Pyrophyllite crushing and processing

.jpg)

Pyrophyllite: An Economic Mineral for Different

2021年12月1日 Attritionscrubbing clearly gives excellent results in separating clay minerals associated with pyrophyllite, which in turn improves the 2022年10月1日 The elastic modulus (B: Bulk modulus, E: Young's modulus, G: Shear modulus) of pyrophyllite increase gradually with augmented pressure and decreases with the process of Mechanical properties of pyrophyllite under the coupling of high In this paper, the physical beneficiation studies for the removal of silica (SiO2%), iron oxide (Fe2O3%), and enrichment of alumina (Al2O3%) in raw pyrophyllite are discussed These Characterization and Beneficiation of Pyrophyllite Springer2024年3月13日 In this paper, the physical beneficiation studies for the removal of silica (SiO 2 %), iron oxide (Fe 2 O 3 %), and enrichment of alumina (Al 2 O 3 %) in raw pyrophyllite are Characterization and Beneficiation of Pyrophyllite

.jpg)

(PDF) Pyrophyllite: An Economic Mineral for Different

There are many ways to make pyrophyllitebased refractories For example, (1) pyrophyllite can be crushed, bonded to sodium silicate, formed into bricks, and fired and (2) small amounts of pyrophyllite can be combined with fireclay, Zeolite NaX and NaA were synthesized by mechanochemical activation of pyrophyllite and pyrophyllitegibbsite mixture followed by hydrothermal reaction in NaOH solution at 75°C Effect of Dry Grinding of Pyrophyllite on the Hydrothermal While partial incorporation of iron into pyrophyllites has been achieved, no synthetic protocol for purely ironbased pyrophyllite has been published yet Here we report about the first artificial synthesis of ferripyrophyllite under Synthetic ferripyrophyllite: preparation, The dehydroxylation of pyrophyllite to pyrophyllite dehydroxylate involves the reaction of the two OH groups, yielding the formation and elimination of one water molecule per half unit cell Pyrophyllite Springer

.jpg)

Research on pressure transmission and sealing performance of

Pyrophyllite B powder blocks from South Africa have the potential to serve as a substitute for domestically produced pyrophyllite without changing the existing superhard material synthesis 2024年3月13日 The representative sample of Pyrophyllite obtained from the mining site underwent a crushing process, reducing it to a particle size of −15 mm using a jaw crusher, as illustrated in Fig 3To facilitate the subsequent characterization endeavors, a sample with a particle size of −74 microns was meticulously prepared through the employment of a universal Characterization and Beneficiation of Pyrophyllite2024年5月30日 This process is designed with 5 steps Crushing and grinding refine the raw ore, magnetic separation removes magnetic minerals, gravity separation further removes impurities, and foam flotation increases the 5 Steps to Process Andalusite–An Excellent Refractory Pyrophyllite is widely used in the fields of sculpture, ceramics, glass, rubber, plastics, papermaking, refractory materials, and synthetic diamonds 03 Mineral processing technology and processing technology Beneficiation and purification ①, crushing and grinding[Huate Encyclopedia of Mineral Processing] This article will take

