Bentonite Fluorite Limestone Processing Production Line

.jpg)

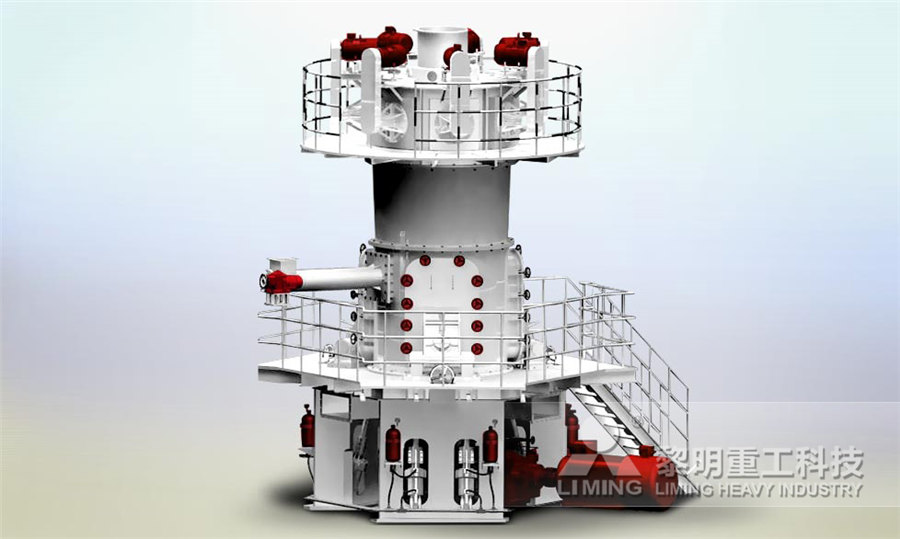

Ultrafine Mill or Ultrafine Grinding Mill Fote Machinery

Ultrafine grinding mill is a kind of Raymond mill It is widely used in the grinding process of ore materials in metallurgy, building materials, 展开Production capacity: 45800 tons/hour Applicable materials: granite, marble, basalt, limestone, quartz stone, river pebbles, iron ore, copper ore, etcStone crushing production line2015年6月5日 1 Bentonite production line Introduction of Bentonite production line: Brand: CLIRIK Type: Micro powder grinding mill Models: HGM80, HGM90, HGM100, HGM100A, and HGM125 Capacity: 05 12t/h Finished size: Bentonite production line PDF Free Download2022年4月20日 After limestone is mined from limestone rock, Limestone crushing and grinding production line 20/04/2022 admin Limestone Properties The processing of limestone is mainly to crush, classify and produce Limestone crushing and grinding production line

Properties, Processing and Modification of Bentonite

2022年4月1日 The key production equipment used in the bentonite grinding production line are jaw crusher, impact crusher, Raymond mill, ultrafine mill, etc +17 [ protected] belt conveyors, dust collectors, fans, 2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine Stone crushing production line process flow The process flow of the gravel production metallurgy and other industrial sectors to crush mediumhard materials such as calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal Common standard configurations of gravel production lines 1 Processing of high hardness Stone crushing production lineprocess flow diagram for limestone processing operations 3 list of tables 6 6 table 1 gross energy to produce one ton of limestone products table 2 water consumption for limestone quarrying and processing table 3 lci inputs for limestone quarrying and processing table 4 lci outputs for limestone quarrying and processing table 5Limestone Quarrying and Processing: A LifeCycle Inventory

Processing Materials SBM Ultrafine Powder Technology

SBM ultrafine grinder is the ideal choice for ore processing Home; Materials; Processing Materials Limestone Kaolin Diatomite Carbon black Calcium carbonate Pumice Bentonite Coal Barite Attapulgite Vermiculite Talc technicians can tailor the best production line for you and provide production line design and configuration 2023年11月21日 Step 3: Procuring Raw Materials and Bentonite Processing Source highquality bentonite ore as the primary raw material for your production line Set up an efficient processing unit to extract, purify, and prepare the bentonite for granulation Ensure that your processing methods meet industry standards and result in a consistent and desirable How to setup a bentonite granules production line2022年8月29日 The production line has simple process, high production efficiency, large output and low operating cost The finished sand and gravel have uniform particle size and good particle shape, which is very in line with the national construction sand standard and highquality material requirements 2 Reasonable equipment configurationDolomite crushing and sand making production line2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process

