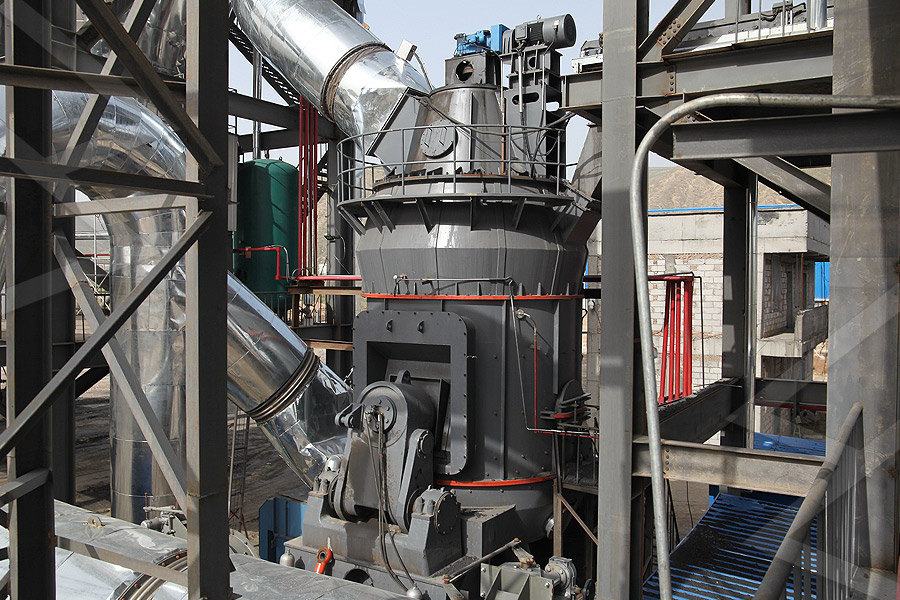

5000 tons raw material vertical grinding roller structure

.jpg)

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mills are an essential part within the production process for grinding raw material (QMR²), coal (QMK²) and increasingly binding agents or slag (QMC²/QMS²) At the end the cement quality is important to serve the marketquadropol® thyssenkrupp Polysius Grinding The discharged materials are sent to the cement grinding system through a belt conveyor to ensure the accurate ratio of each raw material before entering the grinding The mixed raw 5000 TPD Cement Production Line CEMENTLWith many years of experience in technical innovation within the field of cement and slag grinding, CITIC Heavy Industries (CITIC HIC) has successfully developed various models of vertical roller millsVertical Roller Mills Cement Processing Equipment

5000 TPD Cement Production Line CEMENTL

Cement vertical roller mill is a kind of equipment used for cement grinding, mainly used (3,000 tpd), 5,000 tons/day (5,000 tpd), 6,000 tons/day (6,000 tpd), and even 8,000 tons/day (8,000 tpd) and above, which are Optimizing the raw material grinding process and the finished product grinding system can also significantly improve the vertical roller grinding mill GRMR vertical raw mill vertical for limestone stone Contact Process introduction The GRMR raw material vertical mill of CHAENG is a kind of new high efficiency, forces generated during grinding are Vertical roller mill, Vertical roller grinding mill All A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote MachineryVertical Roller Mill Brand SINOMALY Product origin Liyang, Jiangsu, China Delivery time 7 months Supply capacity 10800tph 1 The vertical roller mill is a highefficiency and energysaving grinding equipment widely used in preparing raw materials and clinker, grinding slag, ore, industrial silicon, calcium carbide slag and coal gangue in the cement industry and in coal Supply Vertical Roller Mill Customized Factory SINOMALY

.jpg)

