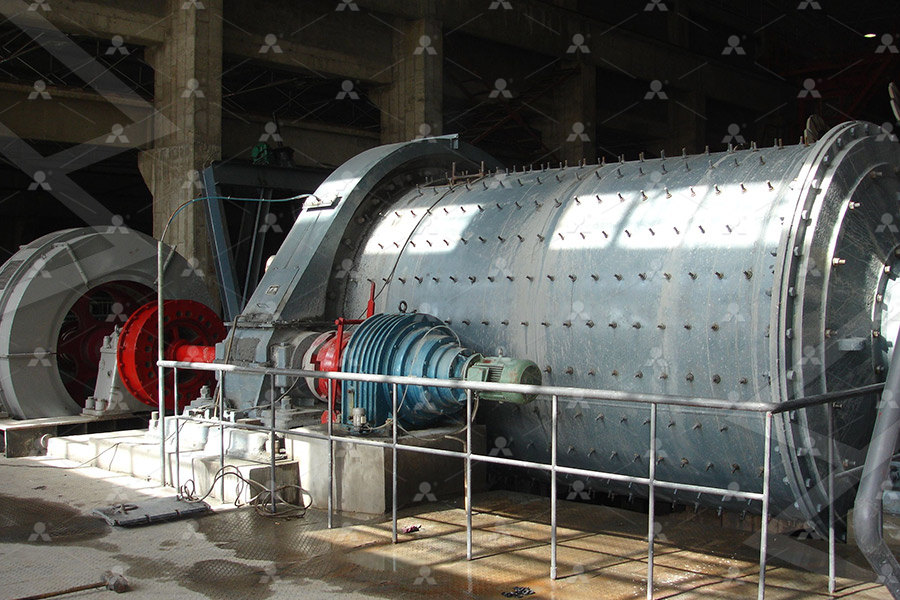

Steel ball grinding system machine

.jpg)

Taurus Ball Mill NETZSCH Grinding Dispersing

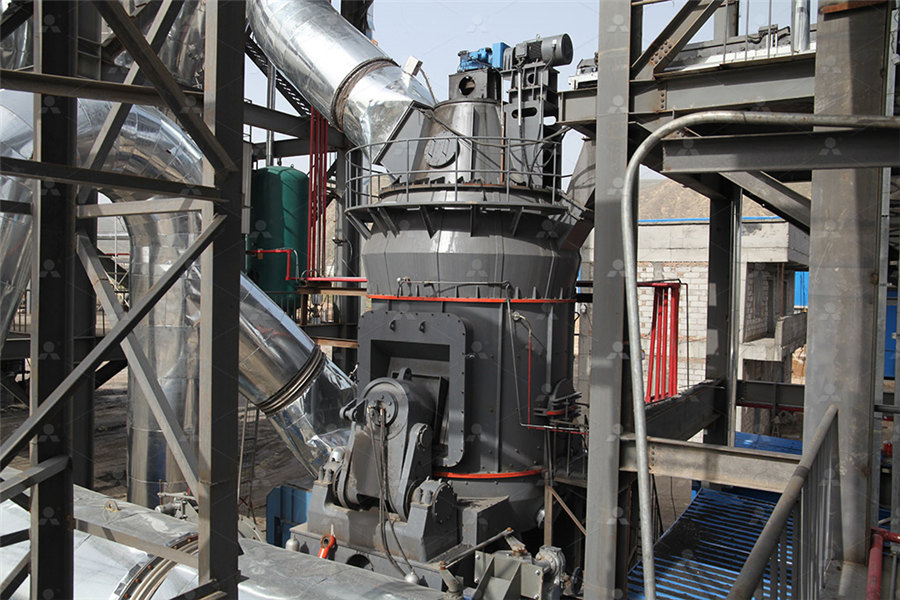

NETZSCH Taurus Ball Mill, the pinnacle of fine and ultrafine grinding technology Achieve precise particle sizes with durable, lowmaintenance equipmentBall mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the Ball Mills a suitable ball mill for every applicationSkew rolling machine is the special equipment which applies the Spiral groove skew rolling forming process to manufacture milling steel ball, bearing ball blanks and other metal ball This skew rolling mill applies the semi closing frame so itSkew rolling machine for grinding balls StaiersRonen Wuhe is one special manufacture for producing steel ball grinding machine in China Have Taiwan Technology level engineers team, and with strict technical monitoring and production Ball Grinding Machine Ball Grinding Machine and Steel Ball

