonate nanoparticles Calcium carbonate particles have been used in the plastics industry for many years The original purpose of adding ground calcium carbonate (GCC) particles as filler material for plastics was to calcium carbonate powder processing of ball mill and air classifier processing of ring roller mill processing of raymond mill gy o l hno ec ing t s es c o r n p io t a ic if d e mo c a rf u ing / s y if s s a l ing / c rind y g r er d d ow e p t a n o arb m c iu c al c CALCIUM CARBONATE POWDERMy novel manufacturing process for producing precipitated calcium carbonate can be advantageously applied to a variety of paper mill or manufacturing plant locations This is because my process can advantageously employ low High speed manufacturing process for precipitated 2016年12月31日 Calcium carbonate is a chemical compound with the formula CaCO3 formed by three main elements: carbon, oxygen, and calcium It is a common substance found in rocks in all parts of the world (most (PDF) Calcium Carbonate ResearchGate

Calcium carbonate Wikipedia

Calcium carbonate shares the typical properties of other carbonatesNotably it reacts with acids, releasing carbonic acid which quickly disintegrates into carbon dioxide and water:; CaCO 3 (s) + 2 H + (aq) → Ca 2+ (aq) + CO 2 (g) + H 2 O(l) releases carbon dioxide upon heating, called a thermal decomposition reaction, or calcination (to above 840 °C in the case of CaCO 3), to Check out calcium carbonate manufacturing process and every other variety of carbonate products at Alibaba's wholesale store All categories Featured selections Trade Assurance Micro Powder Vertical Roller Grinding Mill Lime Stone Calcium Carbonate Powder Processing $100,00000 $105,82000Calcium carbonate manufacturing process2023年11月17日 Scale and Expected Production Capacity The Calcium Carbonate Manufacturing Plant, with a total investment of up to 13 million dollars, is set to be one of the largest stone powder plants in VietnamThe plant is designed with an impressive scale, having an expected production capacity of 780,000 tons per year, which includes 600,000 tons of Duc Thinh Calcium Carbonate Powder Manufacturing PlantThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY

ZME –Zohdy Minerals EgyptFinest Egyptian Origin minerals

We manufacture various ranges of Calcium Carbonate Powder, We qualify best minerals before processing to ensure high quality Calcium Carbonate LimeStone, Purity : 995%, Discover our topquality minerals, which can enhance your manufacturing raw material optionsDownload scientific diagram a Flow chart for the synthesis of PCC by carbonation process, b synthesis of PCC by solution process from publication: Synthesis of precipitated calcium carbonate: a a Flow chart for the synthesis of PCC by carbonation process, b Clirik Calcined calcium carbonatepowder grinding machine and Calcined calcium carbonate micro powder grinder mill can grind noninflammable, nonexplosive and brittle materials with Mohs’ hardness under six Such as calcite, chalk, Calcined calcium carbonate grinding machine2020年7月30日 In this study, to determine the calcium carbonate availability in eggshells waste and factors those affect its extraction The parameters like temperature, the size of the eggshell powder and the (PDF) Calcium Carbonate Synthesis, Optimization

Hubercarb Calcium Carbonate for Powder Coatings

G35, G6 and G8 (High brightness ground calcium carbonate from Marble Hill, Georgia) Q3, Q4 and Q6 (Ground calcium carbonate from Quincy, Illinois) M3, M4 and M6 (Ground calcium carbonate from Marble Falls, Texas) Hubercarb® Calcium carbonate powder plays a crucial role in the manufacturing process of plastic products Widely employed as a filler, it enhances the physical properties of plastic, particularly in terms of strength and hardness, effectively improving the tensile strength and durability of plastic products The fine particles of calcium carbonate powder enable uniform dispersion within the plastic The Application of Calcium Carbonate Powder in Plastic Products Manufacturer of Calcium Carbonate Powder 20 Micron Calcium Carbonate Powder, Calcium Carbonate Powder is also extensively used in the manufacturing and processing of various paints, which provide a greater covering strength to the paintCalcium Carbonate Powder 20 Micron Calcium Carbonate Powder 2020年1月13日 Calcium carbonate manufacturing plant surface modification process Posted: Calcium carbonate is currently the largest amount of inorganic filler in organic polymerbased materials However, calcium carbonate without surface treatment has poor compatibility with the polymer, which can easily cause uneven dispersion in the polymer base Calcium carbonate manufacturing plant surface modification process

.jpg)

Synthesis of precipitated calcium carbonate: a review

2017年3月9日 The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various Since calcium carbonate does not melt at processing temperature, the viscosity of the compound will be higher and flow will be lower Therefore, the number of pipes manufactured per hour from compound A = N1, will be more than number of pipes manufactured per hour from compound B Benefits of calcium carbonate in PVC Processing BausanoIn paper manufacturing, Calcium Carbonate Powder is used to improve the brightness and smoothness of paper It also helps reduce the amount of pulp required, The production process is strictly controlled from mining to processing, ensuring the consistent quality of the productWHAT IS CALCIUM CARBONATE POWDER Global2023年12月26日 This process is widely used in industries for manufacturing calcium carbonate, a versatile compound used in products like chalk, paint, and supplements Commercial Production of Calcium Carbonate Manufacturing Calcium Carbonate for commercial use involves largescale production processesCalcium Carbonate(CaCO3) Limestone Formula, Structure, Uses

