Ball mill zsp300

.jpg)

Ball Mills a suitable ball mill for every application

Retsch visualises the features and strengths of each ball bill model in a diagram to help finding the right model for a specific application In the example shown it is easy to see that the Planetary Ball Mill PM 300 offers advantages in terms of The Micro ball mill GT300 is designed for modern laboratory applications It can process 2 pcs and large batch samples simultaneously in 30 seconds, the sample volume from 02ml to Micro Ball Mill GT300 Beijing Grinder Instrument Co,Ltd2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Ball Mill Critical Speed 911MetallurgistPLANETARY BALL MILL PM 300 APPLICATIONS IN MECHANOCHEMISTRY RETSCH Planetary Ball Mills are perfectly suited for processes like mechanical alloying or mechanosynthesis For most reactions, the 1:2 speed ratio of jar to sun wheel of the models PM 100 and PM 200 is fully adequate, as the ball charge produces enough impact energy PLANETARY BALL MILL GWB Tuoteluettelo

Retsch : 粉碎设备 : 球磨仪 : PM 300

Planetary Ball Mill PM 300 机械化学中的应用 RETSCH行星式球磨机非常适合机械合金化或机械合成等应用。 对于大多数机械化学反应,PM 100和PM 200的太阳轮公转转速与研磨罐自转的1∶2速度比是完全足够的,因为研磨球负载会产生 High quality range of Planetary ball mill PM 300 products available at low cost with Free Delivery available (Terms and Conditions apply) Your basket is empty Fancy a chat? You can contact us on Phone: +353 (0)1 : sales@labunlimited Carl Stuart Limited Tallaght Planetary ball mill PM 300 Lab Unlimited2023年5月15日 During ball milling, solids constantly undergo stress, aggregation, and agglomeration, which allows the material to interact and experience various chemical reactions under mechanical forces [15]In a highenergy mill, the material to be milled is placed in a hollow cylindrical container and a milling medium, ie, balls generally made of stainless steel, Ballmilling: A sustainable and green approach for starch BM400 Mixer/Mill® (part # 8000M) HighEnergy Ball Mill Highenergy ball mill that grinds up to 10 grams of sample Wide selection of grinding and mixing vials available including hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene, methacrylate, polystyrene, and polycarbonateMixer/Mill – highenergy ball mills, mechanical alloying, mixing

Planetary Ball Mills RETSCH fine grinding of materials

Planetary Ball Mills are used for fast and reproducible grinding of materials to analytical fineness versatile in use high energy input Learn More Retsch GmbH English English; Deutsch; we recommend a maximum of 500 rpm in the PM 300 and 550 rpm in the PM 100The TM 300 Drum Mill is utilized for preparing granules and powders through a grinding process conducted in either dry or wet conditions This versatile grinder can function as either a Ball or a Rod Mill by employing the corresponding module To ensure an efficient grinding process, it is essential to use a sufficient number of balls or rodsDrum Mill TM 300 RETSCH laboratory equipmentIdeal for: Grinding and mixing crystalline chemicals, inks, paints, pigments, plants, racks, and soils Features: antistatic rubber roller: keeps jars/pots centered ergonomic and compact design NBR roller with pot guide ring programmable options: 10 steps and 6 programs storage function for the set values of temperature and timer soundproof cabinet for safety and minimum noise (optional Ball mill witeg Labortechnik GmbHThis is our largest batch ball mill Best at dry grinding, it has a grinding chamber of either 150L or 300L (40 or 80 gallons) The 911MPELMBM150/300 is a process and laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard, and LARGE BATCH LABORATORY BALL MILL 150L TO 300L

Planetary Ball Mill PM 300 ATS Scientific

Planetary Ball Mill PM 300 Retsch Sample Preparation Inorganic Introducing the new Retsch Planetary Ball Mill PM 300! A robust and ergonomic benchtop model with two grinding stations for grinding jar volumes up to 500 ml Ideally The ball mill is one of the grinding machines Check out the range of quality and reliable ball mills and accessories on this Across International Australia page, and see more details 1300 118 228 ; Contact Us ×; Home; Shop by category Analytical Balances; Ball Mills; Biosafety Ball Mills: Lab Equipment Grinding Machines, Features PricingThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batchPlanetary Ball Mill PM 100 RETSCH highest finenessRetsch visualises the features and strengths of each ball bill model in a diagram to help finding the right model for a specific application In the example shown it is easy to see that the Planetary Ball Mill PM 300 offers advantages in terms of power, final fineness and maximum jar volume compared to the Mixer Mill MM 500 controlRetsch : 产品 : 粉碎设备 : 球磨仪

.jpg)

