Calcium carbonate processing implementation plan

Scaleup of Calcium Carbonate Looping Technology for Efficient

The SCARLET (Scaleup of Calcium Carbonate Looping Technology for Efficient CO2 Capture from Power and Industrial Plants) project is a large and ambitious project to investigate one of the most promising postcombustion CO2 capture technologies, Calcium Carbonate Looping (CCL)Within the calcium carbonate looping process, two hot gas streams at a high Italiano2023年7月24日 Microbially induced calcium carbonate precipitation (MICP) is a highly effective biomineralization technique that involves the production and deposition of calcium carbonate Application of Microbially Induced Calcite Precipitation (MICP 2024年1月19日 In summary, the choice of the calcium carbonate form and its processing (ie, size reduction, morphology control and polymorph tuning) can be tailored for specific Maximising the benefits of calcium carbonate in sustainable

Application of microbially induced calcium carbonate precipitation

2024年5月29日 The production of carbonate mineral precipitates during the MICP process can effectively reduce the mobility of heavy metals in soils, improve the cohesion of dispersed Hosokawa Alpine provides the perfect process technology for every demand and covers all areas of (fineness) ranges, capacity and logistical aspects in a customerspecific and costeffective CALCIUM CARBONATE (GCC) Hosokawa Alpine2023年8月26日 Microbially induced calcium carbonate precipitation (MICP) is an innovative biocementation technique that facilitates the formation of calcium carbonate within a pore network Initially gaining prominence in the field of Unlocking the Potential of Microbially Induced Calcium 2021年8月24日 The feasibility of a novel method to decarbonise calcium carbonate and coproduce sodium carbonate through simultaneous sequestration of CO 2, and under ambient conditions, is established The core of the Decarbonisation of calcium carbonate at atmospheric

Comparative Kinetic Analysis of CaCO3/CaO Reaction

In this paper, the calcination of synthesized CaCO 3 is modeled using modelfitting methods under two different experimental atmospheres, including 100% CO 2, which realistically reflects reactor conditions and is relatively unstudied 2022年12月15日 The calcium looping (CaL) process is a promising CO 2 capture technology based on a reversible reaction, CaO(s) + CO 2 (g) ↔ CaCO 3 (s), and the forward and reverse Progress in reducing calcination reaction temperature of Calcium Microbially induced carbonate precipitation (MICP) is a ubiquitous biogeochemical process that occurs in nature and is an extensively employed technique for soil consolidation; in this pro Application of microbially induced calcium carbonate precipitation antimony copper electrolyte by calcium carbonate was studied, whereas calcium carbonate meets in the minerals in nature and known in many cases as a waste product The possibility of using calcium carbonate to clean technology solutions in order to bring the content of antimony to the optimum concentration, which subsequent stages of processing STUDYING THE PROCESS OF DEPOSITION OF ANTIMONY WITH CALCIUM CARBONATE

Calcium‐fortified foods in public health programs: considerations

calcium food fortification is the low bioavailability of calcium from different sources, including calcium salts Bioavailability is the amount of calcium that the body absorbs This depends on severalfactorsForexample,bioavailabilityislower if calcium is consumed with an empty stomach comparedwithalightmeal24 Whenadoseof250EL BARAKA FOR MINING AND PROCESSING INDUSTRIES Welcome to El Baraka, a pioneering force in the realm of manufacturing and producing highquality calcium carbonate With a steadfast commitment to excellence and innovation, Develop a precise production plan and set up equipment for optimal efficiencyelbaraka – MANUFACTURING AND PRODUCING CALCIUM CARBONATE2024年8月21日 Crushing: The extracted limestone is crushed into small pieces to facilitate further processing Calcination: The crushed limestone undergoes calcination in a kiln, In the manufacturing process of calcium carbonate, classifiers play a crucial role in ensuring the quality and consistency of the final productThe Ultimate Guide Calcium Carbonate Manufacturing Process2020年9月28日 calcium phosphate, calcium carbonate, and calcium l a c t a t eg l u c o n a t ea r eu s e df o rm i l k ,y o g u r t ,a n d cheese, but the crosslinking between calcium withCalciumfortified foods in public health programs: considerations

