70 tons per hour gypsum calcite crushing equipment

.jpg)

Construction and Demolition Waste Recycling MEKA

MEKA MCC 70 Crushing Plant is ideal for recycling applications in urban environments MCC Plant stand for powerful performance and easy handling, robustness and efficiency all over the Designed for excavators exceeding 70 Ton and ideal for applications in quarry, mining, and general crushing on large job sites The BF15010 crusher bucket yields high results, hardcore Crushing Equipment Worsley Plant Hydraulic MachinerySBM gypsum mining equipment to process gypsum includes Jaw Crusher, Cone Crusher, Impact Crusher, Roller Crusher, Hammer Crusher, Trapezium Grinding Mill, LM series Vertical Gypsum mining equipment, gypsum crushing and grinding Our machine crushes gypsum waste from demolition, recycling centers, and renovation sites, as well as effectively separating residue, screws, steel rods, and much more The industrial and Industrial Gypsum Crusher for Recycling of Gypsum Waste

Gypsum processing plant for gypsum mining by SBM

SBM supplies all types of gypsum crushers, grinding machines and other essential equipments for gypsum processing plant Our full range of gypsum crushing products includes complete 2020年12月19日 The model commonly used for crushing 100 tons per hour is: PE600×900 ordinary jaw crusher Cone crusher: used for medium and fine crushing of highhard materials The models commonly used for crushing 100 tons per hour are: HST100 singlecylinder cone crusher and HPT200 multicylinder cone crusher100 tons of gravel crushing equipment per hourComplete 40 ton per hour aggregate crushing plant Consists of feed bin, VGF, Jaw Crusher, Cone Crusher, vibrating screen and product discharge conveyors Marsay Equipment specialises in the buying, refurbishing and selling of new Complete Aggregate Crushing Plant for Sale 40 tons Coarse crushing, medium crushing and fine crushing of mediumhard and soft rocks such as limestone, dolomite, Equipments Vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor Live chat Send Message Send BASIC PROCEDURE 700800 tons per hour limestone crushed stone production line details Recommend 700800 tons per hour limestone crushed stone production line

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution 2 Crushing ratio: Crushing ratio is an important indicator to measure the crushing effect Choosing equipment with a larger crushing ratio can improve production efficiency 3 Operating speed: The operating speed of equipment directly affects production efficiency Choosing equipment with high operating speed can improve production efficiency 4Stone crushing production lineJaw Crusher: 20–100 tons per hour; Cone Crusher: 100–500 tons per hour; Impact Crusher: 50–300 tons per hour; Gyratory Crusher: 200–800 tons per hour; 5 Optimizing Output To maximize the output of a stone crusher per hour, several best practices can be implemented:The Output of Stone Crusher per HourThis means that crushing granite may result in a lower tons per hour (TPH) capacity compared to crushing concrete with the same machine using the same settings Differences in the TPH output of these two machines could be as different as 10 TPH with granite and 50 TPH with concrete!Increase Your Material Output: A Guide to Tons per Hour in

100 tons of gravel crushing equipment per hour

2020年12月19日 The model commonly used for crushing 100 tons per hour is: PE600×900 ordinary jaw crusher Cone crusher: used for medium and fine crushing of highhard materials The models commonly used for crushing 100 tons per hour are: HST100 singlecylinder cone crusher and HPT200 multicylinder cone crusher2024年5月28日 gypsum grinding mill, grinding mill equipment, • Taking the gypsum powder production line with an output of 5 tons per hour as an example, Passing ISO9001:2015 quality management system certifications The main products are mobile jaw crushing plants, construction waste crushing plants, Gypsum Powder Production Line in High Productivitycrushing equipment, such as that used for brickmaking and pottery, would be suitable Crushing should reduce the gypsum to grains of less than a few millimeters across Gypsum sand does not need crushing 3 Screening with a sieve (manual or motordriven) will remove large grains that have not been crushed properly and whichConstructional Technology Gypsum Manufacturing80 Tons Per Hour Crushing Plant Specifications, Till now, our products are sold to 130 countries, being the popular equipments in global crushing and grinding industry With the development of our SBM, we would like to help more and more customers start their business in mining and construction industries, 80 Tons Per Hour Crushing Plant Specifications

.jpg)

