HOME→Medium speed mill main plant layout diagram Speed mill main plant layout diagram Speed mill main plant layout diagram

Medium speed mill main plant layout diagram Speed mill main plant layout diagram Speed mill main plant layout diagram

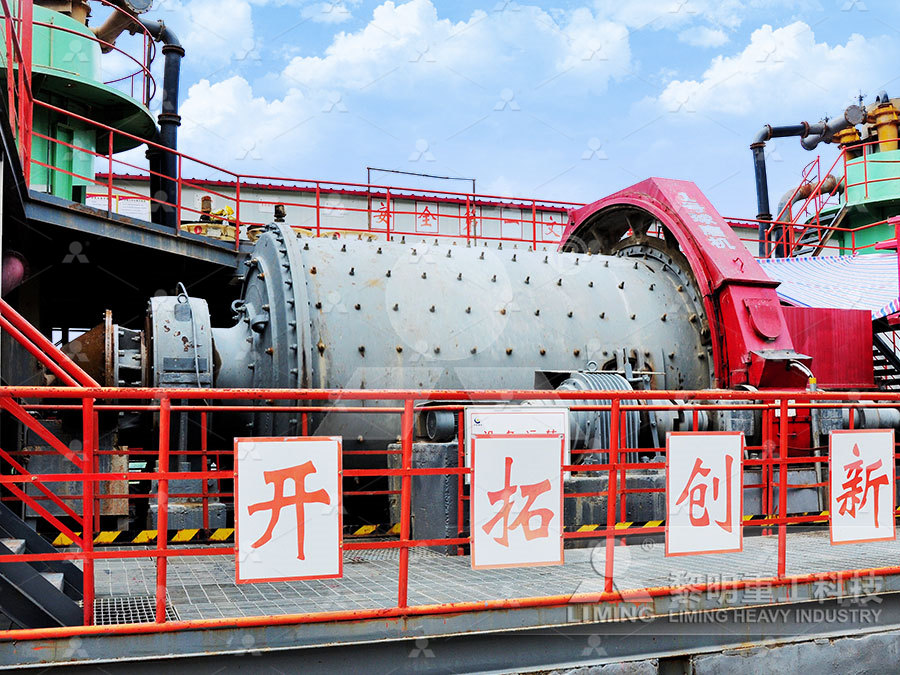

Schematic of medium speed coal mill [5] ResearchGate

Medium speed mills are widely used in largescale thermal power plants, which run at a setting speed of 50∼300 r/min, owing to their efficiency The schematic of a medium speedDownload scientific diagram Schematic structure of the MPS mediumspeed mill from publication: Application of ModelBased Deep Learning Algorithm in Fault Diagnosis of Coal Mills The coal Schematic structure of the MPS mediumspeed millIn this paper, a brannew GAIFCMIDHGF assessment method is proposed Genetic algorithm (GA) is first applied to optimize initial parameters, which is fundamental and significant step to obtainThe structure of MPS mediumspeed coal mill systemContribute to sbm2023/sbm development by creating an account on GitHubsbm/sbm medium speed mill main plant layoutmd at main

.jpg)

Mill Speed an overview ScienceDirect Topics

2011年8月1日 Dipak K Sarkar, in Thermal Power Plant, 2015 462 Mediumspeed mill This type of pulverizer is usually one of two types: ball and race and roll and race The speed of the grinding section of these mills is usually between 75 and 225 rpm Mediumspeed mills are smaller than lowspeed units and are generally the vertical spindle typeExplain the role of critical speed and power draw in design and process control Recognize important considerations in ball mill selection Reading Lecture In ball mills, steel balls or hard pebbles to break particle based on impact and attrition A rotating mill charged with media and ore is lifted against the inside perimeterAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator The performance of tumbling mills is sensitive to the volumetric mill filling which influences grinding media wear rates, throughput, power draw, and product grind size from the circuit Each of these performance parameters peaks at different filling values In order to continuously optimize mill operation, it is vital toOptimization of mill performance by using2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China They are designed and manufactured by the German company Babcock This kind of coal mill has the characteristics of low energy consumption and smooth output and has a small effect on abrasive wear and an overhaul period [13] , [14] Modeling of a medium speed coal mill ScienceDirect

