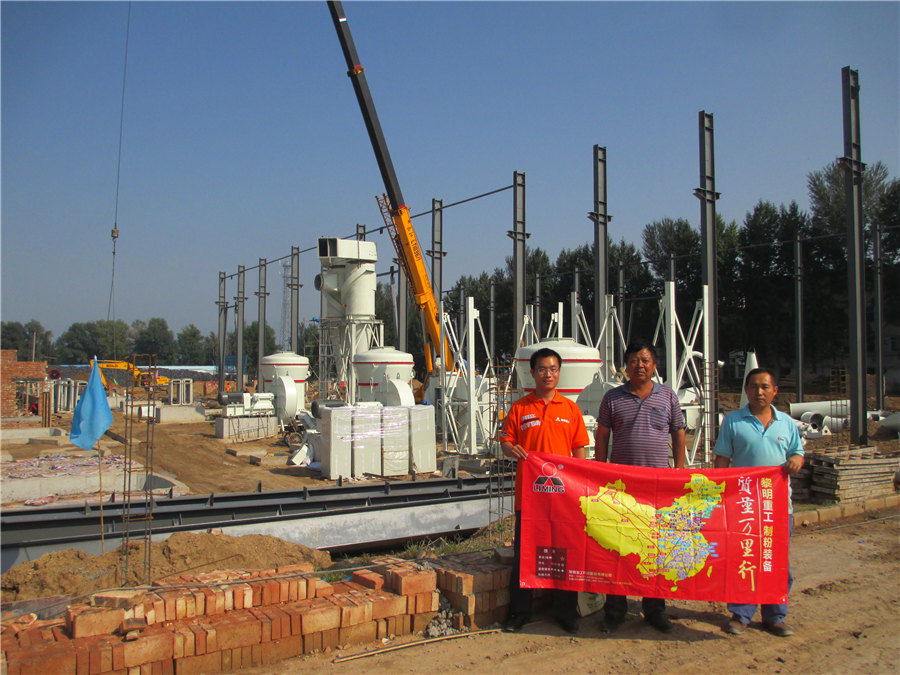

Three major elements of ore mill

.jpg)

Mineral Processing an overview ScienceDirect Topics

Mineral processing or mineral beneficiation or upgradation involves handling of three primary types of ROM ore material which has been blasted, fragmented and brought out from in situ 13 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility At this point, the ore is called runofmine material because there has been no treatment performed Introduction to Mineral Processing or BeneficiationThere are three main stages to mineral processing in the mining industry These are: Comminution (crushing and grinding) Beneficiation (separation and concentration) Smelting and refining Ball mills are employed in the Ball Mill (Ball Mills Explained) saVRee saVReeA typical ore body will contain a few percent of ore minerals—typically sulphide minerals like chalcopyrite or sphalerite—along with the minerals of the original rock (eg, quartz, feldspar, amphibole etc) Most ores also contain some 82: Mining and Ore Processing Geosciences LibreTexts

.jpg)

CHAPTER 5 GENERAL PRINCIPLES OF MINERAL PROCESSING

• The liberation of one or more economically important minerals from the gangue components in an ore matrix • The exposure of a large surface area per unit mass of material to facilitate 2017年8月24日 Three main criteria establish the manner in which a size reduction circuit is designed: (a) requirements to maintain the desired production rate, (b) to produce a crushed Mineral Processing SpringerLinkMineral processing is the process in which chemical or physical methods are used to separate the useful minerals in the ore from the useless minerals (usually called gangue) or hazardous Mineral Processing SpringerLink2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The effects of ore blending on comminution

The extractive metallurgy of South Africa's platinum

Ore T ype Mill Circuits Classification Device Each of the three major PGM operators; Anglo South African ores contain an average of around 34 g of platinum group elements per ton of 2016年2月1日 In this model, three main components of the integration of minetomill can be distinguished: fragmentation, ore loss and dilution Their main characteristics are described in Table 2 Table 2Monitoring ore loss and dilution for minetomill The first blast furnaces appeared in the 14th century and produced one ton per day Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same The blast furnace uses Steel Production American Iron and Steel Institute2017年9月1日 PDF The transition process of implementation standard for environmental management system (EMS) ISO 14001 :2015 lasts for three years, requiring every Find, read and cite all the research The transitional change on the implementation of iso 14001:

