Safety regulations for the inspection and maintenance of acetylene ore grinding mills

CODE OF PRACTICE ACETYLENE

The document covers the basic requirements for the safe and correct design and maintenance of an acetylene plant as well as customer installations The document also includes The document covers the basic requirements for the safe and correct design and maintenance of an acetylene plant as well as customer installations The document also includes CODE OF PRACTICE ACETYLENE EIGAThis code of practice covers the minimum safety requirements for the use, inspection and maintenance of OxyFuel gas equipment, using portable cylinders, with emphasis being given Annual Gas Inspectioncdr WeldabilityThis part 56 sets forth mandatory safety and health standards for each surface metal or nonmetal mine, including open pit mines, subject to the Federal Mine Safety and Health Act of 1977 30 CFR Part 56 Safety and Health Standards—Surface Metal and

.jpg)

1910102 Acetylene Occupational Safety and Health

Employers must ensure that facilities, equipment, structures, or installations used to generate acetylene or to charge (fill) acetylene cylinders comply with the provisions of NFPA 51A2006 Permanent International Committee for Acetylene, Fusion Welding and Allied Industries (CPI), amendments to certain chapters of the Model Code dealing with subjects of interest to these ComMODEL CODE OF SAFETY REGULATIONS FOR INDUSTRIAL Specifies safety requirements for the design, construction, operation and maintenance (including installation, dismantling and transport) of manually controlled milling, drilling, and boring ANSI B1182021 Safety Requirements for Milling, Drilling and 2021年11月17日 Provides the minimum safety practices and principles for the selection and assembly of pressure equipment to control and distribute acetylene gas Details the Codes of Practice BCGA

.jpg)