Mathematical validation and comparison of ball tube and bowl

Two types of mills generally used in power plants are low speed horizontal ball mill and medium speed vertical bowl mill While most plants have a bowl type mill, the ball type mill has a large rotating mass and storage capacity, robust in construction, gives rapid response to load changes and consumes more power2009年4月18日 This document discusses key considerations for planning and life safety in flour milling facilities It covers regulatory codes around occupancy, construction type, height and area restrictions Grain storage, cleaning towers, tempering bins and mills often use slipformed concrete constructionFlour Milling Plant Design PPT SlideShareMedium speed mills are widely used in largescale thermal power plants, which run at a setting speed of 50∼300 r/min, owing to their efficiency The schematic of a medium speed coal mill is Schematic of medium speed coal mill [5]2014年2月1日 The mill automation carries out several functions Some of them are described below Main control desk, with management function mode and rolling speed calculation Regulation cascade speed between stands Main Features of a Modern Bar and Light Section Mill

Plant layout drawing in 5 steps visTABLE®

2023年7月20日 In 5 steps it is shown what to pay attention to and how the plant layout drawing is created Skip to content Menu Menu TRY FOR The following diagram gives you a selection of options available for a plant layout What are the main tasks of a plant layout designer? (Name just three) 2 An important tool in the synthesis of instrumentation and control strategies is the Process Instrumentation Diagram (PID) 22 Process flow diagrams (PFDs) Process flow diagrams Medium Pressure Steam (MPS) 700 to 1400: 160 to 190: High Pressure Steam (HPS) 2700 Fundamentals of Process Plant Layout and Piping Design2017年8月1日 This energy structure also indicates that coalfired power is the main component of China's power generation MPS180HPII medium speed coal mill is used as the research object Modelling Study of Supercritical Power Plant and Parameter Identification Using Genetic Algorithms[C] Modeling of a medium speed coal mill ScienceDirect2024年1月31日 When it comes to designing the perfect rice mill layout plant, there are several factors that need to be taken into consideration [ Location,Size,etc ] MAIL US : singhsp@nextecsolutions CALL US : > +91 11 4509 6171 +91 11 4509 6171 Nextech Grain Processing Engineering Solutions Pvt LtdGuide to Designing the Perfect Rice Mill Layout Plant Nextech

.jpg)

Roller Mill Springer

low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry Roller Mill, Fig 1 Structure diagram of vertical roller mill 2 Roller Mill the hydraulic The column mill is a vertical mill using high speed, medium pressure, and continuous, repeated grinding It consists of HPSeriesMediumSpeedBowlMill 703 Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online HP Series Medium Speed Bowl Mill is used to grind, dry and separate raw coal into qualified fineness for combustion in steam boilers It consists of a grinding bowl, grinding rollers, spring loading device and other componentsHP Series Medium Speed Bowl MillBenefits of a welldesigned Plant Layout Source: Singh (2012) 3 FACTORS THAT DETERMINE THE DESIGNING OF PLANT LAYOUT Some of the goals of designing plant layouts are to achieve a minimum amount PLANT LAYOUTS' ANALYSIS AND DESIGN ResearchGateZGM type Mediumspeed Rolling coal mill compact overall layout, The slag removal process can also be carried out during the operation of the coal mill (see Fig 214) 2 Main technical parameters The performance parameters of ZGM medium speed roller mill are shown in table 211,ZGM type Mediumspeed Rolling coal millpower plant equipment

.jpg)