.jpg)

Industrial Ball Mill Grinder Machines Thomas Scientific

Industrial Ball Mill Grinder Machines are essential tools in various Scientific and industrial applications, primarily used for grinding and blending materials to achieve uniform consistency and fine particle sizesBall milling systems grind dry material and wet slurry alike Each Pulva ball mill features a powerful motor that drives a gear system and causes the barrel to spin at 3040 rotations per HighQuality Ball Mills for Efficient Grinding PulvaRoyal Master Grinders has developed a system to automatically load, grind and unload spherical balls without operator intervention Virtually all materials can be ground, including Polypropylene plastic, Teflon® (PTFE), rubber, wood, glass, Ball Grinding System Royal Master GrindersBall mill drums offer an efficient and inexpensive way to grind materials down to a more usable size, often as fine as 2575 microns Both continuous and batch style ball mills use centrifugal force, gravity and hard media to break up industrial materials into fine pieces or powder Ball milling systems grind dry material and wet slurry alikeHighQuality Ball Mills for Efficient Grinding Pulva

China Grinding Ball Production Line, Heat Treatment

Welcome to wholesale cheap grinding ball production line, heat treatment furnace, steel ball mold, cylpebs, shell core machine in stock here from professional manufacturers and suppliers in China Our factory offers The Φ20mmΦ120mm steel ball rolled in the wearresisting steel ball rolling production line is wearresisting steel ball, also known as wearresisting medium for grinding machine It is a kind of consumables, mainly used for grinding Skew rolling machine for grinding balls Staiers2014年2月15日 A threedimensional model of the fixed plate of steel ball grinding machines is established using finite element methods Its distortion and stress status are analyzed, and the natural frequencies and vibration features are obtained By using the circular area of elastic contacts, the number of effective cutting edges is determined, and a mathematical model is Modeling and optimal design for the fixed plate of steel ball grinding Ball mills are furthermore characterized by significant differences in the sizes of available grinding jars Retsch offers mills with jar capacities from 15 ml up to 150 l and balls are available from 01 mm to 40 mm, see Figure 2Ball Mills Suitable for every application Retsch

Precision Ball Grinding Machines Progressive Machining

Home Precision Ball Grinding Machines It’s applications accommodate ball grinding, flashing, lapping and polishing operations of almost any material used in modernday industry Drive System Geared timing belt ; Motor Size 5HP, 220 or 440 ; VOLT 3 phase (EEC Specs)Steel Ball Processing Machines : Ball Grinding Machine: Ball Lapping Machine: Model: 760 / 813 / 940: 760 / 814 / 940: 660/760 / 813: Disc Dia Steel Ball Processing Machines Ball Washing Machines Bearing Ring Feeding System Fume Extraction Unit Tube Bulding and Flaring Machine Steel Ball Processing Machines Micro Machine ToolsGrinding balls such as Allmax ® grinding balls are extremely robust and have a long working life With a grinding ball sorting machine by Christian Pfeiffer, their use becomes even more efficient This is because the grinding balls can be precisely checked after passing through the Christian Pfeiffer SORTER the grinding ball sorting machine Introduction of CAMINIX Ball Grinding Machine CAMINIX CNC Ball Valve Grinding Machine is designed ,developed and manufactured for precise grinding of the sphere ( Balls) of the ball valves,With range of DN15DN1600 1/2''60''various kinds of balls with materials of carbon steel,stainless steel,alloy steel,Monel,Tungsten Carbide coating, etc All of the machines are Ball Valve Grinding lapping Machine Caminix

About Jengker|Steel Ball Manufacturer Jeng Ker Industrial Corp

We have installed high performance GermanMade grinding machines and SuperFinish lapping machines [ISO9000 quality system], [American AFBMA], [Japanese JIS] and [German DIN standads] About Us Technical Data News Contact Us THE NELL SYSTEM 4–5 STEEL STRIP GRINDING MACHINES 6–35 Straight finish grinding, BSM3000CNC 6–9 scalloped and serrated grinding Onesided processing BSM3000/ECNC 10–11 Doublesided processing BSM3000/DCNC 12–13 tion of FOR STEEL STRIP grinding deburring polishing serrating Berger Hardened Steel Grinding Container: Grinding container with puck, dish, and lid made of 52100 hardened tool steel 69 in diameter x 29 in high, 175 lbs (175 cm x 75 cm, 8 kg) Nominal volume 340 mL, recommended grinding load 20 Industrial Ball Mill Grinder Machines Thomas Scientific2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in ball mills(PDF) Grinding Media in Ball MillsA Review

