Thai grinding powder classification

Material classification for fine powders Processing

2021年10月18日 It is important to take an unbiased look at the various powder classification methods available to identify the solution that will best fit your powder separation needs This article will explore the different types of Various variables affecting grinding, such as air pressure, minerals or materials hardness, feed size were investigated The limitations of grinding of gypsum, barite, ilmenite, quartz and Fine grinding of brittle minerals and materials by jet mill2002年1月1日 Using new classification and grinding technology, we discuss the improvement of the classification and grinding performance This discussion includes closed loop grinding and Improvement of grinding and classifying performance using a 2020年6月22日 This review highlights the information of the main superfine grinding methods in the field of food processing and the changes in performance after superfine grinding treatment Recent advances in processing food powders by using superfine

.jpg)

Classification of Grinding Products SpringerLink

2023年7月27日 Classification of grinding products is a process of dividing the grinding products of wide particle size into numerous products of narrow particle size, which is based on the Classification is a unit operation that improves the characteristics of powder products by separating powder materials according to their particle size, such as removing coarse powder Details of Classification Technology HOSOKAWAMICRON 2020年6月1日 Superfine grinding is one of the most effective techniques to produce micro, submicron, or nano (100 μm1 nm) powders (Gao et al, 2020a), which are utilized to make Recent advances in processing food powders by using superfine Our ambient milling systems can take a variety of materials in pellet, chip, crumb, or powder form and grind, while accurately classifying them into powders ranging in size from 4,000 to 45 Custom size reduction and processing services LyondellBasell

Classifying NETZSCH Grinding Dispersing

With our standard Fine Classifier CFS, fine powders can be cleanly classified High performance classification and efficient results are valid for both coarse material and the separation of fines We supply high tech powder technologies required in petrochemical, fine chemical, electronic materials, ceramics, pharmacy, food and cosmetics industry by securing technical cooperation DAEGA THAIJXSC grinding classification equipment is the key equipment for crushing materials after they are crushed The ball mill can process various grinding minerals, nonferrous metal beneficiation, and new building materials It is Grinding Classification Equipment JXSC Machinery3 Fine crushing or coarse grinding: The feed material is usually comes from the secondary crushers 4 Fine Grinding: The objective of fine grinding is to produce ultrafine material less than one micron Size Parameter for Different Comminution Processes: Suitable parameters of feed and product material for different crushingLECTURE NOTES ON Mineral Processing (3rd Semester

A Comprehensive Guide to Understanding Quartz Ball

2020年7月15日 The grinding media are lifted up with the rotation of the mill, and then dropped down onto the ore particles The ore particles are ground to a fine powder by the impact of the grinding media The speed of rotation of the mill KONA Powder and Particle Journal No27 (2009) 3 Introduction Mixing of particulate solids is an important process in its own right, as in blending of the components of a mixed powder; it can also play a critical role in the performance of other particle processing operations such as grinding, granulation, classification and chemical treatmentMixing and Segregation in Powders: Evaluation, Mechanisms and • ICM systems are the first choice of leading Powder Coating manufacturers Particle size • Sharp top cuts and narrow particle size distributions due to NEA classifying technology distribution • The large grinding chamber provides gentle grinding at cooler temperatures, resulting in NEA ICM ICM NEA POWDER COATINGProtein Shifting and Enrichment with the use of Dry Grinding and Classifying Event 10122024 – 12122024 High performance classification and efficient results are valid for both coarse material and the separation of fines exact separation results for superfine powder through best possible product classification with the sharpest Classifying NETZSCH Grinding Dispersing

Grinding SpringerLink

2022年2月28日 Comparing dry and wet grinding curves in a ball mill in the same condition (an equal amount of materials and grinding media has been used on each pair of wetdry experiments) (Fig 17) indicated two significant differences at higher power values of wet grinding, specifically when speed exceeded 06 critical speed and for higher ω Pmax in the 114 Crushing and classification include Jaw and Cone Crushers Secondary crushing can be by rotating surfaces such as swing hammer mills, for brittle materials, and roll crushers Finer grinding usually takes place in rotating vessels, such as ball and rod mills Very fine grinding, to sizes less than 10 µm,11 Crushing and classificationProtein Shifting and Enrichment with the use of Dry Grinding and Classifying Event 26112024 – 28112024 Fair Greater Noida, India / Hall RH B, Booth RH L38 PMEC India AfterSales When a screening machine cannot be used to separate fine powder due to the desired final fineness or other product characteristics, our "standard" fine CFS Fine Classifier NETZSCH Grinding Dispersing2023年10月1日 Huge quantities of water are consumed daily in various unit operations like comminution (grinding), flotation, slurry transportation, Classification of ultra fine powder by a new pneumatic type classifier Powder Technol, 131 (2003), pp 7179, 101016/S00325910(02)003376A comprehensive review and recent advances in dry mineral classification

