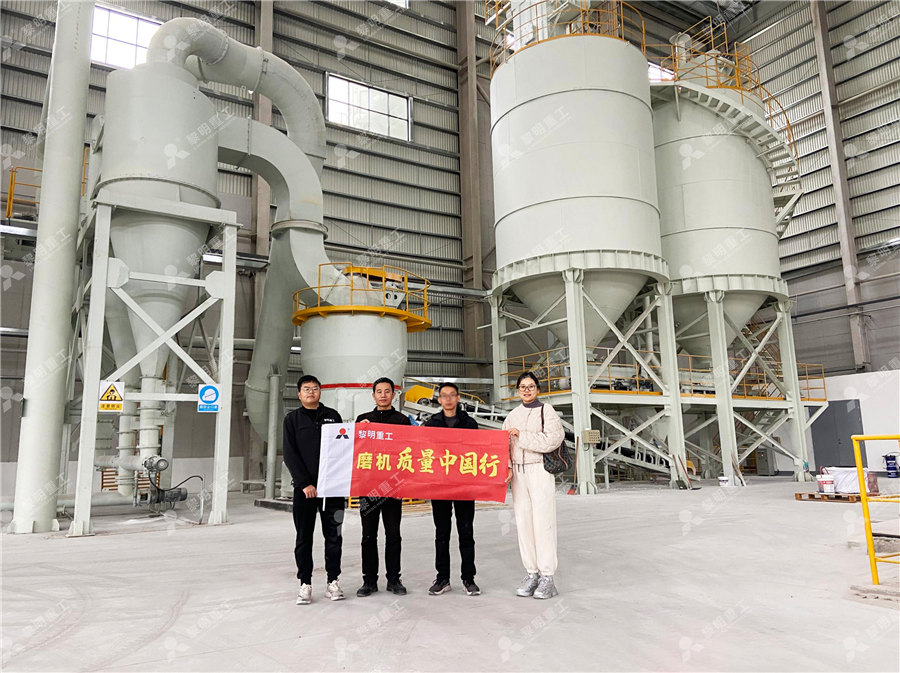

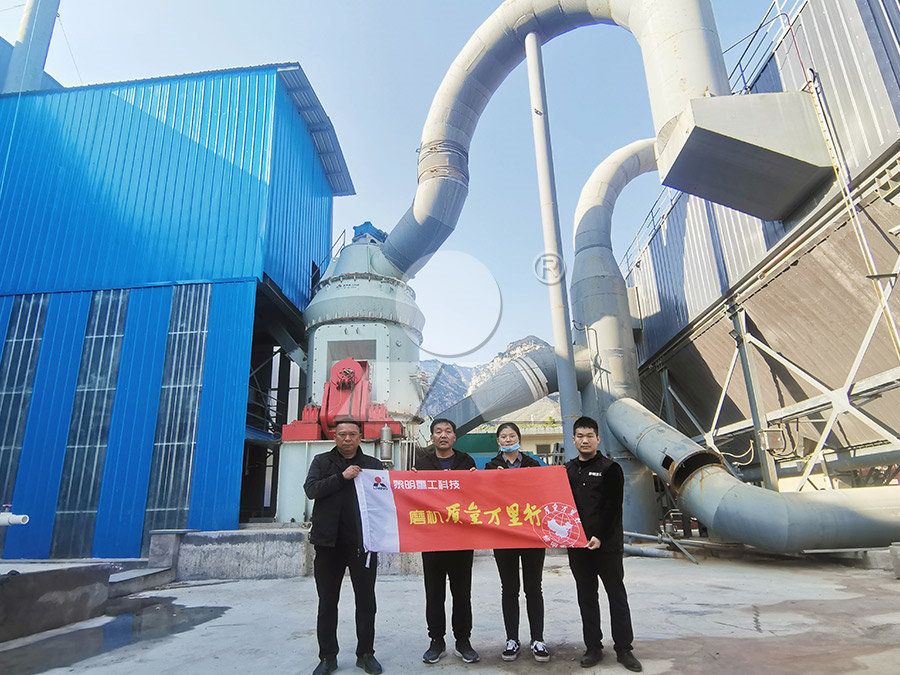

Micro powder grinding belt clip

Resource Library Hosokawa Micron Powder Systems

Hosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the Chemical, Pharmaceutical, Food, Mineral, Cosmetic and The three ring medium speed micro powder mill can grind the material to an ultrafine particle size of more than 3000 mesh through fine processing of the material It is a common equipment for Three ring medium speed micro powder mill SBM Ultrafine The Bepex Pulvocron defines fine grinding for food and industrial applications which rely on a consistently onspec fineground powder High speed impact fractures material into powder Fine Grinding Machines and Micronizing Equipment BepexHGM series ring roller mill is a type of advanced grinding machine designed to produce fine to ultrafine powders for various industrial applications Named after its unique configuration, the SBM Ultrafine Powder Technology Industrial Grinding Mill,

Powder Processing Equipment Systems Qlar

» Gentle Grinding Action – Allows uniform size distribution, resulting in minimal fines generation » Low Heat Generation – Essential when milling fatty, sticky or heat sensitive products » Low MicronMaster® Jet Pulverizers comprise a complete line of advancedtechnology jet energy mills designed to grind any type of crystalline or friable material, producing product in the size range Jet Pulverizer : Leader in Super Fine Particle Size ReductionThe JOYAL Threering Micro Powder Mill (ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, JoyalThreering Micro Powder Mill,Threering Micro Powder Mill It is an efficient and energysaving ultrafine grinding equipment Suitable for processing calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and HWM Series Micro Powder Ring Roller Mill HXZG

.jpg)

Stone Powder Making Machine

① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill 2021年8月3日 This paper proposes a downstroke abrasive belt grinding under micro feeding for noise reduction surface Firstly, a physical model of processing under micro feeding for noise reduction structure was established Based on the flexible contact characteristics of abrasive belt grinding and Hertz contact theory, a mathematical model suitable for this method was The Method and Experiment Research on Downstroke Abrasive Belt 2021年9月30日 The chalk micro powder mill is independently developed and produced by SBM It mainly includes 3 types, namely HGM ultrafine grinding mill (1503000 meshes), CLUM vertical mill (1503000 meshes), and wet stirring Chalk Micro Powder Mill SBM Ultrafine Powder Kimber Micro 9 Note: Grip plates that have raised panels and seat into the frame of the gun are not compatible with this belt clip as well as any laser aftermarket grips Included: (Black) High Carbon Spring Steel belt clip, plated with Teflon Stone Coat 5100 and grip plate replacement screws Quick 5minute install with NO modification requiredTechna Clip Kimber Micro 9 Clip Holster Black Sportsman's

Micro Powder Roller Mill Henan Daswell Machinery Co, LTD

Micro Powder Roller Mill Roller Milling Equipment is a kind of highprecision grinding equipment The product fineness can be adjusted from 325 meshes to 2500 meshes according to customer requirements, and the fineness can reach D97≤5μm2024年9月28日 The production of gypsum powder using an HGM micro powder grinding mill involves a series of welldefined steps, ensuring highquality results suitable for various applications >>Gypsum Powder Manufacturing Process 1 Raw Material Collection Gypsum rock (calcium sulfate dihydrate) is mined from quarriesGypsum Powder Manufacturing Process Using HGM Micro Powder Grinding Dolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment It is mainly applied to ultrafine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤9Dolomite Micro Powder Grinding MillIt is a VERY stable clip as it puts the weight of the gun on the belt and not the pants Perfect for holding up your Glock 19, 1911, SIg P365 XL or Sig P320 slimmed down version of our everpopular SnapLok Clip The Micro SnapLok is made from spring steel and powdercoated to give you a durable and reliable clip for your CrossBreed HolsterMicro SnapLok Clips (Sold in Singles) CrossBreed Holsters

.jpg)

Powder Processing Equipment Systems Qlar

fine grinding, versatility and safety Available with various interchangeable grinding media, this mill offers unsurpassed high energy, onepass size reduction It ensures a controlled size reduction with a high degree of fineness, typically grinding with a milled particle size range D50 of 100μ to 20μ A full range of models are available to Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The fineness can reach to 0006mm; Micro Powder Mill is mainly used for processing gypsum, calcspar, talcMicro Powder Mill KefidHosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the Chemical, Pharmaceutical, Food, Mineral, Cosmetic and Plastic industries Call us at 18005264491Resource Library Hosokawa Micron Powder Systems2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag

HCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra

HCH Ultrafine Grinding Mill,The most Economic and Practical Ultrafine Powder Processing Equipment, the Energysaving and Reduce Consumption Equipment fro ultra fine Powder Processing Welcome to Guilin HCM Machinery Official WebSite! 24 hour service blower, belt feeder, storage hopper, pipe system, pulse dust collector, Techna Clips Belt Clip Kimber Micro 9mm Techna Clip MIC9BR Techna Clip's Conceal Carry Gun Belt Clip is a concealable gun clip that easily affixes to your sidearm to deliver a secure, lightweight and discreet carry optionwithout a holster It installs quickly and requires no gunsmithing to youTechna Clips Belt Clip Kimber Micro 9mm Impact Guns2019年11月14日 SIMEC innovative Ultra Fine Pulverizer is equipped with pulverizing rotor grading impeller made of corundum ceramics, as a result, ultra fine pulverizing and particulate sorting can be completed simultaneously Corundum ceramics are characterized by high temperature resistance, corrosion resistance, wear resistance, and low density (about 1/2 of Ultra Micro PulverizerChina Micro Grinder wholesale Select 2024 high quality Micro Grinder products in best price from certified Chinese Mill Grinder manufacturers, UltraFine Rubber Powder Grinding Plant for Fine/Micro Rubber Powder Grinder US$ 5000 / Set 1 Set (MOQ) Xuchang Huarui Machinery Co, LtdMicro Grinder MadeinChina

Micro powder grinding machine/ Micronizer grinding

Applications of micro powder grinding machine/ micronizer: Micro powder grinding machine/ micronizer is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs hardness under six Such as calcite, chalk, limestone, dolomite, kaolin, gypsum, etc, totally more than 100 kinds of materialsOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Focus on the field of micro powder grinding 10+ Production experience 20+SBM Ultrafine Powder Technology Industrial Grinding Mill, 2021年11月3日 Phosphate mineral powder grinding mills includes ultrafine mills, vertical roller mills, highpressure mills, etc can grind ores into a fine powder +17 [ protected]Phosphate Mineral Powder Grinding Mill SBM Ultrafine Powder CNC Belt Grinding and Polishing Machine that combines precision, c MicroAbrasive Blasting Commonly Used Materials: Aluminum Oxide Powder: Common for general applications and provides a good balance of cutting and polishing Sodium Bicarbonate: Gentle abrasive for sensitive materials Materials Used in Polishing Materials Used in CNC Belt Grinding and Polishing Machine Surface Polisher

.jpg)

Aluminum OxideAlumina Powder Micro Abrasives Corp

WCA is an Alumina powder developed and introduced by Micro Abrasives Corporation in 1957 WCA is known throughout the world for its unique particle shape, aspect ratio and size distribution Each WCA particle is a discrete crystal of alumina having a purity of over 99%Various industrial grinding mills for sale, stone powder processing equipment basement from China! Grind all kinds of ores into highvalued superfine powder!Action speak louder than wordsWhy not contact us now? Superior quality, impeccable serviceShanghai Clirik Machinery Co,Ltd, your customized stone powder grinding mill specialist!HGM Series Threering Micro Powder Grinding Machine ClirikIt is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Micro Powder Grinding MillIntroduction of minerals powder grinding machine Name: HGM minerals powder grinding machine Model: HGM series Brand: Clirik Powder Fineness Process Ability: 3253000 mesh Capacity: according to your demand about powder fineness, the finial capacity can be adjusted between 0545 t/h Use Range: can be used in more than 150 kinds of stone materials powder grinding, 800 Mesh Dolomite Micro Powder Grinding Mill Machine