.jpg)

Calcium Carbonate (GCC) Hosokawa Alpine

E3 Beaters for powder coating manufacturing process: energyefficient high troughput ZPS: Calcium Carbonate (GCC) produced from chalk, limestone, calcite or marble have developed in recent years from just being a simple In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, How to Choose a Calcium Carbonate Grinding MillWith versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate powder of various particle sizes is in great demand around the world As the result, more and more shrewd businessmen want to build or expand their calcium carbonate powder processing plant all over the worldCustomize Suitable Calcium Carbonate Plant DASWELLRSC Manufacturing sodium carbonate an overview for teachers Sodium carbonate (Na,CO,) is used by many different industries as a raw material, and about one million tonnes is produced each year in the UK all of it by the Brunner Mond Company in Northwich, CheshireAlso produced in smaller quantities is sodium hydrogencarbonate (NaHCO,) as well as calcium Part 1 Manufacturing sodium carbonate RSC Education

.jpg)

Processing Plant for Calcium Carbonate YouTube

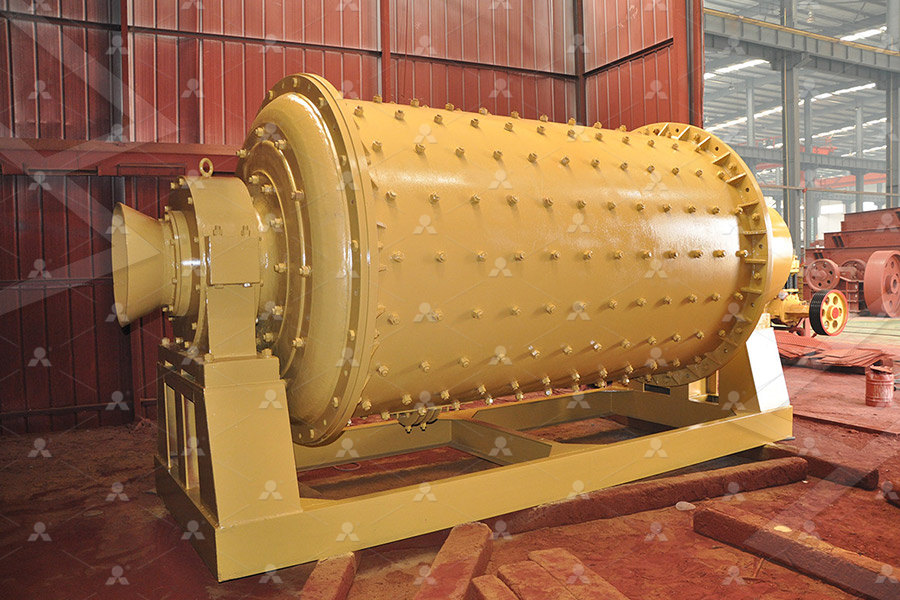

Grinding and Classifying System for Calcium CarbonateThe plant consists of an ALTAI pendular roller mill, a TAURUS ball mill, a SCIROCCO air classifier for fCalcium carbonate (CaCO 3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other industries In the present paper, precipitated calcium carbonate (PCC) has been produced from waste marble powder (WMP) by the CalcinationDissolutionPrecipitation (CDP) methodPRECIPITATED CALCIUM CARBONATE PRODUCTION, SYNTHESIS These fillers can be used in the manufacturing process of many products such as: paper, plastics, paints or rubber In all these processes, Calcium carbonate powder can also be conveyed by specific pneumatic conveying systems under pressure, such as our VFlow Calcium Carbonate Palamatic ProcessPRECIPITATED CALCIUM CARBONATE Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, there are several points in the PCC process where the calcium carbonate can be cubes, prisms, rhombohedrons—have different physical properties such as powder density, surface area and oil Project Report on PRECIPITATED CALCIUM CARBONATE Manufacturing

Calcium Carbonate Powder Calcium Carbonate Drilling

Find here Calcium Carbonate Powder, Calcium Carbonate Drilling Additives manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Calcium Carbonate Powder, Calcium Carbonate Drilling Additives across India2019年12月9日 Precipitated calcium carbonate manufacturing process Posted: Precipitated calcium carbonate/light calcium carbonate is a kind of calcium carbonate Precipitated calcium carbonate powders with a fineness of 125 mesh, 200 mesh, 225 mesh, 300 mesh, 600 mesh, 800 mesh, and 1250 mesh are obtained through precipitated calcium Precipitated calcium carbonate manufacturing process