The Effects of Calcium Carbonate Filler on HDPE Pipe

2022年7月1日 In this study, two natural fillers, calcium carbonate (CaCO3) and gypsum (CaSO4H2O), were added to unsaturated polyester resin (UP) to enhance its mechanical and thermal properties2020年9月28日 For example, bioavailability is lower if calcium is consumed with an empty stomach compared with a light meal 24 When a dose of 250 mg of elemental calcium is given with a meal, the absorption of calcium is 35% from malate citrate, 27% from calcium carbonate, and 25% from tricalcium phosphate 2427 When comparing 11 different calcium salt Calcium‐fortified foods in public health programs: considerations The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2022年9月29日 Calcium carbonate has various applications in many industries And to apply calcium carbonate, we need to process calcium carbonate into suitable fineness In the following part, we introduce the applications of calcium carbonate, calcium carbonate processing plant and carbonate grinding machine Complete Calcium carbonate processing plant4 Steps To Build A Calcium Carbonate Processing Plant Zenith

.jpg)

Calcium Carbonate Powder Processing

Introduction Calcium carbonate, commonly known as limestone, stone powder, marble, etc It is an inorganic compound, the main component is calcite, which is basically insoluble in water and soluble in hydrochloric acid It often exists in calcite, chalk, limestone, marble and other rocks It Differences between ground and precipitated calcium carbonate particles S No Ground Calcium Carbonate Precipitated Calcium Carbonate References 1 Source Extracted from earth Present as crystals in calcite (rhombohedral), aragonite (orthorhombic), and vaterite (hexagonal) forms [28] 2 Examples Examples: chalks, marble 3 ProcessingThe Processing of Calcium Rich Agricultural and Industrial Waste 2022年11月15日 The indirect CO 2 mineralization by using Ca/Mgcontaining industrial alkaline byproducts or wastes is a promising way for mitigation of CO 2 emissions and valorization of wastes, although plagued by the utilization of precipitated calcium carbonate (PCC) if lowvalue product is obtained It is difficult to acquire specific PCC with targeted morphology for Phase transition and morphology evolution of precipitated calcium 2024年7月3日 Calcium carbonate produced by sintering is called ground calcium carbonate (GCC), which is an inorganic material because it comes from natural minerals After secondary processing, adding water to dissolve, adding carbon dioxide and other reactions, and precipitation, a finer texture is obtained which is called precipitated calcium carbonate Circular Economy Implementation in an Organization: A Case

ALPA Calcium Carbonate powder Processing Technology

expert in highvalue treatment of calcium carbonate calcium carbonate powder dry grinding / classifying / surface modification processing technology 02 grinding classifying 10 surface modification 17 project sites 19 application shandong alpa po w de r t e ch n ology co, lt d ©2022 open the catalog to page 12023年8月26日 Microbially induced calcium carbonate precipitation (MICP) is an innovative biocementation technique that facilitates the formation of calcium carbonate within a pore network Initially gaining prominence in the field of geotechnical engineering, MICP has attracted significant attention since its inception (the last three decades) and expanded its reach across various Unlocking the Potential of Microbially Induced Calcium Carbonate In mid 2013, Wilfley made their very first shipment of EMW ® slurry pumps to one of the leading global producers of calcium carbonateThis difficult application was a perfect chance to show off the brand new heavy duty slurry pump and we’re proud to report that all of the pumps are still going strong with all of their original parts still intactEMW ® Slurry Pumps Excel in Calcium Carbonate ApplicationExplore Options to Get a Business Plan Get a Business Plan Schedule a consultation Get a Business Plan Are you interested in starting your own calcium carbonate Business? Introduction Calcium carbonate is a versatile compound with a wide range of applications, from construction materials to pharmaceuticals and even foCalcium Carbonate Business Plan Template – AVVALE