Review of control and fault diagnosis methods applied to coal

2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important 2023年8月2日 By following these tips for an effective rice mill layout, you’ll be setting yourself up for success in terms of productivity, safety, and overall operational efficiency Layout of the Rice Mill When designing the layout of a Designing an Effective Rice Mill Layout Plant Best 2013年12月22日 Fig 4 Mandrel type and mandrel less coil box Automatic width control – In general, the width performance of the hot strip is evaluated using two metrics namely (i) average body width deviation, and (ii) width variability at the Development of Modern Hot Strip mill and its Main Download scientific diagram The structure of MPS mediumspeed coal mill system from publication: Modeling of Coal Mill System Used for Fault Simulation Monitoring and diagnosis of coal mill The structure of MPS mediumspeed coal mill system

.jpg)

Crushing Plant Flowsheet DesignLayout 911Metallurgist

2016年3月11日 Crusher Plant Layout Most crushing plants are now designed on the lines shown in Fig 1, which is a diagrammatic view of a twostage arrangement The ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary breaker, the latter being of the jaw type in the case of a small plant and of the gyratory 2018年12月13日 pulverizing systems with medium speed mill, and the mill is MPS180HPII mill, which is made by Changchun generating equipment plant Input coal composition contents to the program, ma in page (PDF) Program Design and Calculation Example of Direct Fired (1) Production areas (plant): iron and steel plant production area is the main part of the overall layout, should give priority to select the appropriate location According to the nature of the steel production plant, A larger percentage of transportation outside the factory, so should close to interface points of the main mode of transportationOverall Layout Design of Iron and Steel Plants Based on SLP Theory2021年8月1日 However, the faults of medium speed coal mill in po wer plant operation are also more prominent, which directly affect the boiler operation stability , furnace combustion economy , and seriously Fault analysis and optimization technology of HP bowl type medium speed

Pellet line layout and design: A systems approach Feed Strategy

bins over the pellet mill, multiple die changes per day and stringent flushing requirements between production runs The calculated efficiency of the 40 TPH pellet mill is about 8595% in the singlespecies plant, while the efficiency for the multispecies facility could be as low as 35% and may never be more than 70%2023年10月21日 Explore the Rice Mill Layout Plant the innovative solution for optimized rice milling MAIL US : singhsp@nextecsolutions CALL US : > +91 11 4509 6171 +91 11 4509 6171 Nextech Grain Processing Engineering Solutions Pvt Ltd Formerly Nextech SolutionsRice Mill Layout Plant Trends: What’s New in Design and EfficiencyMill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional AMIT 135: Lesson 7 Ball Mills Circuits – Mining 2024年4月12日 3D Plant Layout of a Stock Preparation System By integrating the design models of the machinery within the plant model through an interface, a comprehensive 3D representation of the paper mill plant can be achieved How to Set up a Paper Mill Plant Complete Process

.jpg)

Mathematical validation and comparison of ball tube and bowl mill

coefficients of a medium speed vertical bowl mill and a low speed horizontal ball tube mill located in two distinct coal based power plants in northern India are compared The onsite data is physically obtained from the two plants A coal mill model was developed and model coefficients obtained using GA based on onsite input data of the two Die speed is typically measured at the outside diameter of the die, which is either referred to as the “peripheral speed” or the “tip speed” of the die For the majority of applications, the die speed that is generally used for maximum performance should be 9 meters per second for all easyrunning materialsPellet mill design Feed StrategyDownload scientific diagram Schematic structure of the MPS mediumspeed mill from publication: Application of ModelBased Deep Learning Algorithm in Fault Diagnosis of Coal Mills The coal Schematic structure of the MPS mediumspeed millThe double inout ball mills and the medium speed mill are usually equipped with direct fired pulverizing systems The past three decades, some newtype coal, such as Shenhua coal, has been mined These newtype coal have breeziness thermodynamic property and more suited to medium speed mill So medium speed mills are extensively used owing to itsProgram Design and Calculation Example of Direct Fired

.jpg)