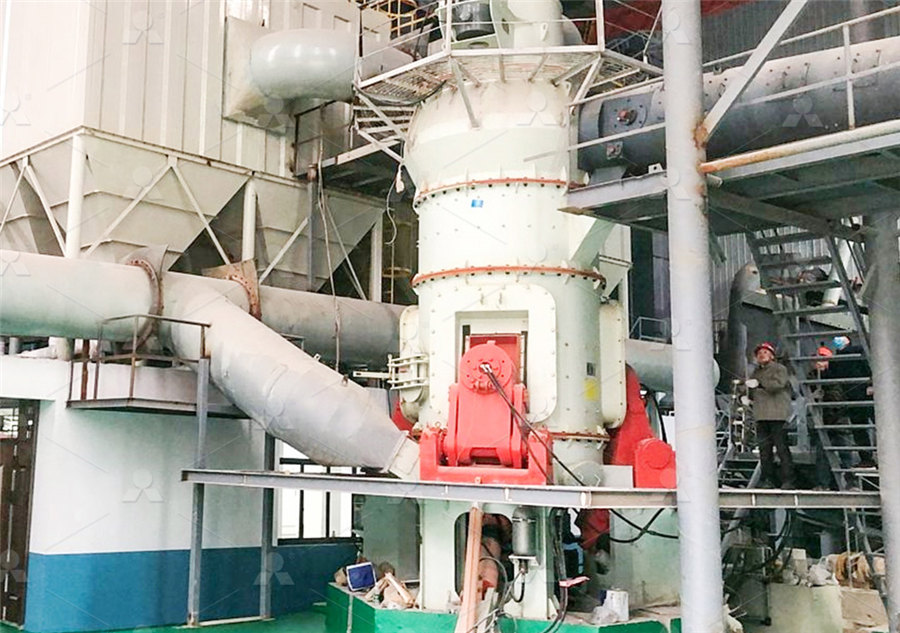

Common pyrophyllite crusher models, how much is a pyrophyllite

2 Pyrophyllite deep processing process: The pyrophyllite crushing production line generally includes the following equipment: feeder, conveyor, crusher, vibrating screening equipment, etc The process flow is as follows: 01 Coarse crushing stage2023年3月15日 ① HGM ultrafine grinding mill: 745 micron (2002500 mesh); D97=5 micron HGM series ultrafine mill has superior performance, stable quality, simple operation and convenient maintenance It can be adjusted arbitrarily to produce finished powder with fineness ranging from 325 mesh to 2500 mesh, which is suitable for grinding hundreds of materials with Serpentine crushing and grinding processing production line 2022年7月20日 Application analysis of limestone crushing, sand making and grinding After testing by several cases and relevant departments, as long as the process of limestone processing sand and gravel materials is reasonable, the finished products can basically meet the requirements stated in the “Standards for Sand and Stone Quality and Inspection Methods for Limestone crushing, sand making and grinding processbetween 3060% of mineral processing/ beneficiation; whilst centrally located plants (near major markets and distribution centres) carry out 2nd and 3rd stage crushing and value addition Transport costs account for up to 65% of sale price In the pyrophyllite industry, location is not important – transport comprises about 2530% of the finalBENTONITE, PYROPHYLLITE AND TALC DMRE

Feldspar Mining Process Equipment Flow Cases JXSC

1 Crushing and grinding The crushing and grinding of feldspar are not only to meet the grain size requirement of the final product, but also to meet the need of the impurity removal process The coarse crushing of feldspar mostly adopts jaw crusher, and the particle size is about 10mmSourcing Guide for Pyrophyllite: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: mining machine, crushing machine, crusher machinePyrophyllite MadeinChina2022年4月20日 The processing of limestone is mainly to crush, classify and produce quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) the ore can be crushed and screened Coarse crushing: The jaw crusher is generally used in the coarse crushing process The jaw crusher has a large crushing force and a large feeding rangeLimestone crushing and grinding production line SBM Ultrafine 2022年8月3日 The iron ore processing and production process mainly includes three processes: crushing, grinding and beneficiation In the crushing process, the threestage closedcircuit crushing is more modern and suitable for high Iron ore crushing and screening process SBM

.jpg)