Grinding Table of Vertical Roller Mill Great Wall

The grinding table is one of the key parts of vertical roller mill It includes drag rings to overcome the deficiencies in structure and make the grinding base bear force equivalently All of these avoid the problem of material’s washout on the not wear 20150 tons: Material: ASTM: A570 / BS: S235JR / JIS: SS400: Application: Vertical Vertical Roller SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powderVertical Roller Mill for Cement Raw Material SINOMALYlarge vertical roller mills for grinding cement raw material Redundancy und interchangeability – große VertikalRollenmühlen für die Rohmehlerzeugung 4DiplIng M Keyssner, Loesche GmbH, Düsseldorf, Germany Reprint from / Sonderdruck aus: Cement International – Issue 2/2007, pp 84–91 Keyssnerdd 1 17072007 11:23:11 UhrRedundancy and interchangeability – large vertical roller mills In the areas with small annual rainfall and low water content materials, the roller mill grinding system is gradually popularized and applied Comparison of Raw Material Preparation Technology Vertical Raw Material Grinding System Vertical mill is a kind of airRaw Material Preparation in Cement Manufacturing Plant AGICO

.jpg)

GreatWall Vertical Mill for raw grinding

2015年4月17日 Vertical Mill for raw grinding is a type of industrial equipment used to crush or grind materials into small particles Vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materialsHighquality cement vertical roller mill manufacturer Tongli ZJTL series cement vertical mill is a very important link in cement production and is the best choice for raw material grinding and clinker grinding As an iterative product of the ball mill, the vertical mill occupies a small area, which is about 50% less than the ball millCement Vertical Roller Mill CEMENTLThe cement raw materials (lime, silica and iron ore) enter the circuit through two apron feeders The raw materials are crushed in a hammer crusher to D 95 of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µmModeling and simulation of vertical roller mill using population 2017年5月1日 For decades vertical roller mills have been in use in the cement industry for the grinding of cement raw material and coal Since the 1980's this mill type has also been used for combined or (PDF) Grinding process optimization — Featuring case

TRM SERIES CEMENT VERTICAL ROLLER MILLTRM SERIES

TRM series Raw Vertical Roller Mill is the specialized equipment for raw material grinding independently developed by us Presently, it has been widely applied in cement production lines of different capacity The followings are the main steps of the development of TRM Series Raw Vertical Roller MillThe limestone powder vertical grinding mill grinds materials by the principle of material layer grinding, with low energy consumption The power consumption of the grinding system is 20% to 30% lower than that of the ball mill, and the energy saving effect is more obvious as the moisture of the raw material increasesLimestone Powder Ultrafine Vertical Roller Millraw material grinding, a modular vertical roller mill with 5 m table diameter and 4 rollers was added The existing kiln systems were partly modernized, one kiln system was replaced by new system Grinding Process Optimization Featuring Case Studies and 2022年1月23日 Vertical stirred mills (VSM) are widely used for powder processing in many situations like mechanical alloying preparation and raw material crushing and shapingAnalysis and Optimization of Grinding Performance of Vertical Roller

HLM Vertical Grinding Mill Vertical Roller Mill

HLM vertical grinding mill and vertical roller mill is a highefficiency energysaving advanced pulverizing equipment integrating drying, pulverizing, grading and conveying, which has been researched and developed by Guilin Hongcheng Company for more than 20 years Hongcheng HLM vertical grinding mill has the advantages of high grinding efficiency, low power Vertical roller mill for raw materials Grinding raw materials needs lots of energy Tube mills had been used for grinding, but the energy efficiency level was lower A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is groundVertical roller mill for raw materialsWorking principle: The raw material is lifted by the bucket elevator and then pass through the iron remover to remove the other object, after that the raw material is fed into the coal vertical roller mill through a star airlock valve, once the material drops down form the top of the coal vertical roller mill landed at the center of the grinding table, through centrifugal force, the raw Coal vertical roller millVertical roller millPRODUCTTongli 2016年9月1日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Operational parameters affecting the vertical roller mill

Slag Vertical Roller Mill

2023年1月10日 Project capacity: 80,000 tons/year Processing material: slag Finished product size: 150200 mesh D90 Equipment configuration: LM vertical roller mill Treatment process: dry method Raw material source: selfgenerated solid waste from the Group's thermal power plant Finished product use: new marble material Process of Slag Grinding Plantincrease, and improve, friction coeffi cient of material in the grinding area directly beneath the mill roller In the 1980s, UBE developed the 2way system shown in Figure 1, where deaeration and compaction of the raw material bed on the grinding table is achieved by subroller pressing, improving the material friction coeffi cientYasuhiro Shigemoto, Hirofumi Kasai and Tatsuya Hinauchi,Vertical roller mill Vertical cement mill is a large cement grinding equipment Tongli has successfully developed various models such as ZJTL vertical ultrafine powder roller mill in the field of cement and slag grinding with technological innovation over the years In 2016, Tongli developed the largest limestone raw material vertical mill and cement clinker vertical mill with a Vertical roller mill CEMENTLThe document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2006 Slag Grinding With MPS Vertical Roller Mills

