Quick lime coal process flow

.jpg)

1117 Lime Manufacturing US EPA

In some lime plants, the resulting lime is reacted (slaked) with water to form hydrated lime The basic processes in the production of lime are: (1) quarrying raw limestone; (2) preparing 2021年9月1日 Industrially produced quicklime from a coalfired rotary kiln was analyzed and compared with laboratoryscale studies of surface interactions between two coal ashes and Coal ash and limestone interactions in quicklime production2023年6月5日 Among the various kiln designs, parallel flow regenerative (PFR) kilns with pulverized coal combustion are the predominant technology The performance of the PFR Transient simulation of heat and mass transfer in a parallel flow Section 2 provides a detailed description of the production process for lime, with discussions of individual lime products, limestone inputs, and costs of production Section 3 describes the Lime Production: Industry Profile

Quick Lime Preparation, Properties and Uses Hebei Yayang

2023年10月11日 Quicklime, also referred to as lime (calcium oxide (CaO)), is derived from high quality, natural deposits of limestone (calcium carbonate (CaCO3)) or dolomitic limestone 2021年10月4日 Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO 3) into quicklime (CaO) and carbon dioxide (CO 2), also called Natural and enhanced carbonation of lime in its different The slagging process is determined by the reactivity of lime, whereas the reactivity is closely related to its microstructure When the quicklime particles are charged into a converter, a Evolution of physicochemical properties of quick lime at converter Quicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, mediumburnt lime, and hardburnt lime In the construction industry, quicklime is added to Quicklime preparation Gebr Pfeiffer

.jpg)

Differences Between Hydrated Lime and Quicklime

2023年11月9日 In the form of alkali, it is the cheapest and very significant ingredient in making caustic soda It is also very important for humans as calcium is the most required component for bones and teeth The density of quick lime is 336g/cm3, and its molecular mass is 56882 g/mol Quick lime’s boiling and the Melting point are 2,860o C and 2578o C2021年8月1日 As calcium carbide (CaC 2) production is an energyintensive industry, a novel low rank coal to CaC 2 (LRCtCC) process has been developed This study is aimed to evaluate the technoeconomic performance of the LRCtCC process A model integrating particle swarm optimization and nonlinear programming (PSONLP) is developed to predict the behavior of Case study of a novel low rank coal to calcium carbide process based 2012年1月27日 However, quicklime’s hydrophobic reaction with water requires a lime slaker to be used in the process The quick lime is generally received in pebbles of about one quarter to one eighth of an inch, or in powder Differences between Hydrated lime and quicklimeDownload scientific diagram The quick lime lumps production process from publication: Experimental Investigation of Traditional Clay Brick and Lime Mortar Intended for Restoration of Cultural The quick lime lumps production process ResearchGate

QUICK LIME AND BYPRODUCTS PEC Consulting Group

Sulfite Process Plants using the sulfite process consumed large quantities of quicklime for the preparation of the calcium bisulfiteliquor capable of dissolving the noncellulosic wood elements This process is disappearing due to waste disposal problems Bleaching lime is used as a bleaching agent for pulpQuick Lime Calcination Plant In calcination process, lime is cooked/calcined at 800°c in a kilnWe are providing shafts kilns and rotary kilns for calcining of limestone/lime sludge with multi fuel options Prior to calcination, exhaust gases of kiln preheat limeHydrated, Quick, and PCC Lime Processing Plant ChanderpurThe application of the lime sinter process is restricted by the high consumption of calcium, “Effect of temperature on phase and alumina extraction efficiency of the product from sintering coal fly ash with ammonium sulfate,” Chinese Journal of An Improved Lime Sinter Process to Produce Al SpringerIt is also the name of the natural mineral (native lime) CaO which occurs as a product of coal seam fires and in altered limestone xenoliths in volcanic ejecta PROCESS FLOW DIAGRAM OF QUICK LIME/SLAKED LIME MANUFACTURING PROCESS OF QUICK LIME IN DETAILS QUICK LIME PROCESSES MAINLY CONTAINS THE FOLLOWING BASIC STEPS 1Project Report on QUICK LIME/SLAKED LIME Manufacturing Process