What is Powder Grinding Mill? JXSC Machine

2021年11月27日 Conveyor Belt; Filter Press Feed Pump; Slurry Gravel Pump; Heavy Plate Feeder; Tubular Screw Conveyor; Twin Screw Feeder; Belt Feeder; pendulum roller mill, highpressure suspension grinding mills, highpressure micropowder mills, straightthrough centrifugal mills, overpressure trapezoidal mills, and micro powder grinding mills2021年9月6日 The motor drives the belt and pulley, The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, energysaving capabilities, and ability to produce fine and ultrafine powders See More>>Marble Ultrafine Powder Grinding MillAfter using vertical grinding to grind nickel slag into micro powder, it is beneficial to recover nickel iron and obtain considerable economic benefits; At the same time, the screened finished micro powder is added to cement to form composite cement, which can greatly increase economic benefits and waste resource utilization, reduce the occupation of land and environmental Nickel slag powder processing solutionLIMING HEAVY INDUSTRY Grinding and deburring for steel and nonferrous metals that also satisfies the highest demands Developed in cooperation with professional users, this belt stands out especially due to its long service life, performance and value Heavy polyester fabric, full resin bond with zirconium aluminum oxide 3 x 79 in [75 x 2,000 mm] Product number: 6 99 03 010 00 0Grinding belts, type Z FEIN Power Tools, Inc

.jpg)

Micro Grinding Machine Manufacturers Suppliers Madein

micro grinding machine manufacturers/supplier, China micro grinding machine manufacturer factory list, Powder Coating Cooling Belt , Powder Coating Mill , Powder Coating Production Line RD Capacity: Own Brand, ODM, OEM Mgmt Certification: ISO 9001, ISO 14001, OHSAS/ OHSMS 18001 Micropowder grinding mill is a new kind of ultrafine processing equipment with high efficiency and low cost It is the crystallization of advanced technology and the best product to replace traditional mills in the field of ultrafine powder processing in the worldMicro Powder Grinding Mill① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill Stone Powder Making Machine2021年8月3日 This paper proposes a downstroke abrasive belt grinding under micro feeding for noise reduction surface Firstly, a physical model of processing under micro feeding for noise reduction structure was established Based on the flexible contact characteristics of abrasive belt grinding and Hertz contact theory, a mathematical model suitable for this method was The Method and Experiment Research on Downstroke Abrasive Belt

Chalk Micro Powder Mill SBM Ultrafine Powder

2021年9月30日 The chalk micro powder mill is independently developed and produced by SBM It mainly includes 3 types, namely HGM ultrafine grinding mill (1503000 meshes), CLUM vertical mill (1503000 meshes), and wet stirring Kimber Micro 9 Note: Grip plates that have raised panels and seat into the frame of the gun are not compatible with this belt clip as well as any laser aftermarket grips Included: (Black) High Carbon Spring Steel belt clip, plated with Teflon Stone Coat 5100 and grip plate replacement screws Quick 5minute install with NO modification requiredTechna Clip Kimber Micro 9 Clip Holster Black Sportsman's Micro Powder Roller Mill Roller Milling Equipment is a kind of highprecision grinding equipment The product fineness can be adjusted from 325 meshes to 2500 meshes according to customer requirements, and the fineness can reach D97≤5μmMicro Powder Roller Mill Henan Daswell Machinery Co, LTD2024年9月28日 The production of gypsum powder using an HGM micro powder grinding mill involves a series of welldefined steps, ensuring highquality results suitable for various applications >>Gypsum Powder Manufacturing Process 1 Raw Material Collection Gypsum rock (calcium sulfate dihydrate) is mined from quarriesGypsum Powder Manufacturing Process Using HGM Micro Powder Grinding

Dolomite Micro Powder Grinding Mill

Dolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment It is mainly applied to ultrafine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤9It is a VERY stable clip as it puts the weight of the gun on the belt and not the pants Perfect for holding up your Glock 19, 1911, SIg P365 XL or Sig P320 slimmed down version of our everpopular SnapLok Clip The Micro SnapLok is made from spring steel and powdercoated to give you a durable and reliable clip for your CrossBreed HolsterMicro SnapLok Clips (Sold in Singles) CrossBreed Holstersfine grinding, versatility and safety Available with various interchangeable grinding media, this mill offers unsurpassed high energy, onepass size reduction It ensures a controlled size reduction with a high degree of fineness, typically grinding with a milled particle size range D50 of 100μ to 20μ A full range of models are available to Powder Processing Equipment Systems QlarMicro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The fineness can reach to 0006mm; Micro Powder Mill is mainly used for processing gypsum, calcspar, talcMicro Powder Mill Kefid