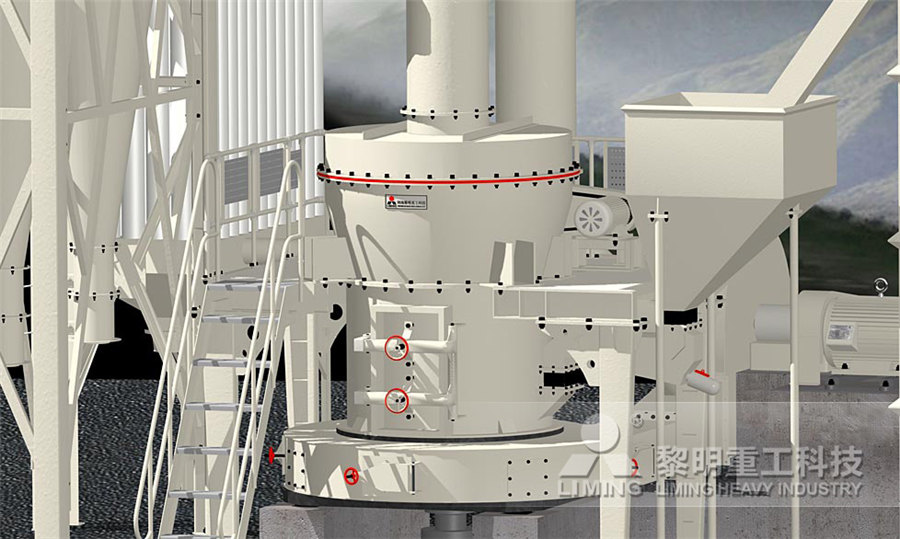

400TPH threering medium speed grinding machine

HGM Micropowder Grinding Mill Baichy

HGM series ultra fine powder grinding mill is a new type mining equipment for make micro powders with three ring rollers It is used to grind limestone, calcite, calcium carbonate, dolomite, gypsum, carbon black, gypsum, kaolin, marble HGM series threering (fourring) mediumspeed mill is mainly suitable for processing nonflammable and nonexplosive brittle materials with Mohrenheit hardness less than 7, such as Threering Grinding MillVanguard MachineryThe three ring medium speed micro powder mill is a kind of processing equipment for fine powder and ultrafine powder It applies a number of national new mill technologies, with novel design, reasonable structure, small footprint, low Three ring medium speed micro powder mill SBM ThreeRing Medium Speed Micro Powder Mill Production capacity: 5007000kg/h Number of fineness: 4003000 mesh Application fields:Calcium carbonate crushing processing, gypsum powder processing, power plant ThreeRing Medium Speed Micro Powder Mill –

Threering Grinding MillVanguard Machinery

Newly designed grinding curves of grinding roller and grinding ring further enhance the grinding efficiency of HGM Ultrafine Grinding Mill With the same fineness and power the production capacity is 40% higher than that of jet HGM series Threering Mediumspeed micropowder mill is designed basing on our 20 years’ manufacturing experience, absorbing the Swedish advanced machine manufacturing HGM ThreeRings MediumSpeed MicroPowder MillFind out all of the information about the Henan Baichy Machinery Equipment Co, Ltd product: roller grinding mill HGM series Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of saleRoller grinding mill HGM series Henan Baichy The tool grinding machine HELITRONIC POWER 400 with CORETechnology is powerful with maximum flexibility for medium to large series It stands for top quality worldwide in the production and resharpening of rotationally HELITRONIC POWER 400 UNITED GRINDING

Planetary Ball Mill PM 400 RETSCH powerful and quick grinding

The PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml It processes up to 8 samples simultaneously which China Medium Speed Grinding Mill wholesale Select 2024 high quality Medium Speed Grinding Mill products in best price from certified Chinese High Speed Machine manufacturers, High Speed Steel suppliers, wholesalers and Hgm Series ThreeRing UltraFine Grinding Mill/ThreeRing Medium Speed Mill US$ 3255 / Piece 1 Piece (MOQ) Henan Medium Speed Grinding Mill MadeinChina2022年12月27日 In order to meet the P2grade bearing grinding requirements, we designed a highspeed internal grinding machine to be used for grinding bearing raceways and inner circlesDesign and Development of a HighSpeed Precision Grinding Machines Manual Lathe Machines Milling Machines Wood Working Machines Sawing Metallkraft Motorized Ring Roller Machine PRM 31 F Can be used horizontally and vertically for profiles, tubes and solid material Metallkraft Motorized Ring Roller Machine PRM 31 F

.jpg)

Roller Mill Springer

and is discharged from the machine (Fig 3) The plumblossom rack, the roller, the grinding ring, the blade, the feeding section, the return windbox, the discharge section, etc There are three to The Raymond mill is mediumspeed fine grinding equipment According to the number of rollers, it can be divided into three rollers By the grinding machine and grinding technology, we want to achieve the precision and lifetime of 7014: 3000 hours’ lifetime for ceramic ball bearings and 2000 hours’ lifetime for steel ball A Highspeed Precision Bearing Internal Grinding Machine andCNC Ring Grinding Machine Standard Features Description of Machine Standard features description of machine (key features description of the machine) Ring grinding machine which can accommodate tungsten carbide ring and entry guide rolls grinding with three axis CNC and driven by CNC C TC Roll Ring Grinding Machine – Preet Group2022年2月26日 Three ring medium speed micro grinding is a kind of ultrafine grinding equipment Its processing fineness is between 4003000 mesh, the power consumption is about 22220kw, and the hourly production can reach more than 50 tonsWhat is Blast Furnace Slag and How to Process It?