Limestone Powder Processing Machine MadeinChina

China Limestone Powder Processing Machine wholesale Factory Outlet Powder Coating Equipment Machine for Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Production Line US$ / Set 1 Set (MOQ Large Scale Grinding Barite Talc Bentonite Processing Vertical Roller Mill Machine US$ 5000 2023年11月13日 Ultrafine grinding mill production line process flow The loader transports the crushed ore with a particle size of less than 500 mm to the firstlevel vibrating feeder, and intelligently adjusts the feeding speed through the variable frequency motor to ensure that large pieces of ore are transported smoothly and evenly to the secondlevel vibrating feederChina Hubei heavy calcium carbonate HGM100P ultrafine ii table of contents 1 introduction 1 2 limestone quarrying and processing operations 2 21 limestone 2 22 limestone quarrying operations 2 23 limestone processing operations 3 3 lci methodology 5 31 lci data collection 5 32 quality of lci data set 5 331 limestone quarry operations 5 332 limestone processing operations 6 4 lci results 7Limestone Quarrying and Processing: A LifeCycle InventoryGrinding Mill, Raymond Mill, Ball Mill manufacturer / supplier in China, offering Big Capacity Stone Quarry Plant Used Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Impact Crusher, Hot Sale Dolomite Pyrophyllite Mineral Phosphorite Marble Perlite Sepiolite Silica Powder Jaw Crusher Price with High Efficient Capacity, Low Cost Calcite Raymond mill; Superfine grinding mill; Vertical roller mill

.jpg)

How to set up a calcium carbonate ultrafine grinding production line?

2024年3月26日 Therefore, the establishment of a calcium carbonate ultrafine grinding production line has broad market prospects The following are some suggestions for +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Processing materials: 2023年3月17日 Some essential components of a silica sand processing plant include a crusher, a vibrating screen, a sand washer, and a conveyor You can also browse this article to learn more about the separation equipment related to a silica sand processing plant (800tpd silica sand processing plant on site picture)Silica Sand Processing: How to Separate Silica from SandRecently, a mine owner from Sudan contacted the Nile for a list of the configuration of a limestone crushing production line with a capacity of 600 tons per hour After understanding the customer’s needs, our technicians immediately carried out the location of the customer’s production site, weather conditions, and specific stone conditions600 t/h limestone crushed stone production line40T/H Bentonite Powder Production Line in China Location: China Machine: 4 Sets MTW175 Grinding Mill Output Size: 75 Micron D90 Capacity: 40T/H 30T/H Bentonite Powder Production Line in India Location: India Machine: 3 Sets MTW175 Grinding Mill Output Size: 75 Micron D90 Capacity: 30T/H 15T/H Bentonite Powder Production Line in Iran Bentonite Powder Processing Machine

.jpg)

Limestone Ultrafine Mill Machine SBM Ultrafine Powder

2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcUganda kaolin ultrafine mill production line Material: Kaolin Fineness: 12002500 mesh Capacity: 100,000 tons/year Purpose: Used as a filler in paints and paints 86 The processing fineness of HGM ultrafine grinding Uganda kaolin ultrafine mill production line2023年8月18日 Bentonite is a versatile clay mineral that is commonly used in various industries, including agriculture, construction, drilling, and more And it is also helpful for fertilizer productionThe process of bentonite production What Is Process Of Bentonite ProductionProduction Line Features: As a common grinding mill for fluorite powder processing, fluorite Raymond mill is an excellent high efficiency equipment calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, Natural dihydrate gypsum (CaSO42H2O) powder

