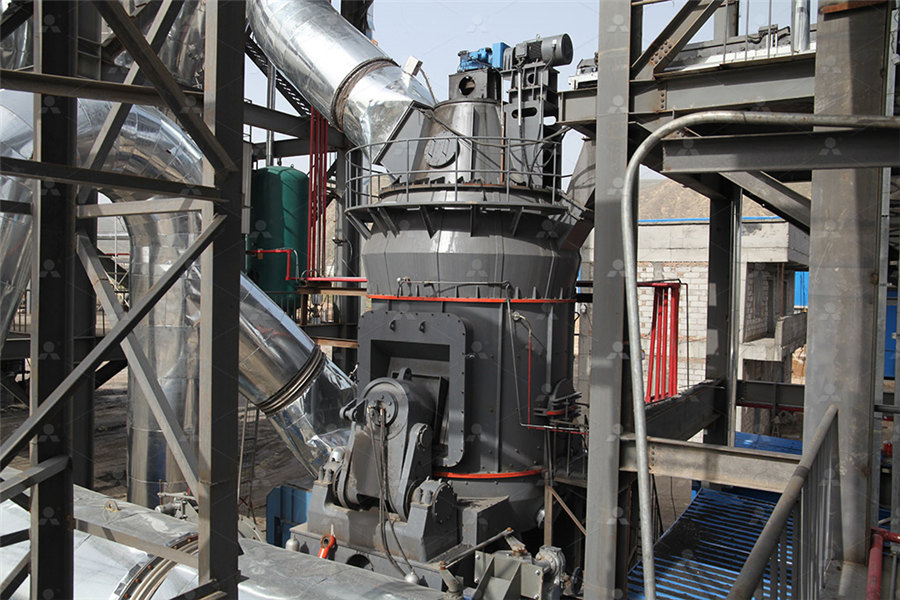

Vertical ore mill that can crush relatively large price

43.jpg)

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr Pfeiffer have been collaborating on the application of this technology in the minerals processing industry2019年4月16日 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is LM Vertical Mill – Stone Crushers Grinding Mills for Mines and 2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) Analysis of vertical roller mill performance with changes in material

Latest Installations And Developments Of Loesche Vertical Roller

2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these 2014年10月20日 This paper presents an overview of the regrind circuits in Brazil that operate with vertical mills and the results of industrial surveys at selected vertical mill circuitsRegrind of metallic ores with vertical mills: An overview 2015年3月10日 It is possible to decrease the operating costs about 381% by implementing vertical roller mill to the existing circuit Vertical roller mills (VRM) have been used extensively Copper ore grinding in a mobile vertical roller mill pilot plant2015年9月1日 In response to increasing energy costs, the industry is seeking energy efficiency milling technologies that can process large tonnages Stirred mills are an attractive option as they have(PDF) THE GRINDING EFFICIENCY OF THE CURRENTLY

.jpg)

Flowsheet of the Future: HighPressure Grinding Rolls, Vertical

With ore becoming increasingly competent, HPGRbased circuits have been proven to substantially reduce direct and indirect energy consumption and reduce comminution costs by 2022年12月2日 Milling specialist Loesche’s Vertical Roller Mills (VRM) can simplify the beneficiation process using improved liberation of the targeted mineral within the ore, even with complicated sulphide oresVertical roller mills highly evolved, green Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill2024年7月17日 Gyratory crushers use the oscillating motion of the crushing cone to compress and crush hard ores and large materials, making them particularly suitable for highhardness and abrasive materials They produce Types of Crushers: Choosing the Right One for Each

.jpg)

Illite Ore Industrial Grinding Mill Machine SBM

2021年11月8日 Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, CLUM vertical roller mill: can produce 1503000mesh illite ore The nonmetallic ore grinding technology design is relatively 2020年8月12日 CMC coal shows relatively better performance since it has lower moisture Vertical Coal Mill Ghalandari et al 2021), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van An investigation of performance characteristics and energetic 2022年1月1日 The majority of world crude steel is made from the BFBOF route Ores carrying very high quantities of hematite (greater than ∼60% iron) are known as "natural ore" or DSO, meaning they can be fed directly into the BFBOF route However, lowgrade ores need to be beneficiated before they can be used to make minution and classification technologies of iron ore2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