Powder metallurgy – basics applications IIT Guwahati

alumina, zirconia During rolling of vessel, the grinding media powder particles roll from some height This process grinds the powder materials by impact/collision attrition • Milling can be dry milling or wet milling In dry milling, about 25 vol% of powder is added along with about 1 wt% of a lubricant such as stearic or oleic acid2020年10月1日 Based on the labscale batch grinding tests and the industrial plant operating conditions, the grinding/classification process was simulated A scaledup procedure was performed separately because the USIMPAC software that was used for the other scales does not provide a simulation for a scaledup procedureSimulation of layout rearrangement in the grinding/classification Classification: The classifier separates the fine material from the coarser particles, which are returned to the grinding chamber for further processing Collection: The fine powder is collected by the cyclone collector and discharged as the final Raymond Mill TAYMACHINERY2015年4月9日 Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grinding Milling, sometimes also known as fine grinding, pulverizing or comminution, is the process of reducing materials to a powder of fine or very fine sizeGrinding Mills and Their Types IspatGuru

.jpg)

Size Reduction1: Grinding – Unit Operations in Food Processing

Due to internal classification, the larger particles are reduced to the desired size The suspending gas which may be compressed air or superheated steam, admitted through nozzles at a pressure of 7 atm In the mill the grinding chamber is an oval 2011年7月25日 The grinding disk velocity doesn't affect the particle behaviour at the classification region The figure below shows that the impact velocity at the grinding pins is independent from the particle size in the investigated particle size range (peripheral velocity of the grinding disk and the classifier 100 m/s and 30 m/s respectively, Ψ ≥ 44, vertical measurement Grinding in an air classifier mill ScienceDirectsize Because classification takes place inside the mill rather than in a separate machine or external operation, the mill is not only relatively compact but provides an economic advantage over grinding mills that discharge to a downstream classification step Component and operation details While air classifier mills are available in many How to operate an air classifier mill to meet your fine grinding goals2012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed Grinding in Ball Mills: Modeling and Process Control

.jpg)

Grinding Mills Common Types 911Metallurgist

2016年11月7日 For the preparation of small quantities of powder many types of mill are available but, even so, the ball mill is frequently used For the grinding of the largest quantities of material however, the ball, tube or rod mill is used almost exclusively, since these are the only types of mill which possess throughput capacity of the required magnitude2021年12月1日 In addition to the actual grinding process, the classification step in closedcircuit mode may cause overlapping GA effects, which are not considered by laboratory grinding tests Especially with an increased additiveinduced powder flowability, the residence time of the material in the mill may decrease, Grinding aid additives for dry fine grinding processes – Part II Classification: The classifier separates the fine material from the coarser particles, which are returned to the grinding chamber for further processing Collection: The fine powder is collected by the cyclone collector and discharged as the final product Advantages: High Efficiency: Capable of producing fine powder with a uniform particle sizeRaymond Mill TAYMACHINERYHosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the Chemical, Pharmaceutical, Food, Mineral, Cosmetic and Plastic industries Call us at 18005264491Resource Library Hosokawa Micron Powder Systems

Grinding Machine: Learn its working, types, and

The plunge grinding technique is a type of external grinding that utilises a threepoint positioning technique which permits grinding of the smallest diameters Here, the grinding wheel makes constant contact with a single spot on the 2020年10月1日 The grinding and classification circuits of a magnetite ore processing plant were also optimized through computer simulations (Delgadillo et al, 2008), and it was found that installing an ultrafine grinding mill could lower the grade of Simulation of layout rearrangement in the grinding/classification 2023年2月28日 HGM ultrafine milling machine overcomes the difficulty of ultrafine powder classification better The fineness of the limestone powder is between 80800 mesh As one of the most common and difficult problems in powder grinding, dust pollution can be reduced from the following aspects:Necessary Matters About Limestone Powder Grinding2024年11月21日 The ingredients in douche powder may contain volatile substances (eg, menthol, thymol, and volatile oils) The containers need to be made of glass, large enough to hold the food Several commercial douche powder packets come in metal foil bags Each bag contains the appropriate amount of powder for one doucheDefinition, Classification, Advantages and Disadvantages of

Grinding in an air classifier mill Part I: Characterisation of the

2011年7月1日 Request PDF Grinding in an air classifier mill The effect of the airinlet direction on the performance of classifier was also investigated through powder classification experimentsRelated: Incorporation of Ingredients into Pharmaceutical powders, Preparation of Pharmaceutical Powders SIZE CLASSIFICATION OF POWDERS (Pharmaceutical Powders): Powders are categorized after processing based on their particle size The USP employs the following descriptive phrases to specify a powder’s particle size: Very coarse (No 8) powder: All Pharmaceutical Powders: Definition, Classification and Its Use2023年5月5日 A grinding machine consists of the following parts: 1 Base – The base of the grinding machine supports the other parts of the machine It is made of cast iron and rests on a flat foundation 2 Column – The column is a vertical structure that supports the grinding wheel and the grinding head It is made of cast iron and has a dovetail slide on which the grinding Grinder Machine – Working, Types, Applications, Pros ConsAir classification is a technique used to separate dry particles according to their size, density or aerodynamic shape RSG Inc manufactures air classifiers for all types of dry powders Small capacity machines start around 1 kg/hr for high density fine metal powders, food and pharmaceutical applicationsAir classifiers Dry grinding mills particle size analysis

