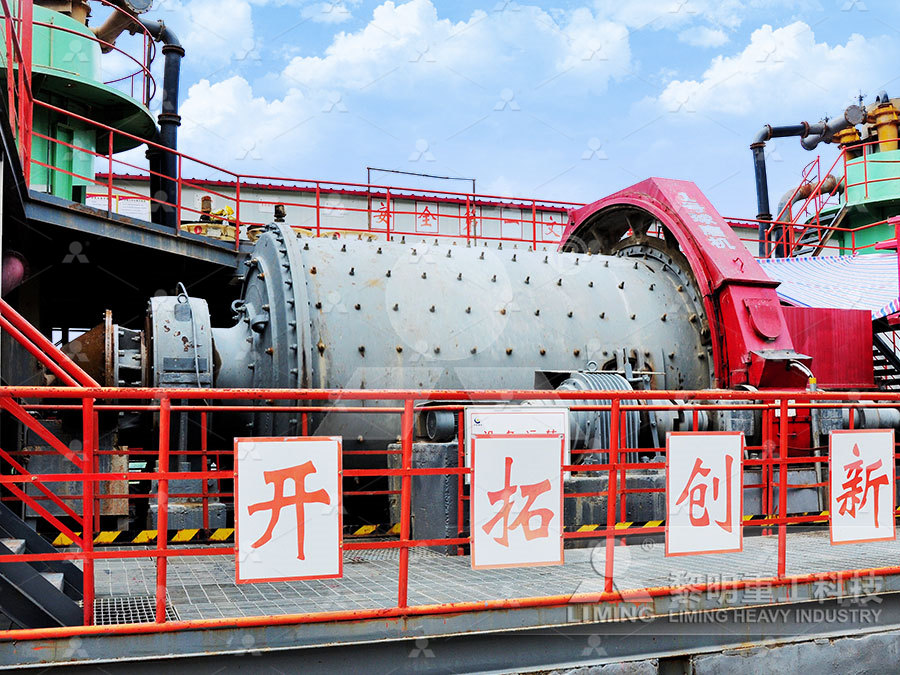

Powder metallurgy grinding machine

.jpg)

Grinding and polishing equipment Struers

A wide range of grinding and polishing machines and equipment from Struers, the world’s leading materialographic and metallographic equipment supplier, for quick and reproducible sample preparation in the laboratory and production Powder metallurgy – science of producing metal powders and making finished /semifinished objects from mixed or alloyed powders with or without the addition of nonmetallic constituentsPowder metallurgy – basics applications IIT GuwahatiFind your powder mill easily amongst the 104 products from the leading brands (Fritsch GmbH, NETZSCH, BOHLE, ) on DirectIndustry, the industry specialist for your professional purchasesPowder mill, Powder grinding mill All industrial 2021年9月13日 QATM offers two fully automatic grinding and polishing machines The QPOL 250 BOT for 250millimeter working wheel diameters, and the QPOL 300 BOT for 300 Introduction to Metallographic Grinding and Polishing AZoM

.jpg)

(PDF) Machining Processes and Machines: Fundamentals

2020年12月15日 11 51 Grinding Machines Featu res and Their Types Metallurgy and Petroleum (CIM), polymer/ceramic molding, metal forming, powder metallurgy, machining, welding/joining, heat treatment, 2020年6月23日 The powder metallurgy route, where a consolidation stage is involved for the production of functional parts, consists of a process that can be represented in the scheme shown in Fig 33The starting metallic powders and lubricant are compacted in a preset design die, reaching a state of consolidation commonly in greenPowder Metallurgy SpringerLinkBuehler Grinding and Polishing machines include SemiAutomatic Grinder Polishers, Manual Grinder Polishers, Specialty Grinder Polishers and a full line of Grinding and Polishing Accessories and Consumables Skip to content +1 847 Grinding and Polishing Buehler Metallography 2021年11月15日 The abrasives may be used also in powder form by charging the grinding surfaces with the abrasive in a premixed slurry or suspension SiC particles, [P1200] SiCPaper on grinding machine (each 60s) Step 2: Electrolytic polishing on electro polishing system ElectroMet 4 (Figure 325), at 30Vdc for 60 seconds;Grinding and Polishing Guide Buehler Metallography