Rock grinder machine

2022年12月1日 We try to make sure that every stone grinder we build does a specific job correctly That’s why we’ve been a leader in the rock crushing and grinding industry Our engineers have designed a series of rockcrushing 2023年11月30日 For industrial flotation foam image processing, accurate bubble size measurement and feature extraction are very important to optimize the flotation process and to improve the recovery of mineral resources This paper Design, Modeling, Optimization and Control of 2022年8月29日 The dolomite after being roughly crushed by the jaw crusher enters the secondary crushing for further medium and fine crushing processing, so as to facilitate better sand making in the later stage Cone crusher has strong processing capacity, and also has the characteristics of automation and intelligence, high production safety and good environmental Dolomite crushing and sand making production line2021年12月1日 associated with pyrophyllite, which in turn improves the processing economy and energy consumption at the level of industry Appl Sci 2021 , 11 , x FOR PEER REVIEW 11 of 18(PDF) Pyrophyllite: An Economic Mineral for Different Industrial

.jpg)

Pyrophyllite Wikipedia

Pyrophyllite is a phyllosilicate mineral composed of aluminium silicate hydroxide: Al 2 Si 4 O 10 (OH) 2It occurs in two forms (): crystalline folia and compact masses; distinct crystals are not knownThe folia have a pronounced pearly luster, owing to the presence of a perfect cleavage parallel to their surfaces: they are flexible but not elastic, and are usually arranged radially in 2023年11月10日 The pyrophyllite material used in this research was created by crushing and sieving pyrophyllite ore from the Parsovići – Konjic site, Bosnia and Herzegovina Except for silicon dioxide (SiO 2) and aluminum oxide 26 Statistic Data ProcessingThe Effect of Pyrophyllite on Yield Components and Pyrophyllite Processing Technology 1Crushing Stage: Big blocks would be crushed into materials within 15mm50mm the feeding size of grinders 2Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder 3Grading Stage:The ground material with air flow would be PyrophylliteSBM Industrial Technology Group sbmchina2021年12月1日 Pyrophyllite (Al2Si4O10(OH)2) is a phyllosilicate often associated with quartz, mica, kaolinite, epidote, and rutile minerals In its pure state, pyrophyllite exhibits unique properties such as low thermal and electrical conductivity, high refractive behavior, low expansion coefficient, chemical inertness, and high resistance to corrosion by molten metals and gases Pyrophyllite: An Economic Mineral for Different Industrial

(PDF) Processing of Pyrophyllite Ore by Acid Leaching

2018年6月19日 In this study, hydrometallurgical processing of a pyrophyllite ore with 236% Al2O3 grade from Pütürge (Malatya, Turkey) which contains quartz and various aluminum silicate clay minerals like 2022年1月15日 Pyrophyllite [Al 2 Si 4 O 10 (OH) 2] is mainly used in the field of refractories and superhard materials due to its excellent thermal properties such as good heat resistance, stable chemical properties and crystal structure stability during heatingHowever, its thermodynamic properties have rarely been fully described at the atomic scale In this study, the Firstprinciples study on the thermodynamic and thermoelastic Efficient processing and utilization of clay mineral can produce various clay products, which can increase the price of clay and increase the market share Clay processing plant A complete clay processing plant is composed of Efficient and moneysaving clay processing plantThe case studies of three solid waste materials—Manganese dump ores, Sericitic Pyrophyllite and Rice Husk Ash is presented Their characterization, processing and enduse application has been enumerated in detail to establish the fact that judicious processing can lead to sustainable resource utilizationSOLID WASTE PROCESSING FOR INDUSTRIAL UTILIZATION— A

Crushing in Mineral Processing 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceVanderbilt Chemicals, LLC offers a number of industrial minerals designed to improve the physical properties of our customers' formulated products CASE composites consisting of a mineral and resin, balanced in an optimized blend, offer performance advantages not easily achieved by resins alone Our line of reinforcing agents provide a range of particle shapes that help to Markets > CASE > Processing and Reinforcing Agents > 2015年4月16日 Pyrophyllite has a significant role in both geophysics as a hydrous phase, which can recycle water into the Earth’s mantle, and many industrial applications, such as petroleum and civil engineering However, very few works have been proposed to fully characterize the thermodynamic properties of this mineral, especially at atomic scale In the present work, we Structural, vibrational and thermophysical properties of pyrophyllite 1993年1月1日 pyrophyllite recrystallizes to mullite and y alumina, while Institute for Advanced †õ Materials Processing, Tohoku University, 211, Katahira, Aobaku before planetary ball milling Both specimens on crushing became white and its' greasy feel still remained in the powder form The chemical compositions of Original Effect of Dry Grinding on the Structures and Physical