Fluorite Ore Beneficiation Process Machinery and

2023年4月7日 Fluorite Introduction Fluorite (CaF2) is an important fluorine mineral, which is mostly used for the production of hydrofluoric acid and as a flux in steel making Other uses are the manufacture of glass, fiberglass, pottery Clirik YGM Series Raymond Roller Mill Introduction Name: Clirik YGM Series Raymond Roller Mill Model: YGM series Brand: Clirik Powder Fineness Process Ability: 50450 mesh Capacity: according to your demand about powder fineness, the finial capacity can be adjusted between 0528 t/h Use Range: can be used in more than 300 kinds of stone materials powder grinding, New Technology Dolomite Raymond Roller Mill for Dolomite Limestone In general, when you plan to prepare bentonite granules, there are some aspects that are popular with bentonite pellets manufactures They are types of bentonite fertilizer, bentonite granules manufacturing process, bentonite granules making machine,etcIf you clearly know these aspects, which can help you to make high quality bentonite granulesBentonite Granules Production Line Manufacturing Process2016年1月1日 This paper presents the results of tests carried out to determine how the dosage of bentonite added as binder, affects the properties of green pellets made of the limestone fines that originate Effects of bentonite binder dosage on the properties of green limestone

Clirik Barite grinding mill Shanghai Clirik Machinery devoted to

Shanghai Clirik Machinery devoted to provide barite processing and grinding solution,barite grinding mill, barite grinding machine,barite processing machine, barite powder production line, barite powder making machine for salePowder production line is suitable for grinding and processing calcite, feldspar, marble, limestone, dolomite, fluorite, lime, active carbon, bentonite, kaoline, gypsum, plaster,etc activated carbon, clay, coal gangue, gypsum, silicon carbide, Processing of nonflammable and explosive mineral material powder with refractory such powder production line Zhongde Heavy Industries Co,LtdThe Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding Mill Clirik Grinding MillIt is suitable for the superfine grinding of all kinds of crisp materials whose Moh’s hardness is below 7, such as calcium carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, white mud, mica, refractory material, glass, total about 1000 kinds of materialsStone Powder Making Machine

.jpg)

Bentonite production line PDF Free Download

2015年6月5日 1 Bentonite production line Introduction of Bentonite production line: Brand: CLIRIK Type: Micro powder grinding mill Models: HGM80, HGM90, HGM100, HGM100A, and HGM125 Capacity: 05 12t/h Finished size: 2022年4月20日 After limestone is mined from limestone rock, Limestone crushing and grinding production line 20/04/2022 admin Limestone Properties The processing of limestone is mainly to crush, classify and produce Limestone crushing and grinding production line2022年4月1日 The key production equipment used in the bentonite grinding production line are jaw crusher, impact crusher, Raymond mill, ultrafine mill, etc +17 [ protected] belt conveyors, dust collectors, fans, Properties, Processing and Modification of Bentonite2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine

Stone crushing production line

Stone crushing production line process flow The process flow of the gravel production metallurgy and other industrial sectors to crush mediumhard materials such as calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal Common standard configurations of gravel production lines 1 Processing of high hardness process flow diagram for limestone processing operations 3 list of tables 6 6 table 1 gross energy to produce one ton of limestone products table 2 water consumption for limestone quarrying and processing table 3 lci inputs for limestone quarrying and processing table 4 lci outputs for limestone quarrying and processing table 5Limestone Quarrying and Processing: A LifeCycle InventorySBM ultrafine grinder is the ideal choice for ore processing Home; Materials; Processing Materials Limestone Kaolin Diatomite Carbon black Calcium carbonate Pumice Bentonite Coal Barite Attapulgite Vermiculite Talc technicians can tailor the best production line for you and provide production line design and configuration Processing Materials SBM Ultrafine Powder Technology2023年11月21日 Step 3: Procuring Raw Materials and Bentonite Processing Source highquality bentonite ore as the primary raw material for your production line Set up an efficient processing unit to extract, purify, and prepare the bentonite for granulation Ensure that your processing methods meet industry standards and result in a consistent and desirable How to setup a bentonite granules production line

.jpg)

Dolomite crushing and sand making production line

2022年8月29日 The production line has simple process, high production efficiency, large output and low operating cost The finished sand and gravel have uniform particle size and good particle shape, which is very in line with the national construction sand standard and highquality material requirements 2 Reasonable equipment configuration2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process