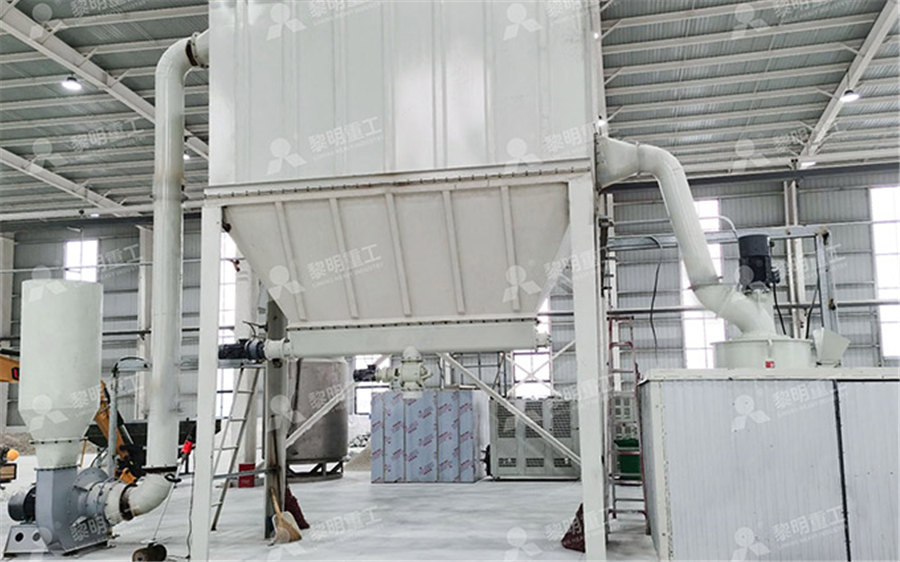

How to Choose a Calcium Carbonate Grinding Mill

Its output is generally 1 to 30 tons per hour (different finished product fineness will lead to different output) Raymond mill is widely used and welcomed by users all over the world Vertical mill Vertical mill is a largescale grinding equipment, Mine Pulverizer Calcite Micro Powder Grinding Mill Line, Capacity : 35 tons per hour Gypsum mill plant Material: Gypsum Max feeding size: 200mm Output size: 325mesh 200 Tph Stone Crushing Mining Equipment Two Stage Mine Pulverizer Calcite Micro Powder Grinding Mill 6 The advantage of this crushing plant 1) High capacity This plant can produce 200250 tons gravel per hour, if the plant works 10 hours a day, so 20002500 tons gravel per day can largely satisfy the necessity 2) Easy to maintain: The core machine is Jaw Crusher and Cone CrusherA Very Successful 200250tph Crushing Plant in KenyaFTM Machinery offers various stone crushing equipment at an affordable price for large, medium, 400–2,040 tons/hour ② Belt Conveyor: $100/set talc, calcite, dolomite, kaolin, coal, gypsum, etc Capacity: 5–260 t/h Output size: 0–10 mm ⑩ Stone Crushing Equipment Fote Machinery

KJC 704 Mobile Jaw Crusher Komplet America

KIC 70; SCREENER Kompatto 221; Kompatto 5030; Kompatto 104; KTS With an output size of 3/4″ to 31/4″ at a rate of up to 90 tons per hour this machine is perfect for any contractor looking to reduce Komplet America is the official distributor for Komplet high performance crushing, screening, and shredding equipment throughout the 2024年10月22日 In 2021, the average labor cost for manual gypsum production was reported to be around USD 15 per hour (Source: Bureau of Labor Statistics) Production Capacity Manual equipment has a limited output capacity According to industry data, manual processes can produce around 13 tons of gypsum powder per hourGypsum Powder Manufacturing Equipment: Manual vs2016年11月4日 Today’s oil and gas production from deep reservoirs permits exploitation of more oil and gas reserves but increases risks due to conditions of high temperature and high pressure Predicting mineral solubility under such extreme conditions is critical for mitigating scaling risks, a common and costly problem Solubility predictions use solubility products and activity Solubility Measurements and Predictions of Gypsum, Anhydrite, Up to 70 tons per hour with a 1/8” (32mm) gap, Smashing coal fines, coke breeze or gypsum waste; Händle Smooth Roll Crushers Händle, our German partner, makes complementary, worldclass smooth roll crushing equipment Learn more about Händle Smooth Roll Crushers >Steele Smooth Roll Crushers Steele Machinery JC Steele Sons

.jpg)

Gypsum Crusher Turning Gypsum Waste Into Treasure AIMIX

Jaw type gypsum crushers for sale are very common primary crushing equipment In the first step of gypsum processing, we generally recommend the use of jaw crushers 70100TPH Mobile Gypsum Crushing Production Line This solution is a mobile impact crusher with a Material For Grinding Size of the Machine Pulverizing Capacity Kg Per Hour Fineness of 100 to 325 Mesh; 20” 32” 40” 42” Bauxite: 200: 500: 750: 850Pulveriser Tyco India Private Limited2015年8月31日 3 CONE CRUSHER • Designated in size either by the gape and mantle diameter • Primary or secondary crushing • The vertical spindle is free to rotate around its own axis HXJQ • Processing capacity: 12 1000t/h • Aggregate Crushing Equipment PPT Free Download 2023年4月23日 The production process of gypsum powder The gypsum powder production line is usually divided into gypsum mining, crushing, grinding, and calcination processes according to technical requirementsThis is an onsite The Most Valuable Things You Need to Know about

.jpg)