Lime kiln Wikipedia

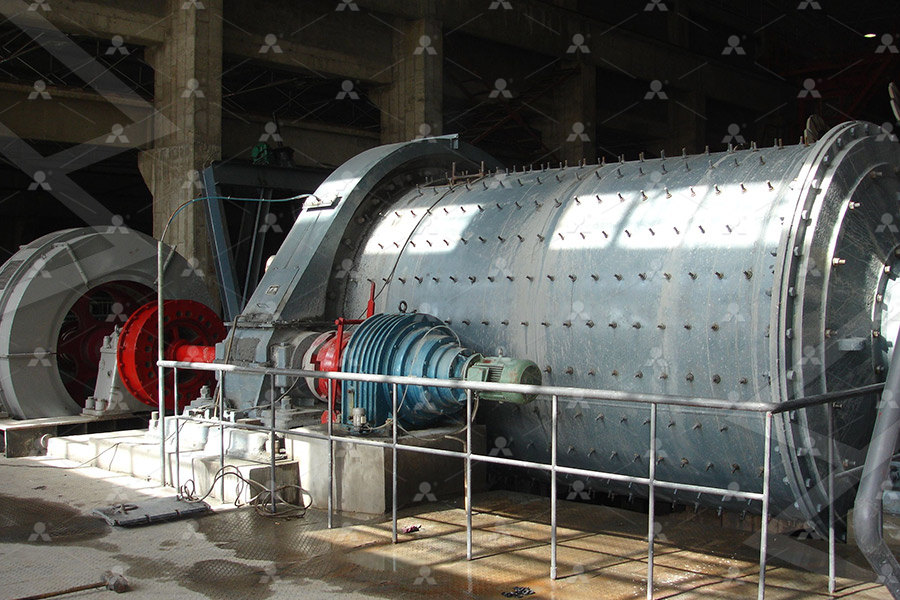

Rotary lime kiln (rustcolored horizontal tube at right) with preheater, Wyoming, 2010 Traditional lime kiln in Sri Lanka A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide)The chemical equation for this reaction is CaCO 3 + heat → CaO + CO 2 This reaction can take place at anywhere above Process Flow of Lime Production Line 1Raw Material Preparation Limestone: The particle size of limestone should be between 10~40mm The proportion of limestone size above 40mm or below 10mm should not be more than 5% The maximum size should be less than 40mm Fuel:Furnace gas, gas, coalbed methane, pulverized coal could be used as fuelLime Production Line AGICO Cement PlantWe can modify the project capacity and project cost as per your requirement If you need any customized project report and BANKABLE project reports as per your requirement, Click here to CONTACT US Or Call us at +91, +91, +91 011 , , for quick response All reports are prepared by highly qualified Project Report on QUICK LIME Manufacturing Process Books Process flow diagram for calcium carbide manufacturing (SCC = Source Classification Code) 1142 EMISSION FACTORS 1/95 is the coal tar pitch binder in the furnace electrode paste Since the maximum volatiles content in the electrode paste is about 18 percent, 114 Calcium Carbide Manufacturing US EPA

Decarbonising the lime industry: Stateoftheart ScienceDirect

2022年10月1日 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is scarce Subsequent hydration of lime would lead to the synthesis of slaked/hydrated lime Ca(OH) 2; the production of a tonne of Ca(OH) 2 emits ∼12 tonnes of CO 2 arising mainly from the Coal, oil, and natural gas may all be fired in rotary kilns Product coolers and kiln feed preheaters of various types are commonly used to recover heat from the hot lime product and hot exhaust gases, Process flow diagram for lime manufacturing 4 (SCC = Source Classification Code) 2/98 Mineral Products Industry 111731117 Lime Manufacturing US Environmental Protection AgencyThe production of quicklime is one of the oldest chemical processes developed by mankind But there is often a lot of confusion between terms like lime and quicklime Are you wondering what quicklime is, and what it is made of? Then you've come to the right page! ScienceStruck gives you a lot of information about quicklime, and explains how it is industrially madeWhat is Quicklime and How is it Made? Science Struck2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is Lime/quicklime for metallurgy – how producing and briquetting