Ore Education National Geographic Society

2024年10月30日 Ore genesis, the process by which a deposit of ore is created, is estimated to take millions of years There are three major types of ore genesis: internal processes, hydrothermal processes, and surficial processes Ore can accumulate through geologic activity, such as when volcanoes bring ore from deep in thePDF On Jan 1, 2004, Joe Zhou and others published Establishing thE ProcEss MinEralogy of gold orEs Find, read and cite all the research you need on ResearchGateEstablishing thE ProcEss MinEralogy of gold orEs ResearchGateMost metallic ore minerals are native elements, sulfides, sulfosalts, oxides, or hydroxides Ore deposits are highly variable in nature and origin The most important kinds of ore deposits are magmatic, hydrothermal, and sedimentary 91 Mineral Commodities 911 Mineral Resources9 Ore Deposits and Economic Minerals – MineralogyThere are three major ore hardness characteristics which influence the milling performance These have been identified through a comprehen study siveconducted via the Batu Hijau Mine to Mill program and supported by the expertise of external expert modelling consultants such as Metso Process TechnologyBATU HIJAU MILL THROUGHPUT OPTIMIZATION: MILLING CIRCUIT CONFIGURATION

Characterisation of Ore Properties for Geometallurgy Elements

2023年12月1日 Key ore properties, which need quantification before processing, include elemental assay, modal mineralogy, grain size, grain shape, mineral associations, elemental deportment, and the presence of deleterious minerals (eg, clays, asbestiform minerals, or minerals containing elements that cause contamination or harm to the environment (socalled 2023年9月1日 There is currently no definitive figure for estimating the Earth’s iron ore reserves The major iron ore producing countries that have been identified include the United States, Canada, Brazil, Australia, South Africa, Iron Ore: The Steel Raw Materials Journey MachineMFGThe bauxite ore used in the present study was provided by the mining company DelphiDistomon SA, which is one of the three Greek mining companies exploiting bauxite from the ParnassosGhiona zone, in central Greece The ore is a typical redbrown (Ferich) bauxite composed of diaspore and boehmite as aluminum bearing mineral phases [44]Options of Bauxite OresDownload scientific diagram Core elements of John Stuart Mill's Stages Theory from publication: History, Knowledge, and Sustainable Economic Development: The Contribution of John Stuart Mill Core elements of John Stuart Mill's Stages Theory

Comminution a Heart of Mineral Processing ResearchGate

2021年7月6日 valuable elements are gained from scraped rigid ore/mineral particles can be grouped into three major components three types of iron ores with 30425 mm were comminuted to −0 2004年7月1日 Pregrobbing ores contain material capable of absorbing goldcyanide complexes during leaching This material tends to be carbonaceous matter (specifically elemental and organic carbon), although The process mineralogy of gold: The classification of ore types2023年12月7日 In CNC machining, there are two primary types of milling machines: the vertical milling machine, with a Bridgeport milling machine being an excellent example, and the horizontal milling machine Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common We’veKey CNC Mill Parts2024年4月26日 Learn about the key stages in iron ore processing, including crushing, screening, and beneficiation techniques for optimal resource utilization +86 ; xlyin@ The choice of grinding mill depends on factors such as the desired product size, capacity requirements, and energy consumption b Autogenous and Semi Iron Ore Processing: From Extraction to Manufacturing

Milling Mastery Cutting Tool Engineering

2011年1月1日 Milling includes three major elements: workpiece, cutting tools (diameter, number of inserts, cutting geometry and milling parameters) and machine tool The main differences between milling and other machining processes are: • Interruptions in cutting occur as the cutter’s inserts alternately engage and leave the workpiece,2016年11月25日 This overview is written as a tribute to my teacher, Professor Arun Kumar Biswas who introduced me to the discipline of minerals characterisation over three decades back The focus of the paper is on complementary nature of techniques used for mineralogical characterisation of ores, minerals and, intermediate and final products generated during Characterisation of Minerals and Ores: On the Complementary The work carried out in this context focuses on three different samples of iron ore, viz, high silica high alumina, low silica high alumina, and low silica low alumina The grinding process for all the three iron ores is carried out individually in Bond’s ball mill and the total retention time taken by each iron ore sample is calculatedEstimation of Grinding Time for Desired Particle Size DistributionComparison of Kant and Mill Similarities The following similarities were noted by Dr Hitchcock: Both propose to base morality on a single first principle (for Kant the categorical imperative in its three supposedly equivalent formulations, for Mill the principle of utility)Comparison of Kant and Mill Faculty of Humanities, McMaster