Verder Scientific Customer Magazine Issue 44 BALL MILLS

The Drum Mill TM 300 with its ball and rod modules is used for fine grinding of solid matter by impact and friction, in wet or dry condition Whatever your requirements may be – RETSCH has the perfect ball mill for your application! THE PERFECT BALL MILL FOR EVERY APPLICATION OVERVIEW Mixer Mill MM 200 Mixer Mill MM 400The PM 300 is a planetary ball mill with 2 grinding station The maximum batch size is 2 x 220 ml Planetary ball mills comminute by impact and friction and achieve grind sizes down to 1 micron, in colloidal grindings even 01 micro;m Thanks to the high centrifugal forces, the mill acieves a Planetary ball mill PM 300 Retsch GmbH DirectIndustryWith the powerful, ergonomic benchtop Planetary Ball Mill PM 300 RETSCH covers a wide range of size reduction applications and increases the throughput thanks to two grinding stations for jars up to 500 ml It is also suitable for pulverizing small sample volumes down to 3 mlTHE NEW PLANETARY BALL MILL PM 300With the development of the Planetary Ball Mill PM 300 RETSCH has closed a gap in the product portfolio This benchtop model with two grinding stations accepts grinding jar volumes up to 500 ml which results in a maximum batch size of 2 x 220 ml sample materialTHE NEW PLANETARY BALL MILL PM 300 RETSCH

.jpg)

High Energy Ball Mills Milling RETSCH

The Planetary Ball Mill PM 300 features a large sun wheel and a maximum speed of 800 rpm, reaching accelerations up to 644 g Together with the option to use four small, stackable grinding jars sized 12 to 80 ml for small scale operations, or two jars sized up to 500 ml for upscaling purposes, this model is highly suitable for research applications in mechanochemistryThe ball mill is made of cylinders rotating on a horizontal shaft They are filled with a grinding charge and fed with the material to be ground The product is ground by impact, friction or attrition thanks to a precise rotation speed (optimised for BALL MILL LAB SIZE Lessine2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911MetallurgistBall mill 300 kg Ball mills are a crucial component of chocolate production These machines are durable, energy efficient, easy to maintain and clean, making them ideal for grinding and refining chocolate Available options (click to view Chocolate ball mill 300 kg Chocolate machines IMSY

.jpg)

Cutting Mill SM 300 Introduction #RETSCH #cuttingmill

2016年8月9日 Cutting Mill SM 300 is suitable for the grinding of soft, mediumhard, tough, elastic, fibrous, and heterogeneous mixes of products Learn more https: Planetary Ball Mill PM 400 for size reduction with the highest degree of fineness powerful short grinding times reproducible results Learn more Retsch GmbH 16 h finegrinding at 300 rpm Hardbrittle: granite 4 x 80 g sample 250 ml agate grinding jar 6 x 30 mm agate grinding balls 15 min at 400 rpm Hard: silicon carbidePlanetary Ball Mill PM 400 RETSCH powerful and quick grinding2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside diameter and Ball Mills 911MetallurgistMicroo ball mill (please order grinding jars and balls separatly) Feed size10mm Final fineness5μm Speed180~1800rpm Time00:01~99:59(min/s) Sample volume02~20ml Rated powe200W Powe supply220V,50Hz Instrument size(W*D*H)380*480*281mm Package size(W*D*H)460*380*660mm Weight34kg The Micro ball mill MBM300 is designed for Micro Ball Mill MRCLab