.jpg)

Calcium Oxide (CaO) Preparation, Properties Uses of Quicklime

Quick lime is an amorphous white solid with a high melting point of 2600 ° It is a very stable compound and withstands high temperatures In the presence of water, it forms slaked lime This process is called the slaking of lime CaO+H 2 O → Ca (OH) 2 It is an oxide that is basic in nature and forms salts when it comes in contact with an acid2013年3月25日 Flow Chart : Chemistry Quick lime is heated with NH 4 Cl to form NH 3 and calcium chloride (by product) Ammonia is used again in this process 2NH 4 Cl + Ca quick lime process flow diagram Mining Quarry Plantinto the exhaust gas, dust collection equipment must be installed on fluidised bed kilns for process economy 212 Parallel Flow Regenerative Kilns Another alternative process that has recently emerged in Australia is the parallel flow regenerative (PR) lime kiln This process combines two advantages First, optimum heating conditions for limeEmission Estimation Technique Manual2023年6月5日 The structure of the investigated industrial PFR kiln with injected pulverized coal is shown in Fig 1 Pulverized coal is injected into the burning shaft through the coal lances The arrow in Fig 1 represents the flow of gas or solids (limestone and quick lime) Different colors of the arrow represent different temperaturesTransient simulation of heat and mass transfer in a parallel flow

Project Report on LIME CALCINATION PLANT Manufacturing Process

process description of lime menufacturing process flow diagram for lime manufacturing process flow diagram for manufacture of calcium oxide (calcined lime) production of quicklime shaft kiln figure: schematic of shaft kiln figure: the heat flow in a pfr shaft kiln rotary kiln schematic figure of a typical rotary kiln the limestone is transported2018年5月25日 Generally, two processes have been proposed for Al 2 O 3 extraction from clays and lowgrade aluminium ores: the first is an acid process that uses sulfuric acid, hydrochloric acid or nitric acid (PDF) Studying the Efficiency of LimeSoda Sinter Quicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industry In the basic oxygen steelmaking (BOS) process, quicklime Quicklime Preparation, Properties, and Applications with FAQs2022年3月16日 The hydrated lime production line is to crush the qualified hydrated lime blocks to a particle size of about 40mm by the jaw crusher, and send them to the hydrated lime storage tank silo through the bucket elevator The digester performs preliminary digestion When the hydrated lime completes the primary digestion, it enters into the Ⅱlevel digestion or the Ⅲ Process flow of hydrated lime production line Gaifeng

.jpg)

Lime, reagent in water treatment Degremont®

Lime is the most widely used reagent in water treatment applications It is supplied in two forms: quick lime: CaO; slaked (or hydrated) lime: Ca(OH) 2 Warning: in both cases, these reagents will contain between 4 and 20% of solid impurities (CaCO 3, SiO 2 ) These impurities must be removed before the product is usedmanufacturers/suppliers of quick lime process flow chart manufacturing process of quick lime quick lime processes mainly contains the following basic steps 1 procurement of raw material (lime stone) 2 lime stone storage and preparation 3 crushing process of raw material 4 screening process 5 washing process 6 storage of lime stone 7Project Report on QUICK LIME POWDER Manufacturing Process Coal, oil, and natural gas may all be fired in rotary kilns Product coolers and kiln feed preheaters of various types are commonly used to recover heat from the hot lime product and hot exhaust gases, Process flow diagram for lime manufacturing 4 (SCC = Source Classification Code) 2/98 Mineral Products Industry 111731117 Lime Manufacturing US EPA2021年12月10日 Integrated process for coal chemical demineralization and spent caustic >95% of the silica and alumina impurities In the second step, 892% caustic soda is recovered by causticization using quick lime Graphical abstract Download: Download The detailed process flow sheet for the spent alkali carbonation process is Integrated process for coal chemical demineralization and spent caustic