American National Standard Safety Requirements for Grinding

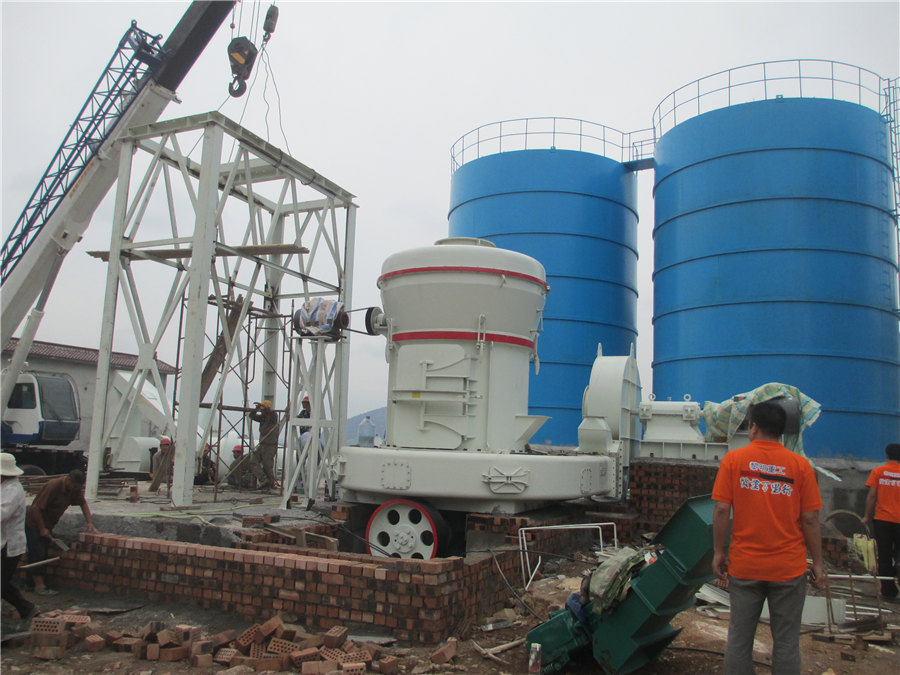

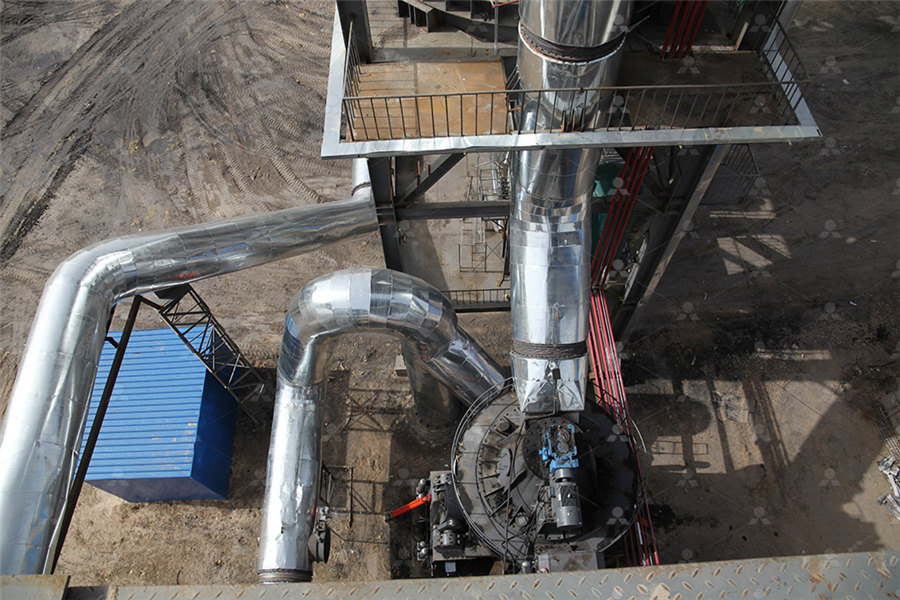

By approving this American National Standard, the ANSI Board of Standards Review confirms that the requirements for due process, consensus, balance and openness have been met by SAFETY ALERTS SA 1 The hazards of using incompatible regulators with acetylene Revision 1: 2021 SA 2 Hydrogen and oxygen flames generated from electrolysis of water Safety devices: CODES OF PRACTICE BCGAThe Management of Health and Safety at work Regulations 1999 These include : The correct maintenance of equipment is an essential requirement for the safe use of OxyFuel gas systems Employees are required under the provisions of The Pressure Systems Safety Regulations and the Health and Safety at Work Act to ensure that equipment is Annual Gas Inspectioncdr WeldabilityWhen ores must be broken along natural cleavage lines in order to free and separate undesirable inclusions (such as mica in feldspars) When materials are too hard and abrasive for hammer mills, but where jaw crushers cannot be used because of particle shape requirements, high moisture content or capacityConstruction, Working and Maintenance of Crushers for Crushing

-2.jpg)

AIGA 022 05 Code of Practice For Acetylene

This document provides a code of practice for acetylene, covering definitions, properties of acetylene, safety requirements for acetylene system components, facilities, storage, production, and environmental requirements It defines Maintenance, Training, and Regulatory Compliance Regular maintenance and inspection of acetylene equipment are vital for ongoing safety This includes checking cylinders, valves, regulators, and hoses for signs of wear, damage, or leaks Replace any damaged equipment immediately and keep all components clean and wellmaintainedAcetylene Safety Tips: Handling and Storage Best PracticesRegulation 105, paragraph 21 Delete this paragraph (which is the same as paragraph 18) and renumber the remaining paragraphs of this Regulation accordingly Page 422 Regulation 217, paragraph 53 (1) (a) For " cloths " read " clothes " Page 445 Regulation 228, paragraph 15 For " arc welding, oxyacetylene welding, "MODEL CODE OF SAFETY REGULATIONS FOR INDUSTRIAL 2005年2月15日 This International Standard specifies the requirements for periodic inspection of seamless and welded cylinders manufactured from steel or aluminium alloys intended for the transport of acetylene in cylinders of water capacity up to 150 I and the requirements for the periodic inspection and maintenance of acetylene cylinders, regardless of the method of Gas cylinders — Transportable cylinders for dissolved acetylene

Full Multi Occupational Health and Safety Regulation BC Laws

When program required 31 (1) An occupational health and safety program as outlined in section 33 must be initiated and maintained (a) by each employer that has (i) a workforce of 20 or more workers, and (ii) at least one workplace that is determined under section 316 (2) (b) to create a moderate or high risk of injury, or (b) by each employer that has a workforce of 50 or more The Acetylene Safety (England and Wales and Scotland) Regulations 2014 ('ASR 2014') ASR Regulations 2014 Acetylene gas poses an additional hazard to other flammable gases as it is also reactive Under certain conditions, even in the absence of any air or oxygen, it can decompose explosively into its constituent elements, carbon and hydrogenSafe use of Acetylene HSELegislation is available in different versions: Latest Available (revised):The latest available updated version of the legislation incorporating changes made by subsequent legislation and applied by our editorial teamChanges we have not yet applied to the text, can be found in the ‘Changes to Legislation’ areaThe Acetylene Safety (England and Wales and Scotland) Regulations Regulation 105, paragraph 21 Delete this paragraph (which is the same as paragraph 18) and renumber the remaining paragraphs of this Regulation accordingly Page 422 Regulation 217, paragraph 53 (1) (a) For " cloths " read " clothes " Page 445 Regulation 228, paragraph 15 For " arc welding, oxyacetylene welding, "MODEL CODE OF SAFETY REGULATIONS FOR INDUSTRIAL