A member of the UNITED GRINDING Group KRONOS

Centerless grinding machine for productive machining of medium workpieces CBN available Technical data Workpiece diameter 15100 mm Workpiece length, max for infeed grinding 395 mm Grinding wheel 610 x 400 x 3048 mm Drive power 37/51 kW Peripheral speed 63 m/s Peripheral speed CBN 90/120 m/s Regulating wheel 350 x 400 x 127/152 mm Drive 2017年10月19日 3 Types of grinding Machine Grinding machines according to quality of surface finish, may be classified as 1 Rough /Nonprecision grinding 2 Precision grinding Rough/Nonprecision grinding To remove more stock than other grinding a)Floor stand and bench grinders (b)Portable and flexible shaft grinders (c)Swing frame grinders (d)Abrasive belt grindersGrinding machine PPT SlideShare2024年10月5日 Highspeed grinding (HSG) is an advanced technology for precision machining of difficulttocut materials in aerospace and other fields, which could solve surface burns, defects and improve Highspeed grinding: from mechanism to machine toolAutomatic Wire Ring Making Machine, Increase the three axis hydraulic ring machine :12X100mm ring diameter R012 Jeans Damaging/ Destroying/ Grinding Machine; Company News; About Us; Contact WhatsApp/WeChat/Phone: Helen Pei +86 Automatic Wire Ring Making Machine Quanjiu

.jpg)

Mediumsized grinding machine All industrial

Spindle speed: 500, 1,000 rpm Power: 4, 75 kW Distance between centers: 800, 1,980, 4,000 mma CNC cylindrical grinding machineThe machine is designed with grinding wheel moves on base by recirculating ball systems The 2022年12月27日 In order to meet the P2grade bearing grinding requirements, we designed a highspeed internal grinding machine to be used for grinding bearing raceways and inner circles The machine has a Ttype layout and a Design and Development of a HighSpeed Precision 2021年11月23日 Following are the types of grinding machines: Bench grinding machine, Hand grinding machine, The job is moved through the medium of a grinding wheel and a regulating wheel There are four main parts of this grinder: (1) Grinding wheel (2) Work rest The regulating wheel forces the job to spin at an equal speed In this way, 14 Types of Grinding Machines [Working, Diagram PDF] The Spindle speed: 500, 1,000 rpm Power: 4, 75 kW Distance between centers: 800, 1,980, 4,000 mma CNC cylindrical grinding machineThe machine is designed with grinding wheel moves on base by recirculating ball systems The workpiece is clamped by headstock fixed Rotor grinding machine All industrial manufacturers

.jpg)

Grinding Machine: Definition, Parts, Working Principle, Operation

2021年5月5日 The grinding machine is widely used to finish the workpiece Do you know why? Because the work removal rate is low between 025 to 05 mm (This can be advantages or disadvantages also for various types of works) Grinding Machine Parts and Function: The Grinding Machine Consists of Following Main Parts: Base or Bed; Column; Headstock June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: Cylindrical grinding machine only outside diameter grinding: PGC Series; High speed Vertical Deep hole drilling machines: PROFIDRILL PDDVHS; Three coordinate single spindle deep can be rolled by increasing helix angle tilt on the machine; Speedup dies are used for highspeed rolling; ThroughFeed System with 2 tools Thread Rolling Technology, Profimach® Roll forming Machines, 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLink

.jpg)

An optimization method for thermal behavior of highspeed

2020年2月21日 As shown in Fig 1, the highspeed spindle of the gear form grinding machine is composed of three sections: one grinding wheel shaft B and two support shafts A and CThe grinding wheel shaft B is connected with the support shafts A and C through two diaphragm couplings, and the support shafts A and C are supported by three sets of angular contact ball Experience efficient ring production with our fully automatic ring making machine Durable, accurate and reliable heavy work load +86 marketing@autolinkcnc Blogs News Contact UsCNC Ring Making Machine AutolinkCNC2003年3月15日 Today, both companies are now managed by Wimmer’s three sons 7 Jul 2024 Investing in New Technology at AccuRounds never overspeed a grinding wheel The speed of the grinder must be compared to the Grinding Wheel Safety: Respect The Maximum SpeedElectric Fuel Pumps and Fuel Valve Grinding Machine / FPG; Injector Fuel System Test Rig / VPU 9003/15002; Automatic honing machine for restoration of medium speed engine cylinder liner geometry and surface Automatic Honing Machine / HON A ChrisMarine