.jpg)

quadropol® thyssenkrupp Polysius Grinding Technologies

Mombasa Cement Ltd ordered a QMK² 24/12 with three roller units for the 5,000 tons per day kiln line In addition, the raw material grinding process will be supported by a QMR² 48/24 For the 4,000 tons per day kiln line Shiva Cement Ltd contracted a quadropol® vertical roller mill for grinding pet coke with a QMK² 32/16Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMA2015年1月1日 Vertical cement mill (vertical mill) is a machine that plays an important role in the raw meal production process of the newtype dry cement, and it is a set breakage, drying, grinding, transport in one []Raw material grinding process is a vital and energy consumption link in the cement productionModeling Based on the Extreme Learning Machine for Raw This paper introduces the large raw material roller press finish grinding system developed by Tianjin Cement Industry Design Research Institute Ltd, which adopts newly developed equipment and process technology, such as the large raw meal roller press, new combined separator, lowresistance and highefficiency cyclone, highefficiency fan, and intelligent Industrial application of large raw material roller press finish

Vertical Roller Mills Cement Processing Equipment

With many years of experience in technical innovation within the field of cement and slag grinding, CITIC Heavy Industries (CITIC HIC) has successfully developed various models of vertical roller millsCement vertical roller mill is a kind of equipment used for cement grinding, mainly used (3,000 tpd), 5,000 tons/day (5,000 tpd), 6,000 tons/day (6,000 tpd), and even 8,000 tons/day (8,000 tpd) and above, which are Optimizing the raw material grinding process and the finished product grinding system can also significantly improve the 5000 TPD Cement Production Line CEMENTLvertical roller grinding mill GRMR vertical raw mill vertical for limestone stone Contact Process introduction The GRMR raw material vertical mill of CHAENG is a kind of new high efficiency, forces generated during grinding are Vertical roller mill, Vertical roller grinding mill All A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery

.jpg)

Supply Vertical Roller Mill Customized Factory SINOMALY

Vertical Roller Mill Brand SINOMALY Product origin Liyang, Jiangsu, China Delivery time 7 months Supply capacity 10800tph 1 The vertical roller mill is a highefficiency and energysaving grinding equipment widely used in preparing raw materials and clinker, grinding slag, ore, industrial silicon, calcium carbide slag and coal gangue in the cement industry and in coal The grinding table is one of the key parts of vertical roller mill It includes drag rings to overcome the deficiencies in structure and make the grinding base bear force equivalently All of these avoid the problem of material’s washout on the not wear 20150 tons: Material: ASTM: A570 / BS: S235JR / JIS: SS400: Application: Vertical Grinding Table of Vertical Roller Mill Great WallVertical Roller SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powderVertical Roller Mill for Cement Raw Material SINOMALYlarge vertical roller mills for grinding cement raw material Redundancy und interchangeability – große VertikalRollenmühlen für die Rohmehlerzeugung 4DiplIng M Keyssner, Loesche GmbH, Düsseldorf, Germany Reprint from / Sonderdruck aus: Cement International – Issue 2/2007, pp 84–91 Keyssnerdd 1 17072007 11:23:11 UhrRedundancy and interchangeability – large vertical roller mills

Raw Material Preparation in Cement Manufacturing Plant AGICO

In the areas with small annual rainfall and low water content materials, the roller mill grinding system is gradually popularized and applied Comparison of Raw Material Preparation Technology Vertical Raw Material Grinding System Vertical mill is a kind of air2015年4月17日 Vertical Mill for raw grinding is a type of industrial equipment used to crush or grind materials into small particles Vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materialsGreatWall Vertical Mill for raw grinding