.jpg)

Crushing Mineral Processing 911Metallurgist

2016年1月17日 Secondary Crushing: In mineral processing, it is assumed, for the present purpose that intermediate crushing is not necessary and that the runofmine or quarried mineral has, in one pass, been reduced in size so that all is below say 6in ring size From this stage forward the utilization of the product assumes primary importanceprocessing and characterization of tubula r ceramic support for microfiltration membrane prepared from pyrophyllite clay st cerc st cicbia 2011 12 (3) 267PROCESSING AND CHARACTERIZATION OF TUBULAR CERAMIC 2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage2024年3月13日 The representative sample of Pyrophyllite obtained from the mining site underwent a crushing process, reducing it to a particle size of −15 mm using a jaw crusher, as illustrated in Fig 3To facilitate the subsequent characterization endeavors, a sample with a particle size of −74 microns was meticulously prepared through the employment of a universal Characterization and Beneficiation of Pyrophyllite

5 Steps to Process Andalusite–An Excellent Refractory

2024年5月30日 This process is designed with 5 steps Crushing and grinding refine the raw ore, magnetic separation removes magnetic minerals, gravity separation further removes impurities, and foam flotation increases the Pyrophyllite is widely used in the fields of sculpture, ceramics, glass, rubber, plastics, papermaking, refractory materials, and synthetic diamonds 03 Mineral processing technology and processing technology Beneficiation and purification ①, crushing and grinding[Huate Encyclopedia of Mineral Processing] This article will take 2 Pyrophyllite deep processing process: The pyrophyllite crushing production line generally includes the following equipment: feeder, conveyor, crusher, vibrating screening equipment, etc The process flow is as follows: 01 Coarse crushing stageCommon pyrophyllite crusher models, how much is a pyrophyllite 2023年3月15日 ① HGM ultrafine grinding mill: 745 micron (2002500 mesh); D97=5 micron HGM series ultrafine mill has superior performance, stable quality, simple operation and convenient maintenance It can be adjusted arbitrarily to produce finished powder with fineness ranging from 325 mesh to 2500 mesh, which is suitable for grinding hundreds of materials with Serpentine crushing and grinding processing production line

Limestone crushing, sand making and grinding process

2022年7月20日 Application analysis of limestone crushing, sand making and grinding After testing by several cases and relevant departments, as long as the process of limestone processing sand and gravel materials is reasonable, the finished products can basically meet the requirements stated in the “Standards for Sand and Stone Quality and Inspection Methods for between 3060% of mineral processing/ beneficiation; whilst centrally located plants (near major markets and distribution centres) carry out 2nd and 3rd stage crushing and value addition Transport costs account for up to 65% of sale price In the pyrophyllite industry, location is not important – transport comprises about 2530% of the finalBENTONITE, PYROPHYLLITE AND TALC DMRE1 Crushing and grinding The crushing and grinding of feldspar are not only to meet the grain size requirement of the final product, but also to meet the need of the impurity removal process The coarse crushing of feldspar mostly adopts jaw crusher, and the particle size is about 10mmFeldspar Mining Process Equipment Flow Cases JXSCSourcing Guide for Pyrophyllite: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: mining machine, crushing machine, crusher machinePyrophyllite MadeinChina

Limestone crushing and grinding production line SBM Ultrafine

2022年4月20日 The processing of limestone is mainly to crush, classify and produce quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) the ore can be crushed and screened Coarse crushing: The jaw crusher is generally used in the coarse crushing process The jaw crusher has a large crushing force and a large feeding range