SCD30 skew rolling machine production line for grinding steel ball

The hot rolling skew rolling mill production line for grinding steel ball include:SCD30,SCD40,SCD50,SCD60,SCD80,SCD100,SCD120 models,It is also equipped with four types for each model: common type, common highspeed type, highspeed type and ultra highspeed type,It can produce φ20~φ125 steel balls and cylpeb,Meet the requirements of NETZSCH Taurus Ball Mill, Wet Grinding Dry Grinding Mixing / DeAerating Dispersing Homogenizing Classifying Dedusting Separating Laboratory Machines / Systems Grinding Media, Grinding Balls Plants/Engineering Confectionery Systems Systems A rotating robust steel drum with liners is supplying kinetic energy to grinding media Taurus Ball Mill NETZSCH Grinding DispersingZQ series Hot steel ball making machine for rolling steel balls can make steel balls diameter between 20 mm to 120 mm, and steel ball material can be medium carbon steel, alloy steel, copper etc, which is widely used in mining industry, steel plant, power plant, cement plant, chemical plant etc Hotrolled steel ball rolling mill machine:Skew Rolling Mill Grinding Steel Ball Hot Rolling Mill MachineEstablished in the year 1992, PRIME MACHINE TOOLS have been leading the way in grinding innovation, delivering machines that offer unrivalled accuracy and reliability from more than last 30 years With a presence in more than 15+ countries, our stateoftheart grinders—backed by responsive service and a global pedigree—are the choice of engineering leadersPrime Machine Tools Roll Grinder Roll Grinding Machine

Sphere Grinding Machine for Ball Valve Manufacturing Caminix

CAMINIX CNC Ball Valve Grinding Machine is designed ,developed and manufactured for precise grinding of the sphere ( Balls) of the ball valves,With range of DN15DN1600 1/2''60''various kinds of balls with materials of carbon steel,stainless steel,alloy 2024年4月26日 Understanding the Manufacturing Steel Ball Process The process of manufacturing steel balls may seem straightforward at first glance, but it involves a sophisticated series of steps that are precisely executed to yield a product that meets stringent industry standards Integral to countless applications, from automotive bearings to precision medical Inside Steel Ball Production: Secrets of Crafting Unveiled Cabaro A section cutthrough of ball mills A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shellBall mill WikipediaSkew Rolling Machine Pictures in Steel Ball Factory: Anyang Skew rolling machines have been exported to Romania, Armenia, Indonesia, Zambia, India, Vietnam, Chile, Iran, etc over 20 countries, machine size 30mm 120mm produce steel balls and copper balls Grinding balls production and Customer Cases videos: Click can open playlistSkew rolling machine used for making grinding balls,steel balls,

.jpg)

Grinding ball Magotteaux

A grinding ball works on the principle of impact and attrition Earlier balls were made from forged steel These days they are much more complex or scientific and Magotteaux manufactures them in a large range of alloys which are GRINDING STEEL BALLS FOR BALL MILLS Specifications Date of validity: 2016 07 – 01 1 FIELD OF APPLICATION This standard applies to steel grinding balls produced by rolling, forging, stamping and used for raw materials and materials grinding STEEL MILLING BALLS FOR BALL MILLS Energosteel Grinding Media Ball Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 150mm according to different grinding requirements In a cement ball mill, generally, φ50100mm steel balls are used in the coarse grinding chamber, φ2050mm steel balls are used in the fine grinding chamber 2 Short CylindersBall Mill Grinding Media Steel Balls for Ball Mills AGICO GroupGrinding Media Grinding Balls Metallic Grinding Media NonMetallic Grinding Media Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and materials to meet an equally wide range of grinding and milling needs As the developer and manufacturer of industryleading particle size reductionGrinding Media Union Process

.jpg)