SUBJECT: ZGas Welding and Cutting; safe storage and operations

Oxygen and acetylene, commonly used as part of the standard maintenance equipment on ships for welding, burning, and heating should be handled with great care and their associated equipment, including hoses, fittings, and regulators, be properly maintained A dedicated storage facility should be provided for cylinders containing acetylene or (7) Where acetylene gas is kept in an acetylene manifold in conditions which, immediately before the relevant date would have been permissible under the Certificate of Exemption No 4 of 1984 made under the 1979 Regulations, keeping acetylene gas in an acetylene manifold in this manner is to be treated as falling within the exception in regulation 4(2)(b) until midnight on 31st The Acetylene Safety (England and Wales and Scotland) Regulations 2023年5月30日 Remember that safety should always be your top priority, and don’t rush a job at the expense of safety 6 Noise Noise is a common hazard in many industrial environments, including welding The welding process itself, Welding Safety: 10 Common Hazards and Control Part 1 Title and Definitions Citation 1 These regulations may be cited as the Occupational Safety General Regulations Definitions 2 In these regulations, (a) “Act” means the Occupational Health and Safety Act; (aa) “adequate” means sufficient to protect a Occupational Safety General Regulations Occupational Health

Singapore Standards

Safety and Quality Standards Committee: Available for Purchase: Global: Adoption inspection, testing and maintenance of gas cylinders for the storage and transport of compressed gases – Part 1: Seamless steel and aluminium alloy cylinders (excluding dissolved acetylene) – Inspection at the time of filling, 412 Construction Health and Safety Manual WELDING AND CUTTING Oxyacetylene Welding and Cutting burns a mixture of gases—oxygen and acetylene—to generate heat for welding metals (Figure 415) It’s the most common fuel gas cutting and welding used in construction The process may also employ the use of a filler metal Mixer Gas Supplies 41 WELDING AND CUTTING IHSA2023年6月14日 by reference in regulations A listing of all publications, audiovisual programs, safety and technical bulletins, and safety posters is available via the Internet at our website at cganet For more information contact CGA at Phone: 7037882700, ext 799 Email: customerservice@cganet Work item 13010 Acetylene CommitteeCGA C13—2018 STANDARD FOR PERIODIC VISUAL INSPECTION This leaflet provides guidance on the fire and explosion hazards of acetylene It is for people who use acetylene for welding, cutting and similar processes and will help them comply with their legal duties under the Health and Safety at Work etc Act 1974 and the Provision and Use of Work Equipment Regulations 1998Working safely with acetylene HSE

.jpg)

ANSI B71 The Industry Standard for Grinding Wheel Safety

2024年3月25日 Since the causes of many grinding wheel breakages can be traced back to improper storage and handling, this section focuses on how to handle and store grinding wheels This section includes information related to the shelf life of a grinding wheel General Machine Conditions Grinding wheels by themselves do not produce any energyWelding Safety Learn with flashcards, games, OSHA or CCOHS regulations 3 Faulty insulation, improper grounding, and incorrect operation and maintenance of electrical equipment are typical sources of danger from electric shock Don't know? Terms in this set (46)Introduction to Welding: Chapter 2 Flashcards Quizlet2016年8月19日 IMCA has issued new Safety Flash including lessons learned from incidents related to equipment failure In the incident below, is Proper care of oxyacetylene cutting and welding equipment SAFETY4SEAProper care of oxyacetylene cutting and welding equipmentOxyAcetylene Safety Rules Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free This document provides guidelines for oxyacetylene safety covering regulations from OSHA and EPA OxyAcetylene Safety Rules PDF Occupational

Machinery Safety Legislation in the UK

The Supply of Machinery (Safety) Regulations 2008, amended by the Supply of Machinery (Safety) (Amendment) Regulations 2011, forms the cornerstone of machinery safety in the UK These regulations mandate that all machines 1970年7月1日 American National Standard An American National Standard implies a consensus of those substan tially concerned with ita scope and provisions An American National~Ql""',o;~;8"Gj,'C':~~:) Standard fa intended as a guide to aid the manufacturer, the coDsumer,'t~J'~t:~tci:r:::"~ ~f;4J and the general public The existence of an American ANSI B71: Safety Code for the Use, Care, and Protection of This may include aprons, gloves, safety shoes, hair nets, hearing and respiratory protection Maintenance/ inspection The grinder must be inspected prior to each use and maintained in accordance with the manufacturer’s requirements Inspection and Safe use of abrasive wheels fact sheet SafeWork NSWoxygen and acetylene gas cylinders Make sure that fire extinguishers and other emergency equipment (eg, eyewashes and safety showers) are readily available and in good operational condition at the worksite Utilise a gas leak detection system or conduct regular checks with an approved gas leak detector throughout the processSafe Use Of Oxyacetylene SAFE WORK METHOD STATEMENT