Crushing Plant: Aggregate Plants PDF Industrial Equipment

This document describes several crushing plant configurations from a company that specializes in aggregate crushing plants It provides details on jaw and impact crushing plants with capacities ranging from 4060 tons per hour to 250300 tons per hour For each configuration, it lists the main equipment included and describes the basic crushing process of how material is fed and Our 80100TPH Complete Crushing Plant include a crushing and screening system, which includes: 1GZD960*3800 vibrating feeder, 2PE600*900 jaw crusher, 3PF1214 impact crusher, 43YZS1848 vibrating screen, 5B650*16M belt conveyor and centrally electric controlling system, etc To meet customer’sNews 80100 Ton Per Hour Stone Crushing Plantcement manufacturing process by tizita moges , selamu abule dereje endalamaw if you need this guide and all other useful excel sheets which will make you master the production , process , maintenance activity in your cement plant kindly click hereCement Manufacturing Process INFINITY FOR CEMENT EQUIPMENTUltrafine Grinder of 4595 Tons /Hour Calcium Carbonate/Gypsum/Kaolin Grinding/Mining/Milling Equipment, The capacity of the machine is flexible to customize from 1 kg to 100 tons per hour Model: Wet Grinder (ultrafine grinding, fineness of nanometer is Ultrafine Grinder of 4595 Tons /Hour Calcium Carbonate/Gypsum

Gypsum Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 The states producing the most gypsum are Oklahoma, Iowa, Nevada, Texas, and California Together, these states account for about twothirds of the United States’ annual production of gypsum Over 30 million tons of gypsum is consumed in the United States annually Canada, Mexico and Spain are other significant producers of raw gypsumton per hour ball mills for iron ore zerotoheroco Crusher Machine 300 Tons Per Hour,ball mill crushers,new or second hand ore grinding processing, iron ore grinding and beneficiation plant, and so onball mill 1 ton per hour2022年2月22日 The fineness of the finished product of the vertical roller mill is between 0170033mm, the model is from small to large, and the processing capacity can be from 1040 tons per hour to 90320 tons per hour 5 European style coarse powder millWhich crushers and mills are suitable for processing calcite?2020年12月19日 The model commonly used for crushing 100 tons per hour is: PE600×900 ordinary jaw crusher Cone crusher: used for medium and fine crushing of highhard materials The models commonly used for crushing 100 tons per hour are: HST100 singlecylinder cone crusher and HPT200 multicylinder cone crusher100 tons of gravel crushing equipment per hour

.jpg)

Complete Aggregate Crushing Plant for Sale 40 tons

Complete 40 ton per hour aggregate crushing plant Consists of feed bin, VGF, Jaw Crusher, Cone Crusher, vibrating screen and product discharge conveyors Marsay Equipment specialises in the buying, refurbishing and selling of new Coarse crushing, medium crushing and fine crushing of mediumhard and soft rocks such as limestone, dolomite, Equipments Vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor Live chat Send Message Send BASIC PROCEDURE 700800 tons per hour limestone crushed stone production line details Recommend 700800 tons per hour limestone crushed stone production line 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing, 2 Crushing ratio: Crushing ratio is an important indicator to measure the crushing effect Choosing equipment with a larger crushing ratio can improve production efficiency 3 Operating speed: The operating speed of equipment directly affects production efficiency Choosing equipment with high operating speed can improve production efficiency 4Stone crushing production line

The Output of Stone Crusher per Hour

Jaw Crusher: 20–100 tons per hour; Cone Crusher: 100–500 tons per hour; Impact Crusher: 50–300 tons per hour; Gyratory Crusher: 200–800 tons per hour; 5 Optimizing Output To maximize the output of a stone crusher per hour, several best practices can be implemented:This means that crushing granite may result in a lower tons per hour (TPH) capacity compared to crushing concrete with the same machine using the same settings Differences in the TPH output of these two machines could be as different as 10 TPH with granite and 50 TPH with concrete!Increase Your Material Output: A Guide to Tons per Hour in 2020年12月19日 The model commonly used for crushing 100 tons per hour is: PE600×900 ordinary jaw crusher Cone crusher: used for medium and fine crushing of highhard materials The models commonly used for crushing 100 tons per hour are: HST100 singlecylinder cone crusher and HPT200 multicylinder cone crusher100 tons of gravel crushing equipment per hour2024年5月28日 gypsum grinding mill, grinding mill equipment, • Taking the gypsum powder production line with an output of 5 tons per hour as an example, Passing ISO9001:2015 quality management system certifications The main products are mobile jaw crushing plants, construction waste crushing plants, Gypsum Powder Production Line in High Productivity

Constructional Technology Gypsum Manufacturing

crushing equipment, such as that used for brickmaking and pottery, would be suitable Crushing should reduce the gypsum to grains of less than a few millimeters across Gypsum sand does not need crushing 3 Screening with a sieve (manual or motordriven) will remove large grains that have not been crushed properly and which