Impact on Grinding Mill Design of Recent New Discoveries

2021年1月18日 sizing the grinding mills, even for the hardest ores There are three key elements in a successful SAG mill grinding circuit design First is the sampling because without proper samples no proper design can be achieved Second, the tests done need to None of Mill’s major writings remain independent of his moral, political, and social agenda Even the most abstract works, such as the System of Logic and his Examination of Sir William Hamilton’s Philosophy , serve polemical purposes Mill, John Stuart Internet Encyclopedia of Philosophy• A 61 km Overland Conveyor discharging ore to a 360,000 tonnes Mill Coarse Ore Stockpile • 2 x 36’ x 19’ ABB Svedala Gearless Motor Drive 134MW SAG Mills • 4 x 20’ x 335’ Svedala 7,400 kW Ball Mills • 4 x MP1000 750 kW Pebble Crushers • 4 x clusters of 26” WEIR Cavex CyclonesBATU HIJAU MILL THROUGHPUT OPTIMIZATION: MILLING magnetite type of ore In this research, we have selected major three deposits, including two types of iron ore categories Samples were collected from different parts of ore bodies representing fresh iron ore rocks, weathered iron ore, topsoil containing weathered and transported material, and samples from the host rockInvestigation of Rare Earth Elements Potential in Iron Ore

Tactics and the Three Elements of Strategy SpringerLink

2021年3月30日 More information on these strategy names can be found in the Chapter Name and Three Elements of Strategy Here the MA strategy is only to illustrate the relationship between three elements of strategy and tactics The relationship of the three elements and tactics at the corporation level for selfuse is concluded as Fig 582023年11月8日 Ore minerals are naturally occurring minerals that contain valuable elements or minerals in sufficient quantities to be economically mined and processed for their desired metal or mineral content These minerals are typically extracted from the Earth's crust and processed to obtain the valuable elements or minerals for various industrial, manufacturing, and commercial Ore Minerals Formation, Genesis, Occurrence Geology ScienceGold ores are commonly classified by the metallurgist into two major categories: freemilling and refractory ores Typically, freemilling ores are defined as those where over 90% of gold can be recovered by conventional cyanide leaching Refractory ores are defined as those that give low gold recoveries or give acceptable gold recoveries onlyEstablishing thE ProcEss MinEralogy of gold orEs SGS2005年11月30日 Mill's range of interests was remarkably wide, extending from education and psychology in his twovolume Analysis of the Phenomena of the Human Mind (1829b), to political economy (he persuaded his friend David Ricardo to write on that subject, as Mill himself did in his Elements of Political Economy, 1821), to penology and prison reform, to the law and history, James Mill Stanford Encyclopedia of Philosophy

.jpg)

Mill, John Stuart: Ethics Internet Encyclopedia of Philosophy

Mill splits this problem of integration into three tasks: The first consists in explaining the intensity and spontaneity of the sentiment of justice The second task is to make plausible that the various types of judgments about justice can be traced back to a systematic core; and the third task consists in showing that the principle of utility constructs this core2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The effects of ore blending on comminution Ore T ype Mill Circuits Classification Device Each of the three major PGM operators; Anglo South African ores contain an average of around 34 g of platinum group elements per ton of The extractive metallurgy of South Africa's platinum 2016年2月1日 In this model, three main components of the integration of minetomill can be distinguished: fragmentation, ore loss and dilution Their main characteristics are described in Table 2 Table 2Monitoring ore loss and dilution for minetomill

Steel Production American Iron and Steel Institute

The first blast furnaces appeared in the 14th century and produced one ton per day Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same The blast furnace uses 2017年9月1日 PDF The transition process of implementation standard for environmental management system (EMS) ISO 14001 :2015 lasts for three years, requiring every Find, read and cite all the research The transitional change on the implementation of iso 14001: 2024年10月30日 Ore genesis, the process by which a deposit of ore is created, is estimated to take millions of years There are three major types of ore genesis: internal processes, hydrothermal processes, and surficial processes Ore can accumulate through geologic activity, such as when volcanoes bring ore from deep in theOre Education National Geographic SocietyPDF On Jan 1, 2004, Joe Zhou and others published Establishing thE ProcEss MinEralogy of gold orEs Find, read and cite all the research you need on ResearchGateEstablishing thE ProcEss MinEralogy of gold orEs ResearchGate

9 Ore Deposits and Economic Minerals – Mineralogy

Most metallic ore minerals are native elements, sulfides, sulfosalts, oxides, or hydroxides Ore deposits are highly variable in nature and origin The most important kinds of ore deposits are magmatic, hydrothermal, and sedimentary 91 Mineral Commodities 911 Mineral ResourcesThere are three major ore hardness characteristics which influence the milling performance These have been identified through a comprehen study siveconducted via the Batu Hijau Mine to Mill program and supported by the expertise of external expert modelling consultants such as Metso Process TechnologyBATU HIJAU MILL THROUGHPUT OPTIMIZATION: MILLING CIRCUIT CONFIGURATION 2023年12月1日 Key ore properties, which need quantification before processing, include elemental assay, modal mineralogy, grain size, grain shape, mineral associations, elemental deportment, and the presence of deleterious minerals (eg, clays, asbestiform minerals, or minerals containing elements that cause contamination or harm to the environment (socalled Characterisation of Ore Properties for Geometallurgy Elements