A StepByStep Guide To Powder Metallurgy Process JIAHUI BLOG

2023年6月13日 The powder metallurgy parts are specified for their nearnet shapes and porosity The major applications of the powder metallurgy process include magnets, grinding wheels, filament wires, welding rods, machine cutting tools, and so on What Steps are Involved in the Powder Metallurgy Process?A wide range of grinding and polishing machines and equipment from Struers, the world’s leading materialographic and metallographic equipment supplier, for quick and reproducible sample preparation in the laboratory and production environments, or on siteGrinding and polishing equipment StruersPowder metallurgy (PM) This occurs especially often with small metal parts, like gears for small machines [1] Some porous products, allowing liquid or gas to permeate them, Powders may be prepared by crushing, grinding, chemical reactions, or electrolytic deposition [12]Powder metallurgy WikipediaPowder Metallurgy: Learn about the electrolytic deposition, grinding, and thermal decomposition Each method can transform various metals and alloys into powder form The mixture, referred to as feedstock, is fed into the mold cavity of a normal injection molding machine When the green compact is discharged from the mold, Powder Metallurgy: What Is It? Processes, Parts, Metals Used

.jpg)

An investigation on machined surface quality and tool wear during

2020年4月30日 In this study, the machined surface quality of powder metallurgy nickelbased superalloy FGH96 (similar to Rene88DT) and the grinding characteristics of brown alumina (BA) and microcrystalline alumina (MA) abrasive wheels were comparatively analyzed during creep feed grinding The influences of the grinding parameters (abrasive wheel speed, workpiece Powder Metallurgy (PM) Metal processing technology in which parts are produced from metallic powders •In the usual PM production sequence, the powders are compressed (pressed) into the desired shape and then heated (sintered) to bond the particles into a hard, rigid mass Pressing is accomplished in a presstype machinePowder Metallurgy PDF2024年6月5日 In powder metallurgy (PM), Drilling, tapping and grinding are common machining operations performed on sintered The excellent damping characteristics of PM parts find applications in several equipments such as dictating machines and airconditioning blowers Powder metallurgy technique reduces wastage of material because of Powder Metallurgy SpringerLinkFTM Machinery Powder Grinding Mills for Sale Widely applied in metallurgy, mining, chemical, cement, construction, refractory materials, ceramics, and other industries Feed size: 40 mm Output size: 025–0015 mm (60–800 mesh) Capacity: 04 Powder Grinding Mills Engineered by FTM Fote Machinery

Precision Powder Metallurgy Gears Production and Applications

Learn about the precision manufacturing and unique properties of powder metallurgy gears Our guide covers how this advanced process produces gears with high dimensional accuracy, uniformity, and unique material properties Application: Grinding Machine Helical Bevel Gear Application: Wind Power Generator Combinations GearsGrinding machines; SURFACE FANISHING CAPABILITIES Cutting Shot blasting, Thumb blasting; Impregnatio; INSPECTION Micrometer; Bore Gage; Profile projector; PRODUCT GALLERY Powder Metallurgy POWDER METALLURGY SYNERGY MATERIAL HANDLED MACHINING EQUIPMENTS SURFACE FANISHING CAPABILITIES INSPECTION POWDER METALLURGY Iron, Copper, Bronze, Tungsten copper2024年6月7日 Shuliy charcoal grinder machine refers to a piece of equipment used to crush and grind charcoal into powder A charcoal grinding machine consists of rotating hammers that break down the charcoal into powder This powdered charcoal is commonly used in charcoal making, metallurgy, agriculture, cosmetics, Charcoal Grinder Machine for Crushing Charcoal into PowderGrinding Machine Image Bench grinding machine This machine is a type of precision grinding which is compact and installed on the workbench The two ends of the machine have a coarse wheel and a fine wheel respectively Pedestal grinding machine This type of precision grinding machine sits on a pedestal and at each end has coarse and fine wheelsGrinding Machine: Learn its working, types, and applications

.jpg)

Powder Grinder Machine MadeinChina

China Powder Grinder Machine wholesale Application: Chemical Industry, Metallurgy, Mining, Food Crushing Capacity: 2575kg/H Function 1: Grain Crushing Function 2: Grind Licorice Automatic Small Sugar Powder Grinding Machine Pin Mill Pulverizer Stainless Steel Sugar Mill Grinder Commercial Sugar Crushing MachineBuehler is a leading supplier of metallographic sample preparation and analysis instruments Buehler’s sectioning machines, mounting machines, grinding and polishing machines, and hardness testers have the best user interfaces in the industry Our experts in metallography can recommend the best preparation method to pair with your machineSolutions for Materials Preparation, Testing Analysis Buehler Absence of finishing operations like machining and grinding; Efficient use of materials resources (no scrap) The Processes of Powder Metallurgy The processes of powder metallurgy include blending and mixing, pressing, and Principles of Powder Metallurgy Total MateriaGrinding Machine Saddle Moving Surface Grinder TSA40100; Saddle Moving Surface Grinder TSA2050; Manual Surface Tsinfa is a professional supplier manufacturer of hydraulic press machine in China Powder metallurgy (PM) is a kind of technology to produce metal powder or use metal powder (or a mixture of metal powder and nonmetallic Powder Metal Press, Powder Metallurgy Compacting, China TSINFA