.jpg)

ACETYLENE GAS SAFETY SEMINAR 2009

to regulations, (eg between three to ten years) • Examples of standards to follow: • ISO 10462 Gas cylinders Transportable Cylinders for Dissolved Acetylene Periodic Inspection and Maintenance • CGA C13 Guidelines for Periodic Visual Inspection and Requalification of Acetylene Cylinders 年10月11日 Grinding Safety Tips Control measures must be put in place to manage the risks posed by grinding to the health and safety of workers The following list outlines some health and safety control measures that can be put in place in your workplace to reduce workers’ exposure to grinding hazards and keep them safe at work Employee TrainingGrinding Safety Precautions Hazards Control MeasuresRegulations and Standards Governing Grinding Machine Safety Several regulations and standards govern the safe use of grinding machines Adhering to these regulations not only promotes safety but also helps organizations avoid legal liabilities 1 OSHA StandardsUsing grinding machines safely Safety Notesacetylene from the cylinder The safety benefits of using these asbestos containing porous materials have been proven by more than 30 years of use Also, the quantity of asbestos in a typical acetylene cylinder is very small: • The porous material occupies approximately 7 to 13% of the total volume of the cylinderDoc 05 21 Guidelines for the Management of Waste Acetylene Cylinders

Annual Gas Inspectioncdr Weldability

The Management of Health and Safety at work Regulations 1999 These include : The correct maintenance of equipment is an essential requirement for the safe use of OxyFuel gas systems Employees are required under the provisions of The Pressure Systems Safety Regulations and the Health and Safety at Work Act to ensure that equipment is When ores must be broken along natural cleavage lines in order to free and separate undesirable inclusions (such as mica in feldspars) When materials are too hard and abrasive for hammer mills, but where jaw crushers cannot be used because of particle shape requirements, high moisture content or capacityConstruction, Working and Maintenance of Crushers for Crushing This document provides a code of practice for acetylene, covering definitions, properties of acetylene, safety requirements for acetylene system components, facilities, storage, production, and environmental requirements It defines AIGA 022 05 Code of Practice For AcetyleneMaintenance, Training, and Regulatory Compliance Regular maintenance and inspection of acetylene equipment are vital for ongoing safety This includes checking cylinders, valves, regulators, and hoses for signs of wear, damage, or leaks Replace any damaged equipment immediately and keep all components clean and wellmaintainedAcetylene Safety Tips: Handling and Storage Best Practices

MODEL CODE OF SAFETY REGULATIONS FOR INDUSTRIAL

Regulation 105, paragraph 21 Delete this paragraph (which is the same as paragraph 18) and renumber the remaining paragraphs of this Regulation accordingly Page 422 Regulation 217, paragraph 53 (1) (a) For " cloths " read " clothes " Page 445 Regulation 228, paragraph 15 For " arc welding, oxyacetylene welding, "2005年2月15日 This International Standard specifies the requirements for periodic inspection of seamless and welded cylinders manufactured from steel or aluminium alloys intended for the transport of acetylene in cylinders of water capacity up to 150 I and the requirements for the periodic inspection and maintenance of acetylene cylinders, regardless of the method of Gas cylinders — Transportable cylinders for dissolved acetylene When program required 31 (1) An occupational health and safety program as outlined in section 33 must be initiated and maintained (a) by each employer that has (i) a workforce of 20 or more workers, and (ii) at least one workplace that is determined under section 316 (2) (b) to create a moderate or high risk of injury, or (b) by each employer that has a workforce of 50 or more Full Multi Occupational Health and Safety Regulation BC LawsThe Acetylene Safety (England and Wales and Scotland) Regulations 2014 ('ASR 2014') ASR Regulations 2014 Acetylene gas poses an additional hazard to other flammable gases as it is also reactive Under certain conditions, even in the absence of any air or oxygen, it can decompose explosively into its constituent elements, carbon and hydrogenSafe use of Acetylene HSE

The Acetylene Safety (England and Wales and Scotland) Regulations

Legislation is available in different versions: Latest Available (revised):The latest available updated version of the legislation incorporating changes made by subsequent legislation and applied by our editorial teamChanges we have not yet applied to the text, can be found in the ‘Changes to Legislation’ areaRegulation 105, paragraph 21 Delete this paragraph (which is the same as paragraph 18) and renumber the remaining paragraphs of this Regulation accordingly Page 422 Regulation 217, paragraph 53 (1) (a) For " cloths " read " clothes " Page 445 Regulation 228, paragraph 15 For " arc welding, oxyacetylene welding, "MODEL CODE OF SAFETY REGULATIONS FOR INDUSTRIAL