LOESCHE vertical roller mills for the comminution of ores and minerals

2001年10月1日 The special challenges involved in producing very large mill components and new mill gear units are described using the example of the orders for two LM 634 Loesche mills2014年11月1日 The methodology is therefore useful for scaleup and simulation of vertical mills, only requiring laboratory tests that can be carried out in standard laboratory batch ball mills with small Vertical mill simulation applied to iron ores ResearchGate2023年3月6日 Vertical roller mills (VRM) are commonly used in the processing of iron ore for dry grinding for several reasons: vertical roller mill Energy Efficiency: VRMs are known for their energy efficiencyWhy is vertical roller millbased dry grinding used in iron ore The specific energy consumption measured in the Vertical Mill was 97 kWh/t, while in the ball mill it was 112 kWh/t It is important to note here that the ore that feeds the Vertical Mill has a higher WI than the ore that feeds the ball mill The Vertical Mill uses a magnetic liner and the maintenance crew did not report any significant problemsRegrind of metallic ores with Vertical Mills Academia

Operational parameters affecting the vertical roller mill

2016年9月1日 Furthermore, VRM separator speed (rpm) is one of the key operational parameters that determines product particle size Increasing the classi er rotor speed from 60 to 80 rpm decreases the particle 2024年4月19日 The primary aim of the primary crushing is to produce a product that can be moved easily by conveyors or feeders to the next step of the crushing Primary crushers are built to process large and abrasive feed materials They Types of Crushers Explained: Everything You Need to China LIMING Heavy Industry Science and Technology Co LTD which mainly manufacture large and mediumsized crushing and grinding equipments and it is widely used in almost every field in ore, LM Vertical Mill LM Vertical Mill Stone Crushers, Mill and GrindingThe Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of an industrial plantVertical Roller Mills used for the comminution of mineral ores

.jpg)

7 Key Differences Between Raymond Mill And Vertical Roller Mill

Raymond Mill: Raymond mill can handle a relatively coarse feed size of around 30mm Vertical Roller Mill: Vertical Roller Mill can process materials with hardness of less than Mohs 7, but it is more suitable for processing largescale materials due to its high production capacity2021年6月15日 Both the vertical mill and the Raymond mill are ore powder grinders, The weight and size are relatively large, and the small ones are also hundreds of thousands yuan 2 It occupies a large area, has a large power, a high price, and a high outputThe difference between vertical mill and Raymond mill2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills Miningpedia2024年1月1日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore Roller Mill SpringerLink

Energysaving and Efficient Vertical Roller Mill Fote Machinery

A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal 2022年11月21日 The jaw crusher has large crushing ratio, which means that jaw crusher can crush large materials over 1000mm into particles smaller than 100mm In crushing and sand production plant, jaw crusher is the preferred equipment for coarse crushing of materials with compressive strength not exceeding 320 MPaJaw Crusher VS Cone Crusher: 9 Key DifferencesChina Crush Mill wholesale Select 2024 high quality Crush Mill products in best price from certified Chinese Crusher manufacturers, Biobase China SemiCircle Vertical Planetary Ball Mill Impact and Crush The Material BkbmV2 US$ 8002200 / Piece 1 Piece (MOQ)Crush Mill MadeinChina2015年3月15日 It can be concluded that the HPGRStirred mill combination was a more energyefficient grinding circuit than the HPGRBall mill combination for PGE bearing chromite ore View Show abstractVertical Agitated Media Mill scaleup and simulation