Neutralisation of acid leachate in a coal processing plant with calcium

processing plant with calcium carbonate P Günther (Divisional Environmental Coordinator) 1, J P Maree 2, G Strobos 2, J S Mtimikulu 1 1 Landau Colliery, an Anglo Coal mine, P O Box 78, Clewer, 1036, South Africa Email: 2 CSIR Complete Calcium carbonate processing plant Generally, calcium carbonate can be divided into heavy calcium and light calcium Heavy calcium: Heavy calcium carbonate, also known as ground calcium carbonate, referred to as heavy calcium, is produced by physical methods using natural calcite, limestone, dolomite, chalk, shells, etc as raw materials4 Steps to Build a Calcium Carbonate Processing Plant Zenith Calcium carbonate nanocomposites Y Lin, CM Chan, in Advances in Polymer Nanocomposites, 2012 31 Introduction: applications of calcium carbonate nanoparticles Calcium carbonate particles have been used in the plastics industry for many years The original purpose of adding ground calcium carbonate (GCC) particles as filler material for plastics was to Calcium Carbonate an overview ScienceDirect Topics2022年9月1日 Field Implementation of Microbially Induced Calcium Carbonate Precipitation for Surface Erosion Reduction of a Coastal Plain Sandy Slope September 2022 Journal of Geotechnical and Geoenvironmental Field Implementation of Microbially Induced Calcium

.jpg)

Field Implementation of Microbially Induced Calcium Carbonate

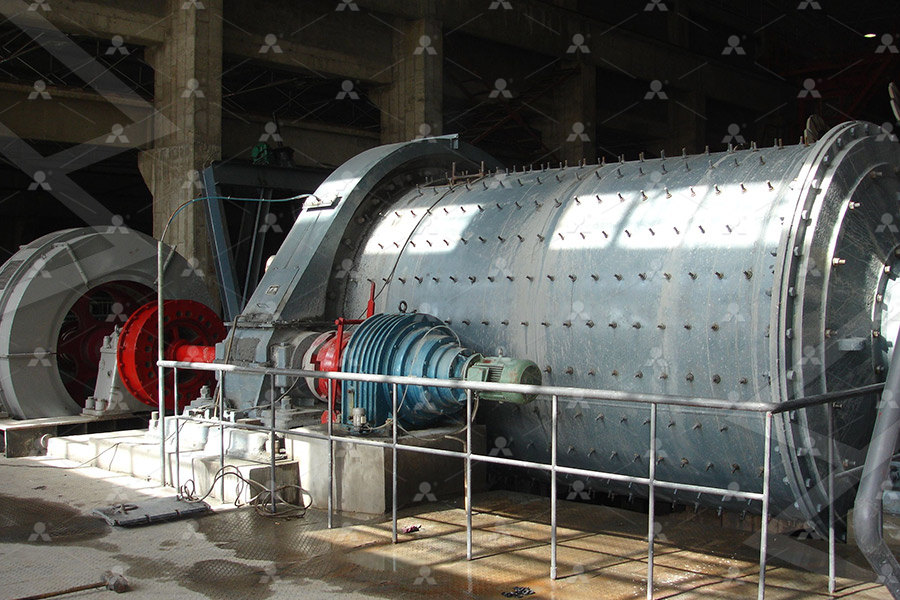

Field Implementation of Microbially Induced Calcium Carbonate Precipitation for Surface Erosion Reduction of a Coastal Plain Sandy Slope Pegah Ghasemi, SMASCE1; and Brina M Montoya, MASCE2 2022年9月27日 One type of calcium that is often consumed and safe for health is calcium carbonate It can obtain this material from chicken eggshell waste, where it is known that the CaCO3 content is 95%(PDF) SYNTHESIS OF CALCIUM CARBONATE (CaCO3) Its raw materials include calcium carbonate (calcite, marble, limestone, chalk), kaolin, bauxite, dolomite, barite, quartz, etc The calcium carbonate powder produced by the ball milling production line can play the role of filling, reduce the cost of materials, and at the same time improve the hardness and whiteness of the productCalcium Carbonate Ball Mill Plant DASWELL2022年5月25日 What role does calcium carbonate play in the soil and what can you produce from calcium carbonate? Here are the answers! Published: 25052022 Calcium carbonate: the formula, properties and MSDS What is calcium carbonate the basis for processing is the implementation of our and third parties' legitimate interests What is calcium carbonate and what is it used for?