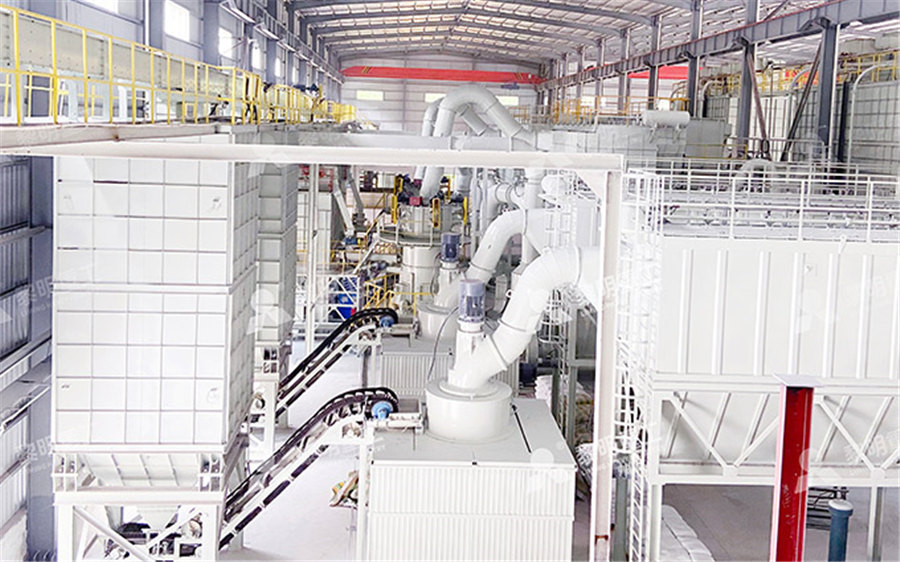

Ball Mill

Ball Mill Ball Mills are mainly used in metallurgy, chemical industry, electric power, cement and other industrial and mining business to make all kinds of ores and other grindable materials by virtue of such characteristics as strong adaptability to raw materials, excellence in continuous production, high crushing ratio and easy to adjust the fineness of the finished productLaboratory ball mill Laboratory ball mill Ball mill 50 kg Ball mill 300 kg Ball mill 500 kg Ball mill 1000 kg Specification Material: Stainless steel AISI 304: Production rate: 5kg per 5 hours: Capacity: 5kg: Power: 220V, 15kW: Additional details: 05 hp engine; 05 hp chocolate pump; Add to cart Get quotationLaboratory chocolate ball mill Chocolate machines IMSYBall mills are horizontal rotating cylindrical or conical steel chambers, approximately one third to half full of steel, alloy steel or iron balls, like that shown in Fig 410 A–C, or flint stones The size reduction is accomplished by the impact of these balls on the material as they fall back after being lifted by the rotating chamberBall Mill an overview ScienceDirect Topics2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Ball Mill Critical Speed 911Metallurgist

.jpg)

PLANETARY BALL MILL GWB Tuoteluettelo

PLANETARY BALL MILL PM 300 APPLICATIONS IN MECHANOCHEMISTRY RETSCH Planetary Ball Mills are perfectly suited for processes like mechanical alloying or mechanosynthesis For most reactions, the 1:2 speed ratio of jar to sun wheel of the models PM 100 and PM 200 is fully adequate, as the ball charge produces enough impact energy Planetary Ball Mill PM 300 机械化学中的应用 RETSCH行星式球磨机非常适合机械合金化或机械合成等应用。 对于大多数机械化学反应,PM 100和PM 200的太阳轮公转转速与研磨罐自转的1∶2速度比是完全足够的,因为研磨球负载会产生 Retsch : 粉碎设备 : 球磨仪 : PM 300High quality range of Planetary ball mill PM 300 products available at low cost with Free Delivery available (Terms and Conditions apply) Your basket is empty Fancy a chat? You can contact us on Phone: +353 (0)1 : sales@labunlimited Carl Stuart Limited Tallaght Planetary ball mill PM 300 Lab Unlimited2023年5月15日 During ball milling, solids constantly undergo stress, aggregation, and agglomeration, which allows the material to interact and experience various chemical reactions under mechanical forces [15]In a highenergy mill, the material to be milled is placed in a hollow cylindrical container and a milling medium, ie, balls generally made of stainless steel, Ballmilling: A sustainable and green approach for starch

.jpg)

Mixer/Mill – highenergy ball mills, mechanical alloying, mixing

BM400 Mixer/Mill® (part # 8000M) HighEnergy Ball Mill Highenergy ball mill that grinds up to 10 grams of sample Wide selection of grinding and mixing vials available including hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene, methacrylate, polystyrene, and polycarbonatePlanetary Ball Mills are used for fast and reproducible grinding of materials to analytical fineness versatile in use high energy input Learn More Retsch GmbH English English; Deutsch; we recommend a maximum of 500 rpm in the PM 300 and 550 rpm in the PM 100Planetary Ball Mills RETSCH fine grinding of materialsThe TM 300 Drum Mill is utilized for preparing granules and powders through a grinding process conducted in either dry or wet conditions This versatile grinder can function as either a Ball or a Rod Mill by employing the corresponding module To ensure an efficient grinding process, it is essential to use a sufficient number of balls or rodsDrum Mill TM 300 RETSCH laboratory equipmentIdeal for: Grinding and mixing crystalline chemicals, inks, paints, pigments, plants, racks, and soils Features: antistatic rubber roller: keeps jars/pots centered ergonomic and compact design NBR roller with pot guide ring programmable options: 10 steps and 6 programs storage function for the set values of temperature and timer soundproof cabinet for safety and minimum noise (optional Ball mill witeg Labortechnik GmbH

.jpg)

LARGE BATCH LABORATORY BALL MILL 150L TO 300L

This is our largest batch ball mill Best at dry grinding, it has a grinding chamber of either 150L or 300L (40 or 80 gallons) The 911MPELMBM150/300 is a process and laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard, and