Vertical Roller Mill MadeinChina

China Vertical Roller Mill wholesale Select 2024 high quality Vertical Roller Mill products in best price from certified Chinese Powder Grinding Machine manufacturers, 3 Roller Vertical Grinding Mill Perlite Stone Grinding Machine Vertical Roller Mill for Ore Material Powder US$ 17000 / Piece 1 Piece 2016年3月11日 To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushingCrushing Plant Flowsheet DesignLayout 911Metallurgist2019年8月29日 Sensor‐based ore sorting can be used as a separation process for coarser grain sizes before the application of fine comminution and separation technologies and is applicable for a large variety (PDF) Sensor‐Based Ore Sorting Technology in Mining—Past, CHAENG can provide various types of vertical cement mills with productivity of 50250t/h The biggest advantage of CHAENG is to have a large casting base and large machining workshops, which greatly shortens the delivery cycle of cement vertical mill GRMK vertical cement mill has the advantages of compact structure and small volumeRoller mill GRMK vertical roller mill Xinxiang Great Wall

Analysis of vertical roller mill performance with changes in

2022年5月31日 For the VRM, scholars mainly consider the research of powder separation performance (Bhasker, 2002, Vuthaluru et al, 2005, Dou et al, 2011) and its application in crushing metal ore (Altun et al, 2015, Li et al, 2020, Boehm et al, 2015) However, there is relatively less research on the crushing mechanism of VRMThe LM Vertical Grinding Mill, launched by SMMVIK Machinery, integrates five functions of crushing, grinding, This mill itself can crush, dry, grinding, classifying, and occupation area is about 50% of ball mill system In addition, it can be installed outside, so it will reduce a large number of investment costs 02 High efficiency: LM Vertical Grinding Mill SMMVIK Machinery2015年9月20日 The SAG mill can be linked to retrogression to the multistage crushball mill route of 50 years ago but with Secondary crushing large volume s of ore has a significant penalt y with (PDF) FULL PRECRUSH TO SAG MILLS ResearchGate2022年1月12日 Ultrafine vertical mills and ball mills are common largescale industrial grinding equipment and are widely used Let's take a look at the difference between ultrafine vertical mill and ball mill +17 [ protected and the initial investment is relatively large Detailed comparison of vertical mill and ball What is the difference between vertical mill and ball mill?

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGate2024年7月17日 Gyratory crushers use the oscillating motion of the crushing cone to compress and crush hard ores and large materials, making them particularly suitable for highhardness and abrasive materials They produce Types of Crushers: Choosing the Right One for Each 2021年11月8日 Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, CLUM vertical roller mill: can produce 1503000mesh illite ore The nonmetallic ore grinding technology design is relatively Illite Ore Industrial Grinding Mill Machine SBM 2020年8月12日 CMC coal shows relatively better performance since it has lower moisture Vertical Coal Mill Ghalandari et al 2021), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van An investigation of performance characteristics and energetic

Comminution and classification technologies of iron ore

2022年1月1日 The majority of world crude steel is made from the BFBOF route Ores carrying very high quantities of hematite (greater than ∼60% iron) are known as "natural ore" or DSO, meaning they can be fed directly into the BFBOF route However, lowgrade ores need to be beneficiated before they can be used to make steel2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant2001年10月1日 The special challenges involved in producing very large mill components and new mill gear units are described using the example of the orders for two LM 634 Loesche millsLOESCHE vertical roller mills for the comminution of ores and minerals2014年11月1日 The methodology is therefore useful for scaleup and simulation of vertical mills, only requiring laboratory tests that can be carried out in standard laboratory batch ball mills with small Vertical mill simulation applied to iron ores ResearchGate

Why is vertical roller millbased dry grinding used in iron ore

2023年3月6日 Vertical roller mills (VRM) are commonly used in the processing of iron ore for dry grinding for several reasons: vertical roller mill Energy Efficiency: VRMs are known for their energy efficiencyThe specific energy consumption measured in the Vertical Mill was 97 kWh/t, while in the ball mill it was 112 kWh/t It is important to note here that the ore that feeds the Vertical Mill has a higher WI than the ore that feeds the ball mill The Vertical Mill uses a magnetic liner and the maintenance crew did not report any significant problemsRegrind of metallic ores with Vertical Mills Academia