.jpg)

Transient simulation of heat and mass transfer in a parallel flow

2023年6月5日 In addition to its impact on CO 2 emissions, the thermal calcination process in the kiln also determines the quality of the produced quicklime The limestone does not decompose completely if the calcination temperature and operating time, which are critical parameters [4], [5], are below or less than the recommended valuesHowever, the activity of the produced Due to the conditions of parallel flow of the kiln charge and the combustion gases in the burning shaft, the parallel flow regenerative kiln (PFR kiln) is perfectly suitable for the production of soft burnt, high reactive quicklime [1] In addition, with regen MAERZ OFENBAU AG New PFR lime kiln process with blast furnace gas and oxygenNew PFR lime kiln process with blast furnace gas and oxygen2023年11月9日 In the form of alkali, it is the cheapest and very significant ingredient in making caustic soda It is also very important for humans as calcium is the most required component for bones and teeth The density of quick lime is 336g/cm3, and its molecular mass is 56882 g/mol Quick lime’s boiling and the Melting point are 2,860o C and 2578o CDifferences Between Hydrated Lime and Quicklime2021年8月1日 As calcium carbide (CaC 2) production is an energyintensive industry, a novel low rank coal to CaC 2 (LRCtCC) process has been developed This study is aimed to evaluate the technoeconomic performance of the LRCtCC process A model integrating particle swarm optimization and nonlinear programming (PSONLP) is developed to predict the behavior of Case study of a novel low rank coal to calcium carbide process based

Differences between Hydrated lime and quicklime

2012年1月27日 However, quicklime’s hydrophobic reaction with water requires a lime slaker to be used in the process The quick lime is generally received in pebbles of about one quarter to one eighth of an inch, or in powder Download scientific diagram The quick lime lumps production process from publication: Experimental Investigation of Traditional Clay Brick and Lime Mortar Intended for Restoration of Cultural The quick lime lumps production process ResearchGateSulfite Process Plants using the sulfite process consumed large quantities of quicklime for the preparation of the calcium bisulfiteliquor capable of dissolving the noncellulosic wood elements This process is disappearing due to waste disposal problems Bleaching lime is used as a bleaching agent for pulpQUICK LIME AND BYPRODUCTS PEC Consulting GroupQuick Lime Calcination Plant In calcination process, lime is cooked/calcined at 800°c in a kilnWe are providing shafts kilns and rotary kilns for calcining of limestone/lime sludge with multi fuel options Prior to calcination, exhaust gases of kiln preheat limeHydrated, Quick, and PCC Lime Processing Plant Chanderpur

.jpg)

An Improved Lime Sinter Process to Produce Al Springer

The application of the lime sinter process is restricted by the high consumption of calcium, “Effect of temperature on phase and alumina extraction efficiency of the product from sintering coal fly ash with ammonium sulfate,” Chinese Journal of It is also the name of the natural mineral (native lime) CaO which occurs as a product of coal seam fires and in altered limestone xenoliths in volcanic ejecta PROCESS FLOW DIAGRAM OF QUICK LIME/SLAKED LIME MANUFACTURING PROCESS OF QUICK LIME IN DETAILS QUICK LIME PROCESSES MAINLY CONTAINS THE FOLLOWING BASIC STEPS 1Project Report on QUICK LIME/SLAKED LIME Manufacturing Process Rotary lime kiln (rustcolored horizontal tube at right) with preheater, Wyoming, 2010 Traditional lime kiln in Sri Lanka A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide)The chemical equation for this reaction is CaCO 3 + heat → CaO + CO 2 This reaction can take place at anywhere above Lime kiln WikipediaProcess Flow of Lime Production Line 1Raw Material Preparation Limestone: The particle size of limestone should be between 10~40mm The proportion of limestone size above 40mm or below 10mm should not be more than 5% The maximum size should be less than 40mm Fuel:Furnace gas, gas, coalbed methane, pulverized coal could be used as fuelLime Production Line AGICO Cement Plant