.jpg)

How Calcium Carbonate is Produced?|Manufacturing|CORE

Particle Morphology Controlling Technique Calcium carbonate has three crystalline polymorphs: calcite, aragonite, and vaterite In the carbonation process, these crystals can be produced by changing various conditions such as concentration and temperature of lime milk, introduction rate of CO 2 gas, and whether or not chemicals are added All reaction formulas are expressed as 2010年9月4日 The mechanical properties and crystalline characteristics of polypropylene (PP) and nano precipitated calcium carbonate (NPCC) nanocomposites prepared via melt mixing in an internal mixer and melt Polypropylene/calcium carbonate nanocomposites—Effects of processing 2020年4月7日 FIGURE 3 The most adapted mineral flotation technology for calcium carbonate is mechanical flotation Optimized Processing Through years of mineral processing knowhow, Imerys has been able to optimize the calcium carbonate processing at each step of the minetoplant process to enable the reduction of crystalline silica in the final productsOptimized Processing to Reduce Crystalline Silica in Ground Calcium 2022年4月26日 Effect of processing temperatures on decarbonisation of calcium carbonate in sodium hydroxide solutions at ambient conditions April 2022 DOI: 1021203/rs3rs/v1Effect of processing temperatures on decarbonisation of calcium

.jpg)

Beneficiation and Mineral Processing of Calcium Carbonate and Calcium

2017年3月3日 PDF Beneficiation and Mineral Processing of Calcium Carbonate and Calcium Sulphate Find, read and cite all the research you need on ResearchGateantimony copper electrolyte by calcium carbonate was studied, whereas calcium carbonate meets in the minerals in nature and known in many cases as a waste product The possibility of using calcium carbonate to clean technology solutions in order to bring the content of antimony to the optimum concentration, which subsequent stages of processing STUDYING THE PROCESS OF DEPOSITION OF ANTIMONY WITH CALCIUM CARBONATEcalcium food fortification is the low bioavailability of calcium from different sources, including calcium salts Bioavailability is the amount of calcium that the body absorbs This depends on severalfactorsForexample,bioavailabilityislower if calcium is consumed with an empty stomach comparedwithalightmeal24 Whenadoseof250Calcium‐fortified foods in public health programs: considerations EL BARAKA FOR MINING AND PROCESSING INDUSTRIES Welcome to El Baraka, a pioneering force in the realm of manufacturing and producing highquality calcium carbonate With a steadfast commitment to excellence and innovation, Develop a precise production plan and set up equipment for optimal efficiencyelbaraka – MANUFACTURING AND PRODUCING CALCIUM CARBONATE

The Ultimate Guide Calcium Carbonate Manufacturing Process

2024年8月21日 Crushing: The extracted limestone is crushed into small pieces to facilitate further processing Calcination: The crushed limestone undergoes calcination in a kiln, In the manufacturing process of calcium carbonate, classifiers play a crucial role in ensuring the quality and consistency of the final product2020年9月28日 calcium phosphate, calcium carbonate, and calcium l a c t a t eg l u c o n a t ea r eu s e df o rm i l k ,y o g u r t ,a n d cheese, but the crosslinking between calcium withCalciumfortified foods in public health programs: considerations 2022年7月1日 In this study, two natural fillers, calcium carbonate (CaCO3) and gypsum (CaSO4H2O), were added to unsaturated polyester resin (UP) to enhance its mechanical and thermal propertiesThe Effects of Calcium Carbonate Filler on HDPE Pipe2020年9月28日 For example, bioavailability is lower if calcium is consumed with an empty stomach compared with a light meal 24 When a dose of 250 mg of elemental calcium is given with a meal, the absorption of calcium is 35% from malate citrate, 27% from calcium carbonate, and 25% from tricalcium phosphate 2427 When comparing 11 different calcium salt Calcium‐fortified foods in public health programs: considerations

.jpg)

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy 2022年9月29日 Calcium carbonate has various applications in many industries And to apply calcium carbonate, we need to process calcium carbonate into suitable fineness In the following part, we introduce the applications of calcium carbonate, calcium carbonate processing plant and carbonate grinding machine Complete Calcium carbonate processing plant4 Steps To Build A Calcium Carbonate Processing Plant Zenith Introduction Calcium carbonate, commonly known as limestone, stone powder, marble, etc It is an inorganic compound, the main component is calcite, which is basically insoluble in water and soluble in hydrochloric acid It often exists in calcite, chalk, limestone, marble and other rocks It Calcium Carbonate Powder Processing