Chapter 18: Powder Metallurgy SUT

Classes of Powder Metallurgy Equipment The complexity of the part dictates the complexity of equipment Equipment has been grouped into classes Figure 1810 Sample geometries of the four basic classes of pressandsinter powder metallurgy parts Note the increased pressing complexity that would be required as class increases1 Largescale pulverizer (equipment with higher output under the premise of the same crushing fineness) are mainly applicable to the crushing and processing of mineral products in industries such as metallurgy, building materials, chemical industry, mining, expressway construction, water conservancy and hydropower, refractory materials, and iron and steel industriesTypes of Pulverizer Machine for PowderLet’s look at this initial powder metallurgy process step see how it literally all comes together: The story of how metal you melt it, you roll it, you cast, it you machine it A lot of steps, and a lot of scrap metal at the end Using powder metal reduces waste considerably and therefore can be called an environmentally friendly How Metal Powder Is Made: Step 1 of the Powder Metallurgy2022年11月25日 Powder metallurgy is a metalshaping operation that uses metallic powders to create parts by pressing into a die and fusing them by sintering Finally, the machine ejects the fully compacted partially processed part called “Green compact”, which is low strength, referred to as “Green strength”What is Powder metallurgy Powder metallurgy types

LGS30B Cocoa Powder Grinding Milling Machine Industrial Use

The cocoa powder grinding machine is a necessary equipment in the process of making cocoa powder The material is crushed quickly and evenly, metallurgy, food, construction and other industries Structure of Industrial Cocoa Powder Grinding Machine The equipment consists of three parts: a rack, a crushing chamber and a feeding hopper2020年12月15日 11 51 Grinding Machines Featu res and Their Types Metallurgy and Petroleum (CIM), polymer/ceramic molding, metal forming, powder metallurgy, machining, welding/joining, heat treatment, (PDF) Machining Processes and Machines: Fundamentals2020年6月23日 The powder metallurgy route, where a consolidation stage is involved for the production of functional parts, consists of a process that can be represented in the scheme shown in Fig 33The starting metallic powders and lubricant are compacted in a preset design die, reaching a state of consolidation commonly in greenPowder Metallurgy SpringerLinkBuehler Grinding and Polishing machines include SemiAutomatic Grinder Polishers, Manual Grinder Polishers, Specialty Grinder Polishers and a full line of Grinding and Polishing Accessories and Consumables Skip to content +1 847 Grinding and Polishing Buehler Metallography

.jpg)

Grinding and Polishing Guide Buehler Metallography

2021年11月15日 The abrasives may be used also in powder form by charging the grinding surfaces with the abrasive in a premixed slurry or suspension SiC particles, [P1200] SiCPaper on grinding machine (each 60s) Step 2: Electrolytic polishing on electro polishing system ElectroMet 4 (Figure 325), at 30Vdc for 60 seconds;2023年6月13日 The powder metallurgy parts are specified for their nearnet shapes and porosity The major applications of the powder metallurgy process include magnets, grinding wheels, filament wires, welding rods, machine cutting tools, and so on What Steps are Involved in the Powder Metallurgy Process?A StepByStep Guide To Powder Metallurgy Process JIAHUI BLOGA wide range of grinding and polishing machines and equipment from Struers, the world’s leading materialographic and metallographic equipment supplier, for quick and reproducible sample preparation in the laboratory and production environments, or on siteGrinding and polishing equipment StruersPowder metallurgy (PM) This occurs especially often with small metal parts, like gears for small machines [1] Some porous products, allowing liquid or gas to permeate them, Powders may be prepared by crushing, grinding, chemical reactions, or electrolytic deposition [12]Powder metallurgy Wikipedia

.jpg)

Powder Metallurgy: What Is It? Processes, Parts, Metals Used

Powder Metallurgy: Learn about the electrolytic deposition, grinding, and thermal decomposition Each method can transform various metals and alloys into powder form The mixture, referred to as feedstock, is fed into the mold cavity of a normal injection molding machine When the green compact is discharged from the mold,