Flowchart Maker Online Diagram Software

Flowchart Maker and Online Diagram Software drawio is free online diagram software You can use it as a flowchart maker, network diagram software, to create UML online, as an ER diagram tool, to design database schema, to build BPMN online, as a circuit diagram maker, and more drawio can import vsdx, Gliffy™ and Lucidchart™ files 08CRUSHERCrushing Plant Design and Layout Considerations Crushing plant design should accordingly or bottom of a crusher plant Electrical cable tray routing and in large crushing and screening plants, General Electrical Layout Of Crushing Screening PlantLayout of Hydroelectric power plant Fig shows the schematic representation of a Hydroelectric power plant The main components are • Water reservoir • Dam • Spillway • Gate • Pressure tunnel • Surge tank • Penstock • Water turbine • Draft tube • Tail race level • Powerhouse hydroelectric power plant diagram Water Hydroelectric power plant – Diagram , Working , AdvantagesPLANT LOCATION AND LAYOUT Abha Kumar STRUCTURE 70 Introduction 71 Objectives 72 Plant Location 721 Locational Analysis 722 Selection criteria 723 Significance 73 Plant layout 731 Definition 732 Importance 733 Essentials 734 Types of layout 735 Factors influencing layout 736 Dynamics of plant layoutLESSON 7 PLANT LOCATION AND LAYOUT DAV University

Schematic of medium speed coal mill [5]

Medium speed mills are widely used in largescale thermal power plants, which run at a setting speed of 50∼300 r/min, owing to their efficiency The schematic of a medium speed coal mill is 2014年2月1日 The mill automation carries out several functions Some of them are described below Main control desk, with management function mode and rolling speed calculation Regulation cascade speed between stands Main Features of a Modern Bar and Light Section Mill2023年7月20日 In 5 steps it is shown what to pay attention to and how the plant layout drawing is created Skip to content Menu Menu TRY FOR The following diagram gives you a selection of options available for a plant layout Plant layout drawing in 5 steps visTABLE®What are the main tasks of a plant layout designer? (Name just three) 2 An important tool in the synthesis of instrumentation and control strategies is the Process Instrumentation Diagram (PID) 22 Process flow diagrams (PFDs) Process flow diagrams Medium Pressure Steam (MPS) 700 to 1400: 160 to 190: High Pressure Steam (HPS) 2700 Fundamentals of Process Plant Layout and Piping Design

Modeling of a medium speed coal mill ScienceDirect

2017年8月1日 This energy structure also indicates that coalfired power is the main component of China's power generation MPS180HPII medium speed coal mill is used as the research object Modelling Study of Supercritical Power Plant and Parameter Identification Using Genetic Algorithms[C] 2024年1月31日 When it comes to designing the perfect rice mill layout plant, there are several factors that need to be taken into consideration [ Location,Size,etc ] MAIL US : singhsp@nextecsolutions CALL US : > +91 11 4509 6171 +91 11 4509 6171 Nextech Grain Processing Engineering Solutions Pvt LtdGuide to Designing the Perfect Rice Mill Layout Plant Nextech low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry Roller Mill, Fig 1 Structure diagram of vertical roller mill 2 Roller Mill the hydraulic The column mill is a vertical mill using high speed, medium pressure, and continuous, repeated grinding It consists of Roller Mill SpringerHPSeriesMediumSpeedBowlMill 703 Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online HP Series Medium Speed Bowl Mill is used to grind, dry and separate raw coal into qualified fineness for combustion in steam boilers It consists of a grinding bowl, grinding rollers, spring loading device and other componentsHP Series Medium Speed Bowl Mill

PLANT LAYOUTS' ANALYSIS AND DESIGN ResearchGate

Benefits of a welldesigned Plant Layout Source: Singh (2012) 3 FACTORS THAT DETERMINE THE DESIGNING OF PLANT LAYOUT Some of the goals of designing plant layouts are to achieve a minimum amount ZGM type Mediumspeed Rolling coal mill compact overall layout, The slag removal process can also be carried out during the operation of the coal mill (see Fig 214) 2 Main technical parameters The performance parameters of ZGM medium speed roller mill are shown in table 211,ZGM type Mediumspeed Rolling coal millpower plant equipment