FOR STEEL STRIP grinding deburring polishing serrating Berger

THE NELL SYSTEM 4–5 STEEL STRIP GRINDING MACHINES 6–35 Straight finish grinding, BSM3000CNC 6–9 scalloped and serrated grinding Onesided processing BSM3000/ECNC 10–11 Doublesided processing BSM3000/DCNC 12–13 tion of The manufacturing process of casting chrome grinding media consists of 6 Main Steps: Melting – Raw material analysis – Molding(making grinding balls) – Separating Cleaning – Heat Treatment – Packaging For each step matches with the certain equipment, including induction melting furnace, balls making production line (metal mold), grinding media separating and Grinding media balls manufacturing equipment,Steel balls STEEL STRIP GRINDING MACHINES Kohlfurther Brücke 69 42349 Wuppertal, Germany Tel +49 (202) 247420 Fax +49 (202) 2474242 info@bergergruppe bergergruppe Heinz Berger Maschinenfabrik GmbH Co KG THE NELL SYSTEM 4–5 STEEL STRIP GRINDING MACHINES 6–37 Straight finish grinding, BSM3000 6–9 scalloped and ball screws and AC FOR STEEL STRIP grinding deburring polishing serrating Berger Grinding balls production line produces grinding media balls from dia30 to 130mm Grinding balls molding line is good for grinding balls making with metal mould technology Grinding balls making machine produced balls can be widely used in mines, cement, power station etcAutomatic Casting Grinding Balls Production Line Hexin Wear

43.jpg)

Steel Ball Grinding Mill MadeinChina

Sourcing Guide for Steel Ball Grinding Mill: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: ball mill, grinding machine, grinding millBall mill drums offer an efficient and inexpensive way to grind materials down to a more usable size, often as fine as 2575 microns Both continuous and batch style ball mills use centrifugal force, gravity and hard media to break up industrial materials into fine pieces or powder Ball milling systems grind dry material and wet slurry alikeHighQuality Ball Mills for Efficient Grinding PulvaWelcome to wholesale cheap grinding ball production line, heat treatment furnace, steel ball mold, cylpebs, shell core machine in stock here from professional manufacturers and suppliers in China Our factory offers China Grinding Ball Production Line, Heat Treatment The Φ20mmΦ120mm steel ball rolled in the wearresisting steel ball rolling production line is wearresisting steel ball, also known as wearresisting medium for grinding machine It is a kind of consumables, mainly used for grinding Skew rolling machine for grinding balls Staiers

Modeling and optimal design for the fixed plate of steel ball grinding

2014年2月15日 A threedimensional model of the fixed plate of steel ball grinding machines is established using finite element methods Its distortion and stress status are analyzed, and the natural frequencies and vibration features are obtained By using the circular area of elastic contacts, the number of effective cutting edges is determined, and a mathematical model is Ball mills are furthermore characterized by significant differences in the sizes of available grinding jars Retsch offers mills with jar capacities from 15 ml up to 150 l and balls are available from 01 mm to 40 mm, see Figure 2Ball Mills Suitable for every application RetschHome Precision Ball Grinding Machines It’s applications accommodate ball grinding, flashing, lapping and polishing operations of almost any material used in modernday industry Drive System Geared timing belt ; Motor Size 5HP, 220 or 440 ; VOLT 3 phase (EEC Specs)Precision Ball Grinding Machines Progressive MachiningSteel Ball Processing Machines : Ball Grinding Machine: Ball Lapping Machine: Model: 760 / 813 / 940: 760 / 814 / 940: 660/760 / 813: Disc Dia Steel Ball Processing Machines Ball Washing Machines Bearing Ring Feeding System Fume Extraction Unit Tube Bulding and Flaring Machine Steel Ball Processing Machines Micro Machine Tools

Christian Pfeiffer SORTER the grinding ball sorting machine

Grinding balls such as Allmax ® grinding balls are extremely robust and have a long working life With a grinding ball sorting machine by Christian Pfeiffer, their use becomes even more efficient This is because the grinding balls can be precisely checked after passing through the Introduction of CAMINIX Ball Grinding Machine CAMINIX CNC Ball Valve Grinding Machine is designed ,developed and manufactured for precise grinding of the sphere ( Balls) of the ball valves,With range of DN15DN1600 1/2''60''various kinds of balls with materials of carbon steel,stainless steel,alloy steel,Monel,Tungsten Carbide coating, etc All of the machines are Ball Valve Grinding lapping Machine CaminixWe have installed high performance GermanMade grinding machines and SuperFinish lapping machines [ISO9000 quality system], [American AFBMA], [Japanese JIS] and [German DIN standads] About Us Technical Data News Contact Us About Jengker|Steel Ball Manufacturer Jeng Ker Industrial Corp