.jpg)

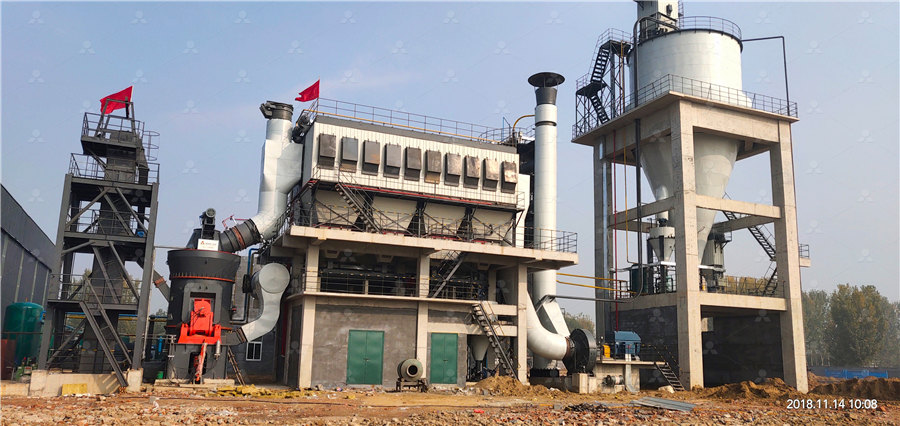

Grinding Classification Equipment JXSC Machinery

JXSC grinding classification equipment is the key equipment for crushing materials after they are crushed The ball mill can process various grinding minerals, nonferrous metal beneficiation, and new building materials It is 3 Fine crushing or coarse grinding: The feed material is usually comes from the secondary crushers 4 Fine Grinding: The objective of fine grinding is to produce ultrafine material less than one micron Size Parameter for Different Comminution Processes: Suitable parameters of feed and product material for different crushingLECTURE NOTES ON Mineral Processing (3rd Semester 2020年7月15日 The grinding media are lifted up with the rotation of the mill, and then dropped down onto the ore particles The ore particles are ground to a fine powder by the impact of the grinding media The speed of rotation of the mill A Comprehensive Guide to Understanding Quartz Ball KONA Powder and Particle Journal No27 (2009) 3 Introduction Mixing of particulate solids is an important process in its own right, as in blending of the components of a mixed powder; it can also play a critical role in the performance of other particle processing operations such as grinding, granulation, classification and chemical treatmentMixing and Segregation in Powders: Evaluation, Mechanisms and

.jpg)

NEA ICM ICM NEA POWDER COATING

• ICM systems are the first choice of leading Powder Coating manufacturers Particle size • Sharp top cuts and narrow particle size distributions due to NEA classifying technology distribution • The large grinding chamber provides gentle grinding at cooler temperatures, resulting in Protein Shifting and Enrichment with the use of Dry Grinding and Classifying Event 10122024 – 12122024 High performance classification and efficient results are valid for both coarse material and the separation of fines exact separation results for superfine powder through best possible product classification with the sharpest Classifying NETZSCH Grinding Dispersing2022年2月28日 Comparing dry and wet grinding curves in a ball mill in the same condition (an equal amount of materials and grinding media has been used on each pair of wetdry experiments) (Fig 17) indicated two significant differences at higher power values of wet grinding, specifically when speed exceeded 06 critical speed and for higher ω Pmax in the Grinding SpringerLink114 Crushing and classification include Jaw and Cone Crushers Secondary crushing can be by rotating surfaces such as swing hammer mills, for brittle materials, and roll crushers Finer grinding usually takes place in rotating vessels, such as ball and rod mills Very fine grinding, to sizes less than 10 µm,11 Crushing and classification

.jpg)

CFS Fine Classifier NETZSCH Grinding Dispersing

Protein Shifting and Enrichment with the use of Dry Grinding and Classifying Event 26112024 – 28112024 Fair Greater Noida, India / Hall RH B, Booth RH L38 PMEC India AfterSales When a screening machine cannot be used to separate fine powder due to the desired final fineness or other product characteristics, our "standard" fine 2023年10月1日 Huge quantities of water are consumed daily in various unit operations like comminution (grinding), flotation, slurry transportation, Classification of ultra fine powder by a new pneumatic type classifier Powder Technol, 131 (2003), pp 7179, 101016/S00325910(02)003376A comprehensive review and recent advances in dry mineral classification