Mounting and Balancing Grinding Wheels

2020年9月8日 The screwin depth (e ≥ 15 x thread diameter of the grinding wheel flange) is a standardized value and must not be changedNote: The grinding wheel must be properly clamped (distance b)If necessary, a distance ring must be mounted 2022年12月31日 for the medium operating machines like milling, it would have maximum speed up to 2000 rpm and the maximum load 15000 psi Using manufacturing catalogue ballDesign and Performance Evaluation of Grain Feed Grinding MachineThe regulating wheel, also known as a drive or feed wheel, controls the workpiece’s speed, preventing the workpiece from speeding up and rotating at the same speed as the grinding wheelThat enables the grinding wheel to remove material from the workpiece Although a regulating wheel might have some abrasive grains in it, it is typically comprised primarily of a Centerless Grinding Machine overviewHGM series of threerings and mediumspeed micro powder grinder is a new type of making micro powder machines through more than twenties times research and improvement Improved utilization rateWhen the wearing between the grinder roll and the grinding ring enlarges to a certain extent, ©2021 Henan Shanky Machinery CoLtdHGM Series UltraFine Mill Shanky Machinery

Design, Analysis and Development of a Studs Grinding Machine

The grinding ring may be in a vertical or a horizontal position Ringroller mills also are referred to as ring roll mills or roller mills or mediumspeed mills The stud grinding machine is comprise of three main units power transmission unit, grinding unit, and delivery unit besidesHGM series Threering Micro Powder Grinding machine (also can be called calcite carbonate grinding machine, chalk grinding machine, limestone grinding machine, Main Shaft Speed (r p min) 230240: 200220: 180200: 135155: 120130: Input Size (mm) ≤10: ≤10: ≤15: ≤15: ≤20: Finished Size (um/mesh) 745 (2002500) 745 (2002500)HGM Series Threering Micro Powder Grinding Machine ClirikFind here Surface Grinding Machine, Surface Grinder Machine, Hydraulic Grinding Machine suppliers, manufacturers, wholesalers, traders with Surface Grinding Spindle Speed 1750[60hz]/1450[50hz] Motor Power 5hp Cross Feed Graduation 002mm Jay Bharat School, Survey No 44, 150 Feet Ring Road, B/h Galaxy Tile, Rajkot , Dist Hydraulic Surface Grinding Machine In Chennai India Business China Medium Speed Grinding Mill wholesale Select 2024 high quality Medium Speed Grinding Mill products in best price from certified Chinese High Speed Machine manufacturers, High Speed Steel suppliers, wholesalers and Hgm Series ThreeRing UltraFine Grinding Mill/ThreeRing Medium Speed Mill US$ 3255 / Piece 1 Piece (MOQ) Henan Medium Speed Grinding Mill MadeinChina

Design and Development of a HighSpeed Precision

2022年12月27日 In order to meet the P2grade bearing grinding requirements, we designed a highspeed internal grinding machine to be used for grinding bearing raceways and inner circlesGrinding Machines Manual Lathe Machines Milling Machines Wood Working Machines Sawing Metallkraft Motorized Ring Roller Machine PRM 31 F Can be used horizontally and vertically for profiles, tubes and solid material Metallkraft Motorized Ring Roller Machine PRM 31 F and is discharged from the machine (Fig 3) The plumblossom rack, the roller, the grinding ring, the blade, the feeding section, the return windbox, the discharge section, etc There are three to The Raymond mill is mediumspeed fine grinding equipment According to the number of rollers, it can be divided into three rollers Roller Mill SpringerBy the grinding machine and grinding technology, we want to achieve the precision and lifetime of 7014: 3000 hours’ lifetime for ceramic ball bearings and 2000 hours’ lifetime for steel ball A Highspeed Precision Bearing Internal Grinding Machine and

CNC TC Roll Ring Grinding Machine – Preet Group

CNC Ring Grinding Machine Standard Features Description of Machine Standard features description of machine (key features description of the machine) Ring grinding machine which can accommodate tungsten carbide ring and entry guide rolls grinding with three axis CNC and driven by CNC controls2022年2月26日 Three ring medium speed micro grinding is a kind of ultrafine grinding equipment Its processing fineness is between 4003000 mesh, the power consumption is about 22220kw, and the hourly production can reach more than 50 tonsWhat is Blast Furnace Slag and How to Process It?Centerless grinding machine for productive machining of medium workpieces CBN available Technical data Workpiece diameter 15100 mm Workpiece length, max for infeed grinding 395 mm Grinding wheel 610 x 400 x 3048 mm Drive power 37/51 kW Peripheral speed 63 m/s Peripheral speed CBN 90/120 m/s Regulating wheel 350 x 400 x 127/152 mm Drive A member of the UNITED GRINDING Group KRONOS2017年10月19日 3 Types of grinding Machine Grinding machines according to quality of surface finish, may be classified as 1 Rough /Nonprecision grinding 2 Precision grinding Rough/Nonprecision grinding To remove more stock than other grinding a)Floor stand and bench grinders (b)Portable and flexible shaft grinders (c)Swing frame grinders (d)Abrasive belt grindersGrinding machine PPT SlideShare

Highspeed grinding: from mechanism to machine tool

2024年10月5日 Highspeed grinding (HSG) is an advanced technology for precision machining of difficulttocut materials in aerospace and other fields, which could solve surface burns, defects and improve